All-terrain vehicles will always be in demand in our country, because... For many territories, this is the only type of transport that can move on roads in autumn or spring thaw, as well as in deep snow, without any problems. Skid-steer swamp vehicles do not choose the road, but go where necessary.

Unit details

There are several ways to make a turning unit, the simplest of which is to assemble it using right and left brakes. If the brake is pressed (right hand), the unit turns to the right, if the left brake is applied, it turns to the left.

It is necessary that one of the tracks turn off when turning, then the engine will cope, the homemade unit will turn.

Required assembly parts:

- Asterisks.

- Gearbox.

- Chain.

- Dispensing block.

- Gears.

- Clutch basket.

- Caliper.

Sun gear

The sun gear is made floating in the form of a long tube, on the inner end of which there are teeth cut, and on the outer end there are splines with which the sun gear is connected to the hub of the driven gear.

The sun gear / is installed on the splines of the axle shaft 23, and the satellites 4 are on the fingers 2 of the carrier 3, which transmits torque to the wheel hub 5.

The sun gear has no supports and is connected to the high-speed shaft by a gear coupling, which allows the gear to self-align between the satellites, ensuring a fairly uniform distribution of power among the flows. The gearing is in most cases straight-toothed. Satellites are often mounted on spherical bearings, which ensures equalization of the load across the width of the rims.

The sun gear / is installed on the splines of the axle shaft 17 with a stop in the collar and secured with a nut 37, locked with a bending plate.

Sun gear S2 of the second gear, like gear S of the first gear, is rigidly connected to the motor shaft.

The sun gear on the motor shaft is also lubricated by splashing from the common oil bath of the gearbox. To prevent gearbox oil from entering the bearing assembly from the output end of the motor shaft, a rubber lip seal is installed in the motor bearing cover. In addition, a special oil sump ring is installed on the shaft.

The sun gear, satellites and epicycle are considered in the model as solid bodies connected by springs Cft, simulating the rigidity of the gear engagement, located along the engagement lines. The carrier is also a solid body fixed in elastic supports.

The sun gear 2 27 of the winch shaft through three satellites 2 39 transmits rotation to the ring gear 2105 of the drum.

The hollow sun gears 29 are made integral with tubular shanks, on the flanges of which the hubs of the brake drums 32 of the planetary gears are fixed. The gears are kept from axial movements by split locking rings and washers. When the brake drums 32 are fully tightened, the sun gears 29 are motionless and the satellites 19, rolling over them, rotate the carrier 28 1 4 times slower than the ring gear.

It is difficult for the sun gear to turn the carrier, which is held in place by the large resistance exerted by the drive wheels. The resistance to rotation of the ring gear is low.

Design of a flatbed all-terrain vehicle

There are many options for all-terrain vehicles on the market that are produced by industry, but their capabilities and price do not always meet expectations. Therefore, from time to time interesting homemade products appear; the owner himself brings his own version of the car to mind. Of particular interest are side-turning all-terrain vehicles. This type of vehicle is capable of making a complete turn on the spot by transmitting torque to one of the sides; this type of turn is their main difference from standard all-terrain vehicles.

The peculiarity of such products is their small size, so they are most often produced by amateur designers. In addition, the size of the car must be such that it can be transported in a trailer. The good thing about a self-made car is that it is made in accordance with the needs and requests of the future owner. The all-terrain vehicle is almost equal in its capabilities to standard swamp vehicles.

Homemade tracked all-terrain vehicle "Khoma": assembly photo, test video

The author of the homemade product built himself the simplest tracked all-terrain vehicle for fishing trips and mushroom picking in the forest, the body of the all-terrain vehicle is a boat, and it weighs only 300 kg.

Technical characteristics of the tracked all-terrain vehicle:

- Front-wheel drive (one drive axle).

- Turning - differential activation.

- Boat hull.

- Track width – 450 mm.

- Center distance – 1180mm.

- Belt clutch.

- The width of the boat is 700 mm.

- The height of the boat is 570 mm.

- The length of the all-terrain vehicle is 2000 mm.

- Width - 1760 mm.

- Maximum speed is 30 km/h.

To assemble the homemade product, the following materials were needed:

- Lifan engine 7 hp

- Gearbox from an Opel Rekord.

- Gearbox from a Luaz car.

- Lada bridge.

- Drum brakes are also from the Lada.

- The frame is welded from a profile pipe 50 x 50 x 2 mm, the upper part is made from a corner 40 x 4 mm.

- Conveyor belt 6 mm thick.

- Galvanized sheet metal.

Gear ratios:

- From engine to gearbox - 5.5.

