A winter summer cottage covered with a blanket of snow is a truly indescribable landscape. But even such beauty has to be removed so that you can move around unhindered. A high-quality and durable snow shovel helps you clear your garden plot in winter quickly and without much effort. You can buy it at any hardware store, but in order not to waste money, it is better to make a snow shovel with your own hands.

Types of homemade snow scrapers

All scrapers have the same device. The equipment consists of a handle and a working blade, which is used to directly clean the snow. However, the shape and size of these elements can be different, depending on the purpose of the tool. For example, roof snow scrapers have a long handle. It can be solid or telescopic. The working blade is fixed perpendicular to the handle. The scraper is more like a rake.

To clear snow from paths and areas, scrapers are made wide. The simplest option is a rectangular sheet of tin or plywood with a handle. The stalk can be one or two, as well as straight or curved. A U-shaped handle is made on wide scrapers.

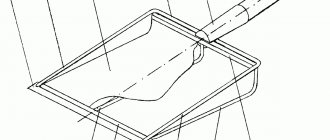

If we talk about assembling a scraper for snow removal with your own hands, then a scraper of this type sometimes has a working blade with side sides. The bucket allows you to capture a large volume of snow mass and transport it to a designated location.

Important! To make work easier when manually cleaning large areas, craftsmen came up with a type of scraper mounted on skis.

There are many configurations of snow removal equipment. However, all homemade snow scrapers have a main difference in the material they are made of. They create a tool from metal, plastic and wood:

- Plastic equipment is most often purchased in stores. However, you can make such a scraper yourself from a used plastic barrel, tray or other household item. The plastic is lightweight and snow does not stick to it. Due to these advantages, the work with the scraper is simplified. The edge of the working blade is usually protected by a frame made of a metal strip, which protects the plastic from abrasion. Store-bought products have stiffening ribs. They give strength to the working surface. Plastic scrapers are lightweight, convenient, and do not stick to snow

- The most popular tool for DIY assembly is a shovel-scraper for snow removal, where the material used is plywood and a wooden handle. It is not difficult to find a blank for such a tool in almost every home. Wood is easy to process, but has one drawback. Plywood strongly absorbs moisture. Over time, it begins to delaminate. A tool swollen with water becomes heavy, and wet snow sticks to the working surface. Wooden equipment is usually made from plywood

- In terms of strength, metal scrapers come first. However, not all equipment is created equal. Metal is a flexible concept. If you use ordinary tin and a pipe for the handle, then such equipment will quickly rust. It's heavy. Snow is frozen to the working surface. Inventory made of galvanized sheet steel is considered optimal in terms of price and quality. The protective coating prevents the rapid development of corrosion. However, the scraper is still a bit heavy. Over time, the galvanized layer wears off and rusty spots appear. Aluminum scrapers are considered the best. The tool is lightweight, rarely freezes with snow, and does not rust. You can also consider stainless steel, but the metal is expensive. Metal scrapers are durable, resistant to moisture and mechanical stress

Despite many disadvantages, wood still remains one of the most popular materials.

What are its advantages and what does it represent?

To call it a shovel, of course, would not be entirely correct; the name soil loosener is more appropriate for it. It is a bunch of one or two original villas, intelligently connected to each other with additional supports for the feet, for more convenient cultivation of the land, and a small handle. It is advisable to make (or buy) a handle in such a way that it is up to your shoulders, otherwise when working in your summer cottage it will be uncomfortable for you, or the meaning of such an invention will be lost.

Its purpose includes such things as:

It’s enough to just dig up various root crops. It’s easy and without any problems to get various kinds of weed (without destroying it into small parts, which is important) And also breaks down and loosens the soil

One of the disadvantages of the miracle shovel is its weight. But don’t worry about the fact that you will constantly drag it around your summer cottage; you will only have to get it onto the soil once and move it along the way with small pulls using the handle. If you compare it with the load that you apply when using a simple shovel, then you will spend 2 times less force on the same area. However, it is impossible to dig a hole with this shovel.

There is another type called “digger”

At first glance, you will immediately notice that you see very large forks with a large handle, to some extent this will be true. They are three times wider than ordinary forks; their powerful handle makes it easy to turn out the earth. The footrest of such a tool is very convenient, since you can stand on it with both feet, which makes it easier to drive it into the ground. If desired, such a digger can be quite easily made with your own hands. But if you decide to purchase a tool, one of the advantages is that the level of the handle can be adjusted according to human height. For this purpose there are special bolts installed on the iron “handle”.

