Homemade SUVs based on UAZ

Making a car of this brand unrecognizable with your own hands is not so difficult. For drastic changes you will need:

- Set of aluminum sheets with corrugated edging for cladding.

- Metal and rubber pads.

- Fixing screws.

- Synthetic rugs.

- Foam rubber.

- Triplex glass.

- Flexible plastic.

- Tools (keys, screwdrivers, accessories).

A homemade SUV, if all manipulations are carried out correctly, will come out no worse in terms of characteristics than its expensive analogues.

Where to begin?

First, you should take care of strengthening the outer skin and frame of the car. It is best to use steel pipes designed for high loads. It is also necessary to take into account the provision of insulation from moisture, especially if you plan to create not just an SUV, but a swamp vehicle.

If it is impossible to weld pipes, you can use the original UAZ body. Sometimes it is modified to give the desired configuration. The side pillars, roof and bottom will require mandatory strengthening.

Sheathing

A homemade SUV is made from a UAZ car by first removing the old trim. Simultaneously with the reinforcement of the body, a new structure made of aluminum alloy is installed, which is resistant to weather disasters and corrosion. When choosing sheets, you should select a material whose thickness is at least one and a half millimeters. The new casing is attached using screws, which are fixed in the frame with special heads. Rubber pads are used to smooth out all unevenness and remove backlash.

If the new housing is installed incorrectly, the structure may be completely vulnerable to mechanical and natural influences. Therefore, installation of the trim should be carried out carefully and carefully, checking all stages, since this part is the most finicky when creating a jeep with your own hands based on an UAZ.

Jeep with a soul - completely homemade cars

Completely homemade cars are a rarity. But such developments are also present in Russia. If you want to act as a car designer, you don’t need to remake an old vehicle, but create a completely new design. The production of such machines begins with the organization of the base and frame. It’s better to make a frame jeep, it will be safer and more passable. The designer also faces the following challenges:

- organizing the supporting structure precisely according to the distribution of weight and size;

- thinking through the suspension mounting system, the main parts that are needed for movement;

- creating a car interior that is comfortable for its use;

- operating normal controls for traveling by car;

- conducting tests in safe conditions for the life and health of the driver.

Such jeeps often do not receive registration plates, but they are the creation and innovation of the creator. Many similar cars take part in trophies and competitions, receive awards and even investments for the development and improvement of the design. A home-made SUV of this kind will be safe only if a series of tests is carried out and the shortcomings are corrected.

Peculiarities

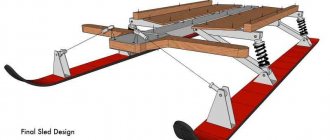

When making a homemade SUV, you need to pay attention to the camber of the wheels when assembling the bridge; you should first weld the lower bearing elements. They are then bolted to the frame. Taking into account the operating characteristics, the type of wheels or even tracks is selected.

Torque is transmitted via a driveshaft from the power unit to the rear axle. Such a unit is advantageous in that it is easy to maintain and repair. First you need to make sure that the mounting slots match each other. Otherwise, you should make the required number of holes.

Finally, you will need to test the updated machine several times. After identifying problem areas, they must be checked and all problems eliminated so that driving a homemade SUV is safe. Almost the entire modernization process is carried out according to a single scheme. From the original, only the power unit and body will be needed.

What should you pay special attention to?

Above we looked at how to make a homemade SUV? Despite all the advantages, this technique has certain disadvantages. In particular, low pressure chambers cause a lot of trouble. Although they do not require servicing, during operation the elements become less maneuverable.

It is also difficult to equip them with protection from flying dirt, since the dimensions are significantly larger than standard wheels.

As practice shows, pneumatics on homemade all-terrain vehicles are less practical than tracks. Otherwise, a homemade SUV based on the Oka or UAZ is cost-effective and convenient, taking into account the fact that its design can be adjusted depending on the operating conditions and climatic factors.

First of all, such equipment is suitable for residents of rural areas and lovers of extreme off-road tourism.

“JEEP” – RELIABLE AND SIMPLE

It used to be that S. Khopshanosov helped stranded fellow motorists by pushing their cars with the front bumper of his all-terrain vehicle.

In his native Armenia, he climbed on it to a height of up to 3000 m above sea level, overcoming off-road conditions, rocky screes, and slopes of up to 30°.

The hardships of the journey are easily tolerated in the comfortable and cozy interior of the car. In hot weather, you can slide any of the four side windows to bring in fresh air. Or, if this is not enough, open the sunroof.

