Making a pipe with your own hands is a long and labor-intensive process. To do this you will need material, tools, skills and experiments. As practice shows, even experienced carpenters' first copies are not of the best quality. What smoking pipes are made of is a whole science.

The smoking pipe is made from wood with your own hands. The optimal material is briar, but it is almost impossible to find it on the open market. Briar is extracted from the root of heather, which grows in the Mediterranean. Therefore, as a rule, cherry or pear wood is taken as the basis - available materials for a smoking pipe.

It is worth saying that creating a smoking pipe with your own hands will cost many times more than buying a new one. This is due to the labor-intensive process of cutting out the base, preparing the material, and also clarifying the internal channels. You will have to ruin more than one blank before you get some semblance of a smoking device.

Many people wonder how to make a pipe from foil or a bong from a bottle. This cannot be called a smoking pipe, since plastic and artificial coatings do not give the same effect as wood and briar.

Technology and production do not allow the use of paper products.

You can focus on pottery and rustication, but the slightest crack will render the product unusable.

Local tree species to create a smoking pipe

However, this tree does not grow in our area, and if you buy it, it will not be cheap. You can make your own smoking pipes, the materials for which can easily be found in local gardens. Fruit trees with dense wood are suitable for making a pipe: apple, pear, plum. But it is best to choose cherry; its fibers are the densest of the listed species, so it will not burn out for a long time. All the others are also good, but they char a little faster. It is advisable to use the root part for harvesting, but branch or stem material is suitable. Fruit trees have a great flavor when smoked. Some people like the taste of cherry, others like apple, it all depends on your own preferences. This is also why it is better to make a smoking pipe with your own hands.

Preparation of material

Having decided on the type of wood, you also need to find out how to properly dry a suitable piece. You cannot cut a living branch or part of a root and immediately make a tube out of it. The cuts on the material are painted over or sealed so that moisture cannot quickly evaporate through them. It should gradually come out through the bark, which in no case should be removed immediately. And so the tree should lie until next year - then the fibers will gradually dry out, and there will be no cracks in their structure. And only after this time will it be possible to remove the bark and grind out the shape of the smoking pipe.

You can also make a smoking pipe from a dried log. To do this, you need to cut the workpiece from its center. Of course, if it was in a dry place. The extreme places with cracks are cut off, after which there is solid wood that has no flaws. After this, the bark is removed and the required size of the workpiece is cut out, but with a margin of five centimeters. Then the wood is put aside for a week, because it must completely dry out, after which microcracks may well appear. If you immediately start grinding out the shape of the smoking pipe, then the revealed flaws will ruin everything. And after a week, even if small cracks open, they will be in the remaining stock, and after cutting it off there will be an ideal surface for carving.

: Glue the halves together

Get some strong wood glue and put some in the places where you didn't cut anything and put a very small amount of glue on the trunk because when you join the two halves together the glue will want to seep into the duct and block it.

Press the two halves together or place them in a vice for a few hours. Once the glue is completely dry, remove the tube from the vice and blow hard into it. If you were able to do this, then you are ready to move on. If not, place the tip of a flat-head screwdriver on the seam where the tube halves meet and tap the screwdriver with a hammer to separate it into pieces. Sand off all the glue and cut the duct a little deeper, then try to glue the halves back together.

Manufacturing process

To begin, cut out a simple angular blank resembling a square or diamond. Its surface must be sanded in order to clearly see the structure of the wood and determine whether there are any defects on it. If everything is good, we mark the future shape in more detail so that we know where the smoking chamber will be, and where the shank is - this is the part where the mouthpiece is attached. You need to mark all the details and holes with a pencil. It is also worth drawing directions to make it easier to maintain angles when drilling.

When making smoking pipes with their own hands, craftsmen first drill a hole for the chamber into which tobacco will be poured. First, you should do this with a thin drill, and then select a thicker one until the hole reaches the desired diameter. But you shouldn’t immediately bring it to the final size; you need to leave an allowance of a few millimeters and then sand it with sandpaper. After all, the drill leaves an uneven surface, but it should be smooth.

After this, a smoke channel hole is drilled on the side in the place where the chibouk is intended. This must be done carefully, because making smoking pipes with your own hands is a very precise and labor-intensive process. The hole for smoke exhaust must be strictly at the bottom of the tobacco chamber. This is a very important point, because if you make it a little higher, the tobacco inside will not burn completely, which can lead to souring, and this will worsen the taste of the pipe and the smoke. This channel can be from 3 to 4 mm. The wider it is, the drier the tube will be. By the way, it is better to equip it with a filter to prevent ash from getting into the middle. In addition, the wide smoke channel makes it easy to clean the pipe with a brush. Once the holes are ready and accurately connected, you can begin to create the external shape.

Of course, it is better to make smoking pipes with your own hands on a machine; it will be much easier and faster. But if you don’t have such equipment, you can still make a good copy by hand.

Next (when working on a machine) you need to make circles that are possible; all other parts are cut out by hand with a well-sharpened cutter. It is important to make the edge of the motiz narrower than the entire width of the shank. This is necessary so that the mouthpiece can be put on and the two parts are on the same plane. After this, the surface is sanded outside and inside with sandpaper. First, the large one removes all the bumps left by the knife, and then the fine one removes scratches from a flat surface. However, you can leave the outer parts unprocessed - here everything is done to the taste of the master.

There is no tool at all

In this case, drilling the briar yourself and making a mouthpiece is out of the question. We will use a pre-drilled hobby block and a pre-made acrylic mouthpiece. Both can be bought, for example, on. True, hobby blocks are not always available there. You can also search for hobby blocks on eBay.

