Tools and materials

The main component of the vehicle is a durable waterproof body. You can make an all-terrain vehicle using profile steel pipes with the following sections:

- 4x4x1.5 cm;

- 5x5x0.3 cm;

- 4x2x0.15 cm;

- 2x2x0.15 cm.

Of course, the greater the load on an individual element, the larger the cross-section of the pipe used should be. The recommended thickness of sheet metal is at least 0.125 cm. It is not recommended to use very thick sheets, because they will significantly make the structure heavier and increase fuel consumption.

For a homemade all-terrain vehicle, you can use air-cooled motors. Their power can be 15-20 liters. s., and this is a very decent indicator, allowing you to move at high speed.

However, the largest tracked all-terrain vehicles are sometimes equipped with engines from the base vehicle, which will help move significant loads without losing momentum.

In a simpler version, gearboxes and axles are taken from the original car. As for the tools, you will predictably need:

- welding machines (electric with suitable electrodes included, but gas can also be used);

- angle grinders;

- wrenches and adjustable wrenches;

- files;

- screwdrivers;

- hammers;

- fasteners.

Conqueror of the taiga

Life in the Siberian forests is so harsh that having your own SUV is not a luxury, but a real necessity; another thing is that not everyone can buy such a car.

The exception is local craftsmen who were able to put half of the VAZ-2106 body on tractor wheels, along with its engine and a cargo compartment attached to the rear, hastily welded from old metal sheets.

Other features of the pickup include reinforced suspension, the use of axles from an old UAZ, as well as benches for transporting passengers.

Where can you use a homemade mini-tractor?

A homemade mini tractor with a VAZ engine can be used in the garden on large plots of land. The homemade product can perform a large sector of agricultural work: from plowing, harrowing, soil milling, planting and plowing potatoes, snow removal, grass mowing to the most difficult work, such as harvesting and loading hay.

To summarize, we can answer the question of how to make a mini tractor from a Lada with your own hands. Creating such a mini-tractor is not very difficult, as it seems at first glance. After all, it is a very useful machine for farming. Moreover, a device made by yourself is in no way inferior to a factory one. It will be even stronger and more reliable, and most importantly, it will cost much less than in the store.

Which model to choose for homemade products

When creating a homemade design, any Lada or Lada car is used. The machine is equipped with an additional frame, the body is attached to the base through rubber pads. The design provides for a transfer gearbox or an additional gearbox, expanding the traction range. The car retains its standard heating and ventilation system, and the original seats and seat belts remain in the cabin.

VAZ-2108

The wheeled all-terrain vehicle from the VAZ-2108 retains the original body and interior, but the wheel arches increase in accordance with the diameter of the wheels. The installation of extenders is provided to prevent contamination of the side windows when driving in off-road conditions. The body is placed on a frame made of steel profile, to which axles, engine and transmission units are attached on leaf springs. Ground clearance depends on the diameter of the wheels, the deflection of the springs and the relative position of the points for sealing the ends of the elastic elements.

VAZ-2106

The design based on the VAZ-2106 consists of a modified car body and a frame assembled from channel sections. The gasoline engine and gearbox of the car are left in their standard places, axles and a transfer gearbox from UAZ SUVs are mounted on the frame. Modified tires from a GAZ-66 truck are installed on homemade wheels (made from standard UAZ parts). The resulting all-terrain vehicle based on the Lada can move through swamps and overcome water obstacles up to 1 m deep.

VAZ-2107

A wheeled snow and swamp-going vehicle based on the VAZ-2107 body does not differ from designs based on other cars. There are original designs on rubber tracks; road wheels are made from standard Zhiguli wheels. Torque is transmitted through the gearbox to the transfer gearbox, which rotates the drive wheels. The increased dimensions of the equipment should be taken into account; driving such all-terrain vehicles on public roads is prohibited.

Transmission

A drive pulley with a diameter of 95 mm is installed on the output shaft of the engine (Lifan 182FD or similar). The pulley has five grooves of profile “A”. Four of them are intended for clutch drive belts and one (outmost) is for driving a generator or hydraulic pump. The shafts on different engines are not the same size and have different keyway widths, so you have to be careful here.

The length of the “A” profile belts (generator from the D-240 diesel engine) is 1250 mm. The belts are tensioned by a roller with two springs. The roller rotates in two bearings 180203. Its axis, for convenience, fits into the bearings using a “sliding” fit, that is, quite freely (by hand). When the axle nut is tightened, the inner races of the bearings are clamped between the spacers and do not rotate.

