Faced with a completely discharged battery somewhere along the way, the car owner finds himself in a difficult situation. You either have to look for a donor car to light a cigarette by connecting the car starter to a third-party power source. An important point: in the trunk you must have special thick cables equipped with clamps. It is not necessary to purchase them - make reliable wires for lighting your own using the instructions below.

Why not buy cables in a store?

The main reason is this: at the moment the market is saturated with inexpensive products of dubious quality, made, as a rule, in China. Finding truly reliable wires becomes problematic - car stores sell cables that are unsuitable for lighting for the following reasons:

- the cross-section of the copper conductors does not correspond to the declared current carrying capacity;

- the insulation is made too thick in order to imitate a large cross-section conductor;

- the end clamps (the so-called crocodiles) are made of tin coated with a thin layer of copper on top;

- the insulating layer is often made of polyvinyl chloride (PVC), which cracks in the cold;

- fastenings at the points of contact of copper conductors with the crocodile are not reliable.

The result of these problems is large voltage losses, in some cases reaching 1 volt per meter of cable length. This is a serious obstacle to starting a cold engine in a car with a completely dead battery. Insulation cracks can lead to a short circuit to the vehicle body and failure of the donor battery. That is why it is quite difficult for a car enthusiast ignorant of electrics to choose wires for lighting; it is easier to assemble the product yourself.

Improvement

As mentioned above, the cigarette lighter socket is used in many devices today. Therefore, one slot may not be enough. Increase their number with the help of special devices sold in auto stores - melters and lighters.

The device is made in the form of a block with two or three (depending on the selected model) sockets. The device is connected to a standard car cigarette lighter using a corresponding plug connected by a wire to the contacts of the T-bar.

The unit can be attached to the car dashboard using double-sided tape or silicone sealant. Thanks to this, the driver has the opportunity to simultaneously connect not one, but several devices operating from the cigarette lighter socket.

In the summer, car owners most often connect only smartphone chargers and DVRs to on-board networks, which consume symbolic electricity. But in the fall and winter, electric heating pads, external heaters, electric mugs, thermal glass scrapers and other car heaters are connected to lighters. All these devices are usually powered by two to five cigarette lighter splitters at the same time, and as a result, many car owners are faced with problems. And everything would be fine if a contact fell out somewhere or a plug melted, but you can burn the car... How not to do this?

Who is guilty?

Physics and electrical engineering make it clear: To carry large currents through plug connections, connectors must have a larger surface area. And the lighter circuit also protects the common OEM fuse in the vehicle's "fuse box."

To change the fork, remove it, remove the fuse and replace the longer spring. The "nose" and flat contact should be carried and connected to you as part of a pair with a soldering iron. On this basis, graphite brushes are made in every electric motor - the wire passes through the spring, becoming a "bypass" for electricity, on which there is no voltage drop and heating. The spring serves only as a contact tip and not as a guide.

This method is quite effective, but whether it is worth getting tired is up for debate. It may be easier to prevent the splitter from being overloaded by using it only to feed low-power gadgets, and powerful receivers like heated seats are connected to a lighter one and alternately.

Requirements for quality conductors

The main task of the cable “cigarette lighter” is to ensure safe transfer of current to the starter of another car with minimal losses for the donor car battery. There are a number of requirements for wires:

- voltage loss - no more than 1 V over the entire length of the cigarette lighter;

- cable type – stranded copper (consists of a large number of thin wires twisted into a single conductor);

- the minimum operating time is 30 seconds, which is exactly what is needed to start a working motor;

- current-carrying conductors must be designed for a current of at least 500 amperes;

- The minimum length of conductors is 2.5 m, the maximum is 4.5 m.

Note. The current value of 500 A is indicated for starters of cars with a power unit displacement of up to 3 liters. For powerful SUVs, small trucks and other commercial vehicles, a wire cross-section is selected that can withstand at least 850 A.

The type of cable insulation plays a big role. On a “cigarette lighter” operated in the middle zone with a minimum winter temperature of minus 40 ° C, the use of an insulating layer of rubber is allowed (for example, a flexible welding cable designed for high currents). For northern regions, a different type of insulation is required, made of frost-resistant silicone that can withstand temperatures of minus 60 °C.

Making your own jumper wires

We suggest you familiarize yourself with the technique of creating wires for lighting with your own hands.

What will it take? This list includes:

- Welding stranded wires;

- Metal terminals.

The surface of the welding stranded wires has a copper core inside. The shell of the product is made of silicone-containing rubber. This material has good frost-resistant qualities.

To create a structure 4 m long, you will need 6.5 m of wire. You can purchase these components in electrical goods departments. The diameter of the product must be at least 9 mm.

Tips for choosing components

You need to understand that a set of high-quality parts will probably cost more than finished Chinese products. But in a situation where your car’s battery suddenly runs out, or another driver asks for help, the cigarette lighter wires will definitely not fail.

