The question of how to make a blade for a walk-behind tractor with your own hands arises before almost all owners of land plots with the onset of winter. Specialized and online stores offer many devices for snow removal. However, not everyone has the opportunity to buy a walk-behind tractor with a factory-made blade. A good, high-quality factory-made snow plow has an impressive price. You can save on an expensive purchase if you show creativity and make a blade for a walk-behind tractor with your own hands. For such work there is no need to purchase special equipment. You can make a homemade blade for a walk-behind tractor from what you have on hand.

Design features of a homemade blade

Many owners of agricultural machinery purchase a blade for a walk-behind tractor in specialized stores, spending a considerable amount of money on the equipment. However, this kind of attachment has the simplest possible design, which makes it easy to assemble it with your own hands, practically from improvised means. To do this, you do not need to have specialized equipment or expensive materials at your disposal - the snow removal attachment for the walk-behind tractor will be quite inexpensive, but at the same time, maximally effective.

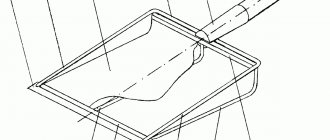

The first thing you need to do before manufacturing equipment is to understand its design features. Any snow thrower for a walk-behind tractor consists of a fairly durable working element, a fastening unit, a mechanism for adjusting the direction in which snow masses are thrown, as well as a power unit that holds the shovel on the chassis of the walk-behind tractor used.

When creating a snow plow for a walk-behind tractor, it is best to focus on any of the store models. It is not at all necessary that a homemade snow blower has those additional options that are included in the design of the factory unit. To begin with, it is enough that the manufactured shovel for the walk-behind tractor successfully copes with its direct task - removing snow. Later, during operation, the homemade device can be equipped with useful additional functions.

Both factory and homemade shovels can have 3 positions:

- front;

- to the left, while the slope angle is 30 ⁰;

- to the right, while the slope angle is 30 ⁰.

Immediately before work, the homemade mounted snow blower used for a walk-behind tractor must be turned left or right, maintaining a slope angle of 30⁰. After this, the device is fixed in a suitable position using steel cotter pins.

When using a homemade shovel, its dimensions play a big role. The most productive, and therefore the most effective in small and medium-sized areas, will be a nozzle for removing snow, 1 m wide and 30–40 cm high. But in order for a device with such dimensions not to break under the weight of wet snow, the thickness of the metal must be at least 5 mm. If a nozzle with smaller dimensions is created, the material, accordingly, can be thinner.

Popular models of snow blowers

Among the huge range of products offered by manufacturers, the most popular is the following equipment:

Megaladon-0.6 rotary equipment for the Salyut walk-behind tractor for snow removal

The rotary snow removal attachment for the Salut model Megaladon walk-behind tractor is used as an attachment for clearing small areas. Installed on the walk-behind tractor from the front using a special fastening device included in the kit.

Principle of operation:

- The main working element is a screw with teeth.

- Rotating, the shaft transfers the snow mass to the center, which then falls into the crater.

- The direction of snow ejection is selected by the operator by rotating the device screen.

- The distance over which the snow will be thrown directly depends on the engine power, as well as on the angle of inclination of the snow exit device.

- The height of snow capture is regulated by special snow blower skids located at the bottom of the device.

Megaladon -0.6 to the Salyut walk-behind tractor

Model features:

- The snow blower is attached to the front of the walk-behind tractor, which eliminates the need to turn the steering wheel and work in reverse gear.

- The ability to continue the operation of the snow blower after stopping the walk-behind tractor due to the transmission of torque from the engine.

- The screw is made using the latest laser equipment from high-quality material.

- Meets all required safety regulations.

- The snow blower chain is located in a special protective cover and is separated from the direct work area.

- The high-precision design of snow ejection ensures that all selected parameters are met.

- Lightweight design of the snow removal attachment.

Technical specifications:

| Characteristic | Meaning |

| Snow fence width | 60 cm |

| Height | 25 cm |

| Snow jet throw range | 7 m |

| Movement speed range | From 2 km per hour to 4 |

| snow blower | Single stage |

| Weight | 42 kg |

| Price | RUB 15,150 |

Snow plow Texas 92000160100 for the “Texas” walk-behind tractor

A specialized snow plow is installed on the Texas walk-behind tractor (as well as on the Husqvarna walk-behind tractor) from the front. The cutter is replaced with wheels. Used for clearing loose snow on narrow paths and small areas around the house. The kit includes a mount along with the blade.

Texas 92000160100

The width of the snow cover is 75 cm. The country of origin of the attachment is Denmark. The average retail price on the market for attachments for garden equipment is 6,436 rubles.

Attachments for Texas walk-behind tractors are selected individually for a specific model, since each auxiliary device is manufactured for a specific machine, taking into account its design features and capabilities.

Sm-0.6 snow thrower for walk-behind tractor "Cascade"

The snow removal attachment for the Cascade walk-behind tractor, model CM 0.6, captures and throws snow using rotating augers driven by the walk-behind tractor engine.

Technical specifications:

| Characteristic | Meaning |

| Snow fence width | 65 cm |

| Height | From 15 to 20 cm |

| Snow jet throw range | From 3 to 5 m |

| Movement speed range | From 2 km per hour to 4 |

| snow blower | Single stage |

| Weight | 50 kg |

| Manufacturer | Russia |

| Price | 14,500 rub. |

| Guarantee period | 1 year |

Snow removal attachment for the Mole walk-behind tractor

Technical parameters of the snow blower for the Mole walk-behind tractor:

| Characteristic | Meaning |

| Snow fence width | 66 cm |

| Height | From 15 to 20 cm |

| Snow jet throw range | From 3 m to 5 m |

| Movement speed range | From 2 km per hour to 4 |

| snow blower | Single stage |

| Weight | 42 kg |

| Manufacturer | Russia |

| Price | RUB 18,900 |

Sp-56 attachment - snow blower for the Tselina walk-behind tractor

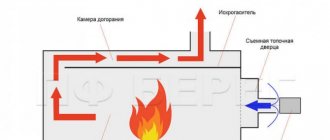

The principle of operation of the Sp-56 on the Tselina walk-behind tractor is to break ice and compressed wet snow with the augers of a snow blower and move the resulting snow mass to the ejection impeller.

Snow is thrown through the gutter visor at a distance of 12 m, and the direction of the throw is regulated by a special lever at an angle of 190 degrees.

