I have been lifting weights for quite some time and in order to improve my strength functionality, I decided to incorporate bodyweight exercises into my training. These parallel bars are easy to make and inexpensive. They are light enough to be moved around and strong enough to perform basic sports exercises. Manufacturing costs can also be reduced depending on what materials and tools you have available. The following describes in detail how to make beams at home.

Materials for assembling floor beams with your own hands:

- 2 square wooden blocks 10x10 cm, 3 meters long

- 2 metal poles with a diameter of 4 cm

- Board 5x10, 250 long

- Box of 7.5 cm wood screws

Tools: (can be replaced by others, but this is what I had at home)

- Table saw

- Drilling machine

- Electric drill

- 4cm hole drill bit

- Spade drill bit for wood 3.8

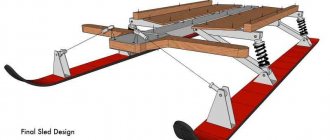

Drawing

Before you start making beams, you need to make a drawing of the future structure indicating the exact dimensions. It looks like this:

- the length of the working crossbars is 5 m each;

- the width between them should be 700 mm;

- the height of four racks is 2.5 m;

- the distance between the working crossbars and connecting elements is 1.4 m;

- the projection of the crossbars beyond the racks should be 800 mm on each side.

This type of design will be convenient for adults and teenagers to play sports. It is important to take into account that the racks will go 50 cm deeper into the ground.

Advantageous characteristics of wooden beams

Such projectiles, made from safe, environmentally friendly materials, have many positive aspects:

- Allow athletes to easily and quickly adjust the device in width and height;

- Provide simple assembly, along with relatively uncomplicated installation;

- Excellent ergonomic characteristics;

- Such a projectile is economically beneficial in the case of purchasing inexpensive, high-quality wood or cutting it down yourself;

- Additional costs for welding, cutting, and the use of special equipment for installation are absolutely excluded;

- After a certain period, you can safely carry out the necessary modernization or complete replacement of the structure;

- If assembled by yourself, the product will have the necessary strength and will last a long time without breakdowns or repairs.

For many, even the fact that timber beams will always be in their place is important. Unlike similar metal ones, which can be stolen if the owner is absent for a long time.

Medicine has long established the fact of a beneficial effect on processes associated with the necessary restoration of human health and its regenerative functions, with regular sports exercises in the lap of nature.

Required material

Before you make beams at home with your own hands, you should prepare the appropriate material. This includes:

- for the crossbars, 2 metal pipes with a diameter of 40 mm and a length of 5 m each are suitable;

- for the racks, 4 metal pipes with a diameter of 57 mm and a length of 2.5 m each are taken.

These are the main elements of the future design.

To increase its strength, it is recommended to install additional connections between the racks using parallel metal pipes.

To firmly fix the posts in the ground, you will need a bag of cement, several buckets of sand and fine gravel.

Let's summarize

Despite the fact that there are a lot of exercise machines equipped with modern sensors, pads, transformable structures and other bells and whistles, the construction of parallel bars in compatibility with a horizontal bar is not only one of the most budget-friendly and effective analogues, but also a platform for training future champions from the surrounding area , where there are no Olympic palaces and large stadiums.

Outdoor horizontal bars are suitable for independent exercise. On the territory of a suburban area or a private house, you can install the device yourself, choosing the optimal type of structure.

Corresponding tool

To complete the work of manufacturing and installing beams, you will need a tool. This includes:

- Bulgarian;

- welding machine;

- building level and plumb line;

- drill with a diameter of 20 cm;

- bayonet and shovel shovels, bucket and trowel.

With the help of available tools, you will be able to create the necessary design yourself.

Recommendations

If you have certain skills, it is quite possible to copy almost any of the industrial analogues. This will require painstaking work on bending, joining and placing pipes and fittings. A big plus is the absence of intermediaries, hired workers and branding, which reduces the cost of the simulator several times, along with its installation.

Regardless of the size of the bars, certain safety rules should be followed. Considering that the main load falls on the shoulders, elbows, and chest, these organs are susceptible to injury, especially with insufficient preparation or poor warming up.