Including there is another version of the miracle shovel called “Lightcopper”

It can be compared with the previous version, since they are almost identical, at first glance, it looks like a large fork, but only with a modified handle. It is made in the form of an arc and does not have the ability to change the height of the handle, which can be attributed to its negative features. Well, as you can see, from the name it is quite easy to use when working on the ground.

The principle of making a miracle shovel at home according to drawings or videos

If you decide to make a miracle shovel with your own hands, then the first thing you need to do is make a frame base. To do this, you need pipes with a diameter of approximately 30 mm and a wall thickness so that they are not less than 3 mm, otherwise the frame will not be rigid and will constantly sag or break. In addition, when making a miracle shovel, you will need hard corners with a thickness approximately the same as the pipes for structural strength.

All you have to do to the prepared frame is to weld the teeth with which you will plow your plot. Many self-taught people use ordinary pitchforks for this, which are first cut and then welded onto the finished structure. The main thing when choosing is to rely on the fact that the pins are quite strong and powerful, preferably with a diameter of at least 8–10 mm. There will not be much difference if the pins are round or in the form of another geometric shape. On average, you will need eight or ten pieces for them, depending on the width of the frame you make, rely on the fact that there should be an approximate distance of 65–75 millimeters between the pins.

First of all, when making a miracle shovel, rely on your capabilities and dimensions, adjust all sizes individually. Don’t forget that the miracle shovel for digging the earth with your own hands is designed to make it easier to spend time at your summer cottage; try to make it with your own hands as suitable as possible for your size.

If you are not a lazy person, then it will not be a particular problem for you to make it the most convenient for digging your garden plot.

How to make a snow scraper with your own hands

Before you start making a scraper, you need to think about its configuration and size. See what material is available. First of all, the equipment should be convenient for work. The cutting is made according to the height of the person. If the working surface is wide, it is optimal to provide a U-shaped handle.

For a wide scraper, a double U-shaped handle is provided

It is optimal to choose metal from the materials for the working surface. However, such a tool can scratch paving slabs. If the yard has such a decorative covering, then it is better to choose plywood or OSB sheet. You can make an excellent plastic scraper for snow from a barrel with your own hands if you cut out a fragment of the side wall. It is important that the plastic is not fragile and at least 5 mm thick.

The material for the handle is a wooden handle or an aluminum tube. It is not advisable to use a regular steel pipe. Such a handle will be heavy, cold, and uncomfortable in the hands.

The tools you will need are a saw, a jigsaw, a grinder, a hammer, a screwdriver, and an electric drill. The exact list depends on what material will be used for the work.

Advice! If you plan to transport the scraper in a car, you need to consider a collapsible or folding handle.

Video of DIY snow scrapers:

Device

The scraper has a simple device. It is represented by the following elements:

- Pen . Most often, it is retractable (telescopic) and consists of several elements that are inserted from each other. This allows you to adjust the length of the product at your discretion.

- Handle . It provides a comfortable grip on the device.

- Scraper . It is this that acts as the working surface. Most often it is made of aluminum or plastic. Wooden models are less common.

DIY snow scraper made of metal

If desired, you can make two versions of metal equipment: with and without sides on the working surface. The easiest option is the second one. For a working blade, a rectangular blank is cut out of sheet metal using a grinder. The height of the scraper is about 50 cm. The width depends on how many people the tool is designed for. If one operator will operate, the parameter is limited to 60-70 cm. For two people, the width of the working surface is increased to 1 m.

The handle is a wooden handle. It is installed alone on a narrow canvas. A wide scraper is equipped with two cuttings, and at the end they are connected by a jumper. The handle is shaped like the letter “P”.

The presence of sides allows you to capture more snow

Using the scraper principle, you can construct a homemade snow scraper with your own hands if you equip it with sides. Here too there are two options. In the first case, the rear and two side sides are bent from metal. If you make them high, the bucket will be convenient not only to scrape off, but also to remove snow from the site.

In the second option, the metal ones bend only the side sides. The back shelf is made from boards. It additionally serves as a solid basis for fixing the cutting.

Requirements

Requirements for scrapers:

there should be no sharp areas or chips on the working surface that could damage the roof;- the telescopic handle should move apart smoothly and smoothly;

- all parts must be securely fastened, not wobble or dangle;

- the length of the telescopic handle can reach 6.5 m;

- the optimal length of the scraper is 65 cm, and the length of the engine is 50 cm; the height can vary within 160 mm for the scraper and 600 mm for the engine.