- Gearbox 1st - 3.64.

- Onboard Luaz - 1.3.

- Bridge - 4.1.

A frame is welded from a profile pipe and a corner, an engine, gearbox, and axle are installed.

Belting.

The tracks are made from angle 25 x 25 x 3 mm. The lugs are welded.

Fangs from a strip of 25 x 4 and 20 x 4 mm.

The height of the fang is 75 mm.

The width between two conveyor belts is 150 mm.

The caterpillar is ready for installation.

At first, the author placed the all-terrain vehicle on two axles.

The author took the all-terrain vehicle to the test site on a trailer and began testing.

As a result of preliminary tests, it was decided to install a middle axis. The central axle is welded 50mm lower relative to the drive and tension axle, which leads to improved turning on hard ground without unnecessary effort.

- Installing a central axis significantly increased the turn of the all-terrain vehicle.

Best models

There are many different models of all-terrain vehicles, all of them are built on the basis of different equipment, but they perform approximately the same tasks, the main one being to provide off-road movement. It is almost impossible to select the best one among them. But it is worth listing those that are distinguished by their originality and good technical characteristics.

Smolensk

The all-terrain vehicle of the Smolensk brand is homemade with good driving characteristics. All components are taken from cars produced by the domestic auto industry. To assemble it you need:

- wheels with a size of 1450 mm;

- internal combustion engine 62 hp;

- brake discs;

- rear window

The all-terrain vehicle with this name is homemade with good driving performance. The body design is of the most common boat type. The car can accommodate 4 people, including the driver.

To assemble the swamp vehicle you will need:

- Trekol wheels;

- several circuits;

- some parts taken from an old Toyota, including a diesel internal combustion engine;

- metal sheets 2 mm thick;

- pipes and profile;

- 100 liter fuel tank.

The maximum speed of the homemade product is 35 km/h.

The assembly procedure is standard. First, the frame is mounted, then the chassis is installed. The front part turns out to be heavier than the rear, so a tank is installed to balance the latter. The body is covered with sheets.

Bel-79

The peculiarity of this model is its compact size and relatively low cost of components.

To assemble the machine you need to prepare:

- Chinese-made internal combustion engine complete with clutch and belts;

- the gearbox can be taken from a passenger car;

- gearbox;

- clutch cylinders.

First, the frame and internal chains are assembled with normal tension. Then the clutches and brakes are installed. All this will further ensure the reliability of the design. Clutch discs are taken from VAZ.

Barnaul

This all-terrain vehicle was developed as an all-terrain vehicle with high reliability. It was created from parts taken from VAZ cars.

The frame is created from a profile by welding.

The result is a car with a cabin width of 123 cm, height of 145 cm, length of 280 cm.

Caravan

Quite an interesting design of a swamp vehicle. All components can easily be selected or replaced if necessary:

- internal combustion engine;

- gearboxes;

- brake mechanisms;

- seat from UAZ;

- brake cylinders from Gazelle;

- frame profiles;

- Additionally, you will need a chain 10 m long with a pitch of 15.8.

After assembly, you get an all-terrain vehicle with the following dimensions:

- length - 320 cm;

- width - 260 cm;

- height - 200 cm;

- clearance - 45 cm.

What is needed to make an all-terrain vehicle

When planning to make an all-terrain vehicle with your own hands, you need to make sure in advance that you have the materials, drawings, and the appropriate tools. For most connections, especially frames, it is recommended to use a welding machine to ensure long service life and high structural strength.

Materials

It can be convenient to use a walk-behind tractor as the basis for an all-terrain vehicle on low-pressure tires, which will significantly reduce costs and simplify the self-assembly process. You will need to find several elements at once, without which the construction of a karakat will be impossible:

- frame of suitable shape and size;

- rear axle, which will be used to mount the rear wheels;

- a seat for the driver, as well as means of protecting him from dirt and precipitation;

- lighting devices that will be required for driving at night.

This type of device is single-seater, but if desired, additional seats can be installed.

All-terrain vehicle from UAZ

You should also make sure that the engine power of the walk-behind tractor used as the basis for the vehicle is sufficient for the selected design. Universal options include walk-behind tractors Neva, MTZ, Ugra, as well as other domestic products with motor power greater than 10 hp.

It is also worth taking care of the cooling system in advance, since when driving at low speed the wind will not be able to lower the engine temperature to acceptable values.

Blueprints

Having studied the drawings of all-terrain vehicles on low-pressure tires, the master can make his own changes to the design of the future product, which will allow him to adapt it to solve specific problems or improve technical characteristics. An example would be a gearbox, which will improve torque performance.

