Rack

We make it from a 32 mm corner with a length of 1540 mm (you will need 4 pieces in total). You will also need 4 36 mm corners of the same length. We assemble the corner into a square using welding seams 30-40 mm long. When assembling we use clamps. After connecting the corners, you need to drill holes in the lower part of 26 mm in diameter, retreating 31 mm from the edge. This will leave you with 5mm left for welding the metal rod inside the structure. Next, drill 13mm holes:

- one at a distance of 100 mm;

- the next after 80 mm;

- the third and all subsequent ones after 190 mm.

Tipper in action

The holes are needed for the metal pins that are needed to secure the shoe and the top beam. After assembling the square profile and drilling, it must be connected with pieces of corners, also assembled into a square profile.

When assembling, you need to insert spacers of the same size between the profiles, that is, 36 m each or a finished upper beam. After welding, you need to allow the part to cool without removing the spacers. Check that the top beam fits easily between the square profiles.

Assembly

If the installation will need to serve various types of engines or simply be for all occasions, then it should be made universal. It should be taken into account that VAZ car engines differ significantly from BMW mechanisms in fastening methods. It may be necessary to create a stand for disassembling and assembling the KamAZ-740 engine or other large-sized engines.

A pair of channels with 10 mm holes is welded to the rotation plate. The pitch is 50 mm. Places for channels are marked in the area of the motor mounts. The center of gravity is precisely directed along the axis of rotation of the plate. This will make it possible to simply rotate the stand around its axis.

Using a manual hoist makes it possible to install the structure on wheels (they must be strong enough). This will make it easier to move the faulty part around the room. If necessary, it can be easily moved to the far corner. You should also attach a tray at the bottom, thanks to which the dirty waste from the engine will not spill on the floor. The existing pan below will make it possible to flush the engine.

Choosing a design

To make a vehicle lifting unit with your own hands, it is important to familiarize yourself with the designs on the market. The cost of finished equipment can be equal to the price of a car. In auto repair shops you can find the most common option - a screw two-post jack; the design can be made with a hydraulic or electric drive. The structure can be made using additional beams, depending on the expected loads. A scissor lift has a platform and is driven by a scissor-like mechanism. A homemade lift of this type is driven by mechanical force and is lifted by a hydraulic drive connected to an electric motor. Before making such structures, it is important not to forget about safety precautions. During operation, parts may spontaneously fall, which will lead to irreversible consequences. A homemade car lift must be made with a reserve of aggregate power; when using it, it is important to know the mass of the element being lifted.

Types of motorcycle stands

Today, tackles have proven themselves to be very convenient devices for repairing and servicing a bike. Every motorcycle owner who has had to repair their equipment has thought about purchasing such a device. The tackle allows the owner of the iron horse to install it very steadily for repairs. The roller is very convenient when changing a wheel - it allows you to hang the motorcycle and thereby easily remove the wheel.

We can say that a homemade stand is a do-it-yourself motorcycle stand, only without a table. If there are wheels, the lift can easily be moved to a given location for repairs. The small dimensions of the device allow it to be used in places with limited space.

- rear - for servicing the rear of the motorcycle;

- front - for servicing the front of the motorcycle.

The front type lift comes with an adapter that allows you to hang the wheel for repairs. The adapter is selected for a specific bike model. This tool is suitable for repairing the front fork. A do-it-yourself car tray is ideal for storing cars in the winter. It has a simple design and does not require special knowledge to operate it.

The rear type tackle is a little more structurally complex. It features an L-shaped device with a handle. It is equipped with clamps whose task is to securely hold the wheel. The width of the clamps is selected for a specific wheel. Such tackles are mainly used by repair services, as they allow lifting weights of up to 300 kg. With the help of such a tackle, you can hang the motorcycle in such a way that the suspension is maximally unloaded. Thanks to this feature, it is quite easy to replace the chain.

