Author: AccheDin

07 March 2015 13:24

Tags: Solar collector jars

118614

12

2

This is an incredibly simple and inexpensive solar collector for additional home heating that heats the air directly. The most interesting thing is that the solar panel is made almost entirely from empty aluminum cans!

0

See all photos in the gallery

The body for the solar collector is made of wood (15 mm plywood), and its front panel is made of Plexiglas / Polycarbonate (you can also use regular glass), 3 mm thick. On the back of the housing there is glass wool or polystyrene foam (20mm) installed as insulation. The solar receiver is made from empty cans of beer or other drinks, which are painted with matte black paint that is resistant to high temperatures. The top part (lid) of the can is specially designed to ensure greater efficiency of heat exchange between the air and the surface of the can. (Please follow the technology!).

When it is sunny, regardless of the outside temperature, the air in the jars heats up very quickly. The fan returns the air back to heat the air and the room is warm.

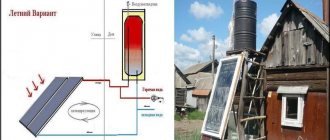

Manufacturing of flat type structures

In a dacha or suburban area, for the domestic needs of a family of three, it is enough to install a water heater with an area of 2 m2 for a 200 liter tank. To assemble a solar collector yourself, you will need:

- absorber body made of plywood and wooden planks;

- sheet steel, copper or aluminum for solar energy absorber;

- a grid of seamless pipes for coolant;

- insulation material (mineral wool, Penofol, polystyrene foam);

- glass thicker than 5 mm;

- capacity 200 l;

- 6–7 m of copper tube for the heat exchanger;

- heat-resistant black paint;

- tools for wood and metal work, welding machine, fastening materials, silicone.

To save money, you can do without a metal absorber, and use the back wall of a wooden case, which must be painted black, as an absorber of infrared radiation. Copper pipes are replaced with polypropylene ones. The cost of tees for their connection is much lower than welding work.

Step-by-step instructions will help you make a solar collector with your own hands:

- A grate for the coolant is welded from metal pipes.

- If there is a metal sheet of the absorber, a grid of pipes is welded to it.

- According to the drawings, the plywood is cut and the body is mounted.

- If plastic pipes are used, they are secured with clips to the base and connected to each other with fittings.

- The body and grille with absorber are coated with black paint.

- Insulation is laid under the sheet absorber or the heater is insulated from the outside.

- To fasten the glass around the perimeter of the body, a frame is filled with strips, in which inlet and outlet holes for pipes are drilled.

- The glass parts of the top cover of the collector are connected with aluminum corners.

- Sealing is carried out with silicone.

The heat exchanger manufacturing technology consists of insulating the storage tank, organizing the inlet and outlet openings for the copper coil through which the coolant will circulate. The collector is installed on a support made of 50x50 mm beams, fastened with metal corners, since the weight of the structure, even without water, is quite impressive.

Collectors made of non-traditional materials

The general diagram and manual for the manufacture of a classic solar water heater gives scope for independent modeling of the design using improvised means, cellular polycarbonate, and a plastic hose. You can make a small collector yourself from the freon circuit of an old refrigerator. The coil is fixed in the frame, the back wall is insulated, and the top is covered with glass.

The simplest pool heater for a summer cottage can be made using a garden hose, which is twisted into a spiral and laid on a foam insulator. Glass creates a greenhouse effect and the plastic pipe heats up quickly. To increase the performance of the system, several spirals are connected in series with each other.

Assembling a lightweight and durable polycarbonate solar collector yourself is not difficult if you buy:

- cellular polycarbonate sheets 1000x2000 mm, 4 mm thick – 2 pcs (for coolant and protective coating);

- foam for back wall insulation;

- 2 m of PVC pipe with a diameter of 32 mm – 2 pcs;

- plugs and threaded corners for pipes – 2 pcs.

The following instructions will help you make a water heater from polycarbonate:

1. Make drawings and assemble the support frame following the woodworking manual.

2. Using a drill with a disk attachment, it is necessary to make longitudinal cuts along the width of the polycarbonate sheet in the pipes.

