If you want to replace a regular mechanical bicycle bell with an electronic one, you can make such a simple device, the circuit of which is described here. The main advantage of this device is the scanty current consumption with sufficient sound volume.

This is achieved by using a piezoelectric sound emitter from an old push-button telephone as an acoustic element in this circuit. It sounds loud, but consumes little current. And in silent mode, the circuit does not consume anything at all, because power is supplied to it only during a call.

Another advantage is the ability to operate in a very wide range of supply voltages, from 3 to 15V. But the lower the supply voltage, the lower the volume. Optimal, in terms of size and volume, is a 9V power supply from a Krona battery or its equivalent.

Regular motor wheel or geared?

It doesn’t matter whether the electric motor is connected via a chain drive (drives in the carriage) or not (front, rear motor wheel, friction gears), the bicycle speed system will still be involved.

The geared motor wheel allows you to move using a reduced gear ratio. It can help a cyclist climb a very steep hill if used with a motor with a high reduction planetary gearbox. This will cause the motor to operate close to its highest point of efficiency as it will maintain high revs. But still, a motor with a gearbox will lose efficiency, since such systems are complex and some friction costs are inevitable.

It can help a cyclist climb a very steep hill if used with a motor with a high reduction planetary gearbox. In this case, the engine will operate close to its highest point of efficiency, as it will maintain high speeds. But still, a motor with a gearbox will lose efficiency, since such systems are complex and some friction costs are inevitable.

The geared motor wheel allows you to move using a reduced gear ratio. It can help a cyclist climb a very steep hill if used with a motor with a high reduction planetary gearbox. In this case, the engine will operate close to its highest point of efficiency, as it will maintain high speeds. But still, a motor with a gearbox will lose efficiency, since such systems are complex and some friction costs are inevitable.

Geared electric bicycle wheel

Systems without gearboxes do not reduce engine speed. Consequently, the efficiency of the engine in them is not constant, but very often depends on the speed of the bicycle. But such systems are simple, so their total efficiency is higher compared to gear motors.

As you can see, there is a problem of choosing between electric motors with and without gearboxes. On the one hand, the former can maintain the same engine efficiency over a wide range of speeds, while the latter have inevitable losses when the speed decreases. On the other hand, electric motors without gearboxes have a high total efficiency.

However, it is safe to say that in other riding conditions, a motor without a low gear will do a better job (especially on frequent long trips) than an overly complex geared system.

Electric chain drive for electric bicycle

Electric bicycle kit with chain drive

In this case, independently converting a regular bicycle into an electric bicycle will be more labor-intensive. Although this electric drive option is more efficient than a wheel motor. With less weight and power, e-bikes with chain drive accelerate to high speeds.

Those who want to make an electric bicycle with their own hands using this scheme can save a little on components if they can find a suitable electric motor, since they can adapt the engine from any household or automotive equipment. Some craftsmen use electric motors from washing machines, car windshield wipers, and even from electric drills.

There are also DIY kits for converting a bicycle into an electric bicycle. Sets from the Taiwanese company Cyclone have gained great popularity in the world. Their product line includes kits with electric motors from 200 to 1500 W, and a set of two 1.5 kW motors accelerates an electric bike to 120 km/h!!!

Advantages of electric chain drive

- lighter weight of the engine and batteries designed for lower voltage;

- higher top speed;

- the ability to use a bicycle gear shift system, which increases efficiency.

Disadvantages of electric chain drive

- more complex installation of the kit and the need to use special tools;

- noises made by the electric motor and circuit;

Prices for such sets start at $400.

Bicycle call from model designer

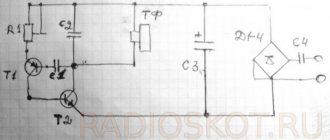

This diagram was published in one of the old issues of the model designer magazine and, despite the outdated element base, it will be very useful for bikers when riding in pedestrian areas, due to the lack of bicycle paths.

When the button is closed, the asymmetrical multivibrator on the first two transistors begins to create low frequency oscillations. They go to a single-stage amplifier built on a compound transistor. At the same moment in time, capacitance C2 is charged from the battery, which, after releasing the button, will continue to power the device circuit. At the same time, the tone of the sound signal increases and the amplitude decreases, reminiscent of the sound of a siren assembled with your own hands. Resistance R3 limits the current consumption and is made from a piece of spiral for an electric stove.

As a sound source, you can use any small-sized dynamic head with a resistance of no more than 10 Ohms, for example, ODGD-6.

