Farmers are interested in what hydraulics are for a homemade tractor, and how to make it with their own hands. Small dimensions are not a hindrance to performing the necessary tasks and proper operation of all functions. This is proven by such agricultural equipment as mini-tractors - perhaps the most popular equipment used by farmers when cultivating lands of different sizes and with varying soil complexity.

How to make hydraulics

Using a similar mechanism on a mini tractor allows you to get a number of advantages. But the most important thing is that it ensures the stable functioning of additional elements.

Self-assembly of such a structure is very simple; it is important to have a sufficient level of technical knowledge, as well as strictly adhere to the diagram or drawings. To assemble such a device, you need to prepare a number of tools and parts. The sequence of work itself in this case looks like this:

- First, drawings of the future structure are created.

- All required parts are being purchased.

- Their installation is carried out, as well as the installation of the hydraulics themselves.

- After this, the parts are calibrated, and the functionality of the structure along with the transmission is checked.

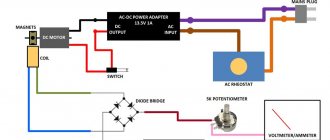

According to its diagram, the hydraulics for a mini tractor with your own hands consists of the following elements:

- Hydraulic tank where oil is poured.

- Power point.

- Hydraulic pump, as well as distributor.

- Connecting hoses.

- Special hydraulic motors, as well as pistons.

Sometimes, to supplement this, various filters are installed that change pressure indicators and other data. This prevents possible contamination of the pump as well as the power plant from contamination. In the process of drawing up a diagram of the future design, it is important to consider:

- The hydraulic pump must be placed under the tank. This will allow the oil to flow to it by gravity, which reduces problems for the hydraulic system during the starting process.

- For the correct functioning of the mechanism for a long time, it is important to first calculate the power of all combined elements in the unit. It is taking these data into account that the hydraulic pump itself should be selected. When the power of one is not enough, additional installation of an auxiliary element is required. The latter will begin to work when the maximum load in the system is reached.

- To ensure long-term and trouble-free operation of the unit, sensors must be installed to measure the pressure level in the system, as well as filters designed to clean the oil.

In order for the fluid to fulfill its role in the system, it is important that it is constantly in motion. A similar function is performed by a hydraulic pump that transports oil throughout the entire system. The power unit connected to it transmits torque, thereby activating the fluid exchange mechanism. The pump itself is connected to the distributor. Based on the position in which the lever is located, the oil returns to the tank or it goes in a different direction to the hydraulic motor or pistons.

As a result, due to the high density of such a liquid, it allows for heavy traction movements. In the form of an engine for such a unit, different options are used, from electric to diesel.

An important condition is the need to provide sufficient power for the operation of the hydraulic pump for the mini tractor.

Selection and procurement of parts

The need for such a system is due to the simplification of the functioning of the pistons, as well as easier movement of the unit. To avoid problems during soil cultivation, a hydraulic system is used, since the minitractor itself has insignificant traction properties. As a result, you need to purchase the necessary elements, modify the design, and then assemble the device. You can buy structural elements separately or as a set. It is important that each group of pistons has its own lever. For small units, 3 levers are sufficient:

- For braking.

- For frame control.

- To start hydraulic motors.

Advanced models use distributors equipped with additional functionality. However, the price of such options is significantly higher than classic products. The selection of the purchased hydraulic pump is carried out based on the following parameters:

- The level of pressure required to start the power plant. If this is insufficient, the hydraulic motor simply will not start working.

- Pumping speed measured in l/min. Determines at what speed the pistons and motors will operate.

hydraulic motor for mower

Questions can only be asked after registration. Please login or register.

I want to make a mower based on the GMSh32D-3L hydraulic motor. Help with specifications. Will it work from NS 10? What speed, etc.

NSh-10 won't hold up. nada 32.

Why are there no factory mowers with a hydraulic motor?

There is a factory one, German, on a manipulator for lawns and hedges. Costs 4500 Euro. Files: clip_image002_4.jpg cosa_0.jpg

it will be too small but I'm like crn something

аleksey77 The Germans have been using hydraulic motors in their equipment for 15 years, including on mowers, but the price of these units is much higher than when using belts and gearboxes, but the weight and size of the units are reduced significantly, and since we are not the richest people in the world, they offer us equipment cheaper and using old technologies

it will be too small but I'm like crn something

grip 90 cm but branches up to 3 cm are pulled down like grass

But if you turn the valve not from the power shaft, but from the hydraulic one, it will be interesting?

Hunter. GMSH - 32, rpm up to 1700, power -24 kW; GMSH-10, same speed, power -8 kW. I've already bought both for myself. In the summer I’ll finish the harvester ZhVN -6, I’ll hang it on a NIVU, I’m going to cut grain. Please take into account that GMSH will quickly burn out if there is no additional cooling of the oil.

Please consult.

