Quite often, drivers encounter difficulties in winter. Snowdrifts and ice pose a great danger. A winter set of tires may not always help here.

Even all-wheel drive vehicles designed for off-road driving may not be able to overcome snowy roads.

For such situations, there is a corresponding modernization of the car - these are snow chains.

In those places where the car will be buried in the snow or skidding due to ice, this device will increase the chances of the vehicle passing.

This article will talk about how to make snow chains with your own hands.

Purpose

This wheel improvement is designed to improve the vehicle's maneuverability in snow-covered areas or particularly slippery sections of the road.

For example, a car enthusiast is driving along the highway. So far he hasn't had any problems getting around. His car doesn't skid. But after a while he will need to turn onto a country road. As practice shows, such sections of the route are not always properly cleared of snow.

In order to eliminate all such situations associated with the car getting stuck in the snow, you should use snow chains. They will increase traction and help the driver a lot.

After driving through the problematic section of the road, they can be removed and placed in the trunk. It does not take a lot of time.

Efficiency

Tests of the operational efficiency of chains were carried out many times, here are some results of one of them (the test was carried out on compacted snow, the values of the vehicle's traction capacity are given):

| Without chain | Chain 5mm | Chain 6mm | Chain 6×8mm | |

| 4×2 | 340kg | 900kg | 1150kg | — |

| — | — | — | — | 1400kg |

As a brief conclusion, we can say that the use of snow chains increases the vehicle's cross-country ability by 3-4 times. Experienced motorists claim that the chains on the Zhiguli turn the Zhiguli almost into a Niva, and the chains on the Niva turn it almost into a UAZ, and the UAZ almost into a tractor.

Here are the test results of one fairly respected automobile publication in Russia:

| Without chain | Chain 5mm | |||

| Ice | Snow | Ice | Snow | |

| Summer tires | 43,5 | 32,3 | 21,9 | 11,8 |

| Studded tires | 23,5 | 17,0 | 7,4 | 5,6 |

| Belts | 27,3 | 25,2 | 10,9 | 8,8 |

| Chains | 23,6 | 21,4 | 5,4 | 5,2 |

As a conclusion, we can say that the cross-country capabilities of summer tires equipped with chains are close to those of winter studded tires, inferior to them in braking on loose snow, but superior to them in acceleration on ice. Polyurethane belts show significantly worse results, while having very questionable reliability.

How to make chains yourself

It is worth noting that you can make snow chains yourself. Here you will need the chain itself. Examine it carefully. There should be no cracks in the links.

Welding should not be present, this can cause the links to break. You will also need an angle grinder and a set of carabiners with a tensioner.

Before you start the work itself, decide on the drawing. The simplest is the ladder. It is recommended to start with it.

Then we measure the length of the chain. It should be enough to wrap around the wheel. We cut off the excess length with a grinder.

We attach carabiners along the edges. They are needed to secure the edges. We equip one of the edges with a tensioner. It will securely fix the device on the wheel.

Doesn't it all sound so complicated? That’s right, it will take a little perseverance and the right tools. The assembly process takes a couple of hours.

If you have any questions about this point, it’s better to watch a video about making snow chains with your own hands. They will tell you what other forms there are and how to make them. And it will be easier to navigate, seeing how the manufacturing process occurs.

Things to remember

The use of anti-slip chains is prohibited when driving on hard-surfaced roads (concrete, asphalt). In conditions of loose snow or soil, it is recommended to maintain a speed of 10-20 km/h. Wheel slip must not be allowed.

After installing the anti-slip device, after driving the first 100 meters, you should stop and check the reliability of its fixation, as well as the tension around the entire perimeter. A poorly tensioned chain can cause damage to suspension and steering components.

Ideal wheels: how to distinguish forged, stamped and cast wheels from each other

When and how to replace the timing chain - step-by-step instructions

How to put chains on wheels

There is nothing complicated here. We do everything with our own hands, without special equipment. There are two ways to put on snow chains.

The first method involves lifting each wheel using a jack. Then we put on the chains, secure them with a lock, and tighten them with a tensioner.

We lower the car, drive a few meters and, if necessary, tighten the device further. This is very important, because if there is no required tension, we will not achieve the desired effect.

The second method does not require a jack. You just need to spread the chains and run over them. Leave a little space on one edge of the chain for ease of putting on.