A driven pulley with a diameter of 260 mm is mounted on a support shaft, which rotates in a double-row bearing from the front wheel of a VAZ-2108 car. A splined bushing from the Zhiguli clutch disc is welded to the end of the support shaft. This bushing includes the input shaft of the gearbox (gearbox) from the VAZ-2106.

The holes in the pulley for attaching it to the shaft are drilled for the flange of the “Zhiguli” propeller shaft. This was done for the versatility of using this pulley. It is not necessary to repeat this at all; you can place the holes on the pulley and shaft flange at an angle of 90°.

The gearbox output shaft is cut to the beginning of the splines. The flange of the Zhiguli driveshaft is mounted on the splines. The shaft pipe is cut to the required length. The second cardan flange is screwed to the input shaft of the chain gearbox, to which the sprocket is welded (z=13, pitch 19.05 mm). The input shaft itself rotates in tapered bearings from the front hub of the Zhiguli, which, in turn, is screwed to a movable plate. By changing the position of the plate, you can adjust the chain tension.

Steering:

1 - fracture site; 2 - bipod; 3 - hinge; 4 - traction; (the chain on the driven sprocket and behind them the transmission brake caliper are clearly visible)

A driven sprocket with a number of teeth z=41 is installed on the transfer shaft of the rotary unit. The transfer shaft drives the main axle gears (from the VAZ-2106) through cardan shafts (shortened from the VAZ-2121 Niva). Drive axles (both front and rear) are from VAZ-2106. The tires on the wheels were both homemade (“torn off”) and industrially produced. I didn't notice much difference in driving performance.

A garage craftsman assembled a dynamic tracked all-terrain vehicle from spare parts from a Zhiguli

An all-terrain vehicle, and even one on tracks, in the understanding of most, is something slow and clumsy. In fact, this may not be the case at all. Today we will tell you about the history of the construction of a rather interesting homemade product. The project is based on a design with a waterproof body, on components and assemblies from the nearest disassembly.

According to the author of the all-terrain vehicle, the most tedious and time-consuming task is making tracks. Conveyor belt, pieces of metal profile, a mountain of bolts, nuts and of course this.

A more interesting activity is creating the frame of the so-called boat, which will have to keep the car afloat.

The power unit was a regular 1.5-liter Zhiguli engine, two axles from a VAZ. One of them had to be turned over. A transfer case from the GAZ-69 also appeared in the design.

The power unit is located at the rear, but all the controls are at the front.

By the way, the issue with the windshield was resolved elegantly. They took the windshield frame from the body of the VAZ-2106 and placed it on the all-terrain vehicle and inserted the glass there.

The Zhiguli bridges helped ensure complete tightness of the hull. They simply became part of the boat, tightly welded to the side walls of the all-terrain vehicle’s bottom.

The controls are like in serious special equipment. Under the right hand is the gear shift lever, on the other side is the transfer case. The brake system and free differentials help steer the all-terrain vehicle. If you slow down one side, then thanks to the differential the wheels on the other side rotate and thereby turn in the desired direction. Simple and reliable.

The side glazing was made using monolithic polycarbonate. The top folds back to allow the driver to take his seat.

As a garage craftsman said in his logbook - drive2.ru/r/selfmade/selfmade/297139/

, the unit can be easily accelerated on virgin snow up to 80 km/h.

A more detailed process of building a homemade machine can be found here.

The garage craftsman's all-terrain vehicle was sold after the first test tests. As they say, the engine had not yet cooled down, and those wishing to purchase the equipment lined up, pushing each other with their elbows.

Source

Driver's cabin

The driver's seat is located behind the engine compartment and is separated from it by a partition made of duralumin sheet on a frame made of pipes with a cross-section of 20x20 mm. The driver's cabin is semi-closed (without doors or rear wall). The seat is from a passenger Gazelle. There is a 60 Ah battery under the seat. The steering column is converted from a Zhiguli one (VAZ-2106), and the upper part of the steering propeller shaft is taken from there. Its lower part is made of a 20x20x2 mm profile pipe, the crosspiece of the steering cardan is 2141 “Moskvich”. The steering mechanism (“rack”) was also borrowed from the M-2141.