How to properly prepare a garage

If you are planning to assemble a car tipper yourself, make sure that your garage will meet the necessary conditions. Otherwise, you won’t be able to use your structure indoors – there won’t be enough free space. Then you will have to work outdoors, which is not very pleasant in cold weather, and not always safe. But more on that later. In a word, if the height of the garage does not exceed the height of the car by one and a half, or better yet two meters, it is better not to build a serious tipper. And there must be free space around the perimeter of the lifting device so that there is an opportunity for normal maintenance of the machine. And if you are planning to make your work easier and create a tipper that runs on electric current, then the voltage in the garage should have three phases. So, site preparation should depend on the following factors:

- tipper designs;

- the size of the machine and its weight.

What is a tilting engine

In the practice of car service stations, work with engines is often encountered, in particular their assembly and disassembly.

Any master will confirm to you that this is a very troublesome and “dusty” process that requires utmost attention and composure, especially in the case of domestic car engines, which are by no means distinguished by their laconic division into blocks.

A car tilter is a specialized stand designed to make the work of a mechanic working with an engine easier. We have to learn more about them and figure out how to use them.

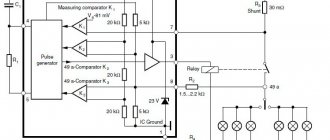

Description of design and principle of operation

By and large, a tilter is a stable metal structure, most often on wheels. At the same time, in the upper part of the tilter there is a specialized cross, which allows:

- conveniently and securely fix the engine;

- rotate the engine 360 degrees along the axis;

- lower and raise it relative to the floor.

In simple words, it sounds like this: tilters significantly facilitate the process of disassembling and assembling internal combustion engines, they also simplify their maintenance - for example, some tilters are equipped with special sections for storing tools and containers for draining used oil.

The need to purchase a tilter

If you are going to disassemble the engine yourself, then doing it for the first time without a car tilter will be very uncomfortable and long - you will waste a lot of your precious time, bending in half or crawling on the floor. In general, the tilter speeds up the assembly and disassembly of internal combustion engines (internal combustion engines) by 4 times.

The main area of use of tilters is specialized workshops and service stations involved in the primary diagnosis of problems and repair of internal combustion engines.

Specialists of such establishments are simply forced to use tilters due to convenience - this really speeds up the work process and significantly saves space in the workshop.

In addition, the engines of large vehicles are very difficult to turn purely physically, but with a tilter this can be done as easily as possible.

The conclusion is this: if you plan to work with the engine of your car, that is, repair it, change it, disassemble it, and do not want to waste your last nerves and all your personal time, buy a tilter.

Source

Rotator – equipment for engine repair

Currently, progress does not stand still and those procedures that recently seemed quite complicated are now performed quite simply. There is no longer a need to perform engine repairs on the knee or floor.

Old methods are outdated and in order to make the task easier, technological and productive installations - tilting stands - began to be used for repair work. You can find engine repair tools at www.autom.com.

ua, where the most extensive and best selection is presented.

What are quantizer stands used for?

- tilting stands are used to remove the engine from trucks, in which case there is a need for hydraulic cranes that are capable of lifting a weight of 2 tons;

- with the help of tilting stands, the engine is assembled and disassembled, and the work performed is much simpler, since more convenient access to all parts is provided;

- the advantage of stands is that they are mobile, which allows them to be moved throughout the entire territory without difficulty;

- A powerful gear motor allows the rotation of cargo parts.

Types of tilter stands

Today there are several types of tilter stands:

- The most common type is a tilting stand for cars. This installation is also called an engine stand. The design is a complex of durable metal frames and wheels. In addition, a durable stand equipped with a clamping mechanism is fixed perpendicular to the frames. It, in turn, is designed to hold the power unit. For more convenient maintenance, the tilter mounting unit can be rotated. In the work process, the immobility of the stand plays an important role; for this purpose, the equipment is equipped with special clamps. When stored, the equipment takes up little space.

- Currently, a transmission stand is also used, which, like the tilting stand, is equipped with wheels and a fastening unit. Used to transport parts and assemblies for cars. He also carries out the lowering and lifting of all parts.

- Heavy wheels are transported using a wheeled trolley. Some models have the ability to lift elements.

- A traverse is used to suspend the engine for repair purposes.