The next step is to secure and check the correct tension. At first glance, this method seems easier, but it will take some practice.

Ways to increase vehicle cross-country ability

To improve the vehicle's maneuverability on muddy or snowy road surfaces, drivers use various methods to improve the traction of tires on a sticky road.

There are two ways to improve a car's cross-country ability:

Tires with appropriate patterns and deep treads create a lot of resistance while driving, which increases fuel consumption. In addition, all-terrain tires are heavy and noisy.

A FullFree device has appeared, which, according to manufacturers and sellers, reduces fuel consumption and protects internal combustion engine parts from low-quality fuel. Let's find out whether fuelfree experts are telling you whether it's a scam or true.

Using the second option, to put on the chains, you need to use a jack or by unfolding the chain and driving over it, followed by fixing it.

Classification

The main difference is the diameter of the wheel on which snow chains will be equipped. In other words, they divide into the following categories: for trucks, for cars and SUVs.

Consequently, for a larger wheel, a chain with large links is selected. The load is many times greater, in connection with this there are such criteria.

Moreover, the do-it-yourself manufacturing process for all types of vehicles, both for trucks and passenger cars, including the VAZ brand, is no different.

Dimensions and pattern

You can also divide these designs by size and pattern.

The size is selected solely according to the parameters of the car itself, namely, what ground clearance, wheel width, etc.Basically, the instructions write for which cars this or that chain is designed. Otherwise, you can measure everything yourself. This is very necessary in order to protect yourself from the possible snagging of this very chain on parts of the car’s chassis.

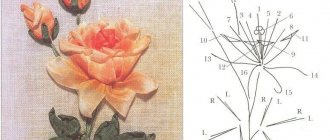

There are 3 classifications of drawing:

- Ladder

- Triangles

- Honeycomb

"Ladder" is the most affordable option. This chain fully corresponds to its name, because the weaving occurs in stripes along the tread, perpendicular to the wheel.

This design is suitable for muddy areas, but due to the small contact with the road there is a risk of self-burrowing. Therefore, in deep snow, this type is not effective.

"Triangles". Great in deep snow, but not effective in muddy areas. If you look at the width of the tread, you can see a zigzag shape.

Honeycombs are intersecting diagonal lines. This option has 100% contact with the ground, which ensures excellent lateral stability. But the design limits the speed of movement.

Bottom line

It is possible to turn any car into a real SUV using chains. The manufacturing process will not take much time, no more than three hours.

The main thing is to choose the materials wisely and carry out the assembly efficiently. If you wish, you can buy this device at a specialized store.

Good afternoon friends!

It turns out that winter is just around the corner, New Year, Christmas, a time of miracles, new achievements and optimistic plans for the future. Mototoxicosis can melt the ice of Antarctica and Desperado, my two-wheeler is freezing in the garage at -28. It turns out that I finally got a Suzuki Djebel 250 motorcycle from 2003. Well, literally a week ago I got it, and I’ve already started messing with it. This is enduro, oh my! This means you can drive in winter!

THERE Arose the question of improving the quality of wheel grip with snow/ice/frozen ground. I don't have a second set of tires at my disposal to do studding. I don't want to buy them and wait. I want to ride! Therefore, as an alternative to spikes, I chose MORDOVKA . In vain, as it turned out.

In this post, I will traditionally tell you in a drug-like way what I got out of all this, describe my impressions of winter trips and the Suzuki Djebel 250 motorcycle itself. So, grab some tea, a bun and let’s plunge into the world of winter endurism together. You won't get bored, I hope. There are a lot of all sorts of photographs there. If I had more time, I would have written less, but so what.

So, I apologize in advance for the chaotic style of presentation. Secondly, I actively accept congratulations on the purchase of a new motorcycle

Well, off we go! The idea of having an enduro bike came to me a couple of years ago, when I went to visit my brother in the village. It turned out that I literally got myself into brown adventures. It was 8 km of hell, horror and sweat through the autumn mud on a cruiser, with stupidity in the head and adrenaline in the blood. In case anyone is interested, you can read it here.

Then I thought that I would drive this part of the road laughing in an endurike. That time I was sweating a lot, and at the last moment I even got a little desperate, I thought I wouldn’t go back. Then my brother reminded me of MORDOVKA . I made them from some kind of plastic rope that is used to tie wheels with hay. It turned out great. I got out of this shithole without falling once.