Bicycle bell on two chips

One of them is a special chip for building jukeboxes. The chip's memory contains a set of melodies that can be played in any order. There are three such melodies in the UMS7-08 chip.

Types of motor wheels

The principle of the motor-wheel operation turned out to be so successful that it is now used in all formats of electric transport and, by and large, has become the main one, displacing the chain drive. Motor wheels are structurally divided into the following types:

- Geared. Equipped with a special mechanism (gearbox) and coupling that allow you to freely regulate the speed. The main advantage of the design is that they allow the wheel to rotate even in the absence of traction. This type of drive is used with low-power gadgets that are operated in relatively “mild” urban conditions. The low weight of such MKs makes them ideal for children's electric bicycles and scooters.

- Gearless. Such MKs do not have transmission mechanisms; the rotor and stator are directly connected. Thanks to this simplified design, these wheels are more reliable, have better traction and speed, and are able to work with heavy loads without problems for 5 years or more.

Also, when choosing an electric vehicle, you should pay attention to the location of the motor-wheel. It can be front or back. This aspect is especially relevant for bicycles, where proper weight distribution is important due to the high center of gravity.

When the MK is located in the front wheel, the rider will constantly feel discomfort due to the additional load on the hands (it is physically difficult to control) and the reduced maneuverability of the “iron horse”. If you have a bicycle with a wheel electric motor located in the rear, then you can only enjoy the ride

Top articles: Bicycle tire pressure

This aspect is especially relevant for bicycles, where, due to the high center of gravity, correct weight distribution is important. When the MK is located in the front wheel, the rider will constantly feel discomfort due to the additional load on the hands (it is physically difficult to control) and the reduced maneuverability of the “iron horse”. If you have a bicycle with a wheel electric motor located in the rear, then you can only enjoy the ride.

When deciding which wheel motor to choose, be sure to take into account the recommendations listed above, based on the advantages of the design.

Donor

First of all, of course, you need the donor bike itself, that is, the one on the basis of which the electric bike will be built. Some already have it, some don’t, and some simply feel sorry or don’t want to turn their favorite bike into an electric version, and buy a separate bike for these purposes.

There are several important circumstances that determine the possibility of electrifying a bicycle:

Wheel mounting type

If you plan to install a motor wheel, then it is extremely important that there is a QR (Quick release) mount. You cannot install a motor-wheel in a mount of another type - an axial mount (although the guys from Electronbikes have repeatedly solved this problem, but this is quite an expensive proposition). Availability of space in the frame triangle

It often happens that there is a shock absorber in the frame triangle, or the top tube is very low - in this case, installing the battery there will be quite problematic, and sometimes even impossible. The option of installing the battery on the trunk, or even more so on the seatpost, is, in my opinion, extremely undesirable due to a shift in the center of mass and swaying when driving.

Making a bicycle flasher with your own hands

A self-assembled flashing light for a bicycle – isn’t that great? There is no need to buy it, it is not difficult to assemble, there is one drawback - it will not beep, but only shine.

The simplest version of a do-it-yourself bicycle flasher is a two-LED system. Let's take KT 315 transistors as a basis. In addition, you will definitely need:

- the base is a breadboard - we will place all the elements of the circuit on it;

- red and blue LEDs;

- capacitors;

- battery 3.76 V + housing with switch;

- power wires.

From the tools we take out a soldering iron from the cabinet - we will use it to connect the cells on the breadboard. In terms of installing the bicycle flasher on the handlebar, you need a plastic case where the entire electrical circuit and battery can fit.

Electrical circuit and parameters of its elements

At the first stage, it is necessary to mark the elements on the breadboard. This way we will know where and what is located and in what sequence we can then connect it all.

What is what:

- green circles – LEDs;

- red circles – transistors;

- purple – capacitors;

- yellow – resistors;

- Hollow circles are empty holes on the breadboard.

Arrangement of circuit elements based on

Next, we proceed to soldering the empty holes using a soldering iron. In order not to damage the necessary holes, we do everything very carefully.

When all connections are ready, we install all the circuit elements in their places in accordance with the markings. At the last stage, the power wires from the circuit to the battery are soldered.

The bicycle flasher is ready, all that remains is to place it on the bicycle. An excellent option would be a housing from another flasher on red and blue plexiglass. Using a classic mount, it can be installed on the steering wheel.

A significant drawback of a homemade device is the lack of an audible alarm. A powerful bicycle horn will partially solve the problem. However, in order not to install only a flashing light and a beep in addition, it is better to purchase a ready-made solution with sound.