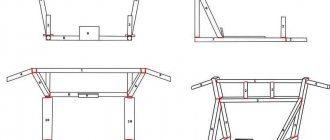

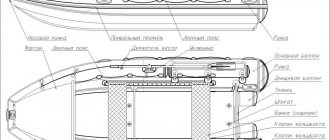

There are many other simple and original design solutions in the car. Here, for example, is how the body works. It consists of a space frame and outer skin. The frame, designed to withstand significant torsional and bending loads, is welded from square and rectangular steel pipes. The less loaded hood, doors and rear window are made of channels, tees and angles connected with rivets.

Rice. 3. Modification of the rear axle:

1 – the lower support cup of the suspension spring is removed. Instead, a spring cushion is welded, 2 – a mounting bracket for the upper jet rod (removed), 3 – a left spring cushion (welded).

Rice. 4. Adapter

The floor in the cabin and the hood trim are made of corrugated duralumin sheets 2 mm thick. The body trim is made of smooth sheets 1.5 mm thick. They are attached to the frame with M5 screws with countersunk heads. The joints of the sheets are hidden by rubber and metal overlays.

The inside of the cabin is lined with a thin layer of foam rubber and soft plastic. Triplex glazing, as well as the doors, are equipped with rubber seals from cars from the Volzhsky Automobile Plant. The floor is covered with rubber and synthetic mats. All this reduces the noise level in the cabin and prevents the penetration of dust.

The instrument panel and glove box are homemade. The front seats with reclining backrests are “Zhiguli” ones. The rear passenger seat, designed for three people, is homemade and has a fixed backrest. Behind it, at the bottom, is a fuel tank with a capacity of 45 liters (from a UAZ) with a neck leading outward above the rear bumper. Above the tank is an internal trunk. Access to it through the rear window.

The principle of “simplicity plus reliability” has also extended to the power plant: the engine and gearbox are taken together with the units that serve them from the Zhiguli-VAZ-2101. Only the paper oil filter has been replaced with one that is cheaper to operate. inertial from ZAZ-968.

Unique DIY SUV

24-year-old Artem Kaychuk, a homemade car maker, dedicated this project to his grandfather. Only the nose part was taken from the GAZ-69, and all other parts went to the homemade jeep from other cars.

The well-preserved Land Cruiser 60 frame was taken as the basis; Artem installed the body of a Nissan Caravan minivan on it, to the front of which a GAZ-69 “face” was welded. In the cabin, it was decided to preserve the original seating formula of the Soviet SUV, where folding seats are located behind two stationary seats. This “custom” is powered by a ZMZ-409 engine from AUZ Hunter and a transmission from Land Cruiser.

Personal attitude

It’s also unusual to find out about the owner of the replica: 24-year-old Artem Kaychuk, who dedicated this project to his grandfather, calling it “In Memory of Grandfather.” How many young people of the “90s generation” are there now with such an attitude towards family history? It must be said right away that Artem has lived by cars since childhood, largely thanks to his professions and hobbies in the family, where everyone is on wheels both at work and on vacation, including on long trips. And now it is not disadvantaged in vehicles - it is possible to drive modern models. But for a long time I also wanted something non-standard, rare, made according to my own understanding and with my own hands, although not without help, of course.

The impetus for creativity in this direction was my grandfather’s “Gazik”, which I had the opportunity to drive, but which was not preserved. However, the skills of “jeep building” were acquired back in 2011 during the preparation of the UAZ-452 that was in the family: they lifted it, installed a Japanese diesel engine, “Barsovsky” axles (geared UAZ with a wide track), a winch, in general, they prepared it for serious off-road conditions. After that, I was inspired by the idea of reanimating the image of the GAZ-69 - I liked the car itself, and I wanted to do something of my own. I had a vague idea of what exactly should happen and how to implement it, so I just decided to start by looking for some primary source.

And I found it. Worn out, half disassembled, decayed in places, without a rear axle, with a Volgov engine - the condition of the "prototype" was least conducive to the implementation of the plan. I didn’t want to deal with obviously “killed” units; it was extremely difficult to return the past in an authentic form, but the sad look in the big “eyes” never left. So I decided to make one out of it, but now donors were needed.