Wooden beams

When dealing with the question: how to make wooden beams with your own hands, you need to take into account some design features.

Note!

Do-it-yourself vegetable garden: new interesting garden crafts for the street at your summer cottage (photo/video review)

DIY ceiling installation: step-by-step description of how to make a ceiling. Review of modern structures and ideas for their design (105 photos)

- Do-it-yourself garage doors - a detailed description of the construction of various types of garage doors (120 photos)

These include:

- the principle of operation remains the same, only the working metal crossbars are replaced with wooden beams;

- you should carefully select the quality of wood for making beams;

- To increase their strength, it is necessary to reduce their length as much as possible.

Types and features of horizontal bars

Sports structures designed for outdoor use are varied and provide exercise to maintain physical fitness. On the territory of a country house, you can make a comfortable horizontal bar with your own hands, which is suitable for adults and children. At the same time, there is no need to build a full-fledged sports ground, since there are universal types of structures. The peculiarity of this approach is the absence of large financial costs for the acquisition of a complex of ready-made sports facilities.

The horizontal bar does not take up much space and is easy to use

With parallel bars

The sports design with parallel bars consists of two vertical posts, at the ends of which there is a horizontal bar. Two such structures are installed parallel to each other and have a height of about 2 m. The parameters of the horizontal bar when manufactured independently are determined depending on the height of the users.

The bars can be a separate horizontal bar or attached to another

The bars can be slightly higher than the user's height or approximately up to chest level. A certain parameter depends on the exercises that will be performed on the structure. In any case, the ends of the upper crossbars protrude to the sides, that is, the length of the elements is greater than the width between the support posts. This provides convenience during sports activities.

Crossbars

The classic crossbar is two support posts, at the ends of which a bar is fixed at the top. The horizontal bar is convenient for pull-ups and easy to manufacture. The height of the product should be approximately 0.7 m greater than the user’s height.

Several combined crossbars are functional for sports activities

A regular crossbar has stable supports, and the top bar is thinner than the posts. This is necessary for convenient operation of the structure. Crossbars are often combined with other options for sports structures, but they are easy to make with your own hands.

Profiled timber

Before you start manufacturing the projectile structure, you need to figure out how to make a profiled beam with your own hands. To do this you need the following tool:

- jigsaw;

- jointer;

- Grinder.

When producing it, it is important to pay attention to the location of the wood fibers. They should be smooth and located along the surface of the beam.

Step-by-step guide to making a horizontal bar

Before starting work, you need to treat the ends of the supports approximately 60 cm with bitumen. Then, at the site where the horizontal bar is installed, 70 cm indentations are made using a garden drill. Sand is poured onto the bottom and compacted in a layer of 5–10 cm. These actions allow you to prepare the basis for installing the horizontal bar.

Further, the set of works involves the following actions:

- Using a welding machine, you need to weld the horizontal crossbar to the supports. The crossbar can be longer than the width of the horizontal bar. In this case, the ends should protrude evenly on both sides.

The crossbar must be round

The concrete supports of the horizontal bar must be strictly vertical

Video: DIY metal horizontal bar

Features of the children's horizontal bar

The construction of a children's horizontal bar requires careful determination of dimensions depending on the height of the child. At the same time, the design should be more functional than a simple horizontal bar for adults. The best option is a combination of a crossbar, a wall bars, and a swing. A small hanging punching bag, rope or removable swing can be easily fixed to the crossbar if necessary.

A children's horizontal bar can be simple, but hanging elements make it functional

If there is no large area for a children's sports complex, you can make two crossbars of different heights. A swing, a net, a punching bag or other devices are alternately fixed to one of them, and the lower one is used for pull-ups. In any case, a children's horizontal bar should be of high quality, reliable and comfortable.

Imitation of timber

There is an option to make metal bars and cover their working surface with wood. This will create a durable structure with a comfortable working surface.

When figuring out how to make an imitation of timber with your own hands, you need to pay attention to the following details:

Note!