Manufacturing procedure

When planning to assemble a homemade swamp vehicle, it is advisable to make sure that you have everything you need, and then follow the following instructions:

- Weld the frame using a metal profile of square/rectangular section.

- If desired, you can make a breakable frame, which will be the best option for traveling in areas with difficult terrain. To do this, you will need to use a kingpin, as well as independent suspension for the front and rear axles.

- Assemble the rear axle, for which you can use a similar part from an old car, for example Moskvich.

- Implement suspension using shock absorbers, connect the bridge to the frame using bolts.

- Install the walk-behind tractor on the frame.

- Place the seat.

- Attach frame protection made of metal or plastic.

- Install wheels, lighting fixtures.

Also, the design of the model may assume the presence of a braking system, which is important for vehicles moving at high speed. In this case, it will be most convenient to use an old motorcycle and install the brakes at the wheel installation stage.

Caracat frame

Make a frame

In order to make a frame, it is necessary to use a steel profile, the pieces of which are held together by welding. The dimensions of the engine and transmission need to be taken into account in this process. When manufacturing the frame, you will also need to establish the points at which the units will be attached.

If the frame is damaged during use and tears or cracks appear on it, the entire load-bearing frame will need to be redone.

The frame must have end plates in which there are holes in order to secure the movable fist - the driveshaft is carried inside it. This reduces the risk of damaging the drive while driving. The half-frames must be provided with points in order to install reinforced bridges.

Simple and complex devices

As noted above, the design of a planetary mechanism always includes a carrier and two central wheels. There can be as many satellites as you like. This is the so-called simple or elementary device. In such mechanisms, the designs can be as follows: “SHS”, “SVE”, “EVE”, where:

- S - sun.

- B - carrier.

- E is the epicenter.

Each such set of wheels + satellites is called a planetary set. In this case, all wheels must rotate in the same plane. Simple mechanisms come in single and double rows. They are rarely used in various technical devices and machines. An example is the planetary mechanism of a bicycle. The bushing works according to this principle, thanks to which movement is carried out. Its design was created according to the “SVE” scheme. There are not 4 satellites. In this case, the sun is rigidly attached to the axis of the rear wheel, and the epicenter is movable. It is forced to rotate by the cyclist pressing the pedals. In this case, the transmission speed, and therefore the rotation speed, can change.

Much more often you can find complex gear planetary mechanisms. Their designs can be very different, depending on what this or that design is intended for. As a rule, complex mechanisms consist of several simple ones, created according to the general rule for planetary gears. Such complex systems come in two, three or four rows. Theoretically, it is possible to create structures with a large number of rows, but in practice this does not happen.

Planetary gear mechanism

Planetary gear mechanisms are also used in differentials and wheel reducers of main gears.

Planetary gear mechanisms can have one or two (or more) degrees of freedom.

Planetary gear mechanisms with two or more degrees of freedom are called differential gears or simply differentials.

Planetary gears are differential mechanisms with a stopped central gear.

Planetary gear mechanisms with three central wheels make it possible for the actuators to have two working bodies, rigidly connected to two central wheels or to one central wheel and a satellite, while the third central wheel is stationary; in this case, the leading link is the carrier.

Planetary gear mechanisms are widely used in mechanical engineering and instrument making.

A planetary gear mechanism with two degrees of freedom (minimum) is called a differential mechanism. Only at two given angular velocities of its links can one determine the angular velocities of the rest. Therefore, the differential does not have a specific gear ratio.

Planetary gear mechanisms are divided into simple and differential. A planetary mechanism with rigid links is called simple if it has one degree of freedom, and differential if its number of degrees of freedom is more than one.

A planetary gear mechanism is a mechanism that has gears with moving geometric axes. Such wheels are called planetary or satellite wheels.

There are differential and planetary gear mechanisms.

It is known that two-stage planetary gear mechanisms with internal gearing have an advantage over two-stage planetary gear mechanisms with external gearing in that, with the same kinematic characteristics, they have a higher efficiency.

Selecting the number of teeth of planetary gear mechanisms for a given gear ratio requires performing a large number of mathematical operations. Therefore, this problem is practically solved with the help of a computer. For this purpose, a program is used to decompose a given ir into factors and subsequently determine z, taking into account restrictions and the smallest dimensions. Sometimes the required uPM/N is entered into the program; z/mm; z / max, k restrictions and by enumeration determine combinations of numbers of teeth, from which the desired combination of z, z2, z3, z4 is selected with minimum dimensions, maintaining a given gear ratio in stages.

