When you have no practical experience, but want to make your own light on a bicycle or car trailer, you need minimal electrical skills, simple tools and affordable materials.

A universal lighting system should be functional, cheap, and tailored to the design of a specific bike. It must also meet the requirements of efficiency, ease of maintenance and repair, be portable and reliable.

Trailer lighting is mounted differently depending on the vehicle. For example, it will be difficult for an American to install a light on a trailer - the rear lights also serve as brake lights, turn signals, and reversing lights. You simply can't find the necessary wires. To properly install the lighting system on a trailer, you should know several electrical details.

Equipment purchase

As a front light element for a bicycle, you can use a regular 25W lamp with a large base, or a 5W lamp with a large base, or a 3W lamp with a small base. You can use old Soviet fog lights, a headlight from a light motorcycle, or buy 2 car LEDs. In addition to the front headlight, you will also need a red tail light.

The power source can be a regular dynamo generator or a 12 V motorcycle lead battery. A NiCd battery pack is also suitable. However, the latter option is too expensive. A dynamic generator will also create certain difficulties during operation. Additional pedaling efforts, high noise levels, and dimming of lights at stops are serious disadvantages of such systems. The optimal solution is lead-acid batteries. They are undemanding in terms of charging mode and have a low price. You shouldn’t take motorcycle ones - they can leak as soon as the bike “lies” on its side. You need to choose sealed batteries, which are purchased at the same time as car terminals of the “male” type.

Wires should be purchased from copper, with a cross-section from 0.5 to 0.75 mm. They are purchased at a car store. You will also need a roll of electrical tape to secure the wires to the frame.

As for electrical devices, you need a unit that can turn the headlights on/off. An iron toggle switch that can handle 30 amps works well. If you use motorcycle switches, there will be too many wires. You will also need to install a fuse. Standard automotive terminals will make excellent connecting elements, and the caps will protect them from external influences. For the battery you need to prepare a stretcher bag.

LED strip for bicycle wheels: detailed instructions

We would like to immediately draw your attention to the fact that there is nothing easy about this. Even experienced electricians spend about one day on such an installation. The process has many features, you will have to re-read several more supporting articles on this topic. But the result will be justified in any case. If you're ready, gather your nerves and let's do everything together.

Cutting the LED strip

First of all, we determine the length of the tape that is needed for the bicycle wheels. To do this, you can attach a regular lace, using it, the result will be accurate. Also read: how to choose a block for an LED strip.

Next, cut the tape in the required place, as shown in the photo.

These are the pieces you should get.

We fasten and solder the tape

To get a beautiful LED strip lighting for your bike, you need to be especially serious about this stage. Here we need to do two serious things at once:

- Solder the tape.

- Attach it to the wheel.

Initially, we begin to solder it - this is the longest process that does not tolerate mistakes. We soldered it a little wrong the first time, and in the end the tape didn’t catch fire. When you start soldering, try to do everything carefully, rushing will only hurt. Read in detail: how to solder an LED strip. In the end result, do not forget to insulate, the connectors are not suitable, use special silicone sealants.

The situation with fastening is simpler; you can use several methods:

- You can buy self-adhesive tape.

- Or we begin to glue each piece separately using hot glue.

This is the final result.

Connecting the power

Here we have to connect everything together, the stage is not difficult, but a little untidy, it is difficult to climb between the spokes.

- Solder two wires to the end of the LED strip.

- We bring them to the power button and bring them to the battery holder.

- The holder can be secured using “Clamps”; we install it on the wheel shaft.

- We secure all the wires.

- Next, we check the functionality - this is important!

- After this, we isolate all the contacts using silicone sealant.

Bicycle lighting with LED strip: photo

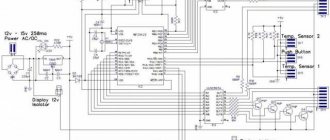

Electrical connection diagram

During the installation process you will need a drill, drill bits, stripper, crimper and scissors for electrical tape.

Installation begins with installing the headlight. It is attached to the reflector stand using a bracket. The rear marker is securely attached to the trunk bar or under the saddle.

The wiring diagram is quite simple:

- from the negative terminal of the battery, the wires go to the ground switch and are led out to the bicycle frame;

- from the positive terminal - to the fuse socket and to the distribution terminal;

- from the distribution terminal - to the rear marker and headlight.

This scheme is the required minimum. The basic rule is not to connect anything that bypasses the fuse, as well as the ground switch. High/low beam modes are equipped by turning on/off the additional headlight LED.

Now it’s worth determining the position of the battery, the mounting location of the marker and the headlight. Depending on their position, the wires are cut to the required length. They should be invisible and not hang, interfering with the movement of the pedals. Contact pairs must be connected with care - if the diodes are connected incorrectly, you will have to buy new ones.