Here, very opportunely, I came across an advertisement for the sale of another rarity - the Land Cruiser 60. Still of the first generation: with two round headlights and a 2F gasoline engine. As acquaintance showed, the years in Russia were not in vain: there were already traces of “import substitution” - spare parts from the GAZ-53, from the Volga, from the UAZ peacefully took root on the legendary Japanese SUV... although in general the chassis was still in passable original condition. We should take it, the bridges will definitely come in handy. They removed the body, which was leaky in places, and underneath it the frame was in almost perfect condition. In any case, I immediately remembered that UAZ-452, where, after installing a diesel engine, the “ridge” began to burst and had to be strengthened. Here, in a nearly 30-year-old sixty, the metal inspired confidence. And why, one might ask, redo something if there is a ready-made solution, a ready-made chassis?

We tried to put the body of a ’69 on it. Just for now, for the experiment, we had to start somewhere. And then it became clear to Artem that he had grown significantly from his grandfather’s Gazika, which he drove as a child: it was cramped, small low windows, the roof was “on his head”, there was not enough volume, there was no visibility. In general, it didn’t fit normally, the space was limited, but the car was needed not only for beauty, but also for everyday use, as well as for long trips. The whole idea suddenly slowed down, unexpectedly brought it to a standstill. What to do now?

The further course of events was suggested by a minibus with a characteristic name - Nissan Caravan, which was gathering dust indifferently and immobilized on the sidelines. It was bought as a donor for tuning the same UAZ-452, the engine and gearbox were removed, but the body remained. And it doesn’t seem to be needed, but it’s a shame to throw it away, maybe it’ll be needed somewhere else. And now it came in handy. We measured everything with a tape measure, the dimensions are quite suitable, even the powerful spars of the type of integrated frame “lay” very well on the LC frame, there is no need to cut off and disturb the power structure.

At first I thought of cutting off the roomy rear part of the Caravan and replacing it with the stern of the 69th. And then it came naturally - why not along with the entire front part, the windshield, and the doors? It is only necessary to cut out the central fragment with the sliding door, since the entire body did not fit into the plan. Then only the nose of the 69 was attached to the flat “face” of the minibus. Even at its base, the bridge of the Gazik’s nose did not cover the wide forehead of the Caravan, but overall it looked good - if carefully fused, a completely harmonious combination of volumes is possible.

Between past and present

So everything started spinning and rattling with iron: sawing, joining, fitting - the front end of the 69 sat at home on the front axle of the LC, with almost no overhang, and the rear wheel arches of the minibus sat on the rear, providing a proportional overhang. As a result, a completely new silhouette emerged on the completely preserved LC 60 base, with a recognizable face, a classic chassis layout, but a different, “minibus” layout in the cabin. In the sense that the result was a free, more vertical landing, but with the engine placed in front, as befits an SUV.

The front seats remained in their place (only different ones); under them, where in the case of the Caravan the engine compartment was located, there was a place for the fuel tank, battery, and small lockers. The side members of the Caravan body are bolted to the LC frame, there was no need to weld anything extra, everything turned out doubly rigid and thoroughly.

At the same time, what was found under the hood was not at all what one might have expected. This part of the project will probably cause the most mixed opinions, but the author proceeded from certain considerations, logical and well-reasoned in their own way. It would seem that the ideologically correct decision came with the LC 60. In-line cast iron six 2F, with a lower camshaft and carburetor power, 135 horsepower at 3600 rpm and 210 Nm at 1800 rpm. The beauty, in a word, was installed on the great-grandfather FJ. And yet, this mighty gasoline “knight” did not suit me: it was heavy, archaic, and had already exhausted its resource. Since maximum identity was not a priority, just as extreme trophy raids were not part of the scope of future responsibilities, I still wanted a lighter, more modern engine.

Again, a diesel engine was asking for itself, and a suitable one seemed to be in the “reserves” - TD27, along with the gearbox and transfer case (transfer case), a ready-made “whale”. Actually, I wanted to install it, but my doubts took on a different meaning: the original units of the “sixty” will remain out of use, and in the bridges it will be necessary to change the main pairs, select a diesel engine for this one, and besides, the exit from the Republic of Kazakhstan is here on the other side. It was decided to take the path of least resistance: leave the transmission completely from the LC, and look for a new gasoline engine for it (that is, it is better to change one unit than all of them in one).

The search for a possible replacement that would suit both the price and parameters was not easy. Of course, Japanese second-hand engines were also considered. And yet, as a result, something “protest” happened: if it has long been common practice to install foreign power plants on domestic cars, then exactly the opposite happened here. That is, for the Japanese chassis the choice fell on the ZMZ-409. He was happy with both the technical side and the “political” side - still, I wanted to bring more Russian into the project.