How to make a snow scraper for skis with your own hands

The disadvantage of all inventory is the complexity of management. While pushing, the scraper collects snow well only on a flat surface, but no matter how smooth it is, the working surface still hits pieces of ice, ground and other obstacles. Each blow is reflected by the load on the back. A cleaning device installed on the skis helps solve the problem.

The working blade mounted on skis does not rest against the ground when raking snow.

To make your own snow scraper, use a grinder to cut off two corners, pipes or tires 1 m long. The ends are bent, otherwise the skids will hit the ground while moving. A U-shaped handle is bent from a tube with a diameter of 15 mm. It is welded to the runners at an angle. Bend towards yourself. The angle is determined individually so that it is convenient to control. A rectangular metal sheet is bolted to the posts of the U-shaped handle. The lower edge of the working blade should be on skis so that it does not rest on the ground.

Model selection

Manual wheeled bulldozers are produced by many manufacturers. The principle of constructing snow cleaning equipment is the same. Dimensions, design and some minor design nuances differ.

Snow shovel on wheels Elektromash

A popular domestic development is a manual two-wheeled bulldozer. Equipment allowing for cleaning work has the following characteristics:

- The blade is made of 2 mm steel. Working width 70 cm.

- Movement occurs due to 2 wheels. The rubber run does not damage the decorative surface of paving slabs.

- The blade is equipped with a mechanism that allows you to adjust the angle of rotation.

- The tool is easy to operate thanks to the adjustable handle. The length is set according to the height of the operator.

- A special stop prevents the lower edge of the knife from cutting into the ground during harvesting work.

The weight of the tool is about 11 kg. Light weight and high maneuverability allow an elderly person to operate the blade.

Wheeled snow shovel Bulldozer

The two-wheeled blade of the “Bulldozer” series is distinguished by increased bucket dimensions. In one pass, the working width of the strip is 80 cm. Plastic wheels do not damage paving slabs. The Bulldozer model has the following characteristics:

- The steel blade easily cuts off ice build-ups and compacted snow layers. Durable metal does not deform from impacts against hard objects during cleaning.

- The adjustment mechanism of the blade allows you to change its angle to move snow accumulations to the edge of the curb.

- The handle is equipped with two adjustment mechanisms. The operator is given the opportunity to change the angle of inclination and length.

Even an elderly person can clear snow drifts with a two-wheeled bulldozer, applying a minimum of physical activity.

Advice! A homemade bulldozer is easy to make yourself. A pipe with a diameter of 200-300 mm cut lengthwise is suitable for the dump. The wheels are taken from an old cart or stroller.

Shustrik-3 device

The two-wheeled device “Shustrik-3” is characterized by increased maneuverability. The tool is easy to move over obstacles; you can simply carry it by hand or roll it on one wheel, lifting one side. Even a child can use the scraper. The handle is equipped with an adjustment mechanism that allows you to change its length. The blade is convenient to maneuver on narrow sidewalks, enter hard-to-reach areas, and go around obstacles when cleaning areas with flower beds, pillars, and sculptures.

The steel ladle is 60 cm wide and 20 cm high. The width of the adjustable handle is 41 cm. The tool is equipped with a rotating mechanism. When removing snow accumulations, the bucket is directed to the right or left. If you just need to push the snow out of place, the blade has a turn to the other side.

The video demonstrates the removal of snow mass by a nimble: Classification of wheeled units

Equipment on wheels makes it possible to clean large areas without burdening a person. Sometimes wheeled models have a motor, which will increase the cost of the device. The simplest mechanisms with wheels are of the manual type.

This technique is driven by a person and operates on the principle of a trolley. There are several designs of snow shovels on wheels:

- Four-wheeled devices. They are often called mini bulldozers. At the base there is a metal frame with a wheel on each side. In front is a blade; its level is easily adjustable, allowing you to collect snow in the direction indicated by the equipment. This cart works even with wet and caked sediments.

- The model with two wheels looks like a regular garden wheelbarrow. Its productivity is lower, but it is easier to work with. If significant unevenness is encountered on the surface, the blade is raised to prevent impacts.

- The most modern device is called the “snow wolf”. This snow blower has one large wheel and a plastic bucket, which makes it maneuverable and very light. With its help you can clean narrow alleys and hard-to-reach areas. How to make a snow shovel on wheels from a metal barrel

In the absence of sheet steel, the ladle is made from a barrel. First, the container is opened with a grinder. If the barrel has a volume of 200 liters, then a segment from about a third of its part will be required. The workpiece already has a curved shape, so there is no need to bend the edge from below.