So, what is our introduction? We have a terrible frost on the street, -28, it’s impossible to beat a tooth, we have a couple of evenings of free time, a new motorcycle, a dozen meters of some kind of chain from a construction market. Oh yes, we also need a pinch of crazy enthusiasm and an iron cable. I have them!

What I don’t have is a second set of studded tires, the patience to wait for them to arrive, if I do buy them, well, I’m a decent beggar. I also wonder why there is so little information on the use of muzzles on motorcycles? There is a lot of information about studding, but nothing about chains. Now it’s clear why, but let’s go in order.

Well, since I mentioned spikes, let’s put together the main types of wheel squeezing:

1) Mounted with M3 or M4 bolts, with washers and a tie with one or two nuts. Cheap, cheerful, very labor-intensive, the material of the bolts is soft and quickly wears off on asphalt and frozen ground.

2) Secure the wheels with self-tapping screws and glue. The screws are screwed into the checkers and only the cap sticks out. Even cheaper, less labor-intensive, much worse than “holders”; if the self-tapping screw falls out, then you can’t screw a new one into the same hole, there is a risk of puncturing the camera from the inside with the tip of the self-tapping screw.

3) Similar, but the self-tapping screws are screwed in from the inside of the tire with the point outward. Optionally, you can screw nuts and washers on top for better fixation. A little more expensive, better grip, better self-tapping material.

4) And finally, an option for real men. Bristle the wheel with dowels. And if you also grab the washer with welding, it will be absolutely delicious. The most expensive, the best grip with Mother Earth, the best stud material, it doesn’t wear off, but it’s the most difficult to make.

But let's return to our scolopendras. It turns out that I went to a hardware store, and a woman immediately jumped up to help me and began to court me in every possible way. I tried to find out why the hell I needed a chain, what load capacity, short-link or long-link, galvanized or hardened. But when I said that I needed a chain for a motorcycle, he somehow immediately dropped his head and was silent for about 15 seconds. “These are for wheels to ride in winter,” I clarified. This interested him and in the end we chose a short-link galvanized chain with a thickness of 5 mm. Wishing me luck, he gave me a parting slap on the shoulder.

Oh yes! Before this whole thing, I was thinking about the “tread pattern” woven from the chain. From the height of my ignorance, I reasoned like this: what is the function of the rear wheel? Push the motorcycle forward. Which plane requires maximum grip? Longitudinal. Those. The rear wheel will work most efficiently if transverse plates are attached to it, like a ship with a paddle wheel drive. What about the chain? Those. we need to make transverse coils of chain around the tire. But this approach is only good in the longitudinal plane. Those. the motorcycle will move forward well, it will row its wheel like a mad boar, but in the transverse plane it will be unstable. It will drag the rear of the motorcycle left and right, roughly speaking. In fact, this is what happened.

What about the front wheel? And the same thing, only its function is to set the direction for the motorcycle to move. How can I get him to do this? Here the front wheel must be stable against lateral movement on the ground. What shape of tread needs to be made so that I don’t fall into brown slush after just a meter of driving? Longitudinal furrows and grooves are needed. This means that the chain on the wheel needs to be laid in such a way that my steering wheel does not break when crossing a snow track. Here I also had the idea of screwing bolts into the chain links so that they formed spikes.

Of course, all this demagoguery is true for soft surfaces such as snow/sand/dirt/semolina. But I went astray in my reasoning. Now I already understand this. The trouble is that compacted snow is almost equal to ice, especially after a thaw. And the chain links are relatively smooth and do not stick into the surface.

Here, armed with writing instruments and parchment, I drew the following designs of protectors:

Well, in general, I tried to figure out by eye how I would weave this whole thing from a chain and became sad. I am quite a hands-on person, so I immediately discarded complex designs. And I want to drive faster! I settled on simple options: for the front wheel, the second chain diagram on the left, and for the rear, transverse chain rings with a pitch of 11 cm, according to the second chain diagram from the right. Why did I get excited about making rings in 11 cm increments? But because there are some unknown grooves in the tire tread, where the links fit well and do not stick out, without touching either the pendulum or the drive chain. In total, 18 rings with a length of 21 cm are required for the rear wheel. This means we need 21*18=3.78 meters of chain.