3. The edges of the polycarbonate are treated with sandpaper and degreased.

4. Plates are inserted into the cuts so that they do not block the gap in the pipe.

5. The joints are sealed with hot-melt adhesive for plastic.

6. Paint with black paint.

7. Connect the fittings and carry out the test.

Preparing the jars

0

To begin with, we collected empty cans from which we will make solar panels. It is necessary to wash the jars as soon as they begin to emit odors. Attention! Cans are usually made of aluminum, but there are also some made of iron. Cans can be checked using a magnet. A punch (or nail) is inserted into the bottom of each jar and neat holes are made, although you can drill it with a drill. The caliper is then inserted and distorted according to the drawing. Instead, you can use special tools or large Phillips screwdrivers. The top of the can is cut with scissors and bent to form a “fin”. Its mission is to promote turbulent air flow to collect as much heat as possible from the heated can wall. (Please follow the technology!) All this must be done before gluing the cans.

The process of assembling a homemade solar collector

The beginning of the assembly of this solar energy product starts with the manufacture of the coil. If you were able to pick up a ready-made coil, final assembly will take much less time. The selected coil should be washed very thoroughly under running water (preferably hot) in order to wash out all blockages from the inside and get rid of freon residues. If you do not have any suitable tubes, you can purchase the required quantity in the store. But in this case you will have to make the coil itself. To make it, cut the tubes to the required length. Next, using corner transitions, solder them in the form of a coil structure. Next, so that the collector can be connected to the water supply system, solder ¾-sized plumbing transitions to the edges of the coil. There are several options for the shape and design of the coil, for example, you can solder tubes in the shape of a “ladder” (if you are going to implement this option, then do not buy corner adapters, you will need tees).

Solar collector assembly

Then you apply a selective coating with matte black paint to a pre-prepared sheet of metal; it is advisable to do this in at least a couple of layers. Wait until the air flow dries the paint and begin soldering the coil (from the unpainted side). The entire coil structure must be soldered along the entire length of the tubes; by doing this, you guarantee the most efficient heat transfer and, as a result, maximum heat transfer to the water supply system. If you do everything correctly, the solar collector you assembled will work as intended.

Personal experiment

For the sake of experiment, I made such an antenna in literally 15 minutes. The final result can be seen in the photo below.

- I bought 10 meters of the cheapest cable and two cans of regular beer. I poured out the contents and turned the jars over so that the excess drops flowed down. I trotted well again to get rid of as much liquid as possible.

- I took a wooden hanger and, keeping a distance of 7.5 cm between the cans, tied the containers to the bottom bar with masking tape.

- I exposed the cable and cleaned the “ears” with a knife so that there was contact with the cable screen and core.

- I connected the “eye” of one can to the core, and the second to the copper braid. To be sure, I squeezed the contact well with pliers.

- At the other end I attached an antenna connector.

Afterwards, I hung the antenna on the balcony outside the window on the third floor.

A connector was inserted into the antenna input. I started setting up digital channels, and as a result, 24 programs were found.

My parents also managed to find channels at home, but in fewer quantities and with a worse signal. I attribute this to the location of the apartment (1st floor) and the presence of obstacles. Moreover, the signal was higher inside the balcony than outside.

Unfortunately, it was not possible to achieve stable broadcasting. The antenna was built and fixed “on the knee”. Therefore, at the slightest touch to the cable or wind, the structure was distorted and changed its direction. Squares appeared on the screen and the image froze.

I am sure that if you approach the manufacturing process efficiently, the reception will be stable.

What materials will you need

To assemble your own solar collector, you can find all the necessary tools and materials in a regular hardware store.

To construct the device you will need to stock up on:

copper tubes measuring 18 mm (will serve as material for creating a coil);

- sanitary and corner transitions measuring 18 mm;

- metal sheet (approximately 0.8 mm thick);

- thermal insulation;

- soldering iron;

- cellular polycarbonate;

- plywood with wooden bars or aluminum sheets and corners;

- spray black paint (must be heat resistant);

- absorber and mineral wool.

TV connection

Connection is not just about inserting a plug into the TV. The following points must be taken into account:

- It is better to make the cable as short as possible. Its length affects the resistance. The longer the length, the higher the resistance. The signal travels harder and losses appear.

- The cable should not dangle on the antenna and mast. The fastening is done tightly. Metal clamps, nylon ties, electrical tape, and other fasteners are used.