- Insulate the foundation with your own hands - a step-by-step description of the use of the best materials and technologies (90 photos)

- Do-it-yourself pergola on a summer cottage: step-by-step instructions with photos and descriptions

- Laying laminate flooring with your own hands: a detailed description of how to lay laminate flooring. Laminate calculation, step-by-step description and installation secrets (105 photos and videos)

- select thin metal pipes in advance for subsequent wood cladding;

- a flat board is selected, from which the lining is cut to the required dimensions;

- these parts are fastened into a single structure using glue and clamps, so the wood completely covers the metal pipe.

The result is a sports equipment of increased strength that is convenient for daily use.

A final word of caution

Such a simulator must be durable, preventing the user from falling and getting injured. Therefore, all material must be durable, do not take anything from used materials, especially fiberboard or chipboard.

As stated above, the product experiences great stress and during operation a obviously defective crossbar or stand may break.

Paint the finished sports equipment or apply another protective coating against wood pests, ultraviolet radiation, and weather precipitation. Repeat this product for yourself at your summer cottage.

- How to choose an air conditioner for your home or apartment

Do-it-yourself bait - composition, application features and storage methods (115 photos and videos)

DIY sliding gates - how to build simple and automatic gates. Schemes, drawings and review of the best ideas (90 photos)

Compact product

There are cases when a person lives in an apartment and does not have the opportunity to go down to the yard. In this case, we make homemade small beams with our own hands. This is done as follows:

- a frame is boiled out of a metal corner and firmly attached to the wall at a height of approximately 1.5 m from the floor;

- two metal pipes with a diameter of 40 mm and a length of 80 cm each are welded perpendicular to this frame, at a distance of 70 cm from each other;

- these pipes should be located parallel to each other, rubber handles are put on their ends.

This design replaces beams and can be located in an apartment. It takes up little space and is convenient for sports.

Don’t be lazy, show your imagination and make home sports equipment on your own. Value your time, exercise at home.

Types and sizes of gymnastic bars. How to make beams with your own hands

From DA

Such a simple but effective exercise machine as parallel bars provides a general strengthening effect on the arms, abs and pectoral muscles. If desired, this structure can be used to work out almost all groups of the body. Sports schools use special devices that have special fastenings and are designed for critical loads. You should not try to make such mechanisms and devices yourself, but you can find out the size of the bars for amateur exercises in order to make a useful exercise machine at home, in the country or in the yard. Let's consider the features of these devices and the real possibilities of their effectiveness.

Additional Tips

When creating a crossbar with your own hands in the yard of a private house, it is recommended to adhere to the following tips:

- finish with special paints (if the product is made of wood, use protective impregnation);

- do not use too thin pipes (the thickness of the crossbar should be from 15 mm, the thickness of supporting pipes - from 20 mm);

- To increase the safety of training, lay a rubber covering in the area of the sports equipment.

A properly installed metal horizontal bar will last at least 15 years. If over time the structure begins to loosen, fixing this problem is extremely simple. It is enough just to install additional stops on the sides.

If the crossbar is installed for children, then the overall height must be reduced. This projectile differs from an adult one in that the crossbar has a thinner diameter so that a child can grasp it even with a small palm. For joint activities in the country, the best option is a cascade design.

The crossbar on the street is an extremely good solution. Exercising in the fresh air has a positive effect on health. By doing pull-ups and dips, you can increase your endurance and gain muscle mass.

When installing a horizontal bar with your own hands, do not use pipes that are too thin

If over time the structure begins to loosen, it is enough to install additional stops on the sides

If the crossbar is installed for children, then the overall height must be reduced

Positive sides

A healthy lifestyle, and diligent physical activity, is a component of good health, a strong nervous system and body, a sculpted body and a toned stomach.

But what to do if you absolutely don’t have enough time for the gym? A sports complex will help you in this matter, which can be installed both at home and outside to exercise in the fresh air.