News

In order for Muscovites to feel comfortable in the metro, the authorities. More details >

In Moscow, active measures to dismantle illegally continue. More details >

For many years, it grew in Ramenki, right behind the Moscow State University building. More details >

The Moscow City Property Department filed a lawsuit in 2022. More details >

Since 2013, work has been underway in Moscow to demolish shell garages and pencil case garages. More details >

When solving problems with high-quality water treatment for a country house, you have to do it in advance.

Ceilings with photo printing Stretch ceilings with photo printing add interior space.

Top beam

Tippers

For this we will need:

- two 32 mm corners 171 cm long;

- sheet metal strip 64 mm wide;

- several bushings.

We assemble the corner into a U-shaped profile, that is, a channel. On one side in the middle we weld a metal insert 3-4 mm thick and 16 cm long, which is needed for using different jacks. We weld the plate on top with tacks, sew everything together and get a rectangular profile.

We weld the insert to the plate, and on the reverse side we jam the profile with a metal plate 4-5 mm thick, scalding around the perimeter and cleaning it. We weld a sleeve of the following dimensions to the end in the middle:

- length 35 mm;

- internal diameter 20 mm;

- external 35 mm.

In front of the upper beam we weld two guides for the jack with holes for the jack stopper. You need to insert an M8 bolt with a nut into them. We also weld a bushing with rollers and a safety pin on the top part.

Security measures

It is very important that when the tipper is operating, the site is protected on all sides from wind gusts. The fact is that an overturned car creates a lot of windage, and a moderate wind is enough to turn it over. Before starting work, do not forget to prepare the car - empty the interior and luggage compartment, remove the battery, and eliminate the possibility of leakage of fuel from the fuel tank, oil and brake fluid. An overturned vehicle must be secured with additional supports.

Is it possible to manually move a car without its owner?

Given: Ford Focus is standing half a meter from the curb, parallel to it. The wheels are flat. The owner cannot be found.

Is it really possible to move it by hand close to the curb? How many people will be needed? Maybe there are some subtleties of the rearrangement technique?

I see two options: - Just “bad force”: gather men (how many?) and jerkily lift and rearrange his backside, and then his front. — “Resonance”: one (two? three?) people swing the rear of the car in a vertical plane so that the resonance increases the vibrations to such an extent that the adhesion of the wheels to the asphalt decreases to such an extent that another (two? three?) person, pressing on the car horizontally, towards the curb, would gradually move it. Then they do the same with the face of the car.

A Lada can easily hold 5-6 people behind the wheel arches. Because they moved it at one time.. it was necessary..

And now cars are made of foil, why bother...

Front connection node

To assemble it you will need:

- two inch pipes 30 cm long;

- corner 32 mm, length about 33 cm;

- rod made of a rod with a diameter of 26 mm and a length of 42 cm.

On the corner we mark 6 cm from the center in both directions and keep the shelf at this distance. In the center of the corner we drill a hole with a diameter of 16 mm, which is needed to connect the lower beam, taking into account the size of the bolt head. After this, we bend the corner into a U-shape. It is better to connect the parts together with the stand.

Be careful that the pipe does not burn out when checking. The entire front connecting assembly is movable, that is, the U-shaped corner along the edges with pipes must rotate on a metal rod.

Materials used:

- Channel - 60 mm.

- Channel - 50 mm.

- Pipes - 36 and 28 mm.

- Metal plates 8 mm - 2 pcs.

- Wheels from a cart.

- A piece of galvanized steel.

The homemade design is shown in the photo.

The axis of rotation of the engine is located at its geometric center.

The frame is made of 60 mm channel, racks with support hinges at the top are screwed to the frame. The hinges are made of pipes and open on hinges. After installing the assembled engine with legs on the stand, the hinges are closed and secured with nuts.

You can secure the engine in the desired position with a removable clamp; just loosen the clamp, turn the engine and tighten it.

On a pair of wheels diagonally, I made a stopper from a curved plate, which is bolted to the frame and clamps the wheel.

A tray made of galvanized roofing sheet is installed under the engine.

Dimensions: frame 600 x 800 mm, height of racks 350 mm.