Doomsday Rover. Test drive a crazy homemade product on caterpillar tracks

Our land is famous for the Kulibins! We have already talked about “Fantasy” by Minsk resident Boris Karavkin. And recently, Yuri Pidgaetsky from Molodechno decided to build an interesting homemade all-terrain vehicle on caterpillar tracks from a Moskvich and a Volkswagen. What came out of the symbiosis of components and assemblies of Soviet and German cars, read in our material.

“Come to Molodechno, we have made a tracked all-terrain vehicle here” - this message recently came to the editorial mail. The designer was unable to send the photos, so until the very last moment we had no idea what we were going to shoot.

And when we arrived at Yuri’s house, we were simply shocked by his all-terrain vehicle. Live it's something incredible! It feels like the car came to Molodechno straight from the set of films about zombies, the apocalypse or Mad Max.

Below is a tracked “trolley”, on top is a shortened body from Moskvich-2141, painted in military khaki color. In person the car looks extremely unusual. This has never happened before in our “Autoexotics” section!

“I’ve been interested in homemade products since childhood, I went to model design circles,” says Yuri Pidgaetsky. — I made a variety of homemade products - a children’s go-kart, a tricycle with low-pressure tires. And two and a half years ago I started making a tracked all-terrain vehicle. For what? I don’t really know myself - I’m just always itching to do something like that...”

Before the trip, we will study the technical component of the “monster”. The car was made without drawings - by eye. A durable frame is assembled from profile pipes and covered with tin. A shortened Moskvich body was later installed on it. Yuri says that he fussed with him the most.

The radiator and heater are located at the front. There is still room under the hood for various little things. So the car almost has two trunks.

There is no back row of seats. Instead, there is a huge trunk, under which the power unit and transmission are hidden. As you can see, the all-terrain vehicle turned out to be very practical.

The most interesting thing is hidden under the trunk floor. The 1.8-liter gasoline engine from the old Volkswagen Passat is located almost in the middle, but unlike a passenger car, it is located not transversely, but longitudinally. Next comes a 5-speed gearbox from the same car with a welded differential.

From it there is a kind of cardan to the rear Zhiguli axle. The exhaust pipes are welded from scratch, the fuel tank is homemade.

The rear axle differential is, naturally, free. Torque is transmitted to the rear rollers. They also have brake discs from an old Volkswagen Golf.

As you already understand, brake mechanisms are needed not only to stop the car, but also to control it. We pull the right control lever towards ourselves - we act on the caliper of the right roller, as a result the car turns to the right. Pull the left lever towards you and turn left. There is no brake pedal - to brake, you need to pull both levers.

Yuri took a week and a half to make the caterpillar from a conveyor belt and metal profile tubes. Regular car rims are used as rollers. Each caterpillar has a tension mechanism. According to the craftsman, the suspension is made from what was there - three struts with springs and shock absorbers are installed on each side.

The interior elements were taken from the same “Muscovite”. Everything works inside, including the radio and heater. Conventionally, the number of seats can be defined as 2+1 - the cabin may be cramped, but three people can fit. The gear shift pattern is reversed.

Now hold on to your chair—Yuri’s all-terrain vehicle can swim! Everything inside is sealed - the Moskvich does not sink. True, I haven’t had the courage to do full water tests yet. The car drove into the lake, but held on to the bottom with the back of the caterpillar. The front part of the all-terrain vehicle did not sink! In general, the car should float, but Yuri has no desire to fully float it yet - it would be a pity to sink such equipment.

The armor is strong and our tanks are fast - we are going to test the equipment in the fields! By the way, the all-terrain vehicle has not yet been properly tested - Yuri has driven it only a few times. So, together with the designer, we will test its capabilities, positive and negative qualities.

But first you need to get into the car, and for this you need to remember everyday life in the army. You have to climb onto a car the same way as in the army on an infantry fighting vehicle, that is, climb as you know how.

The first comment after our Instagram post was: “Will the all-terrain vehicle roll forward under emergency braking?” At low speeds we braked and did not roll over. Still, despite the considerable height, the center of gravity is located low - where the engine, rollers and tracks are. Before us, Yuri reached a maximum speed of 60 km/h, he braked, but not urgently - the car did not overturn. There is no desire to brake hard at high speed yet - first you need to install three-point belts and a safety cage. It seems like the car shouldn’t roll over, but in order to check this for sure, it’s better to first work on safety. Yes, just in case.

You sit behind the wheel, ugh - levers, very high. There has never been such a tall “Muscovite” in history! The cabin is very noisy while driving, but this cannot be said to be a drawback. The noise enhances the driving experience. You really drive like in a tank.