Amateur outdoor equipment

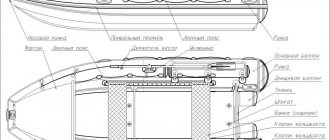

Regular parallel bars can be made in the yard in about two days. The dimensions are approximately the same as for professional ones, take average figures, between the supports - about 2.5 meters, the width between the bars is about 50 centimeters, the height above the ground is about 1.7 meters. We need the following materials - a bag of cement (mortar - three parts sand with small stones for one part of cement), a bucket, a trowel, a shovel, a welding machine, an angle grinder, a level, a drill 20 centimeters in diameter. The crossbars are made of pipes with a diameter of 4 centimeters, the racks are made of pipes with a diameter of about 6 centimeters, they can be taken with a rectangular cross-section; in height, you need to make a reserve for deepening into the ground by 60 centimeters.

- We prime the part of the pipe that will be in the ground.

- We drill holes in the ground or, better yet, in the asphalt, drill strictly vertically, check with a level, check the dimensions, maintaining the spacing and height, and fill with concrete.

- The next day, we weld the crossbars, check with a level that they are horizontal, and also clarify the dimensions so that the width between the pipes is maintained at 50 centimeters.

- We paint with metal paint and wait another day, on the third day you can do exercises.

You can, as an option, not make four racks. but only two, and weld the second part to the existing vertical post of another horizontal bar, the dimensions of such a projectile will be shorter in length, but in fact, for most exercises there is no need for too long pipes, since they are static and do not require swings, as in artistic gymnastics .

Video description

You can see how to weld an outdoor horizontal bar in the video:

Installation of a homemade horizontal bar will take place in several steps:

- First, the structure itself is welded. This must be done before installation, since welding at height is unsafe. Welding must be done carefully, without skipping.

- Then holes are dug in the ground in the right places. A layer of sand 10-15 cm thick is poured onto the bottom and compacted.

- The horizontal bar is installed in place, check the evenness of the installation using a plumb line or level.

- Fill the holes with a concrete solution, secure the structure with wooden supports so that it does not fall, and leave until completely dry.

- At the end, sand is poured near the pillars and between them to level and secure the horizontal bar.

If the vertical posts are made of wood, then they are first installed and cemented, and then the vertical crossbar is secured.

In the house

A wall-mounted horizontal bar may look like a crossbar attached between two side bases, but more often they try to complicate it, for example, make it longer and bend it on the sides at a slight angle, adding handles at the bottom.

Tags

with your own hands. with your own hands with your own hands with your own hands with your own hands with your own hands bars with your hands hold on to the length of your arm bars with your hands bars with your own hands. at your own safety in your place. perform a kind of testing Do-it-yourself exercise machines are cheaper than the store-bought ones made with your own hands free time for exercises. Do-it-yourself exercise machines How to make parallel bars make beams Make this, you can make wooden ones, they recommend making the appropriate one

step-by-step fastening instructions description of work meter reliable all Swedish installation of walls

: Saw holes

Now we need to drill holes for the poles.

Measure 5 cm from the end of each 120 cm wooden post. Accurately mark the center of the post at this point. Drill a hole at this mark using a spade bit (you can drill all the way through if you want, but I chose to only drill to the middle of the block).

Drill the same distance into the post at the same point, but this time use a hole drill bit. Use your finger or a screwdriver to clear debris from the hole.

: Insert poles

The rods will fit snugly into the holes drilled using the wood hole drill bit.

Hold the pole firmly while tapping the back of the wood post with a hammer so that the pole goes all the way to the bottom of the hole. Repeat this step for each end of the poles until you have assembled the homemade push-up bars as shown in the photo.

For convenience, I recorded a short video with the process of assembling homemade beams for the house:

Horizontal bar finishing

Applying an antiseptic and painting wooden or metal structures are the main types of treatment. When operating and constructing the crossbar, the following features should be taken into account:

- the crossbar should not have a rough surface. Wooden or metal elements are carefully sanded before installation, and painting makes the surface more comfortable;

- when performing exercises, you can use different pads and straps to ensure comfort during exercise;

- The area around the structure should be covered with sand or fine gravel. The children's complex can be located on the lawn, but not on an asphalt surface to avoid injury;

- The paint layer of the horizontal bar should be periodically renewed to prevent corrosion of the material.

A sports device located outdoors requires simple maintenance, but the key to durability is proper installation.