- Connections that are not covered by anything can also degrade reception due to precipitation. All connections must be protected from moisture with Tsaponlak and sealed with molten glue.

Once the antenna is connected to the TV, you can start searching for digital channels. First, an automatic search is performed, which will find two dozen channels. If there is no result, then you will have to perform a manual search using the frequencies at which the nearest repeaters operate.

How to make selective coating

A highly efficient collector has a high degree of solar energy absorption. The rays hit a dark surface and then heat it up. The less radiation is repelled from the solar collector absorber, the more heat remains in the solar system.

To ensure sufficient heat accumulation, it is necessary to create a selective coating. There are several production options:

- Homemade selective collector coating - use any black paints that leave a matte surface after drying. There are solutions when an opaque dark oilcloth is used as a collector absorber. Black enamel is applied to the heat exchanger pipes, the surface of cans and bottles, with a matte effect.

- Special absorbent coatings - you can go the other way by purchasing a special selective paint for the collector. Selective paints and varnishes contain polymer plasticizers and additives that provide good adhesion, heat resistance and a high degree of absorption of sunlight.

Solar systems used exclusively for heating water in summer can easily get by by painting the absorber black using regular paint. Homemade solar collectors for heating a house in winter must have a high-quality selective coating. You can't skimp on paint.

Homemade or factory solar system - which is better?

It is unrealistic to make a solar collector at home that can be compared with factory products in terms of technical characteristics and performance. On the other hand, if you simply need to provide enough water for a summer shower, solar energy will be enough to operate a simple homemade water heater.

As for liquid collectors operating in winter, not even all factory solar systems can operate at low temperatures. All-season systems are most often devices with vacuum heat pipes, with increased efficiency, capable of operating at temperatures down to –50°C.

Factory solar collectors are often equipped with a rotating mechanism that automatically adjusts the angle of inclination and direction of the panel to the cardinal points, depending on the location of the Sun.

An effective solar water heater is one that fully meets its intended purpose. To heat water for 2-3 people in the summer, you can get by with an ordinary solar collector, made with your own hands from improvised materials. For heating in winter, despite the initial costs, it is better to install a factory solar system.

Project concept

The essence of the solar collector is that cold water from the reservoir flows by gravity into the collector. The heated water rises up through the channels and flows back into the tank. Thus, natural circulation is created in a closed system. The manifold is made of a sheet of polycarbonate or other plastic with hollow squares inside running lengthwise. To increase the absorption of sunlight and improve the collector's performance (the rate at which the water heats up), the plastic can be painted black. But here it is important to remember that the sheet is made of rather thin polycarbonate, so if it is heated strongly in the absence of circulation, it can soften or deform, which will lead to water leaks. It is also worth noting that this device is not suitable for installation in residential premises for the purpose of hot water supply. This experimental project is more suitable for equipping a summer shower in a summer cottage.

Converting solar energy into electricity

Solar energy is developing in two directions; semiconductor converters generate electric current from daylight. The solar system works thanks to photocells, which consist of two silicon wafers with different conductivities. In one there is an excess of negative particles, in the other there is a deficiency. Under the influence of light, electrons begin to move between the cathode and anode and a current arises. Modern technology makes it possible to produce mono- and polycrystalline silicon wafers; the former have a longer service life and high efficiency, the latter have a low cost.

The performance of an individual photocell is of little importance, so solar cells are assembled from them. The simplest light energy generator is a series chain of semiconductor wafers with a total voltage. Common solar cells have parameters of 3.6 A and 0.5 V. A standard design can be assembled from 36 such plates, which will generate a current of 18 V, which corresponds to approximately 60 W. To increase the current, several solar panels are connected in parallel, thus increasing the power of the system, but the voltage remains unchanged.

Photocells work as energy generators during daylight hours; when darkened, they turn into current collectors and can overheat and fail. To protect the solar installation from daytime losses and battery discharge at night, a semiconductor diode is connected in series to each panel.

They store the energy produced by photocells in batteries with a lower voltage. Since solar panels operate intermittently when darkened, they are connected to the tank through a controller. It provides protection against overcharging the battery and switches the system to a resistor. To use sunlight in a household electrical network, an inverter is installed in the circuit, which converts direct current into alternating current.