Gear motor (wheel motor) Bafang 500 W

This type of motor has a weight of 4.5 kg and a rated power of 500 W

The operating power of these engines turned out to be 500-1000W. Acceleration time to 35 km/h is approximately 6-7 seconds, the speed depends on the model, and on 26 inch wheels it can be from 28 to 45 km/h. It is important to note that gear motors can be high-speed or traction. A high-speed engine accelerates more slowly, but has a higher top speed. The traction motor accelerates faster, but has a lower top speed. The most popular 500W Bafang models are Bafang CST and SWX08

One model is for a ratchet, and the second is for a cassette. Both models, at the request of the customer, can be made high-speed or traction. For example, below is the data for the Bafang CST/SWX08 model, with a 36V battery. The traction version of the Bafang CST engine accelerates in 5 seconds to 25 km/h, maximum speed is 25 km/h. It pulls better uphill. The high-speed version of the Bafang CST engine accelerates more slowly (9 seconds to 25 km/h), but has a higher maximum speed (35 km/h). It pulls worse uphill than the traction version of the same Bafang gear motor. With a 48V battery, the increase in maximum speed was 8-10km/h, and became 40-45km/h. In practice, we realized that the Bafang 500W traction and speed motors pull more than 200kg and reach their maximum speed. The only difference is acceleration and top speed. Therefore, you can safely buy the middle, compromise option.

The main difference between a 500W Bafang gear motor and a 250W one is that the weight is 2 times greater and the acceleration speed is approximately 2 times faster, and their cruising speed is the same.

Schematic diagram

The diagram can be seen in the figure in the text. The circuit is built around one CMOS chip - K561TL1.

Rice. 1. Schematic diagram of a simple electronic bell for a bicycle.

These are four “2I-NOT” logic elements, like the K561LA7, but with built-in Schmitt triggers. The presence of Schmitt triggers, in this case, allows you to build an RC multivibrator on at least one element (for the K561LA7, at least two).

The sound consists of a fundamental tone with a frequency of about 1500-2000 Hz and an interrupting tone with a frequency of about 8-10 Hz. The pitch generator is made on logic element D1.2. The frequency depends on the C2-R2 circuit and is regulated by selecting resistance R2. The interrupt generator is made on logic element D1.1. The interruption frequency depends on the circuit C1-R1 and is regulated by selecting resistance R1.

From the output of the tone generator, pulses are sent to a bridge amplifier based on logic elements D1.3 and D1.4. They invert pulses. The piezoelectric sound emitter BF1 is connected between the outputs of these elements, and it receives antiphase pulses.

As a result, the actual AC voltage swing across BF1 is doubled. Accordingly, the sound volume is greater.

Electra bicycles - features

The battery charge level affects the driving speed. In cold weather, the battery charge decreases and the mileage decreases, but in warm weather, the opposite is true. Cold air temperatures shorten mileage, while warm air temperatures increase mileage.

The more inflated the tires are, the longer the distance traveled will be. The lower the speed, the further the distance traveled, and the speed also decreases depending on the angle of elevation.

The main advantage of an electric bicycle, as mentioned above, is that you can ride it without much physical effort. This is especially noticeable when going uphill or in the event of a strong headwind.

It is also worth noting that the electric motor on a bicycle can be used both without the help of legs, without rotating the pedals, and in conjunction with muscle power. This combination is very convenient, as it allows you to feel the payload without making excessive efforts to overcome long climbs.

By equipping your bike with an electric wheel, you can enjoy riding at any time of the year, including on snow and off-road. If the battery is completely discharged, you can continue riding as on a regular bike.

Charging the battery is very simple - from a 220 volt home outlet, from 2-3 hours to 8-9 hours. On one charge you can travel 40 - 60 km.

Some of the advantages are also the relatively low cost of an electric bicycle kit (an electric bicycle wheel costs from $150 to $250) and the ease of installation and subsequent operation of all parts of the motor wheel. In addition, electric bikes are an environmentally friendly and virtually silent form of transport.

Despite the fact that electric bicycles reach good speeds of 25 km/h and above, even up to 60 km/h, it is not necessary to obtain documents for the vehicle and the right to drive it from the traffic police.

Flaw. The only significant drawback of the electric bike is its considerable weight. The electric wheel and batteries can weigh up to 20 kg, and the entire bike can weigh up to 50 kg. Due to such a significant weight, the speed of movement is reduced; sometimes it is necessary to additionally use the muscle-pedal mode.