If the structure is installed correctly, only minor problems may arise due to technical imperfections in fastenings and connections.

Materials for lighting

Answering the question of how to make an LED strip for a bicycle, initially, you must prepare the following materials. They are not difficult to find; any store has them.

- LED strip (recommendations above).

- Battery holders.

- Two 9 V batteries.

- Switch buttons.

- Silicone sealant; if desired, you can also use regular hot melt glue.

LEDs

If the bike is used infrequently at night, installing a battery will not be practical. At low speeds, when the headlight is powered by a dynamo generator, the road will be insufficiently illuminated, and it will not be possible to constantly accelerate, given the quality of the roads and the instability of the brightness level of the lamps.

There is another simple and affordable way to save electricity from an autonomous system with a fairly high efficiency of lighting fixtures. When using a dynamo, the incandescent bulbs in the headlight must be replaced with simple LEDs. However, they will need constant voltage to power them, so to create a stably operating system, a filter and a rectifier are needed.

There are special drivers to power LEDs. They can be replaced with a simple current stabilizer based on the LM317 chip. A 12V generator can produce 0.5 amperes of current. To power the rear light, you need 2.5V, present on the second contact. Rectifying the 12V AC voltage using a diode bridge on the filter capacitor gives a DC voltage of 16.9V. Depending on driving speed, the voltage will vary greatly.

In order for the headlight to shine normally even at low speeds, you should take the calculated value as 12V. With an operating voltage of one LED of 3.5V, a series connection produces 6.4V. 1.5V drops across the current-setting resistor. The total is 7.65V. The stabilizer chip will have the remaining voltage (12-7.65) equal to 4.35V. The microcircuit is installed on a radiator located inside the headlight housing. Copper will dissipate heat most effectively. Each stabilizer must be mounted in the flashlight body. The larger the capacity of the electrolytic filter capacitor, the more stable the headlight will shine at low speed.

As a result of tests, such lighting produces a stable brightness of the flashlight already at 8 km/h. As the speed increases, it remains the same. This makes itself felt by the stabilizer.

How to install single lamps

At the first stage, we think about how to decorate the wheels. You can go the simple route - symmetrically arrange the lamps along the circumferences of the rims and on the spokes. But you can develop a real design from individual LEDs; all you have to do is use your imagination. But regardless of the idea, the scheme for combining light bulbs into a circuit and connecting them is standard for all solutions.

For work you will need:

- LED light bulbs in the required quantity;

- wiring;

- several 9V batteries;

- clamps for lamps and batteries;

- switch;

- soldering iron, electrical tape;

- sealant.

When the bike is standing, the glowing lights will look like a Christmas tree garland, and when in motion they will leave a “track”. Common colors are red, blue and green. Their combination in equal quantities when the wheels rotate will give a dazzling white light.

Let's start assembling the electrical circuit:

- Use a soldering iron to connect the leads of each lamp to the wires. Wrap the LED pins with electrical tape.

- Connecting lamps in series, as in old Christmas tree garlands, is the simplest solution. The wires, following each other, form an indivisible circuit. Essentially, power is transferred between the diodes. If one of them fails, you will have to go through the entire chain.

- Using clamps, secure the bulbs to the wheel spokes.

- Connect the wires to the batteries. The latter should be placed on the wheel hubs.

- Run a wire from the battery to the steering wheel switch.

Cover exposed areas with additional tape. Problem areas where water can get in should be sealed with sealant. This is how it’s easy to make an electrical circuit to illuminate the wheels of a bicycle. At the last stage, check the functionality.

Combined option

In wet weather, the generator impeller may slip. This can affect the safety of the cyclist, because the lighting practically disappears. A 12V battery can be a good alternative to a dynamo generator. Also, the optimal solution would be a combined option. In this case, you need to install a “battery-generator” relay.

The main thing is to clearly see the road ahead and be visible to other road users. And for this purpose, with the correct installation of all parts, LEDs do an excellent job.

✔ CHARACTERISTICS

Number of LEDs

: 128

Patterns in memory

: 18

Self-programming of new pictures

: Yes

Switch

: manual push-button switch + smart induction

Lamps

: RGB 5050 LED lamp

LED service life

: 100,000 hours

Battery

: 18650 Rechargeable battery (included)

Battery life

: up to 15 hours

Waterproof level

: IPX6

Product length

: 530 x 90 x 50mm

Weight

: 432g

Warranty

: 1 year

Package included:

1 x DIY Programmable Cartoon Style IPX6 Colorful 128-LED Bike Cycling Wheel Light,1 x 18650 Battery, 1 x Battery Charger, 1 x USB Cable, 1 x Bag of Cable Tie, 1 x User Manual

Trailer connection

A car trailer is very important when transporting large cargo. Its stable, uninterrupted operation can be ensured by properly installing the lights. First of all, road safety depends on this. The most popular are seven-pin connectors. The necessary parts are purchased in advance: a socket and plug, a mounting kit, and a power cable.