Pedal units are from Zhiguli. Their location is the same as on a car. The clutch pedal is connected to the tension roller of the clutch belt via a cable. The brakes are transmission brakes, the disc is mounted on the driven sprocket shaft. The pedal is connected by a rod to the main brake cylinder (from the UAZ clutch), which drives the brake caliper cylinders (from the VAZ-2108). The gas pedal is homemade, connected to the carburetor with a Bowden cable.

Under the steering wheel there is a panel on which there is a toggle switch for turning on the headlights, a cable handle for the carburetor air damper, a horn button and a ground switch.

The all-terrain vehicle "Bobik" has been modernized several times, and even has several similar copies, which were distributed to different owners. Therefore, some drawings may differ in some ways from the images in the photographs.

Tanks are not afraid of dirt... Or snow?

One day, a resident of Omsk had to show all his skills as an auto mechanic when faced with a snow drift that completely paralyzed traffic.

As a result, his old “nine” received a powerful visor for clearing snow, and a little later a tracked platform assembled according to the owner’s own design, easily overcoming any off-road conditions and meter-long snowdrifts.

And the neighbors of the talented Omsk resident are especially happy about such changes, who know for sure that 2109 will certainly not leave them in trouble, bringing bread or pulling their car out of the dense snow crust.

Manufacturing

To get a tracked all-terrain vehicle from a VAZ with your own hands, you should first of all carefully select the drawings. The illustration below shows the most general conceptual diagram of the Tazik-1 vehicle. The distance between the centers of the outer track wheels ranges from 208 to 213 cm.

This is what a homemade all-terrain vehicle based on the Oka car will look like with a total length of 3.3 m and a track height of 0.542 m.

And here is a detailed drawing of an all-terrain vehicle with a box from a VAZ 2108.

The classic and already thoroughly tested in practice scheme is “Basin-1”. It is assumed that the engine and gearbox will be installed in the boat.

The crankshaft is machined under the bearing of the original shaft (a steady rest will be required). Additionally, an adapter for a release bearing is installed. A crown taken from the “eight” is threaded onto the motor flywheel; the classic starter is connected via a spacer, and the speed reduction is provided by a transfer unit from Toyota.

Whether to use all-wheel drive in an all-terrain vehicle or use other solutions depends on the creators of the equipment themselves. The front-wheel drive design has the advantage that the nose will not rise up when driving. In addition, there is less danger of “goating” on the road. In a rear-wheel drive version, the vehicle will not “dive” into the mud, but the load on the sprocket increases very significantly. As for the all-wheel drive system in VAZ-based all-terrain vehicles, it is:

- provides greater cross-country ability than other tracked vehicles;

- allows you to make a more durable body;

- more difficult to operate;

- increases fuel consumption (at least the last three properties are indicated by car experts).

All-terrain vehicle fracture Bobik, Toptyga and some others

An all-terrain vehicle is a convenient, and sometimes the only possible, means of transportation for a fisherman, hunter or ordinary villager. To be successful, an all-terrain vehicle must have most of the following qualities:

- high cross-country ability. The technology must overcome any obstacles, cope with any directions, even those that seem to be possible only for a person on foot;

- reliability. There is an opinion that the better the jeep, the further you have to go behind the tractor. It is several times more unpleasant if an all-terrain vehicle breaks down after driving into a thicket of forest or into an impassable swampy area. Even a tractor won’t help here;

- low cost of components. This quality does not require any special explanation. Naturally, it’s nice to use technology that is inexpensive to operate;

- low fuel consumption. The same thing: the less fuel an all-terrain vehicle consumes, the further you can go on it.

Probably, since Soviet times, craftsmen have become accustomed to assembling various equipment that can be classified as vehicles with their own hands. And now many people have a similar hobby. For example, there are people and semi-official companies - based in neighboring garages in GSK - who are engaged in assembling all-terrain vehicles from what is at hand. Break all-terrain vehicles are very popular.

The frame of a typical all-terrain vehicle is broken

Fracture. Where does this name come from?

The breakaway all-terrain vehicle is called that way because of the peculiarities of its design. It consists of two half-frames interlocking with each other. The semi-frames are independent, which is very important. They can move as desired relative to each other horizontally, rise and fall in the vertical plane. Due to this design, the high patency of fractures is ensured, and as a result, their great popularity among the population. Such all-terrain vehicles almost never have wheels hanging out, which guarantees excellent traction.