You can assemble solar panels with your own hands from ready-made solar cells and a homemade frame:

1. The power of the system is determined by the expected loads, then the required number of plates and the area they will occupy are calculated.

2. The bottom of the shallow housing for placing photocells is made of plywood. It is necessary to make holes in the sides for ventilation and equalization of internal pressure.

3. Chipboard is used as a substrate for the plates, and plexiglass is used to protect against precipitation, which will withstand hail impacts.

4. Photocells are laid out face down on the substrate so that there is a gap of 5 mm between them.

5. The connecting conductors of one plate are placed above the solder points on the back of the other. Use a low-power soldering iron, solder and flux.

6. Chains of photocells are connected in series using copper wire or a special bus.

7. The panels are turned over and, together with the substrate, installed in the housing. Attach the diodes and lead the wires through the hole in the bottom to connect to the battery.

8. Cover the frame with plexiglass and seal the joints with silicone. Carry out a control test of the battery.

| System type | Size, mm | Absorber material | Price, rubles | Manufacturer |

| Flat-plate collector for seasonal water heating: | ||||

| Sokol Effect-A | 2000x1000 | aluminum | 16800 | JSC "VPK NPO Mashinostroeniya" |

| Sokol Effect-M | copper | 19400 | ||

| Svetogray standard 2 | 1980x920 | 18680 | LLC "Exmork" | |

| ISolar | 2065x1100 | 19700 | LLC "New Polyus" | |

| Vacuum all-season for hot water supply and heating: | ||||

| 30 tubes with frame | 2370x1430 | copper | 49900 | SGVA (China) |

| SUNRAIN ES-R1 (30 pcs) | 2420x2010 | 39800 | Korsa LLC | |

| SCH-30 | 2400x1900 | 61700 | ANDI Grupp (China) | |

| Battery for electricity generation: | ||||

| CHN150-36M elements 36, 150 W, 12 V | 1480x670 | silicon monocrystal | 14780 | Chinaland Solar Energy (China) |

| Exmork FSM-250M elements 72, 250 W, 24V | 1640x920 | 17750 | Sunny Energy Science and Technology (China) | |

| Exmork FSM-300P elements 72, 300 W, 24V | 1956x992 | silicon polycrystal | 19260 |

Box

Thus, arc-shaped plexiglass or polycarbonate will also serve as a focusing lens, increasing the light flux, and therefore increasing the temperature generated by the collector. To ensure maximum fit of the glass, make a slight bevel in the side walls of the box. Then the gaps, and therefore heat loss, will be minimal.

- How to make a solar collector from beer cans

Collector box

Plywood for holder

For greater heat transfer, you can duplicate this strip with thin sheet aluminum. This is how the top and bottom strips are formed. Don’t forget to provide through holes in the box through which air will be exchanged between the room in the house and the solar receiver.

Aluminum layer

Before stacking the cans, line the bottom with foil-lined insulation. Carefully install the tubes from the cans, treat the joints with the wooden plank with sealant and let them dry thoroughly again.

Battery made from cans

To ensure structural strength, install a mounting support in the middle. Screw two flat-headed screws to it - sheets of plexiglass or polycarbonate will rest on them in the center. Their height should correspond to the height of the rounded side strips of the box.

To hang on the wall, screw the mounting hooks to the back of the panel. You can also make them yourself from scrap sheet iron.

Classification according to temperature criteria

There are quite a large number of criteria by which certain solar system designs are classified. However, for devices that can be made with your own hands and used for hot water supply and heating, the most rational option would be to separate them by type of coolant.

So, systems can be liquid and air. The first type is more often applicable.

Image gallery

Photo from

Step 1: Assembling the Corrugated Pipe Manifold

Step 2: Painting the Solar Instrument Black

Step 3: Installing Air Connections

Step 4: Making a cover for the solar device

In addition, a classification is often used based on the temperature to which the working components of the collector can be heated:

- Low temperature. Options capable of heating the coolant up to 50ºС. They are used to heat water in irrigation tanks, in bathtubs and showers in the summer and to improve comfortable conditions on cool spring-autumn evenings.

- Medium temperature. Provide a coolant temperature of 80ºС. They can be used to heat rooms. These options are most suitable for furnishing private homes.

