Master class on making watches with your own hands for interior decoration or for gifts.

Nowadays, electronic watches with luminous numbers are sold at the price of electronic-mechanical watches, but electronic-mechanical watches have the disadvantage that the clock readings are not visible at night.

Let's eliminate this misunderstanding - make a homemade wall clock with backlight. The presence of such watches in stores was not found. You can't buy it - you can just make it yourself.

How to make a backlit clock with your own hands

Step-by-step instructions for making an illuminated watch

1. We buy or make ourselves a round plexiglass blank with a diameter of 240 mm and a hole in the center with a diameter of 9 mm. It is possible to produce blanks of square, rectangular or triangular shape.

- Download the file and print the dial on the printer. File.

- Attach the dial to the workpiece with pieces of tape.

Dial engraving

- And as shown on the website page, we use an engraver to engrave numbers and marking lines on plexiglass. Unlike glass, it is better to use a carbide bur for engraving. If you work carefully, engraving will take 30-40 minutes. You should not try to make the engraved surface very smooth; the more irregularities, the better the numbers will glow.

- For illumination we use either a super-bright LED or an LED that smoothly changes its color. The wider the LED beam angle, the better. It was not possible to buy an LED with color tints in stores. But, such an LED can be extracted from Chinese night lights powered either from the mains or from batteries. The donor for the LED was a trinket for 36 rubles (2013). Look at the photo.

- We solder extension conductors to the removed LED and carefully insulate them.

Chinese donorBack side The desired LEDExtend the conductors

- Using aluminum tape with an adhesive layer (used in ventilation), carefully paste the dial from the end and along the outer edge with such a reflector.

- At the bottom of the dial, using a round file, we make a U-shaped recess that follows the contours of the LED. The edges of the notch should be made as smooth as possible. We will clear the walls of the recess by wiping with cotton swabs soaked in nail polish remover.

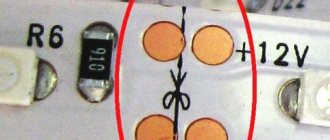

- The LED is powered from an old cell phone charger. Since the operating voltage of the LED is 3.5-4 volts, we will apply the voltage through a resistive divider. After assembling the divider, we check the functionality of the circuit. See photo.

Aluminum tape Covering with reflector Electrical circuit Power supply and divider

- We install the LED in the recess and secure it with transparent tape, and then additionally cover it with aluminum tape.

- The clock mechanism must be selected with either a built-in or overhead bracket for wall mounting.

Install the LED Cover with tape Mechanism with an overhead bracket Mechanism with a built-in hinge

- Tests of the dial showed the difficulty of reading the watch at night - the hands are not visible.

Clock with mirror layer

To do this, a piece of thin plastic with a mirror coating is installed on the back of the dial. With such a reflector, the time could be determined by the reflection of the back sides of the hands.

In the second version, instead of a mirror, slightly crumpled foil was attached and the readings could be read by the shading of the foil. You can also engrave on the free part of the dial. The watch fulfills the role of a night light no worse than the Chinese donor.

When using reflectors at night, the arrows are visible and it is possible to determine the time. Unfortunately, the video does not fully convey the ability to read the arrows.

How to make an illuminated wall clock with your own hands / Crafts Sekretmastera

The clock has been modernized. It was possible to provide power from a 220-volt network, and the standard battery became a backup source for the clock in the event of a power outage. Watch the video.

Illuminated wall clock - finalization of the circuit / Electronic homemade products / Sekretmastera

Another example of working with engraving:

I liked the idea, you can thank the authors!

Source: https://sekret-mastera.ru/masterim/samodelnye-chasy-nochnik.html

Facts about clock lights

Backlights in watches are a necessary component of everyday life; without them it is no longer possible to imagine a modern wristwatch. This is a reality in which the quality of the backlight makes all the difference.

electroluminescent is often found in wristwatches tritium backlighting is also gaining momentum day by day .

Indiglo backlight , introduced by the American company Timex in 1992 , is a perfect example of electroluminescent backlighting . We press a button, electricity is converted into light by applying a voltage of 100-200 volts to phosphorus atoms. Of course, a voltage converter (1:100) plays a role here, without which obtaining even one hundred volts would be impossible. Having received a charge, the phosphorus atoms release photons, which illuminate the dial. “Indiglo” itself comes from the word “Indigo” . indigo color (something between blue and violet) that illuminated the dial of the Ironman . This series of watches was the first in the history of Timex , equipped with Indiglo .