We also need a cable as strong as an elven bowstring. I took a ruler and measured the distance from the center of the wheel to where the cross ring of the chain would end. It turned out to be 29 cm. Let's calculate the length of the cable: L=2*pi*R = 2*3.14*28=1.76 meters of cable. But the cable must be on both sides of the wheel, which means its length doubles.

Let's start fiddling with the chain. We count 10 links and cut the sausages. In total you need 18 pieces. My calculations failed me and one sausage was missing. I had to make it out of sawn links.

When we are done with the chain, we begin to work with the elven bowstring. It is necessary to make two loops at the ends of the cable in order to insert them into the bolt to tension the entire structure. For this purpose, rope clamps are sold in hardware stores. It costs 4 piastres, it looks like this: Oh, here’s another thing. I use a cable with a diameter of 3 mm and a cost of 11 tenge per meter. Well, so, we make two cable blanks for both sides of the wheel, put on chain sausages and fasten them with tape to the tire so that they don’t fall out. Then I glued the cable along the contour of the wheel in the same way to accurately determine the required length. I know my calculations...

I tried to bite the cable with pliers, like Jackie Chan in the movie Police Story 2. I almost broke all the bones in my hand.

Ah-ah-ah! I also brought a motorcycle home! Well, I couldn't resist. But today I slept just great. At night I woke up, a girl was snoring next to me, and opposite, near the wall in the twilight, the menacing but unclear silhouette of Jebel loomed. I smiled like a fool into the night.

But, nevertheless, I had to pull the motorcycle back into the garage, otherwise I risked crushing the floor of the house with chains. I would have gotten it in the forehead. He pulled it out, which means he started to pull the muzzle and an unpleasant incident emerged. It turns out that the long tension bolt bends sideways due to the fact that the cable loop is bent at an angle and the bolt begins to bristle. Then, I replaced the bolts with these things:

But I really wanted to test it, so I tied this bolt to the cable with wire so that it wouldn’t stick out, and I skipped off to test it.

Out into the street... HOLY VISSARION! +1 degree Celsius. Recently it was 29. The snow was compacted and slippery. Okay, I started it and drove off. Well, what can I say? It goes great in a straight line. I didn't throttle very hard. Firstly, it was my first time riding an enduro bike. Secondly, it was my first time driving in the snow. Thirdly, there are no chains on the front wheel. Somehow I managed to turn around, because the front end slides furiously and getting out, even from a small snow rut, is a big problem. Of course, the front brake didn’t work at all, but the rear brake worked great.

In short, I fell. So much so that the steering wheel was bent. Here I was amazed at the stock of curse words and even learned a few new ones. Well, this is necessary! Ruin a new motorcycle. In the first week. Out of season. In winter. About the snow. Fucking Bartholomew...

Then I remembered a similar incident two years ago. The new Desperado has just arrived. It stands, shines, sparkles. I run around, drool and blow dust off him. And so that the beauty of Despera becomes absolute, I decided to erase the auction number written on the plastic windbreaker. I took a rag, acetone and... DISSOLVED THE PLASTIC TO THE HELL! It went from transparent to a cloudy spot. I got scared, began to rub even harder, and it began to corrode even more actively. So I swore then... Remember the movie with Mr. Bean? Where he accidentally sneezed on a painting in a museum, then tried to wipe the sniffles with a rag, and the pen leaked into the rag, so the painting turned blue, then Bean started rubbing it with some kind of product and as a result, he got the same thing as me.

Okay, we’ll take into account the shortcomings, we’ll redo the cable tensioning system, the front chains will be better. By the way, about the front chains. It turned out like this:

It worked out, but it didn’t work out. The transverse links, those that climb to the rim, tend to touch the rubber boot of the shock absorber. What a reptile! And I tried so hard to saw the chain and then connect it back.

Well, okay, I put the chain on the wheel, aligned it, tightened the nuts on the bolts and began to tension the chain with the longitudinal tension bolts. It turned out well, it doesn’t touch anything and looks to be holding tightly. Even more. But still somehow boring. What if the chain slips off the wheel due to transverse forces? We'll have to fence the guy wires. So I bit off 38cm pieces of cable, threaded them into links and tied them under the rim with a rope clamp. And you need as many as 18 of these things. Next, I threaded another piece of rope through them, which will pull them together. I agree, this design is worse than having a cable on both sides of the wheel. But the chain stays on the wheel perfectly, so we’ll see. I think it won't fall apart while moving.