I always dreamed of driving tracked vehicles, but it’s a pity that I couldn’t steer anything in the army. It's time to catch up!

The clutch and throttle are the same as in a regular car, nothing special. It’s difficult to find the gears, the shift pattern is upside down, which blows your mind, there are also problems with clarity, but you can choose any gear, because the car starts at any speed, at least third for sure. There is no “lower gear” in the transmission; the lower row in this car is already done by default, so in first gear you can climb at a snail’s pace.

I switch on the gear (though I don’t know which one), sharply release the clutch pedal and press the gas - the car rears up slightly and takes off with a loud noise! To be honest, I don't even know how to describe the emotions. This is something incredible! There is very little snow, there are no special obstacles, but riding this “monster” just makes you want to scream with delight! Very unusual sensations. The engine is roaring, the tracks are knocking, my heart is bursting out of my chest - this is the most emotional test drive of my career! Words simply cannot describe how cool it is to ride this homemade tracked vehicle.

To turn, you need to apply considerable effort to the levers. But the maneuverability is not bad: we squeeze the gas to the floor, pull the left lever with both hands sharply with all our might - the all-terrain vehicle begins to turn the “nickels” in place! Moreover, homemade tracks do not fall off the rollers—the strength of the structure is felt.

I immediately remember the famous obscene video about the ensign and the tank crews: “Once, with a twist, he turned on the front - and off he went!”

Off-road performance? Ground clearance is 380 mm, there are no overhangs, but there are tracks. It’s a pity, for some reason there was very little snow in Molodechno - we couldn’t check how the car drives in deep snow. But again, there are enough emotions even without off-road obstacles. You’re just driving and your eyes are already popping out of your head!

But we drove along the ditch - the all-terrain vehicle drives through it very well. But for now, Yuri has no idea when the car will start to fall back. That’s why we didn’t take big slides - the driver was simply afraid to overturn the all-terrain vehicle.

Theoretically, everything should be fine - the center of gravity is low. But practically you need to make a frame, belts - and only then try to feel the stability limit of the all-terrain vehicle. There is a feeling that it is capable of a lot, but for now it’s just scary to break it - so much work has been put into the technology.

Finally, we try once again to feel this edge, but on the climb, the connection between the rollers and the engine is suddenly lost! The all-terrain vehicle rolls back and remains on the ice, which is covered with cracks along the edges. An attempt to put the car into gear and move off leads to nothing. All you can hear is the grinding of metal - the car is not moving. We've arrived!

It turned out that the cardan had broken. Moreover, it broke during the first test. However, you don’t even need to worry about it - Yuri already has a solution to the problem. The next driveshaft will be so strong that it can withstand anything.

It's normal for new equipment to fail. So far, only one weak point has been discovered in the all-terrain vehicle; there are no other “snots”. And that's very good! The machine was created from scratch by one person, has not yet been tested - and only the drive breaks. In the evening of the same day, the designer repaired the all-terrain vehicle and drove out of the ditch.

The result is complete delight. You are simply amazed at the talent of Yuri Pidgaetsky, who made such a machine from scrap materials! He had some spare parts, but had to buy some - in the end he spent about $800 on construction. For this money you can’t even buy a frail ATV, but here you have a whole “monster” - an all-terrain vehicle on caterpillar tracks. Bravo to its creator!

DIY gearbox repair

Repairing a gearbox with your own hands is a very difficult task. So, this mechanism is very complex and consists of many parts. When making repairs with your own hands, you can often even disassemble without knowing that you can easily lose a whole bunch of small parts inside, for example, needles instantly fall apart and get lost. Planetary gearbox repairs are best left to the professionals.

Like all gearboxes, it can be either single-stage or multi-stage. If you are going to purchase a mechanism of this type, then it is best to buy it from trusted manufacturers, since repairing it yourself is very difficult, and if it often fails, then a lot of money will be spent on it. In this article we tried to collect general information on planetary-type devices used for the production of cars. It must also be said that this type of device is being very intensively introduced into many areas and industries due to its very significant advantages.

Do-it-yourself crawler all-terrain vehicle: manufacturing features, drawings:

It's no secret that in our vast country there are areas where it is completely impossible to move normally on the roads due to their poor quality. In this case, a special vehicle, which is characterized by high maneuverability, comes to the rescue.

We are talking about an all-terrain vehicle. But, unfortunately, it is almost impossible to purchase a vehicle that is light, economical and inexpensive.

Therefore, many craftsmen with engineering and technical skills decide to create a tracked all-terrain vehicle with their own hands, taking into account their needs and capabilities.

How can tracked all-terrain vehicles be used?