If we continue the conversation about the design of all-terrain vehicles, we can note that, for the most part, such equipment is a piece product, therefore, each vehicle has its own equipment. Of course, the general principle of the device is the same: engine, gearbox, clutch, large wheels, usually with low-pressure tires. But each model has its own characteristics. For example, one designer installs an Oka engine on a vehicle, while the second believes that it would be more expedient to fit a Moskvich engine.

However, studying topics on forums for off-road enthusiasts, one can come to the conclusion that there are already typical examples of all-terrain vehicles that are duplicating, modifying, and creating new models based on them.

Typical models of breakaway all-terrain vehicles

We should focus on two typical models that have gained particular popularity. The remaining, less common all-terrain vehicles are designed, by and large, in a similar way.

All-terrain vehicles will be discussed below:

- Bobik;

- Toptyga.

All-terrain vehicle Bobik

This all-terrain vehicle can move at speeds of up to 25 km/h, carrying a load of up to 300 kg if it moves on land, and up to 200 kg if it moves on water. 300 kg of cargo is great for a fisherman, and not bad for a hunter.

How to make a tracked all-terrain vehicle from a VAZ with your own hands?

Fans of homemade vehicles are constantly looking for more and more new options for remaking seemingly familiar cars. However, it is important for them not just to focus on their imagination, but also to take into account the experience of those who have already walked along the same path. It's time to figure out, for example, how to make a tracked all-terrain vehicle from a VAZ with your own hands with minimal complexity in the shortest possible time.

Lamborghini Reventon

As you can see, most of all do-it-yourselfers love to copy Ferrari and Lamborghini. Externally. Inside this car, designed by Mr. Meath from Thailand, is a quarter-liter Lifan motorcycle engine.

The funniest and most touching creation is by Chinese farmer Guo from Zhengzhou. He made a Lambo for... his grandson. The car has children's dimensions - 900 by 1800 mm and an electric motor that allows it to accelerate to 40 km/h. A battery of five batteries is enough for 60 km of travel. Guo spent $815 and six months of work on his brainchild.

What do I care about snow, what do I like heat, what do I like torrential rain?

Russian craftsmen designed the real beast, equipping the body of a VAZ-2107 with low-pressure wheels borrowed from the all-terrain KamAZ, and posted a video of its practical tests online. And judging by this video, the SUV will not only be immune to winter surprises, but also to floods, because it easily forded a shallow river.

At the same time, commentators doubted the efficiency of the Zhiguli engine, as well as the economy of such a solution, but they turned out to be right, because the developer himself indicated a consumption of 30-40 liters.

Which is better - wheels or tracks?

Before building a homemade all-terrain vehicle, you need to decide on the type of chassis. The tracked design ensures uniform load distribution, which has a positive effect on the vehicle’s maneuverability. The disadvantage is the increased weight of the propulsion unit and difficulties with control, since turning requires the installation of side clutches and additional levers to control the clutches.

Wheeled vehicles are controlled by a standard mechanism that uses extended steering rods.

Wheeled all-terrain vehicles are equipped with low-pressure pneumatic tires borrowed from agricultural machinery. The suspension uses leaf springs that can support the weight of the structure. If you need to manufacture a maneuverable and lightweight all-terrain vehicle, it is recommended to use the “karakat” design. But in this case, it will not be possible to install a closed body from a passenger car.

Recommendations

In some cases, the car body is not changed. However, you will have to install stripped wheels of large diameter, for example from agricultural machinery.

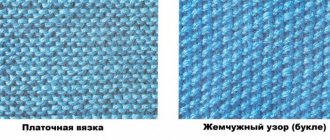

On old tires, fresh tread is cut to improve cross-country ability and make the vehicle lighter.

Installing 2 Zhiguli gearboxes instead of one will help reduce speed and increase traction force. For rubber, you can use a regular conveyor belt of suitable dimensions.

Here are some more tips:

- a caterpillar mover can be obtained by adding a bushing-roller type chain to the belt;

- the tape along the edges is stitched with fishing line with an indentation of 1 cm (so that it lasts longer);

- an alternative option is a caterpillar made from truck tires (it is not recommended to use passenger tires);

- special attention should be paid to the design of controls;

- A diesel engine is more economical than a carburetor engine, but starts worse on cold days.

How to make an all-terrain vehicle with your own hands from a VAZ 2107 car, see below.

Carrying out tuning of the VAZ-2106 engine

Over the years, owners sometimes become so accustomed to their vehicle that they are unwilling, under any circumstances, to consider selling it and purchasing a new vehicle.