- High temperature. The coolant temperature in such installations can reach up to 200-300ºС. They are used on an industrial scale, installed for heating production workshops, commercial buildings, etc.

High-temperature solar systems use a rather complex process of transferring thermal energy. In addition, they occupy an impressive amount of space, which most of our lovers of country life cannot afford.

The manufacturing process is labor-intensive, and implementation requires specialized equipment. It is almost impossible to make such a version of a solar system on your own.

It is quite difficult to make high-temperature solar panels using photovoltaic converters at home

Place jars on glue

0

The tape of glue or silicone on the can is resistant to high temperatures, up to at least 200°C. There are also adhesive products that can withstand up to 280°C or 300°C. The bottom of the can and the top are a perfect fit, apply carefully glue. A detailed cross-section of glued cans can be seen in the figure.

0

In order not to miss the vertical-horizontal, it is better to make a template in advance from two boards nailed together at an angle of 90 degrees. The template in the figure will provide support while drying the cans in order to obtain a straight pipe - a solar tunnel.

0

0

The pipe must be fixed until the glue is completely dry.

Principle of operation

The collector is used to heat water using solar energy. Such a device can be installed near a summer shower or on the roof of a private house.

Factory models consist of a glass outer panel and a pipe system located underneath. There is insulation behind the pipes. Glass helps create a greenhouse effect inside.

Handmade models made of polycarbonate are simpler - the water in them is heated in the cells of the sheet itself. The hot liquid goes into the tank, and cold liquid automatically takes its place. In sunny weather, such a collector allows you to heat enough water for bathing several people.

The solar collector heats the water entering it through copper tubes using solar energy

The main thing is an idea and a clear plan

Solar panels made from cans are an ideal option for home owners. By installing such a simple structure on a wall or roof, you can completely provide heat to one of the rooms. Such a collector will help you partially unload the boiler. The main operation of the entire system is ensured by the principle of convection. The air in the can panels heats up in the sun during the day and, moving, effectively heats the nearby room. And most importantly, no one you know will guess what this “high-tech” solar battery is actually made of.

Procedure

Let's look at how to make a simple collector with your own hands.

Preparation

First, take measurements and determine how much area you can allocate for the device. If the roof is made of polycarbonate, glass or similar relatively weak materials, the collector should not be made too large.

A very convenient design is made of two plates approximately 2.1 x 1 m. One sheet directly heats the liquid, the second plays the role of a protective coating. Polycarbonate should only be cellular, preferably black.

Recommended sheet thickness is 4 mm. The total cross-sectional area of the channels is 35 cm² per linear meter, which is approximately equal to the cross-section of a pipe 6–7 cm in diameter. Thus, 1 m² of sheet will hold up to 4 liters of water. A 10 mm thick sheet will hold up to 10 liters per 1 m².

Before you start building a solar collector, you should draw up a detailed diagram of the entire structure

In addition to polycarbonate, you will need the following materials:

- two PVC sewer pipes 2 m long and 32 mm in diameter;

- 2 pipe plugs;

- 2 flexible hoses with threaded connection;

- 2 polypropylene corner fittings with metal threads;

- foam sheet for insulation;

- galvanized plasterboard profiles and cross slats for the frame;

- silicone sealant.

Polypropylene corners must fit tightly into the pipes, so it is better to purchase them together.

Their polypropylene pipes in the solar collector are fastened using polypropylene corners

The width of the profiles must correspond to the total thickness of the polycarbonate and foam sheets.

You will also need a device for cutting pipes - an angle grinder or a drill with a saw attachment.

If you are unable to obtain black sheets, you will need the appropriate paint. Polycarbonate can be painted with nitro enamel, water-based acrylic paints or plastic aerosols.

Amplifier installation

You can try to upgrade the antenna so that it receives signals from more distant towers by connecting an antenna amplifier. This will not make the design any more complicated.

- Connect the cable to the amplifier board.

- Screw the tabs with bolts and nuts to the board.

- Unscrew the plug box of the amplifier unit. Strip the cable at the free end and secure it to the board with the already built-in bolt mounts.

- Hang the antenna close to the window. Insert the plug into the antenna socket of the TV. Plug the power supply into a power outlet. Try setting up channels, check the signal quality.