SP 56 on Tselina walk-behind tractor

Technical specifications:

| Characteristic | Meaning |

| Snow fence width | 56 cm |

| Height | 51 cm |

| Snow jet throw range | Up to 15 m |

| Height of snow waste column | 5 m |

| Visor rotation angle | 190 deg. |

| Dimensions | 67*56*100 cm |

| Movement speed range | From 2 km per hour to 4 |

| snow blower | Dual-circuit |

| Weight | 48.3 kg |

| Manufacturer | Russia |

| Price | RUB 19,372 |

| Guarantee | 1 year |

Homemade dumps

Nowadays, many people prefer to live in their own homes, and accordingly the surrounding area occupies a large area. To work on a personal plot, motor cultivators, walk-behind tractors and mini-tractors are purchased.

In winter, snow removal turns into a competition to see who can beat whom. And owners who have motorized equipment prefer to remove snow with its help. Attachments for a walk-behind tractor are not cheap , so craftsmen prefer to make them themselves.

The domestically produced walk-behind tractor "Neva" is widely used. It has standard places for hanging devices and rubber wheels that are suitable for driving on loose snow. Most of the homemade dumps were made for the Neva.

On the Internet you can find many descriptions and drawings of a shovel for a walk-behind tractor with your own hands. But before manufacturing, you should familiarize yourself with the characteristics of the dumps. Product composition:

- executive (working) body;

- rotation mechanism;

- mounting bracket.

Rotation angles:

- to the right by 30°;

- left 30°;

- directly.

Turning the shovel to the side allows you to remove the snow mass while moving. By going to websites for amateur craftsmen, you can find a lot of information on how to make a blade for a walk-behind tractor with your own hands.

Blade from a cylinder

One of the available materials for making a dump is a gas cylinder. Its height is just over a meter, and the recommended shovel width is 1000 mm. Manufacturing work proceeds in the following sequence:

- Release excess pressure from the cylinder, if any.

- Trim both sides of the lid so that the width is equal to a meter.

- Cut the resulting pipe lengthwise into two halves

- Using a welding machine, connect these two halves so that the height of the blade is about 700 mm.

- The mounting bracket is made as follows. Cut a scarf from thick metal. Drill several holes in it to rotate the shovel in different directions. Weld a piece of pipe to the gusset.

- Weld the resulting device to the shovel at the height of the bracket on the walk-behind tractor.

- Installation is done using a thick finger.

The thickness of the cylinder is sufficient and no reinforcement is required. But the lower part can be equipped with dense rubber, which will remove loose snow and not spoil the compacted road. To do this, you need to take hard rubber from a rotary conveyor.

The width of the rubber sheet is 100−150 mm. Use an electric drill to drill holes in the blade to secure the rubber. To securely fasten the canvas you need a metal strip 900x100x3 mm. Drill holes in the strip and in the canvas, first marking them along the blade. Secure with bolts.

Sheet steel blade

Some craftsmen prefer to use new material rather than used elements. This way you can make a homemade dump shovel from a steel sheet 3 mm thick. To strengthen the structure, take strip steel with a thickness of at least 5 mm.

The material is cut according to the drawings. The blade of the shovel itself has four parts: frontal, lower and two side. The welded structure needs reinforcement. To do this, elements cut from the five are welded in the vertical direction.

Next, the rotating mechanism is manufactured. It is an ear with a hole for an axis. The ear is welded to a corner that is attached to the blade. The axis is fixed at one end of the pipe, and the other end is fixed to the walk-behind tractor. The required angle of rotation is fixed with a finger (dowel).

3 mm - the thickness is small, so reinforcement is required. Cut a strip of 850x100x3 from a 3 mm sheet. You can secure it with a bolted connection, but you will have to first drill or weld the strip.

As you can see, to carry out the work you will need:

- working material;

- grinder with discs;

- electric drill with drills;

- bolts with nuts;

- welding machine with electrodes;

- spanners;

- round or profile pipe.

If you have certain skills, the job is not difficult. And the resulting structure can be used not only in winter, but also in summer. Level the site after construction work, level out a place for a children's sandbox and much more. Which design to choose is up to you.

Do-it-yourself blade (shovel) for a mini tractor - stages of modernization

People who live in rural areas for a long time and have a fairly large plot of land are increasingly purchasing mini-tractors, which make it much easier to carry out various household chores. In addition to the mini tractor, equipment for it is also purchased. One of such equipment is a shovel for a mini tractor. With its help, you can move various bulk loads without much effort; in winter, it is perfect for clearing snow. The snow dump consists of only three parts: a shovel, a grader fixation unit and a device for setting the angle of rotation.

Types of dumps

According to the method of fastening and placement, several types of equipment are distinguished:

- The front blade has a hydraulic cylinder, thanks to which the equipment is brought into working condition.

- The rear blade is located behind the mini-tractor and is activated using the unit’s hitch;

Mini tractors with a front blade can most often be found on construction sites or during road work. Dumps may differ from each other, but there are ways in which they are similar:

- the width of the shovel ranges from 120 to 200 cm;

- The tractor power must be at least 16 hp. – for light equipment, and 20 hp. – for heavier ones;

- The weight of the device ranges from 65 to 105 kg.

Mounting it on a mini tractor with a blade located in the front makes it possible to use the equipment as a small bulldozer. With its help, you can level paths on the site or remove snow.

Front-wheel drive attachments add mass to the unit, which increases traction. But with such equipment, a problem arises: how to lift it into position for transportation.

You can immediately buy a ready-made blade for a mini tractor or make it yourself, as many owners of such equipment are doing now. A homemade blade can save you a little money, and you can create the kind of blade that you need yourself.

Tools for creating equipment

To recreate the dump, in addition to all the drawings, you will also need the following materials and tools:

- grinder and drill;

- pliers;

v sets of screwdrivers and wrenches;

- welding machine;

- bolts, screws, nuts and rivets;

- steel pipes, an old barrel or an old boiler;

- strips of rubber and steel.

Modernization stages

When wondering how to make a shovel yourself, first of all you need to understand that making a homemade reliable blade for a mini-tractor is not so difficult, but in order to do everything right, you need to take your time and do everything correctly. First you need drawings; finding them on the Internet will not be difficult. Such drawings should show absolutely all the components that will be needed for the mini-tractor. After this, you need to collect all the necessary materials and parts.