I went out for the second time. ABOUT! It got much, much better. Now it’s not scary to take turns at all. Well, without fanaticism if so. It goes well in loose snow, but the backside wanders a little. Longitudinal snow tracks still need to be driven more carefully, especially icy ones. Not bad overall. It’s better on asphalt, of course, but probably better on spikes too. Well, what's done is done.

There are no photos of the ride, sorry. I ride mostly after work and it’s already dark, and it’s a little scary to take a camera with me. I'll fall and break it.

Now, let me go over the motorcycle a little. This requires a separate detailed post, but I’ve already made a graphomaniac here, but oh well. My first impression of Jebel when I unpacked it was: “Damn, why is it so big?”

I thought the endurik would be small, but no! Huge, you bastard! I sat down and my hands immediately fell comfortably on the steering wheel. I was immediately pleased that the handles were rubber and not iron, like Desperado’s. They will not scroll in your hands. The saddle is a bit hard, but I can deal with that. Or I’ll sew something soft or make my butt softer. But he stood firmly on the ground with both feet. The motorcycle has a lot of spring. He pushed the girl onto the saddle behind him. I have it compact, he says it’s convenient. I hope he won’t complain, and if he does, he’ll get it from me! It's time to start! Well, I started it for the first time in my room. Well, I really wanted to. Literally started up like crazy. I was even surprised. Still, maybe the battery is dead, or maybe I didn’t charge it well, but it’s good to start it by simultaneously pressing the engine start button and pulling the kick. And when I was riding, I was pleased with the unexpectedly bassy and brutal sound, if I accelerated properly. You immediately feel the lack of torque at idle and slightly higher speeds. If you can drive the Desperado freely from idle, then no, no. Also, neutral is caught worse. Maybe because the oil is bad? I was very pleased with the headlight. Shines like a star.

About endurism in winter. Yes, this is awesome! No, really. Make spikes/chains and you don’t have to close the season at all! Not at all as cold as I feared. And if you drive a little faster than a pedestrian, it gets hot. Well, I myself live in a very provincial area, which I am incredibly happy about, and I don’t have much asphalt here. So this is awesome too! Such a haven for rides. And there’s also a wide river nearby. Although, I didn’t dare visit her. The ice is thick, actually, but the chains don’t hold on to it well. In short, there is somewhere to ride. It’s true that people look at me like I’m crazy, but my eyes are hidden behind my helmet, so I don’t care. We have an excellent ski track in the forest here. Wide, with snow trampled by skiers, with many branches in the forest, with hills and hills. I really want to go there and drive. But I’m afraid that especially skiers will catch up with me and stick a stick in... for damaging their ski track. But, damn it, it's a hunt!

So, let's summarize. Pros and cons of muzzles: + easy to make + the tire does not deteriorate i.e. you can use one set for winter and summer + good grip on soft ground + looks cool

— poor grip on ice/well-packed snow - wheel unbalancing (although not relevant at low speeds) - risk of the chain falling off when driving - considerable weight (for the rear wheel the weight is 1.7 kg, for the front wheel - 2.5 kg)

That's all, I guess. The main conclusion is - don’t listen to me and make spikes from dowels like normal white people.

Be healthy, friends.

Photos of do-it-yourself snow chains

https://www.youtube.com/watch?v=pER-Ayn95g8

Types of castles

There are 3 types of connectors used:

- S-shaped.

- Hook with spring.

- With ratchet.

The first option is simple, but has a number of disadvantages:

- inconvenient to install (you have to tighten it with a wrench);

- unreliable (there is a risk of unscrewing);

- cannot be adjusted.

The spring-loaded hook lock is fastened in one movement and cannot open spontaneously. For this reason, this variety is more common. A screwdriver is required to secure it. Experienced users recommend additionally tying the parts of the lock with wire with a diameter of 1-3 mm in order to increase reliability.

Ratchet parts are the most complex and cost more than others. At the same time, they are the most practical:

- provide high reliability of fixation;

- snaps into place without the use of tools.

A budget option for a lock is a long bolt with 2 wide washers and the same number of nuts. Installation is carried out in 2 stages: first, the anti-slip device is tightened by screwing on the nut, then it is secured with a second one.