Such homemade tracked devices come in different sizes and are used for a variety of purposes. With their help, heavy loads are moved, which are placed either in the body or in a special trailer. If a crawler all-terrain vehicle, made by yourself, is used for a summer residence, then in this case various construction materials are most often transported.

In addition, such a vehicle has transport versatility, and if any unforeseen circumstances arise, you can quickly, without any difficulties, get to a certain destination over rough terrain.

What to pay attention to when creating a homemade all-terrain vehicle?

If you decide to make a crawler all-terrain vehicle with your own hands, you must clearly understand for what purpose it will be used. Be sure to consider the following points:

- Weather conditions during operation.

- Dimensions. The width affects the cross-country ability of a self-made crawler all-terrain vehicle, the length is calculated based on the number of seats or the presence of a luggage compartment, and the height should be optimal when creating the amphibious properties of the unit.

- Motor power. The more powerful the engine, the easier it is to overcome hard-to-reach sections of the road.

- Target. Depending on the purpose for which the mobile device is intended, its design may vary.

- Number of wheels. Most often, a homemade tracked all-terrain vehicle, made with your own hands, has wheels from two to eight pairs, which are necessary to support the caterpillar track.

Create a drawing

The most important stage is making a sketch of a tracked all-terrain vehicle. Do-it-yourself drawings with the location of the mechanisms of the unit and its components are drawn after this. They must be very accurate. When creating such a vehicle, they usually use both homemade parts and ready-made factory-produced elements. They are drawn separately, with the calculation of the compatibility and performance of parts and assemblies.

Design features

A crawler all-terrain vehicle, created with your own hands, must have an engine. Basically, this element is taken from cars, most often domestic ones. You can also borrow it from a motorcycle. The chassis consists of rubber tracks, a tension system, suspension, and rollers. Car tires are often used to make tracks. The chassis base consists of a bathtub, frame or any other metal frame. For the control system, various components are taken or ready-made control elements of motorcycles or cars, as well as tractors, are used. A homemade tracked all-terrain vehicle, made with your own hands, has a power system, which is represented by a fuel tank, gasoline or diesel. Gas equipment is used much less frequently.

Manufacturing technology

Lightweight tracked all-terrain vehicles are made by hand using a certain technology. Their creation begins with the construction of the body, which must have high strength and complete waterproofness.

The base of a homemade transport must be rigid, so steel pipes are used that can withstand any physical stress arising from movement. Then they begin to make the tracks. To do this, take ordinary sheet rubber and create ring rubber.

Small aluminum blades are placed on its outer side using rivets, and the necessary limiters are installed on the inner side, the step width of which is equal to the width of the tire tires.

The next stage is that the bridges are removed from the car through holes that were specially made in the body for this purpose. Rubber couplings are used as protection.

The rubber band is attached so that the wheels are located directly in the center of the stops. In addition, additional wheels are also attached. They are necessary to maintain the track tension.

To complete the work, heavy-duty glass is installed in the cabin of the all-terrain vehicle, which was made by hand.

Remaking the walk-behind tractor

The question of whether it is possible to make a functioning all-terrain vehicle based on a walk-behind tractor is most pressing for those who own farms, small agricultural lands or summer cottages. Such a vehicle is very functional, because additional equipment can easily be attached to it.

The equipment will be an excellent assistant in gardening and gardening work. The walk-behind tractor has many useful functions, but if it has been sitting idle for some time or a new unit has come to replace it, then yes, it is quite possible and feasible to build a functioning all-terrain vehicle from it. The only question is how to do it correctly.

A walk-behind tractor equipped with a second or fourth stroke engine is suitable for this work: it is important that it has an air cooling system. In order for the walk-behind tractor to be returned to its original form, you should not be overzealous with its conversion.

To ensure that the equipment operates correctly and does not let the owner down at the most inopportune moment, some points should be taken into account that may have a further impact on the future all-terrain vehicle.

- There are different design options, but in order for the vehicle to perform efficiently, it is necessary to provide it with independent suspension.

- The design should be supplemented with pneumatic wheels with low pressure. In the future, if desired, tracks can be installed instead.

- The all-terrain vehicle frame can be anything. Its choice should depend on the option suitable for the specific type of wheels, as well as the purpose of using the vehicle.

How to create an all-terrain vehicle design from a walk-behind tractor.

- The strut and steering bushing are connected to the side members.

- Then chambers from a truck or agricultural trailer are used: it is desirable that they have low pressure. The need to use them is due to the fact that it will be much more convenient to attach wheels to them.

- After this, you need to attach the suspension, as well as the motor, which must be taken from the same walk-behind tractor.