And yet this does not mean that the project developed smoothly like clockwork. It took a good two years of painstaking work to convey the “spirit of the times” and at the same time meet at least modest modern requirements in design, comfort and control. And it’s not just a matter of joining the ZMZ-409 with the LC 60 gearbox, when it was necessary to build an adapter plate, and also make an extended input shaft of the box on special order. After all, we also had to transfer the right-hand drive control of the LC 60 and Nissan Caravan to the left side - this was “demanded” by the image of the GAZ-69 and our own desires. And if you consider that the LC 60 had no power steering, and I didn’t want to remain without it for the sake of the “spirit of the times,” a big deal lay ahead.

And this business required a considerable investment: the gearbox with hydraulic booster in working condition found from a left-hand drive LC 60 alone cost 25,000 rubles. It also took a lot of time to redesign the controls itself. The clutch is “UAZ”, but they didn’t bother with the brakes at all: native Japanese ones in front and behind (disc and drum). The leaf spring suspension is also unchanged, as are the wheels. The pursuit of “extreme” was not initially intended; according to the conventional classification of SUVs, the project was prepared rather as a “light” expedition vehicle, therefore no elevator and no “Kraz” size tires. “Thirty-one” Maxxis Mudzilla was considered a completely acceptable option for traveling on different roads.

Not only to “glue” the body together from three main parts, but also to bring it to the desired state - this was another task with many conditions. Although the nose of the 69th fit onto the frame of the LC 60 as if it fit into its nest, the dimensions and width did not match. In order to cover the track of the “sixties” with its graceful wings, it was necessary to perform “plastic surgery” - cut the wings lengthwise and implant strips six centimeters wide. The “expanded” face in this way only benefited 69 - this is a normal phenomenon with age.

The LC 60 itself offered a replacement for the missing original headlights - its round “lenses” fit perfectly into the rare metal “frame”. But Artem specifically looked for original dimensions in order to preserve the charm of that era as much as possible. To fully decorate the front end, a modified bumper from the UAZ-469 came to the rescue, but at the same time it was necessary to additionally “cover” its junction with a splash-proof apron so as not to overwhelm the headlights in mud baths. Regarding the rear arches: it was possible to leave their shape along with the Caravan body and make some kind of overlays. But why, after all, there were the original “arcs” of the rear wings of the 69th: they fit perfectly here, transforming the stern to suit the general retro style.

The retractable air intake for the “stove” was functionally preserved as an exclusive element, but the original windshield wipers, of course, were no longer suitable. However, the “wipers” from the Caravan itself were not suitable, because they “shallowed” from left to right, leaving a large uncleaned angle for the driver when moving the steering wheel to the left side. We tried to adapt something “ours”, but in vain. A way out of this impasse was once again suggested by the Japanese auto industry, but this time more modern: the Honda Odyssey minivan has “universal” swing-type wipers that perfectly clean the windshield from edge to edge. During the "showdown" we managed to buy this complete system and, after modifications to the rods and levers, it was ideally adapted here, preserving all operating modes, and not just "on." and "off"

A separate story is the front panel. After all sorts of unsuccessful experiments to “connect the incompatible,” including an attempt to “cork in” a panel from Istana, it was decided to make the “face” of the interior ourselves. They welded the frame, sheathed it with steel plates, selected all the necessary indicators: the flat shape of the panel and round instruments conveyed the “spirit of the times” in the best possible way, they even installed a handle in front of the passenger, everything was like in the 69th.

How does the car drive? As it should be: sedately, waddling, with leisurely reactions to the steering wheel, with the need to steer a little. But it drives confidently: there is enough power not only for normal start and acceleration, but also for maintaining a cruising speed of 110 km/h. And the traction with these wheels is enough to crawl in first gear at idle without connecting the downshift.

On average off-road, the engine quite justifies itself, but on the highway a fifth gear would be useful: in fourth at a speed of 90 km/h the engine spins loudly at 2500 rpm, if you increase the speed, you would like to shift. On a bumpy road, the ride of an empty car may not be as smooth as that of a 60, but still without any special shocks or vibrations. And if you directly compare it with the 69th, then there is no need to talk about its famous “goat” disease. Fuel consumption is as follows: on the highway around ten liters, in the city up to 15 and above.