However, I also don’t really want to silently contemplate how my favorite “horse” gives in to powerful foreign cars, so the only option arises, which involves tuning the VAZ-2106 engine.

The power in the standard VAZ-2106 engine is not enough, so the owners of this vehicle often decide to tune it

Indeed, tuning a VAZ-2106 engine with your own hands is a process that requires certain knowledge, but this condition should not slow down the desire of the car owner, since on the Internet you can find a lot of useful recommendations, based on which even a novice car enthusiast can successfully tune a VAZ carburetor engine. 2106.

- Engine tuning technique

- Engine boring

- Crankshaft tuning

- BC installation

- Carburetor tuning

Engine tuning technique

Refinement of the VAZ-2106 engine is aimed at improving many characteristics of the “heart” of the car. In particular, adherents of the domestic “six” know that the manufacturer provided the vehicle with a capacity of 75 horsepower.

At the same time, in order to achieve the maximum speed, which again is indicated by the manufacturer, you should take a pause. However, experienced craftsmen point out that tuning the VAZ-2106 engine allows you to increase the power of the engine, help increase the maximum speed of the car, as well as reduce the time at which this speed is achieved.

Of course, such assurances are welcomed by “six” car owners who are ready to turn their “swallow” into a fast and slightly “aggressive beast” on their own. Those who have studied the recommendations on how to improve the VAZ-2106 engine will carry out all manipulations at a high quality level and will be able to surprise others when the “six” begins to easily overtake prestigious and vaunted foreign cars on the highway.

Engine boring

Refinement of the VAZ-2106 engine involves boring the cylinders, as a result of which the engine power rapidly increases.

The VAZ-2106 engine has a volume of 1600 cubic centimeters. To increase this figure, remove the cylinders and subject them to boring, removing layer by layer of their inner surface. Boring should be done as long as possible. Unfortunately, it is impossible to carry out such manipulations privately, since this requires special equipment.

When carrying out this process, you should know when to stop and take into account some factors. In particular, the thickness of the cylinder walls is directly proportional to the number of kilometers the car can run, so by reducing the thickness of the walls, you thereby reduce the mileage.

Snow blower from Zhiguli? Why not!

The next VAZ was put on a caterpillar track by an enthusiast from Barnaul, who decided to re-equip his old “seven” in this way.

However, unlike previous modifications, the author of this project decided to go even further by equipping the front part of the Zhiguli with a wide shovel, which made it possible to use the car for snow removal.

It is worth noting that this is not the first creation of the master, who has already created a tracked all-terrain vehicle with an electric motor, and not the last, because the creative Barnaul resident has plans for a swamp vehicle.

It's a Lada on the outside, and a BMW on the inside. How to turn an old VAZ into a wild but fun vehicle

“There were thoughts of lowering it...” Vlad, the owner of this VAZ-2101, begins the story. However, fate turned out differently: instead of stens, the guy was carried away into a winter drift, and from there into a summer one. “Kopeyka” took on the appearance of a wild but cute “cramp” that can be seen on the streets of Minsk.

How the old Lada turned into an “evil” car and what the car has in common with BMW is below in Vlad’s story. For those who like to watch and listen, we present a short version from our Instagram:

View this post on Instagram

Publication from ABW.BY (@abw.by) May 21, 2022 at 10:32 PDT

— My friends gave me this car for my 18th birthday, when I got my license. It turns out that this “penny” has been with me for three years already. It was purchased in Minsk for about $200, but much more was invested.

The story was this: I wanted to buy it myself, but didn’t dare. There wasn’t enough money, my parents and brother said that taking a Lada as a first car was not an option. But then winter drifting came into fashion, and Lada cars were the best choice for it. So my friends helped - they bought the car and gave it to me for my birthday.

“Kopeyka” was all rotten. I immediately sat down in it - the seat was wobbly. Friends said that the fastening was broken. I lifted it up on a lift, pulled out the carpet - the floor was rotten. It's good that the seat didn't fall out on the ground! Everything was boiled down, sandblasted, painted so that it would be perfect, without rust. How upset I was when I hit her for the first time at a competition! The second time I wasn’t so sad, and then in general... Every time you just go out and laugh. We have adequate guys in drifting, we initially agreed that there would be no conflicts. There's nothing wrong with blows.