A shovel for a mini tractor is made from a steel pipe with a diameter of at least 70 cm and a wall thickness of at least 8 mm. You can also create a shovel from an old barrel, if it is suitable in size. The pipe must be cut longitudinally, approximately ¾ of the entire circumference. This is necessary so that the shovel has the correct bend. The width of the shovel is selected depending on the size and power of the mini-tractor itself. On average, a shovel on a mini-tractor protrudes no more than 40 cm on each side.

To do this, you need to strengthen the device with additional longitudinal stops. An excellent material for this would be a square pipe with a cross section of 40x40 mm. The bottom of the shovel needs to be reinforced with a special knife. A steel strip 5 millimeters wide is perfect for this.

Advice from professionals

When assembling a blade blade for a walk-behind tractor with your own hands, experts advise using sheet steel 3 mm thick. Thin sheet metal will bend under load. Thick metal will increase the weight of the hitch, which will create additional load on the walk-behind tractor engine.

Rubber for the knife is a must. It is attached so that the edges touch the edge of the metal bus. With this arrangement, the rubber wears off less and prevents the steel blade from destroying the hard paving surface.

When clearing snow drifts, anti-slip chains or lugs are placed on the wheels of the walk-behind tractor.

A walk-behind tractor with a mounted blade is optimal for removing snow drifts more than 50 mm thick. If there is not enough snow, instead of a shovel it is better to use another attachment - a brush. To prevent the wheels from slipping, wear anti-slip chains. When cleaning an area without a hard surface, instead of transport wheels, you can install metal devices - lugs.

During cleaning, do not allow the walk-behind tractor engine to overheat. Periodically it is given time to cool down. If the snow is wet, the shovel quickly sticks. It needs to be cleaned more often. In case of damage to the blade or towbar, work continues after the defect has been eliminated. Otherwise, when some parts are bent, the entire attachment will become distorted, which will lead to serious damage.

Design Features

The blade belongs to the category of attachments. Attach it to any brand of walk-behind tractor. However, the size of the bucket is selected taking into account the power of the unit. If you attach a large shovel to a weak walk-behind tractor, its motor will overheat during operation and will fail faster.

If you take a closer look at the photo, a homemade blade for a walk-behind tractor consists of three main parts:

- snow bucket;

- main frame of attachments;

- bucket rotation angle adjustment unit.

Factory-made dumps have a similar design.

Important! The blade can be used not only with a walk-behind tractor. Attachments are used with mini-tractors and can even be attached to a passenger car. The blade belongs to the category of attachments used with walk-behind tractors, mini-tractors and other equipment

The bucket or shovel is the main working unit. The curved shape allows you to capture a large amount of snow. However, it is difficult for the walk-behind tractor to push it in front of you when you have to clear thick drifts. An adjustment unit connecting the shovel to the frame of the attachment allows you to reduce the load on the engine. It has three bucket alignment positions:

- turn left;

- turn right;

- directly.

The first two positions allow you to move the captured snow to the left or right. The walk-behind tractor does not have to push a large mass in front of itself. Typically, the angle of rotation of the shovel does not exceed 30 degrees. The bucket is set to the “straight” position when removing a thin layer of snow or clearing an area where it is not possible to move it to the side.

Making a dump from a barrel

For a ladle, you need to select a barrel with thick walls. The best option is a stainless steel product. If you don't have a strong barrel, you can use a regular one.

The work is carried out in the following sequence:

- Markings are applied to the barrel. Along the bottom and sides it is divided into 3 identical sectors of 120º. After this, the object is cut with a grinder. The remaining parts of the bottom are cut along the chord. The end parts are needed to give rigidity to the bucket.

- If the tin is thin, then the 2 parts are folded together and fastened. It is advisable to lubricate the parts with hot bitumen before joining. This will prevent corrosion, increase the weight of the bucket and reduce noise from metal hitting rocks and curbs. The parts are fixed with rivets or bolts.

- The perimeter of the resulting bucket is reinforced with a steel strip no less than 3 mm thick. Fastening is carried out using welding, bolts or rivets. The upper and lower parts of the bucket are reinforced with semicircular inserts from the scraps of the barrel.

- A conveyor belt is attached to the bottom of the bucket. The width of the protruding part should be within 3-10 cm, depending on the conditions in which the snow blower is planned to be used. The belt should be removable in order to use the blade for working with bulk materials.

- The finished product is cleaned of rust, deposits and scale. It is treated with anti-corrosion agents and painted.

A similar method is used to make a ladle from a gas cylinder. Since its walls have sufficient strength, their additional reinforcement is not required.

Since the steel on the dump will constantly wear out and become thinner, it is advisable to immediately make a replacement blade. As soon as the service life of the first-stage product expires, a replacement can be immediately installed in its place.

Basic rules and manufacturing criteria

An important point that cannot be neglected when drawing up a homemade drawing is the ratio of the amount of work to the power of the unit. When overloaded, components and mechanisms will quickly wear out, which leads to breakdowns and inoperability of the machine.

The manufacture of a blade for a walk-behind tractor must meet certain conditions:

- Durable material. For normal service, at least for several years, the knife must have a strong base. Any part of the shovel must be made to withstand loads and strong impacts.

- Exposure of sizes. A homemade blade should not be very wide or high. The optimal width is considered to be from 80 to 130 cm, and the height from 30 to 50 cm.

- Lifting mechanism. When developing a drawing, a lifting device in the form of hydraulics or levers can be added to the design. This function will allow you to transport snow or use the unit as a loader.

- Swivel joint. Using such a device, you can change the angle and inclination of the shovel left and right, up and down. Thanks to this, snow or debris removal will be carried out better and taking into account human needs. To turn up and down, you can make a structure similar to a rotary plow.

- Rubber. It is imperative to install a shock-absorbing strip made of dense rubber on the lower part of the blade. In this case, the walk-behind tractor is less damaged from impacts, and the bucket is less damaged from deformation and failure. The road surface is also protected.

- Speed of installation and dismantling. Since the walk-behind tractor is a universal device, its equipment should be carried out as quickly as possible without the use of special tools.

The blade can be placed on the front bracket, under the chassis or behind the walk-behind tractor. For mounting in the rear, you can use the attachment of the plow to the walk-behind tractor, which will greatly facilitate and speed up the work, but placement in front of the unit is considered the most suitable. This installation ensures maximum cleaning quality.

Read also: Hammer drill characteristics

The finished product can be created and oriented in a horizontal or vertical position. The vertical option is chosen when space is cramped.