You can, of course, get smart about the ergonomics, saying that not everything is ideally located, there are not enough adjustments for a universal position behind the wheel, and so on. But why? For himself, Artem set everything up normally, it’s convenient for him, and, as they said, he made the car not just for the soul and as a memory, but so that it would travel a lot. Registered as a GAZ-69 with conversion, active operation began in the summer of 2014, and by November the mileage had reached almost 4000 km! About half of it was the “break-in” period: both for the new engine and for the old units - despite their preliminary preventive maintenance, it was necessary to replace some oil seals, a cardan cross, in general, in small things.

Now, after the “break-in”, when all the shortcomings have been eliminated, all the capabilities of the SUV have been studied, long-distance expeditions await it. In conclusion, let’s say this: privately, it was approximately possible to create what the whole plant could not at one time (remember the attempt to reincarnate the GAZ-69 in the form of the conceptual “Kombat”), in a single, but running copy.

Homemade SUV from Oka

For regions with difficult roads, it is quite possible to make a swamp vehicle even from a small car. In the process, you can use various available means, ranging from spare parts of a broken car to scraps of pipes and metal sheets.

Universal equipment on a pneumatic base or on wheels with low pressure is in great demand among craftsmen. Creating a jeep based on the Oka is a very profitable solution in terms of finance and practicality.

Volkswagen Golf Syncro

The all-wheel drive installation of this car has its roots in Togliatti. After all, it was these components that were used to create and assemble all-wheel drive VAZs. These cars were called "Victoria". But, unfortunately, they did not go further than prototypes. To assemble an SUV yourself according to this scheme, you will need:

- Angular reducer;

- Rear axle gearbox;

- Viscous coupling;

- 4 axle shafts (VAZ).

This is enough to assemble a fully functional off-road vehicle. A feature of this type of transmission will be the transmission of force to the rear wheels through a viscous coupling. It works as follows. The coupling contains silicone fluid. As the load on the rear wheels increases, it heats up, its viscosity increases, and more torque is transmitted to them. Therefore, despite permanent all-wheel drive, the torque supplied to the wheels will vary depending on conditions.

To attach the rear axle shafts you will have to find a subframe from Golf Syncro. The cardan transmission is assembled from two axle shafts. From the box, torque is transmitted using an angular gearbox; it transmits force to the rear wheels through a viscous coupling. To attach these elements you will have to use a special plate. It should be done by an experienced turner. Perhaps this is the only thing that cannot be done in a simple garage. This plate is secured with bolts. You should also make a suspension for a homemade cardan. You can use the standard one from the classics.

As a result, you will get a great SUV. In terms of driving performance, it is not inferior to many light SUVs. You can safely drive such a car in almost any dirt. If everything is done correctly, then you can safely go even on serious hikes.

Stages of work

Homemade SUVs, the photo of which is presented above, can be made from Oka by following the following sequence:

- Choose the basis for a new vehicle. It could just be a frame from an IZH or Ural motorcycle.

- Make the rear axle and suspension. At this stage, a strut is used, connected by parts of the side members.

- By fixing the strut and steering bushing, a single suspension unit is created.

- You can use tubes from trucks as wheels, which are attached using an adapter hub.

- After installing the frame and suspension, an updated engine, brake system and transmission are installed.

Preparation for work, tools and equipment

First of all, you need to carefully consider when, where and for what purposes the future ATV will be used - hunting and fishing, motorcycling in nature, transporting goods, etc. It is on this basis that you need to make a choice of a “donor” vehicle, deciding how powerful the engine is needed, what kind of suspension is suitable, what kind of trunk, etc.

The suspensions, like the steering system, must be taken from the car. On the front it is necessary to provide space for installing the gearbox.

Installing an all-wheel drive model requires not only special skills of the craftsman, but also additional labor costs. The alternative is to buy a ready-made all-wheel drive unit - it costs money.

Frame

Making the body is far from the simplest stage of the story called “how to assemble an ATV with your own hands.” Suitable materials are fiberglass and fiberglass; it is easier to make a body kit from the second.

First, you need to draw, cut and construct a “blank” of the body from pieces of durable foam plastic, glued or fastened with polyurethane foam. Then apply several layers of fiberglass on it, coating each with epoxy resin and inserting metal fasteners between them to attach the body to the frame. In conclusion, dry the body thoroughly, then prime, sand and paint.

Six-wheeled Ukhta: she also swam!

Fascinated by the creation of all-terrain vehicles, home designers and technologists even turned to six-wheeled vehicles. They were made not for daily driving, but for periodic outings into nature.

The most famous six-wheeled car was the Ukhta of Alexander Kulygin, who was known thanks to his futuristic sports Pangolin.

All-wheel drive, 6x6 floating Ukhta by Alexander Kulygin.