Alterations began immediately after purchase. We first thought about taking a Ford Sierra or Scorpio with 2.0 DOHC as a “donor”. We looked for them, but they were hard to find: we needed an option with a radiator, box, and wiring. That's why we bought a beat-up BMW E36. My brother and I did all the work ourselves - we have a team, he has his own service station. Many improvements are his merit.

It was very difficult to fit a BMW engine into a Lada, as space is limited. We cut out half of the body, inserted a vehicle tunnel from the rear seats to the engine compartment. The five-speed gearbox here is also from BMW, manufactured by ZF.

There are no problems with the engine at all, although it is constantly at the limit, constantly revving. True, in the heat it overheats a little. However, it’s okay, we’ll improve it.

The suspension is not completely “Zhiguli”. It was made from scratch by a Russian company for a larger wheel offset and a wider range of adjustments. At the front there are tubular levers, reinforced Zhiguli brakes. In the rear suspension, the only thing left from the Lada is the axle. It was not changed so as not to turn the Lada into a completely different chassis. The front has already been changed, and if the back is also changed... The question arises: would it work the way it works now?

It steers perfectly - you can do everything with one hand. At Drift Studny in January we had a problem with tires. The rest of the Zhiguli were within 100 horsepower or less, they didn’t need much grip, but I had too much strength and didn’t have enough grip. I had to constantly play with the clutch to get the car to cling to the ice. It’s just that according to the regulations it was impossible to install cooler tires; everyone was driving Nokian Hakkapeliitta 8.

The interior is equipped with “half-buckets” purchased in Belarus in not the best condition. They were changed. Very good, comfortable: two sports safety belts. Inside is not only a BMW steering wheel, but also the entire column, steering cardan, and rack. In fact, only the appearance remained “Zhiguli”.

Why didn't you remove the back seat? This was done specifically so that two or three more passengers and friends could be seated. There was recently a stage in Gomel where an official drift taxi was organized - there were a lot of people, not everyone had time to take them for a ride: they ran out of gas and tires.

Spoiler is a separate issue. It can be even higher and wider. This is purely for fun. It does not provide any functionality. I would never do that for a regular car. We made it almost entirely ourselves. I only bought the top, the “shop”, I found it on some website. We developed the stands ourselves; they are made of polycarbonate - they definitely won’t break, most likely they’ll just bend. There were a lot of fittings, but we put everything together in a week - friends helped with drawings and grooves.

Vinyl has only recently appeared due to the fact that the “jambs” on the rear fenders are much less visible. The car got hit a lot, drifting is a contact sport, and in winter there were a lot of hits. And this is how the three-meter rule works—from a distance it seems like it’s intact.

The car is stored at the service station, there is a protected area. I don’t leave my car in the city - it’s a Lada, they’ll open it very quickly. And I have expensive seats, belts... Maybe some drunk will beat me up or climb in to sit.

For winter drifting, Lada is the most budget option. Nothing complicated, for pennies you can go to the store, buy a package of spare parts - and it will all work. This cannot be done with used BMW E30/E36 or old Japanese ones. "Zhiguli" in terms of chassis and suspension are excellent for drifting.

How much did you invest in building the car? I don't know. When we crossed the $5 thousand mark, we stopped counting. I don’t even want to count now, because I’ll only get upset.

“Wet Drift” is constantly held in Lipki, we ride there every weekend. About once a month you need to change the wheels in a circle. I don't buy new ones, I always buy used ones. This is about 100 rubles if you immediately change the kit.

I top up with gas and don’t do anything else for now. As the car was built, nothing has changed in it. Thank God, she behaves adequately, nothing breaks in her.

I won’t say anything about consumption because I don’t drive long distances. I have it purely for drifting, I don’t drive it every day, although there is such an opportunity. On an “everyday” basis, I have a Mercedes C-Class W204 with a 1.8 Kompressor engine, nothing supernatural about it.

In Lipki I drive the “penny” under my own power. In the summer, inspectors never stopped me - I don’t know why. Just lucky. But in winter there was an interesting situation: I decorated the car for the holidays, a Christmas tree, garlands on the roof. But if they stopped me, they only asked me “my license” and checked whether I was adequate.

What makes me most happy is that we built the car specifically for winter. But we came to the “Wet Drift” and realized that it drives very well, even better than some summer cars. Professional drifters who skate in the summer championship sat down and they say that it steers perfectly.

The car turned out to be universal: it was made for winter, but it also drives on wet asphalt in summer. It’s a little heavy in the dry, after all, 140 horsepower.

