Creating a table for an echo sounder for many fishing enthusiasts will be an ideal solution to save budget and conveniently locate not only the device, but also spinning rods and other necessary gear. You can make a table for an echo sounder with your own hands from plywood pre-treated with a special impregnation, from fiberglass laminate, or from high-tech foamed PVC coated with automotive anti-gravel and other durable materials.

The latter type is used in the creation of advertising structures. Its most acceptable thickness should not exceed 10 mm. Any of the selected materials must be coated with reliable special means to protect against moisture. Many craftsmen still use self-made aluminum mounts. You can study the description of making a table for PVC boats from manufacturers and amateur craftsmen.

Materials for making a simple table design

A self-made boat structure for an echo sounder in a PVC boat is carried out using the following tools:

- calipers;

- pencil;

- plywood up to 10 mm thick;

- fastening screws 30 - 45mm;

- screwdriver, screwdriver and other wood tools.

If desired, drawings will help you build a table for an echo sounder on a PVC boat with your own hands, or according to individual parameters, with holders for spinning rods, cans and other fishing gear necessary for a successful catch. The diameter of the cylinder, the location of the liquid cable, and the compartment according to the size of the battery are also taken into account.

Why do you need tuning?

Such work to improve the vessel allows you to avoid the financial costs of purchasing a new boat. You can adjust the appearance and technical capabilities of an existing swimming device.

Modifying a PVC boat for fishing with your own hands helps to increase the level of safety for a person to be on this vessel while fishing, and also allows you to increase the life of the boat. To improve these functions, the following work is carried out:

- install a parking anchor;

- equip the product with a protective awning;

- modernize the fisherman's chair;

- equip the vessel with various bags for storing small items necessary for fishing;

- install a camp table;

- make a similar staircase;

- install an electric or gasoline power unit;

- make a sail;

- install mounts for fishing rods, gas tank and echo sounder;

- install special pumps for boats.

All these modernization works improve the level of comfort and safety of the fisherman. The user can strengthen the bottom of the vessel, make a hard floor, increase the level of protection of the sides from mechanical damage, and install fastenings for additional safety ropes and cables. And to increase the service life, it is recommended to use parking and transportation covers made for such boats.

Options for installing an echo sounder on a PVC boat

You can also install the echo sounder on a special factory bracket made of two plastic parts. Many craftsmen perform it themselves with their own hands. Rubber bosses are also used, which are used to secure the handrail in an inflatable boat. You can build structures according to ready-made drawings, but there are often options when the echo sounder is installed in a tool box. In particular, a bracket is attached to the lid of the box into which the echo sounder is installed for operation. When not in working condition, you can safely store the echo sounder structure in the same box.

Drawing

The manufacture of any boat begins with the preparation of a drawing. You can do it yourself, order it from a specialist, or find a ready-made drawing on the Internet. In cases where you try out some ready-made boat drawing from the Web, it is recommended that you first make a small-sized vessel according to this plan, if necessary, reducing all the details to scale. This is required in order to check the correctness of the drawing. And in order not to waste expensive PVC, such a model can be made from dense polyethylene.

Tuning PVC boats - installing seats, holders for spinning rods, and tables for echo sounders

After purchasing a PVC boat, many owners think about changing not only the appearance, but also improving its functionality.

There are various reasons for tuning your boat. For example, some bought a PVC boat when modern accessories were not yet in production, while others now bought a budget option without frills, assuming that they would buy all the necessary accessories later.

The fishing portal FishingSib, together with an expert in this topic, the SibLodki store, invites you to consider the most functional, interesting accessories for your PVC boat.

Finishing

As for finishing, it not only improves the aesthetics of the product, but also extends its service life. To do this, the product is treated with special impregnations, varnish and moisture-resistant paint .

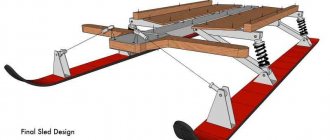

The design is simple enough to allow further modifications as in the following photos:

Spinning rod holders in PVC boat

Every fisherman, while fishing from a PVC boat, constantly torments himself with the thought of where and how to safely transport spinning rods while driving.

Therefore, the selected holder model will solve the problem of placing several rods at once and save space in the boat.

One of the most popular options for such attachments in Novosibirsk are universal spinning rod holders made of wood with metal tubes. Such holders have a number of advantages.