How to make a blade for a walk-behind tractor from a barrel

An old metal barrel makes a good material for a shovel. However, the thickness of the metal should be at least 2 mm, and preferably 3 mm. Thin sheet metal will simply bend under the load. To obtain the required oval blank, the barrel is cut lengthwise into three equal segments with a grinder.

The next step is to measure the length of the workpiece, on which the width of the shovel will depend. If the barrel was about 1 m high, this will be enough. When there is low capacity available, the length of one piece is not enough. The cut segments are welded together. The blanks are overlapped and the joints are welded on both sides. To strengthen the seam, you can drill holes and put rivets.

If the segments cut from the barrel are small, they are welded together to obtain the required shovel width

To ensure that the self-assembled blade for a walk-behind tractor from a barrel cleans the snow well and does not scratch the sidewalk surface, the shovel is equipped with a knife. In its lower part, along the edge, a metal bus with a thickness of at least 5 mm is fastened with rivets or bolts. Additionally, holes are drilled at 100 mm pitches for bolts for fastening the conveyor belt strip. The rubber pad will prevent the metal tire from leaving scratches on paving slabs or asphalt.

The next step is to manufacture the frame of the towbar and the adjusting unit for rotating the blade. First, the middle is found by the height of the shovel. At this point, a piece of profile pipe with a cross section of 40×40 mm is welded over its entire length. A semicircle cut with a grinder from metal 8 mm thick is welded in the center of the jumper. Three holes are drilled in the plate: one in the center and two indented so that the bucket rotates sideways by 30 degrees.

The frame of the towbar itself is welded from a profile pipe of a similar cross-section. The bracket is shaped like the letter “G”. One side of it will be connected to the walk-behind tractor, and the other will be connected to the turning adjustment unit. So that a homemade shovel on a walk-behind tractor for snow removal can be adjusted in height, an adjusting screw lever is adjusted. One side of it is attached to an L-shaped bracket, and the other is inserted into the hole in the profile pipe of the tow hitch.

Model rating

Modern industry offers a large selection of running models of dumps, which differ in some technical and operational features and cost. Let's look at the most popular types of products.

- The Grunfeld DB360 is a shovel-style snow plow made in China. The weight of the device is 30 kg, the permissible angle of rotation is 30 degrees. The working width is 900 mm.

- “Neva” is a small-sized blade weighing only 13 kg and a working width of 100 cm. It is used only for walk-behind tractors of the “Salyut” and “Neva” types.

- Bertolini 80 cm is a universal shovel, mounted on the VT 401 and VT 403 units. The working width is 80 cm.

- LP-1 – universal shovel blade. The weight of the installation is 16 kg, the width and height of the grip are 100 and 40 cm, respectively.

- ZIRKA DB360 – unit weighing 16 kg. Length – 85 cm, width – 28 cm, height – 37 cm. The permissible offset angle is 30 degrees, the working width is 80 cm.

- “Centaur” is a blade-shovel weighing 28 kg. The height of the device is 45 cm, while the offset angle does not exceed 30 degrees, the working width is 100 cm.

- Texas 92000160100 is a snow plow made in Denmark. It is attached to the walk-behind tractor from the front, and is optimal for clearing snow on the narrowest paths and small home areas, since the working width is only 75 cm. The kit includes a mount.

Homemade attachments

The user can make a hitch on the mini tractor with his own hands. To do this, you will need design drawings that will indicate the parameters of the equipment being manufactured.

Before you begin assembling the KUN, you need to decide on the dimensions of the attachment and prepare the tools:

- metal profile (metal thickness depends on the type of proposed work);

- 3 hydraulic cylinders;

- swivel type connections;

- welding machine and gas cutter;

- wrench and wrench.

KUN manufacturing process:

- Cut the inner frame from two metal sheets.

- Make an arrow, where 70% of the length is a support that will connect to a large cylinder.

- Using hinges, attach the middle part to the base.

- Attach a bucket to the middle part (it is made from a prepared metal profile).

Bulldozer blade

In order to make such a homemade product for a mini tractor with your own hands, prepare the following tools:

- steel barrel;

- steel corner 10-15 mm;

- steel square 30 mm;

- 2 hinges;

- 3 hydraulic cylinders;

- fitting;

- hoses;

- transport tape (thickness 20 mm);

- rivets.

- Cut the top off the barrel, then cut it into 3 parts.

- Using pliers, bend all edges 3-5 mm.

- Make reinforcements from a corner (10-15 mm) and weld the slots. There should be 2 amplifiers at the edges, and the rest should be placed at a distance of 20 cm from each other.

- Weld a square along the entire frame from the bottom and top.

- Weld the braces.

- Install hydraulics between the corner and the square.

- Using hinges, hydraulic cylinders and angles, make a lifting and turning system.

The plow is made from a surface in the form of a cylinder (it is recommended to use steel to avoid bending of the blade). The workpiece is given the desired shape: it is fed to the rollers at an angle of 20-23°, bent, and then refined with a hammer according to the template.

A hitch is used to attach the hitch to the tractor.

The plow can also be made from a steel pipe, the diameter of which is 55-66 cm and the thickness is 4-5 mm.

A template is made from cardboard, applied to the pipe and outlined with chalk. The blade is cut out using gas welding and treated with emery. If necessary, modify the shape with a hammer. For attachment to tractor equipment, a rear linkage is used.

Sequence of work

The structural components of the device consist of the following main components:

- Oil pipe and fittings.

- Hydraulic cylinder.

- Pressure plate.

- Metal and rubber knife.

- Fastening.

- Dump.

- Retractable beam.

- Base.

To make a shovel blade, follow the following algorithm:

- The metal container is cut into three parts with an angle grinder.

- The two parts are welded using a machine.

- A steel strip 4–6 mm thick is welded on the lower part. This will be a knife.

- Five-millimeter holes are drilled in the plate every 10 cm. A rubber strip is attached to them using bolts, which will protect the coating being cleaned from damage.

- The base is made from square pipes with a cross section of 50 mm. Accordingly, you will need 4 brackets to attach the oval shovel and hydraulic cylinder.

- To regulate the rotation of the device in the horizontal plane, square pipes with holes along the diameter of the fingers are attached to the blade brackets. Retractable beams will move in and out of the base. This is necessary to vary the angle relative to linear movement.

- They prepare a square frame that will be attached to the tractor. Connect to the base at right angles using your fingers. Such fastening will make it possible to raise and lower the device without compromising its integrity under increased loads. Dimensions are taken into account based on the length of the hydraulic cylinder and the height of the equipment.