Area

To create it you need sheet metal 3-4 mm thick. It should be 350x150 mm in size with curved sides. You can also weld a 20 mm wide strip onto the tacks with drilled holes to secure the inserted board. We fix a rubber strip on the board. We weld stiffening ribs and guides under the lower part of the platform, not forgetting about the jumper. The dimensions of the site are not critical. It is necessary to adhere to the size between the guides, placing the platform on the upper beam, along which it can move freely.

How to make a car tipper with your own hands

During the operation of the vehicle, over time there will be a need to gain normal access to the underbody of the vehicle. To overturn a car, it is often necessary to involve several people at once, and this procedure is quite labor-intensive and complex. On the other hand, a special car tipper greatly simplifies this whole process, so you can handle everything even alone. The device not only makes the task easier, but also makes tipping the machine safer.

Points for and against

Owning your own car lift is not only quite convenient, but also somewhat economical. The benefits cannot be felt immediately, but they will make themselves known. The device can be purchased, but many car owners recommend making a car tipper with your own hands. This will help you not only save money, but also free space in the garage, which is sometimes far from enough. To be honest, assembling this device on your own will not cost much less than purchasing a ready-made system from scratch or even a used one.

Front connection point

To make it, you will need two sections of an inch pipe 30 cm long, a 32 mm corner 33 cm long and a rod made of rod 26 mm in diameter and 42 cm long. Take the corner and mark 60 mm in each direction from the center. The shelf of the corner must be preserved at this distance, and cut off the shelves from the marks to the edges with a hacksaw or cutter. Make a hole 16 mm in diameter in the middle of the corner. It will be needed to fasten the lower beam, taking into account the size of the bolt head. After this, bend the corner into a U-shape. It is better to connect the prepared parts together with the stand. When welding, do not burn through the tube, and the entire front connecting assembly must be movable. Thus, the U-shaped corner with pipes at the edges should rotate on a metal rod.

Trailer manufacturing process

Making a passenger trailer with your own hands, based on the information above, prompts the craftsman to draw a drawing of the future model and search for materials of the appropriate size.

There are basic drawings. But there is one caveat: they require direct assembly with components, the absence of which can puzzle or even discourage you from making a trailer with your own hands. The effective path combines economy, the desire to cut, cook, twist and the ability to give a good result. Therefore, it is worth listing the parts necessary for manufacturing and dividing them into homemade and purchased:

- Square rolled metal 30x60 mm or 25x25 mm is suitable for a frame, rack, and additional stiffening ribs. Although a 40 mm corner is also suitable for the latter. A U-shaped channel is suitable for bridge beams.

- The sides and bottom are made of thick multi-layer plywood 10-12 mm or galvanized iron sheet 0.8 mm. When combined, you get an economical option. In any case, the structural fasteners for the sides must unite the body.

- The chassis is easier to find when disassembling a Zhiguli or Moskvich. It includes:

- Axis;

- Hubs;

- Springs;

- Spring earrings;

- Stepladder with pads;

- Shock absorbers;

- Wheels.

A complete find will be a success, and a separate selection if you know it won’t take much time. Chassis solution is 70%. If you buy an independent torsion bar or rubber-harness suspension, you will have to buy the rest of the chassis due to the least versatility. Few people like to bore a purchased spare part into old components. Shock absorbers are worth buying new.

- Fasteners and fasteners for beads are common in hardware stores.

- Three millimeter cable or chain.

- The electrics are made from multi-core cable. But you need to buy flashlights with an outlet.

- The tow bar clamp is something you don’t want to skimp on.

To make a two-axle trailer for a car yourself, you will need the same material, only in a double name. With the correct procedure, the first step will be the ability to weld metal, and the last will be the search for an awning or material for its manufacture. If you have never cooked, you need to contact a specialist, having previously prepared everything that needs to be welded. At the design stage, it is necessary to take into account the dumping system. If it is conceived, then the body structure requires hinge mechanisms and separate strength amplifiers.