Compatibility. Most of the handles of modern spinning rods will fit into the “glass” of the holder without any problems.

Fixation strength. The spinning rod will not fall out of the “glass” in a given position.

Versatility. Suitable for different boat models, easy to move to different place on it.

Installation. Fast and easy.

Usage. The main advantage of such a holder is its use both while stationary and while trolling. It is securely attached to the PVC cylinder of the boat, and does not dangle or become loose while moving through the water.

Field testing of a spinning rod holder for structural distortion and tackle flying out during waves.

Table for echo sounder in PVC boat

In addition to holders for spinning rods, some fishermen are thinking about purchasing various modifications of tables for echo sounders. The photo shows the three most popular options, from the simplest (UKB) to the multifunctional, which involves installing a lead battery up to 12 mAh.

It is the latter that can be considered the most functional. Thanks to a special belt, you can securely attach the battery to the echo sounder. This means that the wires from the battery will not stretch across the boat and interfere with fishing.

Awning or umbrella for shading

Modern tuning of plastic boats involves various procedures, and most often they are aimed at increasing the comfort of their operation.

In addition to installing mounts for tables and chairs, such boats can be equipped with an awning or canopy, shading the interior of the vehicle on hot days and protecting from precipitation.

Seats for PVC boats - types, recommendations for selection

Most often, rigid types are used as seats for PVC boats - benches or special swivel and folding chairs with backs.

Hard seats for PVC boats. The regular ones included in the standard package are most often rigid ones made of moisture-resistant plywood or plastic. Seat fasteners can be stationary or movable. Stationary - when the fastener is glued to a specific place, and there is no way to move the bench. Movable - the so-called lykpaz-lyktros. Thanks to this fastener, the benches can be moved along the cylinders without difficulty.

This gives the seats the ability to move inside the boat's cockpit, passengers can be seated comfortably, and the cargo can be properly distributed when the boat motor is installed.

Tuning seats for PVC boats.

You must admit that it is not very comfortable to sit for a long time on a hard seat, which is included in the standard equipment of almost all boats. Discomfort is most often felt while riding, when the boat rides on a wave, and the hard seat bounces every blow of water against the side. To avoid discomfort, you can use one of two options for improving your seat.

Firstly, special seat pads are used to increase comfort. They can be either simple soft ones or with special compartments for additional gear. It’s very convenient; you can take a thermos of tea and a bottle of water with you into the boat, and be sure that all this will not roll along the bottom of the boat.

In addition to the option with an overlay, you can use special swivel chairs. They are installed quite simply. To do this, we take a special bracket, which, thanks to metal guides, can be easily pulled together on the seat.

Interestingly, inside such a bracket there is a bearing that allows the structure to freely rotate around its axis.

And the chair itself is already mounted on top of it.

The seat chosen for demonstration is equipped with a folding backrest made of plastic with soft inserts made of high-quality vinyl. The main advantage is that it can be installed on most models of PVC boats.

Konstantin Kozhushko, head of the SibLodki fishing store:

— Thanks to personal experience in using such a design, I advise all fishermen to mount such a mechanism not on one seat, but on two. The fact is that an installed chair can tip over when simply leaning on its back. The width of attaching one bench to the lyktros is not enough to hold the fisherman, but two benches are enough.

Booking

Almost all assembly seams are “bandaged” - glued with additional tape made of the same PVC material, which improves the strength and tightness of the seam. Although many manufacturers on budget class boats assemble the seam either by overlap or simply “on a bandage”, but without additional bandage. So the bandage is a good indicator. The generally accepted width of the bandage is on average four centimeters.

But welded seams are usually not bandaged.

The fact that the seam is welded can be understood by its slightly melted edge. Whereas the edge of the glued seam has a pronounced structure of cut PVC.

Directly booking the finished product is done with a special beam made from PVC material.

We can say that it is mandatory to book the keel. This is perhaps the most vulnerable part of the bottom. And in most cases, for the bottom, a beam 90 mm wide is sufficient. Often, manufacturers, in order to save a little money, use 60 or 70 mm, but this, as a rule, is a little lacking, as eloquently evidenced by the appearing “burrs” on the keel itself. So 90 mm is the best option.

If the keel is armored along its entire length, then it is enough to armor the cylinders in the most dangerous places at the bow and stern, which often rubs against the shore when pulling the boat out of the water. One can, of course, argue with this option, but that is for sure that it is minimally sufficient.