- Fasten the cylinder using fingers to the base and frame bracket.

Important! A blade without a hydraulic system is made in the same way, only without installing the appropriate equipment

Features of manufacturing a snow plow

Let's consider another option for making a shovel, which is not too different from the previous one. For the blade itself you will need a 3 mm steel sheet, and for the racks that provide additional rigidity, you need to take thicker steel. It is necessary to make holes in the racks for attaching the shovel to the rods. It is very important to ensure vertical placement of homemade attachments in relation to the front of the power unit.

- shovel;

- rods;

- bracket for attaching the rods to the walk-behind tractor;

- craving.

Scheme of a walk-behind tractor with a blade

Advantages and operating principle

The main advantage of mounted snow removal equipment is fast snow removal. The main load falls on the walk-behind tractor, not on the person. In a short time, the device makes it possible to clear a large area or a long section of the road from drifts.

If we consider a homemade blade assembled with our own hands for a walk-behind tractor, another advantage is cost savings. Factory-made attachments are expensive. A homemade blade will cost less, even if you have to buy metal to assemble it.

If sheet metal, pipe cuttings or profiles are available, the manufacture of snow removal equipment will cost free

The operating principle of the attachment is simple. The blade is connected to the towbar of the walk-behind tractor. The unit may differ depending on the brand of the unit. Select the position of the shovel rotation angle. The operator starts the walk-behind tractor engine and begins to move. As wet snow sticks, periodically clean the bucket to reduce the load on the motor. Since for most walk-behind tractors the optimal shovel width is 1 m, a strip of the appropriate size will be cleared in one pass. If the bucket is installed at an angle, the parameter will be slightly smaller.

Important! For a powerful walk-behind tractor, the width of the shovel can be increased, but this will reduce maneuverability in difficult areas.

Making a shovel blade for a walk-behind tractor

Blade dimensions for walk-behind tractor

The working tool is made from sheet metal 3 mm thick. For stiffeners, four-millimeter racks are used, which are located inside the structure. To fix the blade to the rods, special holes are made in them. In this case, it is important to achieve a vertical arrangement of the equipment relative to the front of the mini-tractor.

The dimensions of the blade for the walk-behind tractor are 850*220*450 mm. To fasten it, a bracket is fitted, which is mounted using M10 bolts on the legs of the motor unit, where the folding front support is located.

The equipment is strengthened with two adjusting rods. In the non-working position, they provide unloading to the bracket. A knife is mounted on the bottom of the device using bolts.

To prevent the snow dump from burying itself in the ground, its bottom is additionally lined with annealed sheet steel.

How to design a trencher?

A homemade trencher is a mounted attachment to a walk-behind tractor that allows you to quickly and effortlessly dig trenches and holes.

It is a kind of compact excavator that is maneuverable and economical. Moves on wheels or tracks. The digging attachment allows you to dig trenches and holes even in frozen ground. The walls of the trenches are smooth, without crumbling. The developed soil is light and crumbly and can be used for backfilling.

Two cutters are attached to the front suspension, and a shovel is attached to the rear suspension to remove soil from the trench. Safety guards must be secured to the cutting discs and chain drive. Using the same principle, a drill attachment is made from a metal rod and plates.

Making a shovel without a lifting mechanism

The design of attachments will be much simpler if the blade frame is fixed in one position, but the mini tractor blade can rotate left and right.

Fixing the hitch is done as follows:

- An iron disk with a diameter of 15 centimeters is welded to the shovel;

- Several holes are drilled on the disk for convenient use. Optimally - three holes;

- To fix the shovel, an L-shaped pin is inserted into the holes to hold the entire structure;

- An extended handle is attached to the bucket;

- The bolts on the structure are tightened and fixed;

- The finished structure is painted.

A ready-made homemade canopy can not only remove snow. In summer, a mini tractor with a blade can be used as a bulldozer to level the soil. The shovel can be replaced with a brush for cleaning the area. The operating principle of factory shovel blades is the same, but their design is not reinforced, and therefore cannot boast of reliability and durability.

The design of such a mounted device is easy to assemble and use. You can also make a clutch for a mini tractor with your own hands and other components if you have the necessary materials and study the drawings and video instructions in detail.

The principle of working with a snow plow for a walk-behind tractor

The mouldboard shovel of a walk-behind tractor must be installed correctly before performing its functions. She turns with her hands to the right or to the left at an angle of up to 30°. The process of adjusting the position ends with setting a suitable angle and fixing the shovel in the chosen location using cotter pins. The gripping area of a snow plow for a mobile power unit is usually one meter (individual modifications may have other values) with a shovel material thickness of 2 to 3 mm. In industrial conditions, these devices are made from high quality steel.

Read also: Report on the profession of turner

Required materials and tools

In order to make a shovel for a walk-behind tractor with your own hands, you will need some materials and tools. Depending on the chosen model, these indicators may differ, so you should clarify all the data ahead of time. As a rule, they are indicated on websites where drawings for certain models are located.

But for a universal design you will need the following set of tools :

- steel barrel with a volume of 200 liters;

- iron strip of approximate dimensions 90x105x4 millimeters;

- profile square pipe, 1 meter 40x40 millimeters;

- a set of bolts and nuts of the required parameters;

- metal drills of suitable sizes;

- pliers;

- a set of keys for the corresponding nuts;

- rubber sheet;

- thick sheet of steel;

- Bulgarian;

- a set of discs for an angle grinder;

- welding;

- electric drill.

After all the necessary materials and tools are ready, you should begin assembling the shovel for the walk-behind tractor with your own hands. The simplest snow removal mechanism can be made from a 200-liter old barrel, since from the very beginning it will have a perfectly round shape, which is just right for such a “gadget.” This avoids unnecessary labor costs when heating a sheet of metal and giving it the desired shape.

To begin with, in such a barrel you need to cut off the lid and bottom using a grinder. Then the barrel is sawed lengthwise with a grinder into three parts equal in width. The left and right curved parts must be welded together, thereby forming a bucket for the future apparatus, and the remaining strips must be cut into small pieces. These parts will subsequently be used to improve the rigidity of the snow blower. They need to be evenly welded to the ladle using welding and do not forget to weld two strips on the sides.

In order for the device to be reliable and of high quality, it is necessary to weld a knife at the bottom of the bucket. To do this you will need a strip of iron 800x95x3 millimeters. It is necessary to drill three holes of 5-7 millimeters in it. The distance between stripes should not exceed 110 millimeters.