A friend said that instead of a hydraulic motor, you can use an NSh type hydraulic pump. Is this possible or is it a falsehood?

Please consult.

A friend said that instead of a hydraulic motor, you can use an NSh type hydraulic pump. Is this possible or is it a falsehood?

NS used vRUM as a guide. but they have little strength, since the oil support area is small, and the speed depends on the amount of oil in the supply pump minus leakage through the drainage. Drainage is necessary, this is an additional outlet on the back side of the drive. Force can be obtained through a re-drive by reducing the speed by 20 times. The efficiency is low, axial-plunger hydraulic motors are much better, but they also have a lot of their own problems. Files: dsc01270.jpg dsc01268.jpg

Source of the article: https://fermer.ru/forum/samodelnaya-selskokhozyaistvennaya-tekhnika/41887

Advantages

Having figured out how to make hydraulics for a mini tractor with your own hands, it is worth considering the main advantages that such home-made devices bring. Positive properties include:

- Possibility to use attachments.

- In the process of creating a diagram of the future unit, it can be supplemented with other devices.

- Controllability increases, as well as the ability to customize it “to suit you.”

The main disadvantage is the waste of time required to create such a structure. By assembling the hydraulics for a small mini tractor yourself, you can significantly increase its performance and also simplify its management. It is important to strictly adhere to the drawings, purchase high-quality parts and avoid inaccuracies.

Advantages of a tractor with hydraulics

Installing do-it-yourself hydraulics on a mini tractor will give the agricultural machine many advantages:

- It is easy to operate - a hydraulically driven tractor can turn around almost in one place, which makes it possible to increase its efficiency when performing some work - plowing the ground, mowing grass.

- You can connect various attachments - seeder, harrow, mower and others.

- Improved brake system - hydraulics provide braking by reducing the volume of lubricant supplied. If the handles used to control the load distribution are set to the neutral position, the wheels of the agricultural machine will be completely blocked. This method is intended for intensive braking and can be used instead of the parking brake.

- The hydraulic drive on the tractor is quite strong, due to which it can withstand significant loads without increasing the pressure on the machine.

- It is possible to connect additional attachments. When creating the circuit yourself, the hydraulics may differ from the standard one and can be supplemented with other devices (hydraulic pump, pistons, sensors, etc.).

- Improved tractor control - when assembling and installing hydraulics, you can customize all its components “to suit your needs.” This will increase the accuracy of machine control, and working on it will become more comfortable and convenient.

DIY mini tractor

Sooner or later, any person living “on earth” is struck by the idea of the need to use a mechanical assistant on the farm. Plow or level the area, uproot stumps, transport several bags of cement, dig a ditch, etc. - there's a lot to do. But the prices for walk-behind tractors, motor-cultivators, garden mini-tractors and industrial-made snow blowers “bite”, and every time renting them is “a toad’s choking”. Therefore, the “Kulibins” of the FORUMHOUSE portal prefer to roll up their sleeves and make the necessary unit or mechanism themselves. It is this type of model, capable of giving a head start to its branded counterparts, that will be discussed in this article.

- How to make a universal hydraulically driven mini tractor.

- What tools are needed to make a homemade mini tractor.

- How much does it cost to build a homemade mini tractor?

Side-swivel baby with hydraulic drive

A topic by a portal user with the nickname RoteRatte about how he made a universal flat-rotating hydraulic platform on wheels caught the attention of many. Of course, the “baby” in the photo below is capable of a lot.

Lift and transport FBS blocks weighing 200 and 500 kg.

Remove the fertile soil layer from the area.

Use a bucket to clear snow on roads in SNT in winter.

Moreover, as various attachments are manufactured, the range of tasks that a mini-tractor loader can solve will expand significantly.

About a year ago I took up the task of landscaping my site. There were a lot of things to do - level the site, pull out the old FBS blocks on which the old house stood, uproot stumps, etc. I was thinking about ordering a small-sized tractor to remove the topsoil, but the price tag for working on two sites with a total area of about 250 sq. m. I was charged 30 thousand rubles. Moreover, the “firms” also fed me with promises for 2 weeks. So I thought and thought and made a mini tractor, and then completed this job in 2 days.

From the idea to the implementation of the mini tractor in metal, it took RoteRatte about 7 months. The key to success is careful calculation, planning, as well as the maximum use of ready-made factory components and parts from automotive equipment.

After developing the concept of the device, the user ordered and purchased units that you can simply put at home and not think that their prices will rise. These are the engine (“390th” Champion with an electric starter, 13 hp), hydraulics (hydraulic pumps, hydraulic cylinders), drives and wheels.

Rolled metal was left for later. RoteRatte also thought out the layout of the mini tractor in such a way as to minimize turning work.

Of the main tools RoteRatte used:

- angle grinder (angle grinder);

- household welding inverter;

- simple drilling machine;

- drill;

- hammer.