- The last step will be to attach the clutch, brakes, and ensure that the exhaust gases are released.

Also interesting: Reliable crossovers: ranking of the best cars by reliability in 2022

Features of structural materials and schemes

However, a fixed component is not always necessary. In differential systems, each element rotates. Planetary gears like this include one output controlled by (controlling) two inputs. For example, a differential that controls an axle in a car is a similar gear.

Such systems operate on the same principle as parallel shaft structures. Even a simple planetary gear has two inputs, the fixed ring gear being a constant input of zero angular velocity.

Do-it-yourself crawler all-terrain vehicle: manufacturing features, drawings:

It's no secret that in our vast country there are areas where it is completely impossible to move normally on the roads due to their poor quality. In this case, a special vehicle, which is characterized by high maneuverability, comes to the rescue.

We are talking about an all-terrain vehicle. But, unfortunately, it is almost impossible to purchase a vehicle that is light, economical and inexpensive.

Therefore, many craftsmen with engineering and technical skills decide to create a tracked all-terrain vehicle with their own hands, taking into account their needs and capabilities.

How can tracked all-terrain vehicles be used?

Such homemade tracked devices come in different sizes and are used for a variety of purposes. With their help, heavy loads are moved, which are placed either in the body or in a special trailer. If a crawler all-terrain vehicle, made by yourself, is used for a summer residence, then in this case various construction materials are most often transported.

In addition, such a vehicle has transport versatility, and if any unforeseen circumstances arise, you can quickly, without any difficulties, get to a certain destination over rough terrain.

What to pay attention to when creating a homemade all-terrain vehicle?

If you decide to make a crawler all-terrain vehicle with your own hands, you must clearly understand for what purpose it will be used. Be sure to consider the following points:

- Weather conditions during operation.

- Dimensions. The width affects the cross-country ability of a self-made crawler all-terrain vehicle, the length is calculated based on the number of seats or the presence of a luggage compartment, and the height should be optimal when creating the amphibious properties of the unit.

- Motor power. The more powerful the engine, the easier it is to overcome hard-to-reach sections of the road.

- Target. Depending on the purpose for which the mobile device is intended, its design may vary.

- Number of wheels. Most often, a homemade tracked all-terrain vehicle, made with your own hands, has wheels from two to eight pairs, which are necessary to support the caterpillar track.

Create a drawing

The most important stage is making a sketch of a tracked all-terrain vehicle. Do-it-yourself drawings with the location of the mechanisms of the unit and its components are drawn after this. They must be very accurate. When creating such a vehicle, they usually use both homemade parts and ready-made factory-produced elements. They are drawn separately, with the calculation of the compatibility and performance of parts and assemblies.

Design features

A crawler all-terrain vehicle, created with your own hands, must have an engine. Basically, this element is taken from cars, most often domestic ones. You can also borrow it from a motorcycle. The chassis consists of rubber tracks, a tension system, suspension, and rollers. Car tires are often used to make tracks. The chassis base consists of a bathtub, frame or any other metal frame. For the control system, various components are taken or ready-made control elements of motorcycles or cars, as well as tractors, are used. A homemade tracked all-terrain vehicle, made with your own hands, has a power system, which is represented by a fuel tank, gasoline or diesel. Gas equipment is used much less frequently.

Frame, body

To create the frame you will need steel pipes with a square or round cross-section. Both welded and screw type connections are used. The option of using a monocoque body is rarely used, because it does not provide resistance to heavy loads.

In addition to strength, it is worth paying attention to such a point as resistance to destruction by corrosion: for this, as well as to reduce weight, plastic or aluminum cladding is used. If the vehicle must be buoyant, the lower part of the hull must be sealed - the entry of water is limited to the place where the drive outlet is located, using seals.

What are clutches

Clutches are clutch units in a gearbox that transmit torque. They are made of high-strength steel in the form of a disk onto which the cover is glued.

There are two types of frictions:

- Fixed, they are in conjunction with the gearbox housing; metal discs have a lining.

- Rotating clutches move with the gears. These elements are made of soft material (for example, graphite-coated cardboard).

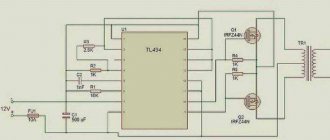

Layout example:

- 3 calipers 2108 are installed on one shaft.

- On the rotating carriage there is a disk from 2108, as well as sprockets (32 teeth).

- A gasket is mounted in one support; it ensures the transfer of fluid to the caliper.

- The driven sprocket is placed between the disk and the support.

The maximum number of revolutions is 360 per minute. The drive sprocket receives torque from the internal combustion engine.