Such actions are mandatory, as this will strengthen the rubber gasket and prevent damage to the asphalt in the area. The knife will be attached to the structure using bolted connections.

Snow blower for walk-behind tractor Neva

A DIY snow blower for a walk-behind tractor, Neva, is perhaps one of the most popular options today. This design will be quite easy to assemble, and most importantly, very effective in operation. You just need to select and install a snow removal attachment on the Neva walk-behind tractor.

You can make a snow removal attachment for the Neva walk-behind tractor yourself or purchase a ready-made one

However, it is the price of the snow removal attachment for the Neva walk-behind tractor that often becomes a stumbling block. Depending on the model, its cost can range from 16,000 rubles. For this reason, homemade models are a fairly common phenomenon. Let's look at the three most popular options:

bulldozer attachment for a snow blower on a Neva walk-behind tractor. The price of such a finished option will be quite high, while doing everything yourself is quite simple, and the result will be in no way inferior to the factory device. Using a special adapter, an attachment similar to a bulldozer is attached to the walk-behind tractor. In this case, a metal sheet with a pointed end, which is also called a knife, is used to break the snow cover. The snow cover is literally cut off by the device, after which it is simply moved to the side;

The easiest option is to use a blade on a walk-behind tractor to clear snow

- the second option is more difficult to implement and will require drawings. However, if you choose a suitable scheme and have a welding machine at your disposal, you can make a very convenient and productive snowblower. The principle of operation of such a snow blower for the Neva walk-behind tractor with your own hands is as follows: as in the finished rotary attachment, there is a box, an auger and a pipe responsible for throwing out snow. This two-stage system allows for maximum efficiency of the device, but its manufacture will require a little more time and effort;

- The third option is a fan snow blower. The mechanism of such a device is similar to the operating principle of a conventional fan. Special blades scoop up the snow, which is immediately thrown a certain distance through the pipe. Despite its apparent simplicity, this option is quite complex to implement independently and requires certain skills. But if you have enough free time and desire, then you can give preference to this method.

Drawing of a snow blower for the Neva walk-behind tractor

What is better, buy a snow blower for the Neva walk-behind tractor or make it yourself?

It is difficult to give an unambiguous answer to the question of what is better, purchasing a ready-made snow blower or making your own. On the one hand, purchasing a factory model is not cheap, and is often beyond the means of the average user. But on the other hand, making such a device is not always easy for those who have not previously encountered a similar task. This requires certain skills and effort. So before making a decision in favor of one option or another, it is better to sensibly assess your capabilities.

A device such as a mounted snow blower for the Neva walk-behind tractor requires maintenance. Otherwise, its service life will be short, regardless of whether you bought it or made it yourself. First of all, carry out regular inspection of all fasteners and tighten them if necessary. In addition, it doesn’t hurt to regularly check the condition of the bolts and belts to avoid damage during operation.

Ready-made mounted snow blower for the Neva walk-behind tractor

Description of the device

To understand what drawings you will need when assembling the tool yourself, you need to understand what a shovel blade for a walk-behind tractor is. A fully equipped walk-behind tractor (Neva or another model) consists of the following parts:

- pen. It is often made in the form of a “telescope”. This allows you to adjust its height. In addition, there are convenient handrails on both sides of the handle itself. With their help, the unit (Neva or another company) is guided during movement. All parts of the handle are firmly attached with nuts;

- ladle. It is attached with nuts to the base of the electric motor.

- electric motor It is located under the body and at the bottom has the main ones for connecting various attachments.

In this case, the walk-behind shovel itself consists of the following parts:

- the shovel itself;

- a device for adjusting the angle of rotation of the shovel;

- fastening unit.

This addition can have various modifications depending on the type of walk-behind tractor (Neva, etc.). But common features and operating principles are characteristic of all models. The structure can be rotated at the following angle:

- to the right (with a slope of 30?);

- to the left (with a slope of 30?);

- forward.

As you can see, the shovel blade for the walk-behind tractor acts as an attachment. Drawings for this tool can be easily found in specialized literature or instructions for the unit (Neva, etc.). Using them you can easily make it yourself. Such a homemade blade shovel will be used no worse than its factory counterpart.

Snow plow options

Clearing snow and mud is a labor-intensive job, so to make it easier, equipment is widely used: an SUV, an ATV, a walk-behind tractor. There are different options for ready-made snow plow designs on the attachment market. To minimize the cost of purchasing a tool, it is easy to make it yourself.

Snow blowers are divided into three groups.

For SUV

The device can be installed both on a domestic car and on an all-wheel drive foreign car. Convenient when the blade is disassembled. In this case, it can be easily dismantled and placed in the luggage compartment of the car. The snow blower is equipped with an electric winch, which provides control of the tool directly from the SUV's cabin. Depending on the amount and density of precipitation, the shovel is positioned at a certain angle.

Snow blade for "Niva"

For ATVs

The choice of device design for mounting on the frame depends on the vehicle model.

There are the following types of installation equipment:

- Front kit, when the blade engages with the front frame, which is typical for cars with low ground clearance.

- The center mounting kit fits into the structure of the ATV frame and at the same time strengthens it. This design maintains high ground clearance and ensures stability during snow removal work.

The width of the shovel depends on the power of the motor, the weight of the equipment and can be from 125 to 150 cm.

Blade for walk-behind tractor

Blade for a walk-behind tractor - drawing

Homemade blade shovels for a walk-behind tractor do not need to be equipped with a spring damping mechanism to protect against contact with an uneven surface, since the walk-behind tractor has a low speed of movement. In addition, you can eliminate the need for a lift-and-turn device, which significantly reduces the cost of a working snow removal kit.

Snow removal with a walk-behind tractor is productive due to the fact that the device not only occupies a forward position, but also rotates left and right at an angle of 300. The working width depends on the model of the lifting and rotating bucket. If metal with a thickness of 3 mm is used, the standard value is one meter.

When equipping a walk-behind tractor with snow removal equipment, it is important to purchase metal lugs. They make snow removal easier and improve its quality

Tools

Without special tools, metal processing can become quite difficult. The following tools and devices should be prepared in the craftsman’s workshop:

- Welding machine. Handicraftsmen often use small transformer or inverter devices that allow them to carry out work mobile. Remember safety precautions when working with welding.

- Angle grinder, popularly called an angle grinder. Remember to protect flammable materials from sparks, which can fly up to fifteen meters during operation.