Transom wheels for PVC boats - mounting options, installation

The most popular accessory that helps deliver a PVC boat from the assembly point to the water is still considered to be transom wheels, which are installed on the rigid side of the inflatable boat. If you often go fishing alone, then you should think about installing similar wheels on your PVC boat.

Mounting options

The principle of operation of transom wheels is based on the fact that, depending on whether the boat is moving on land or has already been launched, the wheels occupy one of two possible positions and are fixed in it (photo 1,2,3).

By the way, for PVC boats with an inflatable bottom, curved racks are used (photo 1), and for boats with a soleplate bottom, straight ones are used (photo 2).

There is another option for installing transom wheels on a PVC boat - removable. To do this, special fastenings are installed on the transom, and while the boat is moving through the water, the stand with the wheel can be easily removed (photo 4).

All accessories for fastening wheels are usually sold complete with them; you only need tools: a drill, a screwdriver, sealant and a ruler.

Installation of transom wheels

To ensure that both wheels are installed parallel to each other, use a ruler to make markings on the transom. Next, we apply the fastener to the marked line and mark the points where we will drill. We drill holes for fastening, fill it with sealant, insert bolts into the fastening and screw it to the transom. Installation completed.

Adviсe. The wider the transom wheels are spaced, the more convenient and easier it is to manually transport the boat. But before drilling holes for the brackets, check whether the wheels will touch the cylinders when lifted to the non-working position and interfere with the rotation of the motor when moving. Also, the wheels must be strictly parallel to each other - otherwise it will be difficult to move the boat on land, and the wheels themselves will quickly fail. The axis of each mounting hole must be perpendicular to the plane of the transom so that the bolt heads and washers contact the entire surface of the elements being connected.

Bottom reinforcement

The PVC fabric that serves as the bottom of the boat is quite durable, but it is inconvenient to move on. Since the bottom is not hard, every angler experiences a number of inconveniences. Therefore, strengthening the bottom is the primary task. In the future, the reinforcement will have to be repaired, but not the bottom of the boat. This will cost less, and it will be easier to replace the reinforcement with a new one or repair it. It is possible to carry out both full and partial reinforcement of the bottom of the boat. The bottom is reinforced by gluing a special PVC tape, which is called a “fender bar”. The fender can have a thickness of 1.2-3 mm with a width of 60-235 mm. It is attached using 2-component glue. This will make the bottom harder and more protected from various underwater surprises.

Keel reinforcement

The operation boils down to gluing PVC tape (fender) over the factory tape. Similar reinforcement extends to the keelsons.

Transom reinforcement

For this element of the boat, reinforcement is simply necessary, since the transom is protected by only one layer of PVC fabric.

In order not to suffer with individual elements, the bottom of the boat can be completely sealed using a fender. If you are careful and careful, and also choose the right glue, you can do the operation yourself. This approach will solve many problems associated with the deterioration of the boat’s performance.

If the boat has a hard floor, you will have to install duralumin profiles. Since the boat is deformed while moving, the hard floor pads touch the inflatable parts of the boat and a friction process occurs. This can lead to abrasion of the fabric, which is undesirable and can compromise the strength of the boat. In the bow, where the profile of the boat has a curved shape, stringers are not installed.

Such fixation, in my opinion, should be provided in any boat, despite the various options for floorboards or inflatable bottoms. By securing the gas tank in place, you don’t have to worry about its safety and location even in stormy weather. It is more convenient to carry out any fastenings in the boat using half rings and slings.

Depending on the type of bottom, the half rings can be installed using screws, self-tapping screws, or glued using special pads. Exactly the same fastenings can be placed in any part of the boat cylinder to secure any equipment and inventory. In this way, you can secure small bags, hermetic packaging, tubes with spinning rods, and, most importantly, the anchor, securing it with rings from spontaneously falling overboard.

Mounting the echo sounder sensor

Stable echo sounder readings at speed largely depend on the correctness and reliability of its mounting on the boat transom.

The lower edge of the transom board is in close proximity to the surface of the water, which makes it the most convenient place to place the mounting elements for the echo sounder sensor.

There are several options for brackets for the echo sounder sensor, which, thanks to a clamp, are attached to the PVC transom of the boat. The main differences between them are the availability of insurance. That is, at the moment of impact with the bottom or other underwater obstacles, thanks to a special mechanism, the bracket rod together with the sensor leans back.