All-wheel drive, 6x6 floating Ukhta by Alexander Kulygin.

DIY jeeps - successful projects of Russian craftsmen

August 30, 2014

August 30, 2014

To build a real jeep, you don’t need to be the owner of a huge factory with excellent technological and modern machines. At least this is proven by the successes of Russian craftsmen, who can easily make an SUV with their own hands. And such a jeep will easily overcome obstacles that even expensive production models of crossovers and more off-road vehicles cannot do.

A lot of videos have been shot and an incredible number of texts have been written about how to make excellent cross-country equipment with your own hands. All this is freely available on the Internet, and we invite you to take a look at the most incredible creations of Russian craftsmen.

A capable jeep based on Oka

The last car that comes to mind when the terms SUV or crossover are mentioned is the small and full of factory problems Oka. At one time, this car became a bestseller only because of its low cost. Today, car owners who previously purchased this miracle of technology are converting their vehicles into real SUVs exclusively with their own hands.

Often, an attempt to make a crossover out of this car ends in complete fiasco, because the body is not designed for serious loads. But those people who can create a real miracle with their own hands produce good SUVs with the following characteristics:

• completely changed suspension, which allows you to install larger wheels; • tires with high tread and a variety of other ways to increase ground clearance; • all sorts of changes to the body to make the car more like a crossover; • sometimes the engine is replaced, since it is impossible to make a passable jeep on a construction platform.

They also produce with their own hands a variety of winches and other means that make it possible to bring the once helpless Oka closer to the title of a traditional off-road SUV with increased cross-country ability. Interestingly, on the basis of this car, amphibious vehicles that can move on water are often produced.

Caste of homemade jeeps based on GAZ 66 - Russian Hummers

If the Americans believe that only they can assemble an incredibly capable and durable military Hummer H1, then they are very mistaken. In Russia, such cars are assembled in garages by fans of DIY SUVs. There are many videos that show the process of assembling such a vehicle based on the GAZ 66 military truck. This is one of the most successful developments of the GAZ concern in its entire history, so the design of the base of this vehicle is suitable for such purposes.

Of course, the result is impressive, but it is not always possible to create proper reliability. Several similar Hummers have the off-road capability of a compact crossover, but some options have serious advantages:

• excellent maneuverability; • ground clearance of a military truck; • durable engine that cannot be broken; • enormous traction force; • light weight and increased power make the car unstoppable.

Such features, created with your own hands, may surprise a person far from the world of cars. But specialists manage to assemble incredibly technically successful cars in their garage and do it professionally. I wonder why not a single Russian automobile concern can do this given its technical capabilities?

A unique video about a jeep assembled with your own hands

If you're dreaming of a crossover, don't be discouraged by the high prices for cars in this class. You can assemble not only a crossover, but also a real jeep from the materials you have at hand. For example, the heroes of the following video did not particularly alter the design of the latest military GAZ 66, building a wonderful SUV out of it, and did all the work exclusively with their own hands. Of course, the production and assembly process is a proprietary secret.

Let's sum it up

If you want to assemble a car with your own hands and register it with the traffic police, then it is better not to start this process, because you will not be able to legalize the vehicle. SUVs and compact crossovers created by garage craftsmen remain just a means for driving around the fields. This car cannot be driven on public roads.

However, the enthusiasm of the creators of such technology is growing by leaps and bounds. Every month new interesting materials appear with unimaginable alterations and homemade products.

Source

Improving the cross-country ability and power of an old car

If you have a car that can be used for a complete makeover, it makes sense to use the transformation of this car into an SUV. Today, many make homemade SUVs, ordering Chinese parts of factory origin, but it is much better to follow the Japanese disassembly and buy productive spare parts for pennies. Alterations should affect the following aspects:

- completely modified chassis of the old car, reinforced struts with long travel;

- large wheels with special tires - sometimes incredibly large rims should be used;

- changing the drive system, using various parts from the disassembly of SUVs;

- implementation of those jeep functions that you need and will use in the future;

- raising the body above the ground, increasing the minimum ground clearance to 25-30 centimeters;

- installation of a more powerful motor, which can also be purchased assembled with a disassembled gearbox.

These modifications will become the basis for the cross-country ability and efficiency of your transport. Be sure to consider the various features of operating the machine so that it is efficient and effective. Remember that they will often film the homemade product and try to leave reviews about your car. So everything must be presentable. Often the creators of such cars are given a chance to sell their car and make many more home-made SUVs for use.