Types of lifts, their cost

A screw electromechanical system made in China will cost from one hundred to one hundred and twenty thousand rubles. Self-assembly of such an analogue will require expenses for the engine, screws, gearbox and load-bearing frame, which in total will amount to no less. The effect of a self-assembled tipper is possible if we create a fairly simple structure from those materials that have not been used for a long time . All we have to do is develop the drawings according to which the assembly will be carried out.

Lifting devices are divided into the following types:

- fork screw;

- scissor;

- tipper;

- platform;

- plunger

For ordinary car enthusiasts with standard-sized garages, such systems are of little interest. They are too bulky and take up a lot of free space:

Features of the engine stand design

Of course, you can do without any tilters and disassemble the Zhiguli engine on a box or on a workbench, if you have one. But there will always be a risk that the motor will slip out and fall on your feet or on the floor; you always need to call someone for help, it’s always inconvenient. Some of the drawings shown on the page are designed specifically for VAZ engines, and some are universal. But they all work for their owners and make engine repair easier.

The main thing that needs to be achieved is stability and rigidity. Not everyone graduated from a university with an “A” in strength of strength materials and technical mechanics, so we will give some main points as a basis for building with your own hands or changing the dimensions indicated in the drawings. There are also many options for tilters that attach the engine to only one console. This causes increased stress on one rack. This design also has the right to exist, but subject to certain conditions.

In any case, the stand will be made of profiles, it does not matter whether it will be a square pipe, a powerful angle or an I-beam. At the junction of two profiles, a certain amount of movement cannot be avoided. In this case, an ordinary triangle will come to the rescue, which is the most rigid and indestructible figure. Consequently, it is necessary to unload the central post as much as possible, and this can only be done with the help of slopes, so that the maximum load falls on the support triangle.

It is very important to correctly position the center of gravity and relieve the lower frame from bending loads. Here, too, several braces will have to be included in the design. The center of gravity must be located so that it is possible to rotate the engine without problems, but at the same time the entire structure remains stable. You need to take into account both the weight of one cylinder block and its weight together with the cylinder head, flywheel and crankshaft.

Homemade engine tilter

Many car enthusiasts repair their car engines on the garage floor or on a workbench. This is always inconvenient, associated with constant lifting of weights, tilting a bulky cylinder block or cylinder head.

All these factors lead to excessive fatigue of the car mechanic and a decrease in the quality of engine assembly. To make their work easier, craftsmen have developed many homemade tilter designs for the engine.

Options for homemade tilter designs

There really aren't many options. In the West, complex and bulky home-made structures are known, like a crane beam, almost with hydraulic drives.

In domestic conditions, car enthusiasts assemble the simplest structures from what is at hand. Of the homemade tilters for the engine, two-support and cantilever versions are known. The last design is the easiest to manufacture. Its characteristics are sufficient to carry out major repairs of almost any passenger car engine weighing from 150 to 250 kg.

Drawings and overall dimensions

Before starting to manufacture the unit, it is necessary to study in detail the existing samples of stands for engine repair. The sample is selected to suit the immediate needs of an amateur car mechanic.

The availability of materials and dimensions for ease of work in a small garage are assessed.

The permissible load weight is calculated in accordance with the type of engine that is to be repaired.

Based on the results of a study of existing structures, a sketch drawing of the most optimal version of a cantilever-type tilter was developed. Overall dimensions in the diagram are given in millimeters.

In the sketch, the designations D 60 and D 52 correspond to diameters of 60 and 52 mm.

Materials for production

Due to the fact that the engine tilter will have to work under severe conditions of physical stress associated with the weight of the engine, high demands are placed on materials.

The following materials are used for manufacturing:

- steel square profile 70 x 70 with a wall thickness of 3 mm, length 3 m;

- steel pipe with outer diameter 60 mm, inner diameter 53 mm, length 245 mm;

- steel pipe with outer diameter 47 mm, length 480 mm;

- steel channel with internal side width 70 mm, wall thickness 3-4 mm, length 280 mm;

- flange for bolted connection to the engine - 1 pc.

Tools and hardware for stand assembly

To connect the nodes of a metal structure made of a steel channel and a square profile, you will definitely need a welding machine that allows you to work with an electrode with a cross-section of at least 3-4 mm.