Main technical characteristics of the mini tractor:

- length – 2050 mm;

- width – 1100 mm;

- height – 1400 mm;

- speed – 3-4 km/h;

- weight – 400 kg.

Although the user calculated various parameters of the hydraulic system and drives on special calculators, the “baby” turned out to be stronger than intended. For example, a mini tractor can easily lift and drag concrete foundation blocks weighing 200 kg.

Necessary tools

Each specific case may require its own set of tools and materials required for assembly. Their main set:

- welding machine;

- Bulgarian;

- drill;

- drill;

- taps for thread cutting;

- set of wrenches.

The list can be supplemented with items depending on the assembly conditions.

- hydraulic pump;

- hydraulic distributor;

- hydraulic tank;

- transmission belt;

- hoses and their fastenings;

- hydraulic cylinders;

- bolts and nuts;

- clamps;

- oil filter;

- various fasteners, the name of which is determined by each specific case.

The main components are shown in the photo.

Homemade mini tractors

Basic concepts and topic of the article: Mini tractor with hydraulic motors, or do it yourself, homemade mini tractors, hydraulic motors

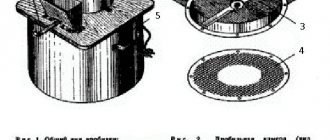

The choice of power unit determines the quality of all the functions of a homemade tractor with hydraulic motors , its, so to speak, ability to work. In the actual implemented project, the engine from the SZD motorized wheelchair was used as the main supplier of finished parts. Any similar engine with at least 14-18 hp will do. To ensure a safe connection between the engine output shaft and the hydraulic pump, it is best to install an elastic coupling. On the Internet or engineering books you can find a lot of materials on making such a coupling. A hydraulic pump of the NSh-50 brand is connected to the engine through a coupling; the maximum oil pressure it creates in the hydraulic system is 100 atm. In practice, these pump indicators were able to ensure the normal functioning of the hydraulic motors, which ultimately ensured the normal movement of the hydraulically driven tractor itself. It also allowed the parallel use of any attachments with hydraulic motors or the installation of a power cylinder for the attachment mechanism of additional equipment on the minitractor. The hydraulic motors themselves were taken from machines that spread sand during icy conditions, but it doesn’t matter where they are taken from, the main thing is that the power of each individual motor must be more than 3.5 kW with an output shaft speed of about 2200 rpm. Such parameters of hydraulic motors are balanced for the presented version of the mini tractor design .

Design features of a homemade mini tractor with hydraulic motors

as distributors and oil bypasses in the hydraulic system for the hydraulic motors of the minitractor ; their operating mode is controlled through a lever with a handle. They were placed on the sides of the car, symmetrically to the longitudinal axis. There are no special restrictions on the design of distributors; if manufacturing is possible, home-made units or other types are welcome - multi-spool devices in a cast housing (from an MTZ-80 excavator).

The rotational motion of the hydraulic motors is transmitted to the axle shafts of the drive wheels through double-circuit chain transmissions. It is advisable to use factory-made sprockets for gears; remove them from old machines: cars, tractors, motorcycles or scooters. A possible compromise is to make with your own hands only part of the gear wheel - the hub. This was done with the driven sprocket Z=54 of the drive wheels. Wheel design parameters can be found in the technical literature.

The rear drive wheels were borrowed from the T-28 tractor; they will also fit the T-40 model. These are their front steer wheels which use 6.5 16″ tires. Their peculiarity is the ability to change the track by rearranging elements, or by turning the entire wheel 180° relative to the rocker.

Despite the use of special wheels on a mini tractor, it is necessary to use lugs . Since the tractor will be specific, therefore, they are quite unusual. The lug consists of two identical closed chains; “travel” chains are used, or similar ones with a large pitch will do. In order for the chains to stay on the tires, their length must be 50 mm less than the perimeter of the wheel. The lugs themselves, in the form of a rigid link, connect the two chains. The lug is a welded structure made of a pair of 40x100 mm plates in the form of a gable roof, the material used is 5 mm St 3 sheet. Two M10-150 studs are screwed into the plates so that their ends evenly peek out from behind the plates. These edges of the “microroofs” are hooked onto the chain rings and screwed with M10 nuts until they stop. To put on the chains, you first need to lower the chambers and place the chains in the middle of the wheel, then return the pressure in the chamber to operating condition with the pump.

System Operation

Instructions for controlling the hydraulics of a mini-tractor

The system is controlled using a lever(s) in conjunction with a hydraulic distributor. Its (their) main function is to change the positions of the distributor control valves, supply pressure to the desired section, and disconnect the fluid circulation circuit from the final units of the unit.

A simple hydraulic system has three control lever positions:

- neutral - oil circulates separately from the pistons;

- expansion of the piston - pressure forces it to take the most extended position;

- movement of the piston - the pressure is released, the vacuum created by the escaping liquid pulls it along with it, returning it to its original position.

At the moment the piston(s) move, the attachment performs the work intended for the purpose of its production.