The diameter of the trunnion (the tenon of the mouthpiece) and the mortise (the hole for the trunnion) must be compatible, therefore it is advisable to buy the mouthpiece and the hobby block from the same seller.

You will still have to buy some minimum tool. Namely, a file and several sheets of sandpaper from the coarsest to 1000 grit.

You will have to sharpen the shape of the tube with a file. Be prepared for the fact that this will take a lot of time. You can roughly cut off the excess material with a hacksaw, but then, in addition to the hacksaw, you will also have to buy a vice.

Next, when the mold is ready, move on to the “grinding and polishing” section.

Manufacturing process

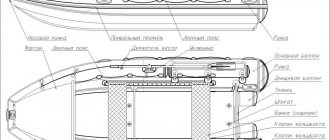

You need to take a stick of ebonite or acrylic with a length of 10 to 15 cm. To ensure that the smoke has time to cool when smoking, make your own smoking pipes no shorter than 10 cm. Taking this into account, we choose the size of the mouthpiece. A hole is made in it along the entire length with a drill, the diameter of which is 3 mm. They start from the part where there will be a connection with the chibouk. After this, the hole is expanded by half the length to the diameter of the smoke channel. Then this step that forms needs to be smoothed out. To do this, you need to cut a triangular tip on a wire with a diameter of 4 mm. It needs to be pushed in all the way and carefully turned several times.

After this, the channel is sanded using a thin wire with sandpaper glued to it. The place where the mouthpiece will be is expanded horizontally to create an oval of 5-6 mm. This will make it easier for the smoker to absorb the smoke. On the other hand, the hole in the mouthpiece is widened so that it fits tightly onto the shank, but without much effort.

External molding of the mouthpiece

Mouthpieces, like smoking pipes, are processed with your own hands. You can grind it on a machine or use improvised tools. The form is also arbitrary. After this, you need to sand the surface first with fine sandpaper, and then with felt with GOI paste. If you make an ebonite mouthpiece, you can bend it and give it a different shape. To do this, it is heated over a gas stove or candle and then bent.

Do-it-yourself wooden smoking pipes can be waxed or etched - this way their surface will look elite, and the wood pattern will be much clearer and, of course, this is an excellent protection for the wood surface.

Dart

Currently, there are several varieties of darts for shooting from blowguns on the market.

Darts with weights at the end are used as a training tool for developing skills. The lightest - long - options are used for maximum precision, sniper shooting from long distances. Thanks to their balanced weight and shape, products in this category demonstrate stable movement in space. As for the shortest options, they are most often equipped with wide blades. Blowpipe hunting using such darts is possible for small game. In particular, cases of slaughter of ducks and hares using the specified ammunition have been recorded.

Waxing

There is a great and simple way. Wax required. 100 g of it needs to be finely chopped, then add mastic (12 g), instead of it you can crushed rosin (25 g). The selected mixture is put on fire until everything becomes liquid. Then remove it from it and immediately pour in 50 g of warm turpentine. After this, the mixture must be thoroughly stirred and poured into the required container. The composition is stored in it until it is needed to be used. Take the mixture, apply it to wool or cotton fabric and thoroughly rub it into the wood.

Cleaning a smoking pipe

This should be done when the tube has completely cooled down. You must carefully disconnect the mouthpiece by unscrewing it clockwise. If you pull it out using extraordinary force, you can damage both parts of the tube. The mouthpiece is cleaned with special brushes, starting from the side of the mouthpiece. It is better to have several of them for a more convenient process.

It is necessary to clean the chibouk after each smoking session. The brush is started from the side where the mouthpiece was. After everything is cleaned, the brush is left inside the pipe until it is time to fill the pipe with tobacco. Cleaning of the product is completed by wiping all its external surfaces. The tube is then purged to remove any carbon or debris that may have remained inside.

For general cleaning of the tube, wax, alcohol, and various other liquids are used; it is carried out as it becomes dirty. And only the owner himself knows when simple maintenance is not enough.

Nowadays, a pipe is more of a decorative element; it is rarely smoked because it needs to be looked after. Now they are like fine wine, which is only savored from time to time. There are also many accessories for such a delicacy (stands for smoking pipes, for example), which can come in different shapes and sizes.

How do the most expensive and collectible pipes differ from ordinary ones?

First of all, it is an ideal material – briar. In the most expensive collectible pieces, the fibers of this wonderful tree are visible, woven randomly, but the master presents them as if they were grown specifically for this smoking pipe. They, like rays that envelop the smoking chamber, pass into the chibouk. Such an object of art as a collectible smoking pipe always receives enthusiastic reviews not only from knowledgeable people, but also from ordinary people. After all, a masterpiece always has a special aura and, of course, appearance. And looking at it, you cannot catch yourself thinking that you can change its shape or appearance. This is precisely where the master’s talent lies.

A little history

The mouthpiece came to us from Germany; it was in this country that they created the original accessory, a separate long tube into which a cigarette was inserted. Initially, the purpose of such an item was to preserve the tobacco mass to the last crumb and not allow even a grain of this dust to go to waste . The mouthpiece was invented at a time when hand-rolled cigarettes and primitive rolled cigars were in use.

Tobacco was a valuable and expensive product in 19th-century Europe. Therefore, we spent it very sparingly, trying not to lose a single grain from the tobacco mass.

In those days, the smoking process was not particularly pleasant, the paper where the tobacco was wrapped became wet, bitter grains of tobacco got into the mouth, and the smoke was acrid and irritating. And the moment came when someone named Charles Peterson came up with a wonderful device from a small hollow tube. A rolled-up cigarette was inserted into the pipe, and the smoker received long-awaited pleasure.