The ubiquitous Japanese corporation Casio could not stand aside, in 1995 responding to the invention of the Americans with the Illuminator . Casio Illuminator backlight is similar in design to the Indiglo . In Japan, the Illuminator is called "Fox Fire" .

Only the hands and markers of an individual dial can be equipped with tritium backlighting , while electroluminescent backlighting illuminates the entire dial. But don’t rush to jump to conclusions!

The use of tritium backlighting in dials is a much more complex process than installing electroluminescent backlighting. Tritium backlight does not require pressing buttons and does not use auxiliary energy sources - be it a watch battery or sunlight. Accordingly, such illumination does not affect the reserve of “vitality” of the watch’s energy carrier.

Tritium does not pose a radiation hazard because it is enclosed in sealed borosilicate glass containers. But even if the watch dial suddenly cracked, and the sealed container with tritium was damaged, then nothing would threaten our health. The containers located on watch dials contain a relatively small amount of tritium, which, if leaked, will have time to escape into the atmosphere without harmful consequences for humans. The most important thing is not to inhale or swallow tritium. Especially when the leak occurred from a large container.

Illumination of the clock on a VAZ car

Needless to say, a watch is a useful thing. But this element of the interior of the VAZ of the tenth family was not ignored by the designers. The fact is that the illumination of the dial is not uniform, only certain parts are illuminated, and the hands are difficult to see. We are studying the question of how you can improve the clock lighting with your own hands . The easiest way to make the backlight of the watch uniform is to replace the light bulbs in the watch with LEDs . If instead of two light bulbs you install LEDs in the standard sockets, the backlight will become more uniform, the result depends more on the diffusion of light from the diodes. You can achieve a better result if you install only one instead of two LEDs and place it in the center. For comparison, the first photo shows the standard clock backlight, the second photo shows the clock backlight with an LED in the center.

Blog@off

Found out, checked, shared.

Repair of backlight in electronic watches.

Option for obtaining springs from Evgenij Chulkov:

“Pin springs are suitable for attaching the strap to the watch. We take two pliers by the ends of the pin and pull it out, one of the two pulls out, there is a spring inside, it is a little longer, but you can remove the excess with pliers.

DIY electronic watch

For those who have at least a little knowledge of microcontrollers and also want to create a simple and useful device for the home, there is nothing better than assembling a digital clock with LED indicators.

Such a thing can decorate your room, or it can be used as a unique handmade gift, from which it will acquire additional value.

The circuit works like a clock and like a thermometer - modes are switched with a button or automatically.

Electrical diagram of a homemade clock with a thermometer

PIC18F25K22 microcontroller takes care of all data processing and timing, and the ULN2803A is responsible for coordinating its outputs with the LED indicator.

DS1302 chip works as a timer of precise second signals, its frequency is stabilized by a standard quartz resonator of 32768 Hz.

This complicates the design somewhat, but you won’t have to constantly adjust and adjust the time, which will inevitably be delayed or rushed if you get by with a random untuned quartz resonator of a few MHz. A watch like this is more of a simple toy than a high-quality, accurate timepiece.

If necessary, temperature sensors can be located far from the main unit - they are connected to it with a three-wire cable. In our case, one temperature sensor is installed in the block, and the other is located outside, on a cable about 50 cm long. When we tried a 5 m cable, it also functioned perfectly.

The clock display is made of four large LED digital indicators. They were originally common cathode, but changed to common anode in the final version.

You can install any others, then simply select current-limiting resistors R1-R7 based on the required brightness.

You could place it on a common board with the electronic part of the watch, but this is much more universal - suddenly you want to put a very large LED indicator so that they can be seen from a long distance. An example of such a design of a street clock is here.

The electronics themselves start at 5V, but to make the LEDs glow brightly you need to use 12V.

From the network, power is supplied through a step-down transformer adapter to the 7805 , which generates a voltage of strictly 5 V.

Pay attention to the small green cylindrical battery - it serves as a backup power source in case the 220 V network is lost. It is not necessary to take it at 5 V - a 3.6 volt lithium-ion or Ni-MH battery is sufficient.

For the case, you can use various materials - wood, plastic, metal, or integrate the entire structure of a homemade watch into a ready-made industrial one, for example, from a multimeter, tuner, radio receiver, and so on. We made it from plexiglass because it is easy to process and allows you to see the insides so that everyone can see - this watch was assembled with your own hands. And, most importantly, it was available