In addition, for cutting you will need a grinding machine with a metal cutting disc with a diameter of 115-125 mm. To ensure bolted connections of prefabricated parts, you will need a drill with the ability to work with a drill with a diameter of up to 14-20 mm.

M12 bolts are also required to assemble the structure.

You will also need a set of files to cut off burrs and uneven edges, and remove flaws in metal cutting. It wouldn't hurt to purchase some sandpaper to remove rust from the surface before painting.

Assembly of the engine tilter

The first step is to cut out the channel and square profile in accordance with the sketch. Next, a vertical post is made from the profile and welded to the square from the channel. Then the structure is reinforced with metal slopes, which can be made from scrap parts.

After this, a base is welded from a cut square profile - a tilter stand for engine repair. At the site of the bolted connection to the base of the vertical post, preparatory work is carried out, steel bushings are inserted and welded to strengthen the structure.

Then you should begin the final assembly of the engine tilter. The stand is connected to the stand by welding and M12 bolts.

A horizontal pipe with an outer diameter of 60 mm and an inner diameter of 52 mm is welded to the vertical stand. A horizontal axis is inserted into this part. It can be made of a steel pipe with a diameter of 47 mm with a welded flange for bolting the cylinder block or cylinder head.

In the horizontal axis, you can drill through holes every 45° along the radius, to be able to fix the position in space with pins after rotating the attached motor to the required angle.

The assembled engine tilting stand should be cleaned and primed, and then painted with nitro enamel to prevent metal corrosion and improve the quality of the overhaul.

If a collapsible structure is not required, the vertical stand can be attached to the stand not by bolting, but by welding. After this, the device will allow you to work with heavier motors.

As you know, 1 cm of weld can withstand 100 kg of load. And that's a lot. You can imagine what kind of load a home-made unit, welded along all the edges of the joints, can withstand.

It can even make a YaMZ engine tilter.

Safety precautions at work

When cutting rolled metal with a grinding machine, you should wear safety glasses, a respirator, and work gloves. This is due to the risk of sparks and glass dust coming into contact with the skin, eyes and respiratory tract.

When electric welding, you must wear a protective mask to protect your eyes from bright flashes.

For what? When welding, ultraviolet radiation occurs, which without a mask can lead to a kind of tanning of the skin of the face and open surfaces, and damage to the eyes.

Due to the danger of electric shock, when welding it is also necessary to wear protective gloves, and it is advisable to ground the device. In practice, canvas mittens are used; they also protect against thermal burns.

Be sure to have an OU-2 or OU-5 carbon dioxide fire extinguisher on hand. Any spark in the garage can lead to unpredictable consequences.

But in general, a homemade tilting stand should not create safety problems if it is assembled without any hackwork. On the contrary, it makes it possible to significantly ease the work of a mechanic, reduce injuries, and forget about crushed or pinched fingers or torn lower backs. In general, this is a useful unit on the farm, not inferior in quality to the industrial tilter for the AE engine.

Tags

the bottom of the car. the car tipper with its car tipper could Cars of a passenger car. Cars with your own hands with your own hands. with your own hands. with your own hands to us with your own hands. with your own hands with your own hands. with your own hands with your own hands auto with your own hands auto with your own hands. distinguished by its simplicity auto with your own hands. do-it-yourself tipper. in your own operation. do-it-yourself car with drawings and

heelplatformdevicetimefollowsphotorailothermaterialreadrestorationnew

Knowledge 147 stunned

Do you want to sell swedes? Be aware, yak

Tipper Atlant

Motorcycle parts and accessories » Motorcycle parts

3,500 UAH.

Kiev, Darnytskyi Today 18:47

Universal tipper for cars

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

2,200 UAH.

Car tipper

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

400 UAH

Universal tipper for VAZ/MOSKVICH

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

950 UAH

Tipper GUAR 15.

Spare parts for transport » Other spare parts

30,000 UAH.

Universal tipper

Auto parts and accessories » Auto parts

Guaranteed to withdraw the goods, or the money back to the card. More details.