The power, to be honest, is annoying - I want more so that it drives better on dry surfaces. But it’s difficult to fix something - you need to change the motor. It's easier to build a new project.

I haven't hit the ceiling, there is something to do next. But not on this body, otherwise you’ll have to completely “uproot” it. Everything will start from scratch: take out the engine - install another one, remove the suspension - install another one. In short, this is a very large budget needed. If we start building from scratch, it will be a different car. It's in the plans.

Selling a penny? No. And who will buy it?

Notes in the margins

“Once I left my car in the city, they tore off the letter from my last name,” Vlad chooses only guarded parking.

“Handbrake” is one of the ways to put a car into a skid. In the “penny” it is hydraulic, like in serious summer cars.

“At Gazprom Neft gas stations, gas attendants constantly ask if they can put fuel in my car. I answer: well, try it,” the owner of the car at that moment smiles slyly and opens the gas tank flap. Where should I pour it?

Since this is a “cramp”, then its tank is made using racing technologies - it stands separately in the trunk and is protected from inevitable drift impacts. But the “deceptive” hatch remained. For fun, so to speak.

Vadim ZENKEVICH Photo by the author, video by Olga-Anna KANASHITS ABW .BY

Brother

Little is known about this masterpiece, although its authors have opened a separate YouTube channel for their brainchild. So, given: a VAZ-2108 body, a welded rectangular frame, UAZ locking axles, as well as a gearbox and an 8-valve engine from a VAZ-2115, which replaced a less powerful manual transmission and an engine from OKI.

Solution: a fairly powerful swamp vehicle, the power units of which may not withstand truly serious and dangerous off-road conditions. But it looks impressive, yes.

Homemade all-terrain vehicle from VAZ

A village craftsman built an original all-terrain vehicle for off-road forest travel, hunting, fishing, picking berries and mushrooms.

The all-terrain vehicle frame is made of channels, axles and a transfer case from an UAZ are installed. A VAZ body was installed on the frame along with the engine, gearbox and attachments.

The wheels are made from old GAZ-66 tires, with new treads cut out on the tires.

As a result of the alteration, ground clearance has increased significantly

The all-terrain vehicle moves well in deep snow.

Also, the all-terrain vehicle can move and stay on the water due to its large wheels. The photo shows how the all-terrain vehicle crosses the river.

As a result, the guy made such a real SUV from old Lada cars! The result was a very good all-terrain vehicle, although fuel consumption doubled.

Source

How to trim the rear axle of a VAZ for a mini tractor?

When independently constructing a unit from a Zhiguli, we are faced with the need to shorten the VAZ axle for a mini tractor. This is a rather responsible and difficult stage of work. To properly shorten, first read the diagram, which shows all the dimensions of the future structure:

Subsequent work should be performed according to the following algorithm:

- The spring cup is cut off and the end flange is removed.

- Part of the removed axle shaft is cut off, and a groove is made from the edge.

- A hole is drilled inside the cup.

- We dock and center the axle shafts, weld them according to the drawings.

- We insert the finished part into the bridge.

- We weld the bridge on both sides.

- Welding seams must be of high quality. At the end of the welding work, the seams are heated and cooled several times.

- We attach the bridge to the frame using a V-shaped structure.

For clarity, we also suggest that you watch the video, which shows in detail the process of shortening the VAZ bridge:

To shorten the front axle, you can use the diagram below:

Universal all-terrain vehicle for village life

It all started with the fact that a family that moved to the village had to think about the future fate of their “six” after 20 years of its operation.

As a result, it was decided to put the VAZ body on the frame of a UAZ purchased for 9 thousand rubles, the owners of which were going to hand it over for disassembly. It is noteworthy that the latter’s units were also used, and they turned out to be in fairly good condition.

How to resolve legal issues?

If it was decided to make a mini tractor with a VAZ engine, then the farmer should take into account several important legal nuances.

These include:

- if you buy an old Zhiguli car, you must go through the procedure of re-registration;

- after this, you need to inform the traffic police representative about further plans for remaking the car;

- Upon completion of the assembly of the mini tractor, the farmer will need to register it in his name and obtain new license plates. This is necessary if the agricultural machine will be operated on public roads.

If the owner of a mini tractor does not resolve all these issues, then, at best, he will face a considerable fine. During a repeated violation, traffic police officers have every right to confiscate the unit.