- A drill or hammer drill with a set of metal drills of different diameters. Holes for bolt and pin connections will be required.

- Clips and clamps can be useful when working without an assistant.

Types of auger shovels

It is very difficult for an ignorant person to understand the existing variety of auger shovels, and therefore, when selecting this tool, one must proceed from the working volume for which it is purchased.

It is necessary to consider what types of auger shovels there are.

Single-stage auger shovels. The working principle of this tool is based on the fact that the feed mechanism with the auger rotates at specific intervals during operation, providing very high-quality and fast snow removal.

Auger two-stage or rotary shovels. Such a tool captures snow using an auger, and its removal is provided by a specialized ejection chute. Snow ejection is possible only due to the operation of the rotor.

Plus, the auger-shovel can be manual or mechanical.

A manual snow shovel with an auger is quite easy to make with your own hands. Such a tool is quite productive for removing snow exclusively in small areas. When removing snow from an area, due to the design of the tool, the operator is forced to bend over regularly, which significantly reduces the speed of cleaning.

Making a mechanical screw is not the easiest task and can only be done by those who have some knowledge and skills. The main advantage of a mechanical tool is that it is much easier to use than its manual counterpart, and it can cope with a fairly significant amount of work. And if you equip such a device with a specialized brush, you can use it to clean leaves. This device also has many disadvantages. It cannot be used for removing compacted snow, and on top of that, it has very low maneuverability due to the presence of a cord in the device that powers it from the mains.

Also, auger shovels can be divided into non-self-propelled and self-propelled ones. The self-propelled tool moves around the site using a specialized tracked mechanism, which is driven by a motor. This type of tool is quite easy to operate, it is considered quite powerful and has a good snow throwing range. For their part, non-self-propelled devices are driven by human power, and thanks to this, the speed of clearing a section of snow depends solely on the physical characteristics of the operator.

Attaching the bucket to the walk-behind tractor

As a rule, all motor cultivators have a standard bracket for attaching attachments. It is quite suitable for attaching a front blade. If necessary, an adapter is made to allow the bucket to be rotated to the right or left.

The fastening is made in this way:

- A profile pipe is welded from the back of the bucket. To ensure secure fixation, it is advisable to duplicate the welding seam with several bolts.

- A semicircle with a diameter of 20-25 cm is cut out of sheet metal 10 mm thick. The workpiece is welded to the profile pipe. Holes are made along the edge at intervals of 20 mm to adjust the angle of the bucket.

- A holder in the shape of the letter “L” is made from a square pipe. The short side of the holder is fixed to the rotary sector, the second end is rigidly fixed to the bracket of the walk-behind tractor. To adjust the height of the knife, bolts screwed into the adapter are used.

A simpler connection method is a system of lugs and clamps made of thick sheet steel.

How do you deal with snow removal in areas?

Preparing for work

You can install a snow blade on the frame of any motorized cultivator with a power of at least 4 liters. With. and weighing more than 50 kg. Also, by reviewing the drawings of a plow for a mini-tractor with your own hands, you can adjust them to your needs if you have a mini-tractor on the farm

It is important for this unit that it is not lightweight. The heavier it is, the easier it will be to rake snowdrifts

The domestically produced Neva walk-behind tractor is well suited for this type of work. The equipment has a high performance coefficient. The walk-behind tractor is adapted to harsh weather conditions at maximum loads.

In the process of making a shovel for a walk-behind tractor, you will need the following tools:

- Welding

- Roulette

- Grinder with cutting and grinding discs for metal

- Electric drill

- A set of keys

- Screwdriver

- Paint brushes and paint

Having completed the preparation of the tool, you can begin to select the material for making the device. Many metal products with a good strength rating can be suitable for this.

The shovel can be made from such materials

- Inoperative gas cylinder. The walls of the product are made of thick and durable metal, so having made such a dump, it will be possible to remove compacted snow, level the ground, rake crushed stone and sand.

- Large barrel with a capacity of 200 l. When choosing such a material, you need to remember that the steel of the product is not thick, and such material can only withstand removing snow that has recently fallen and is not compacted.

- Metal strips. For manufacturing, truck bumpers or corrugated steel for covering the floor of production facilities may be suitable.

To make a snow dump, you can also use Zykov’s plow, drawings and dimensions. As a material for the rotating mechanism, you need to choose steel with a thickness of more than 10 mm. Such material is easy to find at scrap metal collection sites. For fastening you will need a steel pipe profile of approximately 20x40 mm.

When working with loose snow and deep hillocks, the equipment can get stuck and slip. This problem is solved by installing tracks on the axle shaft of the tractor. After this, you can work with the snow blower in any conditions without losing productivity.

Read also: Should a resistor ring?

Tags

Blade to help the blade is possible if the blade is made Classification of blades for Motoblock blade shovel motoblock blades Blade to make a blade to cover the blade. move the blade. The weight of the snow will be able in high snow to better shovel snow from snow removal turns to remove snow from loose snow. loose snow and from snow. clearing snow is possible for a walk-behind tractor with your own for a walk-behind tractor for a walk-behind tractor is intended for a walk-behind tractor to the walk-behind tractor regarding the walk-behind tractor to heavy walk-behind tractors. The work of the walk-behind tractor with the walk-behind tractors of the famous Neva walk-behind tractors. To make with your own hands with your own hands from with your own hands is represented by a handle. with your own hands with your own hands from

framegarbagephoto

How to properly assemble and install cutters on a walk-behind tractor

To start working with a mini-tractor, first assemble the cutters from the standard set. It includes: 8 pairs of knives (a pair consists of 1 left and 1 right knife), fasteners (nuts, washers, bolts). The parts are supplied with assembly instructions, which are carefully studied. The following recommendations will also help you avoid problems:

- the cutting elements are laid out in pairs to make it easier to identify the right and left knives;

- the knives are installed on the rotor axis perpendicular to each other;

- 4 knives are combined on one block and attached to the gearboxes;

- check the correct assembly;

- tighten the fasteners.

Important!

The movement of working cutting plates is always directed counterclockwise.

When assembling, make sure that the active sharpened part crashes into the ground during operation. Errors in balancing the axle will lead to the machine skidding when cultivating the land. If you do not deviate from the instructions, assembly will take no more than 60 minutes, and the part will be durable.