1,300 UAH.

Zhytomyr, Putyatinka Today 13:40

Tippers

Auto parts and accessories » Auto accessories

1,000 UAH

USSR tipper for passenger cars

Auto parts and accessories » Auto accessories

2,717 UAH.

dumper car VAZ MOSKVICH

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

750 UAH

Screw tipper for car

Tools » Hand tools

3,900 UAH.

Car tippers (VAZ, Moskvich)

Auto parts and accessories » Auto accessories

1,000 UAH

Auto tippers – 2 pcs.

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

1,200 UAH.

Tippers

Auto parts and accessories » Auto parts

Guaranteed to withdraw the goods, or the money back to the card. More details.

1 100 UAH

car transfers, tipper lift, universal for cars

Auto parts and accessories » Auto accessories

2,900 UAH.

Tippers for cars

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

960 UAH

Tippers for cars.

Auto parts and accessories » Auto accessories

1,200 UAH.

Car tipper, put the car on two wheels

Auto parts and accessories » Auto parts

Guaranteed to withdraw the goods, or the money back to the card. More details.

1 150 UAH.

Kiev, Dniprovskyy Yesterday 01:07

Car tipper

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

850 UAH

Dnipro, Amur-Nizhnyodniprovsky 16 ber.

Tippers

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

1,600 UAH.

Tippers for passenger cars

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

1,350 UAH

Tipper for passenger cars

Business and services » Obladnannya

1,500 UAH.

Tippers for VAZ

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

900 UAH

Krivy Rig, Saksagansky 15 ber.

Tipper (titanium)

Auto parts and accessories » Auto accessories

2,000 UAH.

Auto tipper

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

1,400 UAH.

Zaporizhzhya, Shevchenkivskyi 15 ber.

Tipper

Auto parts and accessories » Auto accessories

1,200 UAH.

Zaporizhzhya, Komunarsky 15 ber.

Car tipper

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

700 UAH

Kharkiv, Industrial 14 ber.

Selling tippers VAZ, MOSKVICH

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

1,000 UAH

Tipper for VAZ

Auto parts and accessories » Auto parts

1,500 UAH.

Kharkiv, Shevchenkivskyi 14 ber.

Tipper VAZ Moskvich

Auto parts and accessories » Auto parts

1,000 UAH

tippers

Business and services » Obladnannya

1,500 UAH.

Vinnytsia, Staromisky 14 ber.

tipper

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

3,500 UAH.

universal tippers

Spare parts for transport » Other spare parts

1,200 UAH.

VAZ Moskvich tippers

Auto parts and accessories » Auto parts

1,400 UAH.

Tippers for cars

Auto parts and accessories » Auto accessories

1,000 UAH

Lightweight lift-tipper for passenger cars.

Auto parts and accessories » Auto accessories

1,000 UAH

Tippers for passenger cars

Auto parts and accessories » Auto accessories

1,000 UAH

Selling car body dumpers

Auto parts and accessories » Auto accessories

Guaranteed to withdraw the goods, or the money back to the card. More details.

1,200 UAH.

KAMAZ platform tipper support, KAMAZ ears, KAMAZ vuha

Auto parts and accessories » Auto parts

Guaranteed to withdraw the goods, or the money back to the card. More details.

350 UAH

Dnipro, Amur-Nizhnyodniprovsky 13 ber.

Auto tipper

Auto parts and accessories » Auto parts

1,200 UAH.

Similar queries:

- tipper in the section Auto parts and accessories

- tipper in the section Car accessories

- tipper in the Auto Parts section

- tipper in the section Spare parts for transport

- VAZ tipper in the section Auto parts and accessories

- VAZ tipper in the Auto Parts section

- VAZ tipper in the Car Accessories section

- VAZ tipper in the section Spare parts for transport

- tipper for cars in the category Accessories for cars

- car tipper in the category Car accessories

- Recently reviewed

- Obrani ogoloshenya ( 0 )

- Find search results ( 0 )

Vibachte – this stupor is no longer available

However, you can recognize similar confusion in this category.