To make your own cigarette lighter wires, you should purchase the following components:

- stranded copper cable, brand KG or KOG, with rubber insulation, working cross-section – 35 mm2;

- stranded wire KOG1 with a cross-section of 16 mm2;

- brass crocodiles for wires, designed for a current of 500 A;

- contact connecting sleeves type GML for cable 35 square – 4 pcs.;

- terminal lugs for M8 screw and cross-section 16 mm2 – 8 pcs.;

- short M8 bolts – 8 pcs.;

- heat shrink insulating tube.

Reference. Cable products such as KG and KOG with rubber insulation are used to connect holders of electric welding machines.

The length of the wires, consisting of a thick welding cable 35 mm2, is selected simply: the “cigarette lighter” should be enough to connect two batteries with a small margin. As a rule, a length of 3 meters is enough.

A thin stranded wire of 16 squares will be used to connect the “crocodiles” with the main current-carrying conductors of large cross-section. Why is the transition to 2 cables of smaller diameter made:

- The 35 mm2 stranded conductor is quite thick. It is quite difficult to screw it directly to the clamp with one screw.

- Insulated crocodile handles cannot be pulled over a powerful cable with a cross-section of 35 squares.

- To ensure reliable electrical contact with the battery terminals, voltage should be applied to both jaws of the clamps. It is for this purpose that the manufacturer provides 2 mounting screws on each side of the crocodile.

To connect the main conductor to the clamps, it is enough to purchase 1 m of welding cable KG with a size of 16 mm2. To avoid buying expensive heat-shrinkable tubing (sold in lengths starting from 1 m), use cheaper cotton insulating tape used in electrical installations. Choose tinned copper sleeves and tips.

Rules for using wires for lighting batteries

It doesn’t matter what product is purchased: a popular expensive model or an inexpensive device. If it is used incorrectly, a positive result will not be achieved. You can not only not revive the battery, but also “light it” so that all the wiring on one or two machines burns out at once. There are certain rules for using starter cables. How to connect? The process follows the following scheme:

- Cigarette lighters are inspected. If they are different colors: red and black, then everything is clear. If there is no color marking, then you need to correctly determine the polarity. This is especially true for do-it-yourself structures.

- Determine the cross-sectional area. You can use the visual method. If the machine starting current is 200 A, then you need to choose a cable with a cross-section of at least 25 sq. mm (or 8 mm in diameter). The current limit value is indicated on the packaging.

- Make sure the quality of the clamps. There should be no exposed elements. This may result in charring of the contacts. The clamps are connected to the metal sections of the terminals.

- Connect the clamps. The positive cables are connected first, followed by the negative wires. If the sequence is not followed, the negative cables may accidentally fall onto the car body and cause a short circuit. There is no need for haste in this matter. It is better to check the polarity and strength of the clamps several times so that they do not fall. You can find an assistant to hold the clamps.

- Start the donor engine. It is better not to turn it off until the dead battery starts up.

- Make a short attempt to start the engine. At the same time, observe the starter cables. If they change shape or become very hot, the process should be stopped immediately.

- If the start is unsuccessful, you should check the temperature of the clamps, conductors and ignition cables. You need to repeat the ride after three to five minutes. For each subsequent start, you must wait at least 10 minutes. If a positive result does not occur for a long time, you should abandon the idea and seek help from a stationary charger.

The most common mistakes are:

- Electrical appliances operating during the lighting period.

- The “donor” has the engine running.

- The capacity of the donor battery is less.

- The sequence of actions is broken.

- Poor quality products purchased.

- Violation of technical safety rules during work.

You can make similar elements for lighting yourself. Detailed instructions are available on the Internet. You need desire, a little experience in this matter, appropriate materials and equipment, and free time. If your family budget allows, you can visit a specialized retail outlet and purchase the products you like. If you want to save money, you can order the product online in an online store, having previously selected the appropriate length of the product and the type of cigarette lighter clips.

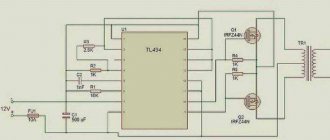

Preparing the cigarette lighter for converting it into an infrared soldering iron

First you need to disassemble the cigarette lighter and remove unnecessary parts. It's very easy to do. We unscrew the plastic handle (it will come in handy), unscrew the nut located under it, and remove the plate. There will be a spring underneath that you can throw away.

Next, the cigarette lighter can be easily disassembled. We definitely won’t need the metal shell anymore, but the ceramic insulator will come in very handy. It will protect the plastic handle from overheating.

If a different cigarette lighter is used to make an infrared soldering iron, you should look on the Internet to see how it is disassembled. For example, for parts from newer VAZ models (2115 and the like), you first need to unscrew the central button from the plastic shell.

This ceramic insulator is necessary for making your own infrared soldering iron.

Let's look at all the parts that make up the cigarette lighter. In the photo example you can see everything necessary for our work. They are marked with red arrows.

These parts are needed to make a soldering iron, and the rest can simply be thrown away