Adviсe. First of all, the bracket you choose should be universal and quick-release. Must have mandatory immersion depth adjustment. The bracket fittings must be either metal or durable plastic so that it does not break when it hits the bottom or driftwood. If the bracket is metal, then its coating must be of high quality, that is, highly resistant to corrosion.

Glue

In the production of PVC boats, polyurethane glue is used, which was originally used in the shoe industry. Boat spare parts are usually equipped with adhesives without a hardener. They glue well, but until the patch is heated to a certain extent by the sun. Some manufacturers put two tubes in the spare parts kit, one contains glue - resin, the other contains a special hardener; this repair kit is of the highest quality. But in any case, the repair kit was created so that if something happens, you can install a temporary patch and calmly continue fishing. For quality home repairs, a two-component adhesive is desirable. Moreover, it is the most durable and highest quality glue, which has a high bonding temperature. As a rule, about seventy degrees.

There are also cold adhesives; their gluing temperature is 21 degrees, and such adhesives are in most cases used in industrial production in order to increase labor productivity. That is, the less time it takes to heat up, the faster the seam is assembled, and the faster the seam is assembled, the faster the boat itself is made. The warranty period for such adhesives is one or two years, and they take care of it, but after six to seven years, the “cold” glue becomes thermally unstable, and when strongly heated by the sun’s rays, it begins to “float.” The hardener stops working, and the glue itself turns into resin without a hardener, and accordingly, the seams begin to separate.

When repairing a boat on a pond, it is also a good idea to warm up the patches. At the same time, you need to know that you need to heat the patches not from the glue side. An open fire, when heated from the glue side, promotes the formation of a film on it, which significantly impairs the quality of gluing. You can warm up the material with a traveling iron mug with boiling water in it, and the main thing is that at least one layer of the material warms up well. By the way, it is not recommended to use the so-called “second” glue, since it cannot be removed from the PVC surface, and in no way. The patch with polyurethane glue is removed in the reverse order - heat it and remove it. If the patch was on “second” glue, then it will only have to be cut out. By the way, in industrial production the patch area is first covered with masking tape or electrical tape so that the glue does not extend beyond the boundaries of the patch. In principle, glue can be spread anyway, this does not greatly affect the quality. But polyurethane glue tends to turn yellow in the sun, which can subsequently ruin the appearance of the seam.

Platform for accessories in PVC boat

We looked at the main attachments for a PVC boat, but there are also glued ones, thanks to special platforms.

As an example, let's take the most standard one, which can be glued using special glue. It is installed depending on what will be hung on it - an anchor eye, a holder for a spinning rod or other equipment that will correspond to the platform connector. Most often, various types of anchor eyelets or cable rollers are installed on it using special self-tapping screws.

Also, fishermen mount various modifications of holders for spinning rods on them.

Manufacturers and products

Among the manufacturers, Chinese companies can be noted. They produce goods of good quality, but at a low price. There is also production in Russia. This is what he does. This company is distinguished by high quality products. It is durable and resistant to environmental conditions. Some Italian companies are also involved in the production of eye glasses. They sell high-value goods, however, there is no doubt about the quality.

Cheap analogues have a straight leg. This means that gluing the mechanism will be more difficult. You will need to press the device harder against the boat. Expensive options have a curved base. This is convenient for gluing, as well as for transportation. The increased contact area with the boat will make the bond stronger.

The price of this product varies greatly. It ranges from 300 to 8,000 rubles (2019). This is due to the fact that some mechanisms come complete. It includes fastenings and an anchor roller. Also, the price depends on the diameter of the rope that the eyelet fits under. The thicker it is, the more expensive the mechanism. The stronger material guarantees efficiency when using the anchor.

To learn how to glue the anchor eye, see the following video.

Handles in PVC boat

The photo shows the four most popular options for PVC handles.

- This handle is the softest and does not cause any problems for the fisherman when deflating and packing the boat.

- A handle glued to the bow is designed for comfortable dragging of an already inflated boat. It is especially convenient if the boat has transom wheels and you decide to go fishing alone.

- This type of handle is called hard. The advantage is that it does not corrode.

- Another hard handle, but unlike the previous type, it is slightly modified. Thanks to the grooves, you can easily wind the anchor rope around it.

Fishermen choose stick-on PVC handles for boats because of two advantages over hard ones:

- lightness - excess weight installed on a boat is not always convenient to carry from shore to car, and vice versa.