The Russian scheme looks like this:

- 1 contact is the left turn signal (yellow);

- 2nd contact - refers to the fog lamp;

- 3 outputs to ground;

- Pin 4 is the right turn signal;

- 5 - reserve;

- 6 contact goes to the brake light;

- 7 is responsible for dimensions.

When choosing a socket, special attention is paid to its appearance. There must be a seal on the inside. It provides waterproofing.

If the towing vehicle has LED lights, install a relay box and run a power cable. It must be stranded and have a cross-sectional size greater than 1.5 mm. If the car is inexpensive, you can connect through the rear lights. The socket is attached to a bracket on the towbar.

To properly install a lighting system on a trailer or bicycle, you do not need to buy expensive devices. You can get by with structures you assemble yourself. The main thing is to follow basic safety precautions.

Write comments, additions to the article, maybe I missed something. Take a look at the site map, I will be glad if you find anything else useful on my site.

How to make bicycle wheels illuminated? | Crazy-Riders.ru – Bicycle blog

Published: 06.11.2014 at 11:23 / Sergey Khmaruk

Hello to all blog visitors! Today I continue the topic of bicycle tuning and in this article I want to tell you how to make your own bicycle wheel lighting using LED strip. Using my example, you will learn in detail how to do this correctly and avoid making basic mistakes. So sit back and study this material.

Let's start with a little background. In general, I somehow saw enough videos on YouTube with all sorts of options for illuminating bicycle wheels and got the idea to make something similar for myself.

I had two options: to make lighting using cocktail tubes, which is undoubtedly easier and faster, or to take an LED strip and tinker a lot, but get a more effective result. Without thinking twice, I chose the second option, because...

the level of complexity of the undertaking did not scare me, because I still had the skills to use a soldering iron from my school days.

After watching several videos, I decided to start working, but before that I had to select the material necessary to implement this project. I had to find out how much LED strip would be needed to stick it on one wheel.

Having the data for one wheel (26 inches, 36 spokes), I realized that I would need an LED strip with 120 LEDs per meter, because... the distance between the knitting needles is 4 cm, and this tape has a cutting ratio of just 2.5 cm.

A standard tape with 60 diodes will suit you if your wheel has 32 spokes and the distance between them is 5 cm, this is exactly the cutting ratio of such a tape. Okay, now let's look at what you'll need if you have the same wheels as my bike.

Material required for ONE wheel:

- LED strip SMD 3528 in silicone (120 led/meter) – 1 m.

- Internet cable "twisted pair" - 1 m.

- Battery compartment with crown switch - 1 pc.

- 9 V Krona battery.

- Detachable connection for power supply “mother-father” - 1 pc.

- Plastic ties 25 cm – 3 pcs.

- Silicone sealant (transparent) – 1 tube.

- Glue “Moment” (transparent) – 1 tube.

List of tools for work:

- Soldering iron with a thin tip 25 W.

- Tin and flux.

- Stationery knife, scissors, wire cutters.

Mounting a bicycle light with your own hands

The fastening is a very important element of this accessory, since further operation will depend on the fastening

It is very important that the mount is reliable and allows for the required angle of inclination.

How to make a mount

The fastener manufacturing process consists of the following steps:

1. Preparing the mount itself

The headlight mount can be made from a clamp. This clamp can be made from two staples to hold two inch staples together. Steel brackets with a diameter of 2 mm are most suitable for bicycle handlebars. In order to attach the staples you need to make holes in them.

Making precise holes is very important because correct installation will depend on them. You also need to take into account the fact that they are done at the very edge and one wrong movement and the staples will become unsuitable for further use

2. Base.

As a base, you can use a 3 mm aluminum corner. Then you need to glue a gasket onto it on both sides - this will ensure good stability and the entire structure will not slip. We drill a hole in the corner and screw it to the bicycle handlebar using a 6x32 screw and a nut. After this, it is advisable to file the screw.

How to properly attach a headlight to a bicycle

The final stage of all work is attaching the headlight to the bicycle.

It is carried out as follows:

- The bracket mount is installed on the bicycle handlebar. The lower and upper brackets are installed using gaskets;

- Fastening the headlight and fasteners with a bolt and nut;

- Gluing the threads with special glue and painting.