The frame for the shovel will be the frame of a wheelbarrow with one or two wheels.

The frame is welded from pipes, exactly as in the example of a sheet steel structure. If you have a car at home, then you should refuse unnecessary work. The body is simply removed from it, and a segment cut from a barrel is fitted in front. Moreover, the car will fit even with one wheel. At the end of winter, the instrument will be re-equipped, returning the body to its place.

How to make a snow scraper from plywood

For snow removal equipment you will need a plywood sheet 6 mm thick. The workpiece is sawed off to a length of 0.8-1 m and a width of 50 cm. The plywood is bolted to a U-shaped handle curved from a metal pipe or assembled from wooden cuttings. The scraper is almost ready, but it’s too early to clean the snow with it. In this form, the ends of the working cloth quickly wear out. The plywood begins to delaminate and break off in splinters.

It is optimal to frame the plywood with a steel strip

To improve the design, the lower end of the working blade is framed with a steel strip. It is fastened with rivets through through drilled holes.

Advice! A good handle for a scraper can be made from the frame of an old clamshell. The aluminum tube is durable, lightweight, and comfortable to hold with your hands.

Do-it-yourself scraper for removing snow from the roof

Snow covers not only paths, but also roofs. On the one hand, he doesn’t interfere there. However, it needs to be removed. Large accumulations of snow can cause the roof to collapse, and when an avalanche falls from the roof, there is a risk of injury to a person. A regular scraper won't do the job here. A long-handled device will be required. There are many options, but one of the simplest designs is considered to be a rake scraper.

They begin to assemble a homemade scraper with their own hands for removing snow from sawing off boards. The workpiece is taken up to 800 mm long and up to 200 mm wide. In any case, the board must cover the rake teeth, otherwise they will damage the roofing.

The board is fixed to the rake with a steel tire and self-tapping screws

The board is laid on the ground. A rake is placed perpendicularly on top. In this position, the teeth are parallel to the plane of the board. Now the elements need to be securely fastened. To do this, take a tire. Its length should exceed the width of the rake. Holes are drilled in the tire, placed on the teeth, and screwed to the board with self-tapping screws.

Snow is cleared from the roof by moving it towards you with a rake.

The only drawback of the design is the short handle of the rake. It is extended with an aluminum tube or a long wooden strip is used.

Main stages of work

Next, you will need to make the side walls of the scraper, which will be attached to the plywood. And for this, the master cuts two blanks from the board. If you have an edged board available, the work will not take much time.

At the next stage, you will need to screw the plywood to the side walls with self-tapping screws. For reliability, it is better to glue the boards and plywood together. PVA is not suitable for this purpose - it is afraid of moisture, but you can use polyurethane foam.

Then all that remains is to strengthen the lower part of the bucket with a galvanized strip and attach the handles, which the master made from wooden slats. To protect it from moisture, it is better to coat the scraper with a layer of varnish.

You can watch the detailed process of making a homemade snow scraper from plywood and boards in the video on our website.

How to make a snow scraper from 0SB

When you urgently need to remove snow, and you only have a piece of OSB board at hand, you can make a scraper using simple manipulations with a jigsaw. To assemble a scraper with your own hands for clearing snow, you don’t need drawings, but you need to build a pattern.

On the OSB board, draw the shape of the future scraper with a pencil. Towards the bottom, the drag scraper is expanded to 1 m. The corners are slightly rounded. Toward the top, the plate is narrowed approximately 30 cm from each edge. Two oblong holes for handles are drawn on the pattern. Now all that remains is to cut off the excess parts of the OSB board using a jigsaw according to the markings. The area near the handles is carefully sanded with sandpaper. For convenience, they can be wrapped with electrical tape.

DIY snow scraper with brush

The store-bought version of a scraper with a brush resembles a double-sided rake, only instead of teeth there are bristles on one side, and a rigid base is fixed on the other side. When cleaning, first scrape off the bulk of the snow, and then sweep away the remains with a brush.

A shop scraper with a brush is usually equipped with an aluminum telescopic handle, which allows you to remove snow from a height, such as a roof.

In the DIY version, you assemble a snow scraper with your own hands from plywood, securing a long handle perpendicular to the rectangular blank. One side is framed with a tin strip. Bristles from a plastic broom or brush are applied to the other side of the workpiece, pressed with a metal tire and secured with self-tapping screws through the drilled holes.