Friction clutches

Friction clutches, as a rule, are made of multi-plate dry permanently closed clutches. The driving part of the coupling is shaft 1 (Figure a) of the main gear with a drive drum 2 located on its splines. Longitudinal grooves are made on the outer cylindrical surface of the drum, in which thin steel disks 3 are installed with internal teeth.

The driven part of the coupling is drum 4, mounted on the drive shaft 6 of the final drive. On the inner surface of the drum there are grooves into which the outer teeth of disks 5, equipped with friction linings, enter. The driven and driving disks are assembled through one another. A pressure disk 9 is installed on shaft 1, rotating with the shaft, but having the ability to move along its axis. Pins 7 are screwed into disk 9, passing through the hole in drum 2. Springs 8 are installed on the pins, resting on one side against disk 9, and on the other, against washers mounted on studs 7. Springs compress disks 3 and 5, and the clutch, being in a closed state, creates the required friction torque. In this case, the torque from the main gear is transmitted by clutches to the final drives - the tractor moves in a straight line.

To turn the tractor, you need to disconnect the corresponding caterpillar from the transmission, i.e. disengage one of the rotation clutches. When this clutch is turned off (Figure b), disk 9 moves horizontally, springs 8 are compressed, disks 3 and 5 are released and the rotation of the driven drum and drive sprocket stops. At this time, the other clutch remains closed, as a result of which the tractor rotates around the disconnected track.

Options for homemade turning mechanisms

Rotation mechanisms are differentiated into 3 types:

- Fixing the block at a point that maintains a constant speed during a turn, while the crankshaft and gearbox do not change the torque parameters.

- By the number of calculated turning radii. The speed of one caterpillar remains constant, the speed of the second decreases.

- When the lagging and advancing caterpillars reduce their speeds.

When creating mechanical transmissions, the second and third types are more practical.

They implement an automatic reduction in the speed of the all-terrain vehicle.

The first type has a disadvantage: turning occurs by changing gears, because otherwise the power plant will not cope with the load and will stall.

Simple planetary gear

Planetary is a two-stage gear transmission in which there are fixed axes. Thanks to this design, within the axis of rotation it is possible to add and expand angular velocities (or torque). A planetary gear consists of gears of different diameters: one axis is fixed, the other is stationary. The gears on the fixed axle contact each other through toothed wheel elements that are mounted on the moving axles.

Based on the number of gear elements, transmissions are differentiated into:

- single row;

- double row.

The first ones come with fixed axes and planetary ones. According to the layout of the axles, final drives are divided into coaxial (located on the same line) and non-coaxial.

For 6x6 all-terrain vehicles

6x6 vehicles have excellent cross-country ability. Such tracked units are reliable, durable, and easy to operate.

Required blocks:

- Quite a powerful power plant.

- The suspension should be soft and reliable.

- The wheels in such a car are all driven, with two pairs of steering wheels.

- Cross-wheel differentials can be locked.

- Each wheel has an independent suspension.

- “6x6” weighs around a ton, engine power is 30-50 hp.

Tires, tracks

If necessary, by reducing the pressure, you can transform the wheel - thanks to the expansion of the support, you can significantly reduce the load on the road surface. It is worth remembering that a low distance from the bottom to the ground creates inconvenience when trying to overcome a high obstacle.

https://www.youtube.com/watch?v=wCAQ7qE98yg

When building a crawler all-terrain vehicle, spring steel rods can be used. Drum brakes are often replaced by planetary gears. There are times when there is no factory caterpillar available from any equipment, and then you can make it yourself.

The most common way is to use a conveyor belt and lugs.

You can add many important and useful details to the design:

- windscreen wipers;

- autonomous stoves;

- rear view mirrors;

- acoustics and music centers;

- indicators and control devices;

- electric seats;

- lighting equipment and other additional elements.

Read news about the new Niva

- How to replace the pump on a Niva Chevrolet yourself

- Review from the owner of a LADA (VAZ) 2121 (4×4) 2022 (I Restyling (2020)): Urban 1.7 MT (83 hp) 4WD | Auto RU

- Choosing front springs for a Chevrolet Niva, recommendations on the AutoPasker website

- distribution work | SUZUKI CLUB RUSSIA

- Do-it-yourself car diagnostics via a laptop: scanners, programs, work procedures, adapters based on the ELM327 and VAG chip -

- Color spectrum

- Relays and fuses Lada 4×4 (VAZ 21214, 21314) » Lada.Online

- Do-it-yourself Niva suspension lift. How to lift the front and rear suspension of a Niva car?