- packaging - hard handles; during deflation and assembly, PV boats will only interfere with the process.

Attachable accessories for PVC boats greatly simplify life for anglers of any skill level. They allow you to equip the boat with exactly those instruments or devices that are necessary to perform a specific task on any body of water. At the moment, in this market segment, every fisherman will be able to choose the right elements for himself.

We thank the SibLodki store for creating the article.

- Novosibirsk, Pisareva st., 60, office. 1.6

- Phone: +7-913-741-3110

- Opening hours: Mon-Fri from 10:00 to 18:00.

Table for echo sounder in PVC boat.

There is not much space in a PVC boat, and over time there are more and more things. At first you fish with one spinning rod, then more appear, an echo sounder appears, but it requires a battery, etc.

So I decided to make a table to combine everything together and not get in the way.

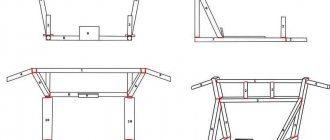

For the table I took 9mm moisture-resistant plywood. I sketched out a drawing, having first removed the pattern from the boat’s cylinder, since the table will stand at the side and be attached to the cable so that it does not move around the cockpit.

Because I already had experience with the table and it became clear that connecting the parts with various screws and nails is not the best solution, it was decided to connect the parts with grooves into each other and glue everything with epoxy resin. I cut out the parts according to the drawing.

These are the side walls of the table, with grooves for the top and middle shelves, and for the back wall. Well, they are rounded to fit a 430mm cylinder, the height is taken from the floor, the table should stand on the floor and not hang on the cable cable.

Back wall. If at the bottom it is exactly the width of the table, the width is such that a car battery that will be located below will then fit.

Top shelf with grooves for the side walls.

Middle shelf with grooves for the side walls.

The main details are cut out, you can try it on and see how it will look. Because I don't use a CNC machine and cut it with a jigsaw, not all parts are perfect. Therefore, we had to assemble it in a certain sequence, but this gave the table even more strength.

Top shelf first

And these other small parts are simply attached and not secured in any way. There are still not enough caps on top.

Side projections of the top and middle shelves for spinning rod holders. I didn’t take any photos of the drilling, so it was assembled right away.

The pipes are ordinary PVC. The holes in the middle partition on the top shelf are for electronics, there will be a voltmeter, USB chargers for the phone, and two cigarette lighter sockets.

This is what it looks like on the finished table.

When all the parts are connected to each other, I glued them with epoxy resin with the addition of wood flour; a lot of it remains from the cut. After the fillets have dried, the entire table is brushed with epoxy resin with a small addition of solvent to make it more fluid and impregnate the plywood. It is also better to heat the plywood for this. Because I worked in the garage and when it was no longer so warm, I used a hairdryer, heated it and coated it at the same time. This way the table will not become moldy from moisture.

There are never too many holders, so in addition to vertical ones, I also added side ones, which can be used for onboard fishing rods, whether it’s an onboard feeder or if you’re fishing for sprat from a boat.

All that remains is to secure the echo sounder. The echo sounder will be located on the top cover. My echo sounder is a Garmin Echomap 73sv CHIRP and it doesn’t have a swivel mount, so I had to come up with my own.

To do this, I simply cut a piece of plywood in the shape of the echo sounder mount and bought a furniture bolt with a large washer and a wing nut to make it easy and quick to remove the echo sounder.

The bolt is inserted in the middle, and the original echo sounder mount is already attached to this structure; this will be the rotary mount.

We put everything together and go fishing. This is what it looks like when working on a boat.

There is a battery at the bottom. On the middle shelf there are various small items, cigarettes, a multitool, a knife, etc. On top, under the back cover, are all the wire connections; under the front cover, usually the phone is lying on charge, or I just throw baits taken from the spinning rod there.

PS: Why do I use a car battery? We just have a permanent camp on the islands and we stay there for several days, so the table is removed from the boat and taken to the gazebo, where it powers the lighting and charges the phones.

What happens?

The boat stand for the echo sounder and the battery for the lyctros differs depending on the installation location and mounting method. It is worth thinking in advance where exactly the shelves and space for mounting the gadget will be placed, since this affects the comfort of fishing. Before installing the stand, it is recommended to consider several nuances:

- it should be located perpendicular to the surface of the water, since such a detail will subsequently affect the accuracy of the readings;

- Bubbles should not form near the sensor, as this will become an additional inconvenience while the vessel is moving.