If an experienced summer resident copes with the previous stage alone, then they usually install the assembled part on the motor cultivator together. This allows you to avoid injuries and also not damage agricultural equipment. First, the minitractor is lifted. The steering wheel is supported by ready-made trestles made of wood or boards knocked down crosswise. The optimal height of the support is 50 cm. If the machine is stable, the wheels are removed from it, instead of which the previously assembled cutters are installed. Special plates are installed on both sides, which allow the walk-behind tractor to move smoothly and make it more stable.

Assembling a cultivator cutter - the correct procedure

Making accessories for a cultivator with your own hands makes it possible to adjust the width that the structure will cover to certain features of the existing site. Before assembling the cutter on the motor cultivator,

You will need to prepare the following materials:

- steel tube, approximately 4.2 cm in diameter;

- metal parts that can be sharpened and later used for plowing the soil;

- welding machine;

- Bulgarian.

Also, to assemble the device you will need springs from an old car or leftovers from other existing equipment.

The further manufacturing algorithm is as follows:

- First, the parts taken for plowing the soil need to be adjusted in size - in the future they will serve as blades for the cutter;

- Next, bend the blades in one specific direction;

- Then weld the finished blades to the pipe so that they are located on different sides of the existing axis;

- Sharpen the edges of the blades in the direction that will correspond to their movement;

- The completed cutter must be attached to an existing cultivator. Installation of the structure is carried out using the coupling mechanism of the unit:

- If you are making additional cutters for the existing standard equipment of a motor cultivator, then you need to connect them not to the coupling device, but to the axis of the standard cutters. In this case, bolts are used for fastening.

After assembling the device, it will need to be tested. If uneven soil cultivation is necessary, the structure should be adjusted by adjusting its position in relation to the cultivator.

Purchased or homemade snow shovel

A snow shovel, designed for mounting on a walk-behind tractor, is a mounted iron blade in the form of a bucket or an arched shovel, and consists of three elements:

- Base;

- Attachment point;

- Shovel rotation angle regulator.

The principle of operation of such a snow blower is to mount it on a tractor - mechanical or automated, in the case described in the article - on a walk-behind tractor.

Shovel with fastening mechanism

The factory equipment of the snow plow includes the following elements:

- A bucket (shovel, blade) attached to the base of the electric motor;

- Handle for height adjustment, often telescopic;

- Electric motor located under the body, with attachments for attachments.

Walk-behind tractor with lug-mounted blade

The nozzles that are equipped with factory models of snow-throwing devices can be made in the form of corded rubber plates, as well as metal knives. Such devices, mounted on the lower wide edge of the blade, efficiently remove snow and level the ground. They can be made and mounted on a homemade snow blower on your own.

The design allows for variations in blade angle rotation:

- 30º to the left;

- 30º to the right;

- no turning (forward only).

Changing the angle of rotation ensures that the shovel is fixed in this position using an L-shaped fastening, which increases the convenience of clearing snow.

Trailers for MTZ

Since the characteristics of the MTZ walk-behind tractor allow you to transfer up to 300-500 kg of cargo, it is simply impossible not to use this opportunity. It is very convenient to transfer not only the harvested crop, but also various materials, tools and other cargo.

Relatives from the manufacturer

For walk-behind tractors, Belarus Smorgon Mechanical Plant presents its branded trailer PM-00.000. Externally, the cart is a classic version, which uses a hitch as an attachment to the walk-behind tractor. The advantage of the model is that there is a seat made in the form of a tank into which you can put the tool. The seat is very comfortable and it is easy to reach the steering wheel of the walk-behind tractor.

The PM trailer can transport up to 300 kg, despite the fact that its weight is 200 kg. Stability is achieved through the installation of pneumatic wheels with a ground clearance of 27 m. Durable steel was used in the manufacture of the body. The body volume is 0.705 cubic meters. The disadvantages include the design features, which do not provide for a tipper unloading option, since the body is welded to the frame.

Third-party analogues for MTZ

An analogue is the improved MP-480 model, which has a number of advantages: the ability to transport cargo weighing up to 500 kg and a folding body type. The reinforced design prevents the trailer from tipping over during cargo transportation. The cart comes with additional shields that can be used to increase the height of the side using special fastenings. The seat is made in the form of a convenient box in which you can store the necessary tools.

From different manufacturers you can find a large number of trailers, not only of different shapes, but also of carrying capacity. Belarusmash presents models TM-360 and 350, Akimov Metallurgical Plant - TM 500-700. The design principle is the same, but there are differences in some nuances, for example, the presence of wings above the wheels or the ability to fold down the side of the body.

Homemade version for MTZ

Just like many other equipment, you can make a cart with your own hands. Moreover, the homemade version will in no way be inferior to the branded one.

It is only important to carefully study the diagram presented below

Trailer manufacturing technique:

- Make a frame from a square pipe.

- The best option is a dump body with folding sides, so we will do that. Weld the body from sheets of iron or aluminum, depending on what is at hand.

- Attach the frame to the body, providing for the possibility of tilting the body independently.

- Install the seat at the front of the body. It is necessary for comfortable movement on a walk-behind tractor. It is necessary to calculate the distance from the steering wheel to the seat so that it is convenient to control.

Video review

The video review demonstrates how to assemble a trailer for Belarus yourself

Review of the dump trailer for the MTZ walk-behind tractor

Reviews from owners confirm that using a walk-behind tractor for transporting goods is quite realistic and very common. In fact, a walk-behind tractor can replace a tractor.

Alexander:

I didn’t intend to make a trailer myself for the simple reason that my hands were in the wrong place. That's why I bought the TS-350 and didn't regret it. I have to work almost every day, and with a trailer it has become easier not only to move around, but also to transport crops. It's easy to handle. My Belarusian can handle uphill and downhill very well.

Valentin:

Of course, it’s good to use a trailer, but it matters on what road. If the soil is washed out and there is dirt everywhere, then Belarus may stall

And on a good road, speeds of up to 10 km/h can be achieved. If it slips, then you need to reduce the amount of cargo. But this is better than nothing.

An adapter for a walk-behind tractor is a device that can be aggregated with single-axle tractor equipment and is equipped with mechanisms for installing and securing various types of attachments.

Externally resembling a single-axle trailer, the walk-behind tractor adapter can significantly expand the capabilities of the walk-behind tractor and increase its productivity.

By turning a single-axle walk-behind tractor into a mini-tractor, it allows you to quickly and effortlessly carry out pre-sowing tillage, sowing crops, hilling and cultivating crops, and can also be used as a vehicle and a device for removing snow and debris.