The sensor is usually mounted on the transom, the bottom of the boat, or remotely. It is necessary to think through the mounting in such a way that the gadget stands securely on the shelf and practically does not move while moving. It is preferable that the place be hard (especially important for PVC boats). On the bottom you can achieve the most accurate readings.

We advise you to immediately think about how to attach the gadget’s screen. This can be done using glue, a bracket or an ordinary suction cup. A common option is to place the bench in any place suitable for such purposes.

If the fastening is planned on the bottom or side surface, then the methods remain unchanged, but with the exception of the bracket (this is not a very reliable option when the boat is moving). Also, each echo sounder has its own mounting system, which lies at the base of the table.

Factory installation is considered the most popular. Fastening occurs using a clamp or bracket. It’s worth considering immediately so that such a design does not cause inconvenience during maneuvering. The priority location for fastening is the space near the side. The bracket allows you to adjust the angle of inclination, which is useful when the depth changes and due to the movement of the vessel. The main advantage of this method is that the structure is quickly installed and dismantled; another visible advantage is the reliability of the structure.

The table for the echo sounder along with the mount can also be made by hand. The materials you will need are chipboard, a metal-plastic pipe, a pipe made of a material that does not rust, a clamp, bolts and washers. This option is much cheaper than the factory one, and this is the main advantage. The main disadvantage is that if the structure is assembled incorrectly, then in the future there will be difficulties with the transmission and accuracy of the signal, which will cause discomfort during fishing. It is advisable to make your own table for an echo sounder only if you have previously had experience in performing this type of work. It is recommended to choose mainly factory fasteners - this is much more reliable.

PVC boat table

Edik » August 24, 2015, 03:21 pm

Re: PVC boat table

by lera7423 » Aug 24, 2015 04:14 pm

Re: PVC boat table

ArteM84 » 24 Aug 2015, 16:38

Re: PVC boat table

Edik » August 24, 2015, 04:44 pm

Yeah! According to the type of fastening of the UKB. Also an option!

Re: PVC boat table

by lera7423 » Aug 24, 2015, 4:52 pm

Yeah! According to the type of fastening of the UKB. Also an option!

Re: PVC boat table

Edik » August 31, 2015, 11:09 pm

Re: PVC boat table

Andrey Zemtsov » 04 Jan 2016, 20:12

Re: PVC boat table

by gektor » 05 Jan 2016, 15:24

Re: PVC boat table

by gektor » 05 Jan 2016, 15:25

Re: PVC boat table

by gektor » 05 Jan 2016, 15:26

Re: PVC boat table

belgsi » 05 Jan 2016, 17:16

Re: PVC boat table

by artemov » Jan 05, 2016, 10:22 pm

Re: PVC boat table

by gektor » Jan 05, 2016, 11:08 pm

Re: PVC boat table

by mazatrucker » Jan 16, 2016 09:08 pm

Re: PVC boat table

by gektor » Jan 17, 2016 1:46 pm

Re: PVC boat table

why not drink » 17 Jan 2016, 18:51

Re: PVC boat table

by gektor » Jan 17, 2016, 8:52 pm

Re: PVC boat table

Dan » Jan 18, 2016 11:46 am

Re: PVC boat table

by gektor » Jan 18, 2016, 1:20 pm

Re: PVC boat table

by lera7423 » Jan 18, 2016, 1:26 pm

Re: PVC boat table

Thunder » 29 Feb 2016, 20:18

Here's my version. I did it on the weekend, in about an hour and a half.

There are some small things left: make an edge on the tabletop and a grab bar on the shelf so that the beer doesn’t fall out. Well, that’s all with yacht varnish!

Re: PVC boat table

Zhekka » 29 Feb 2016, 20:37

Re: PVC boat table

Thunder » 29 Feb 2016, 21:14

Re: PVC boat table

by Baksus » Mar 01, 2016, 11:15 pm

[quote=”Thunder”]And here is my version. I did it on the weekend, in about an hour and a half.

With the table, everything is more or less clear. I am more interested in the transport fastenings of the sninning rod(s), but not the vertical ones (a la channel pipe). I see you have brackets for oars? For a float?

Re: PVC boat table

by Baksus » Mar 01, 2016, 11:25 pm