Top Articles: Best Bicycle Brands

And it’s easier to climb a too-steep hill on foot, rolling a bicycle nearby. Among the disadvantages, it can be noted that the batteries, on average, last for 1000 charges and a specialist is needed to fix the breakdown of an electric bicycle wheel.

Thus, by installing an electric wheel on your bike, you can enjoy your ride without much effort!

Details and setup

As for the sound volume, you need to take into account that when operating at the resonance frequency, the piezoelectric sound emitter sounds several times louder. Therefore, when setting up, the selection of the frequency of the tone generator (with resistor R2) should be done not according to the most pleasant, but according to the loudest sound. The cutoff frequency (R1) can be set according to what you think is the most pleasant sound character.

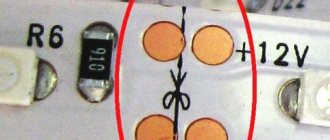

Rice. 2. Printed circuit board for the bicycle bell circuit.

The installation is made on a printed circuit board made of foil fiberglass. The housing is made from a square, waterproof electrical outlet. Its contents (block with contacts) have been removed.

Instead, this board and power supply are installed there, and a piezoelectric sound emitter is installed in the recess for the plug. The S1 micro-toggle button, without locking, is located on the end of the case.

Attaching the engine to the scooter

Another important advantage of the wheel motor is its ease of installation. Its fastening does not cause any difficulties. The drive wheel can be installed either front or rear. The latter option will be convenient for frequent hill climbs. In this case, the drive is carried out by installing a chain transmission, which also requires the presence of a gearbox.

Often on the Internet you can find the request “motor mounting mounts”. Experienced craftsmen suggest assembling a scooter from a bicycle and an engine from a lawn mower. Then you will need to know some features of proper fastening.

The rear wheel is connected to the motor through the bike hub. This will allow you to coast by inertia, accelerating to the desired speed and releasing the gas. This will also help avoid unnecessary fuel consumption and dangerous overheating. There is another way. The torque is transmitted directly to the tire. Although this option is considered unprofessional.

You need to disassemble the rear wheel. It is worth removing the entire carriage and cutting off the spokes. It is necessary to remove the extra stars, because... only one is needed. The wheel should have a larger sprocket, the motor will need a smaller one. The key is to determine the engine speed, otherwise the scooter will be too fast.

To attach the carriage you will have to be patient. It is necessary to make gaskets, bushings and some other parts. Then you need to connect it all.

It is desirable that the lawn mower has a centrifugal clutch. Otherwise, operating the scooter will be inconvenient. Once the engine is activated, it will simply drive away immediately. The engine will operate at idle without any problems. And the movement will begin only after the crankshaft speed increases.

The piece of shaft that goes behind the clutch should be cut off from the engine. Weld the sprocket to the remaining shaft. It needs to be carefully centered. This can be done using a suitable ready-made or homemade bushing.

It is important that the mounts are compatible with the metal frame. Therefore, you should first make a template from wood

You will need to make a new rear fork. Its task is to hold not only the wheel, but also the motor. Steel pipes would be a suitable option. They are cut strictly according to the pattern and carefully welded. It is necessary to make a mount for the engine. To do this you will need a piece of durable steel plate.

In the end, all that remains is to drill a hole for the clutch and four more for installing the engine. The sheet needs to be welded to the rear fork. Now everything should be put together.

Electric bicycle horn

The device runs on standard batteries, which are inserted inside the case. It is installed on the bicycle handlebar - in the middle or on the side, whichever is more convenient. The working part of the electronic device is connected through a wire to a button. It is, in fact, that we set the buzzer into action.

Electric bicycle horn equipment:

- audio machine - a small compact device, no more than 7 cm in length;

- horn mount;

- the wire;

- button;

- button fastening.

The optimal location on the steering wheel is the horn in the middle or closer to the center, the button next to the grip/shifter. This makes it more convenient to press and release it without being distracted from the controls.

Standard Electric Bicycle Horn Kit

Advantages of an electric signal for a bicycle:

- simplest installation;

- excellent audibility, especially on noisy streets (intensity up to 105 dB ─ no joke) - much more effective than a bell;

- compactness;

- universal design: can be installed on both road bugs and cooler bikes.

The disadvantages of this device go side by side with the advantages:

- very sharp sound: harmful to the cyclist himself and unsafe at short distances from other road users;

- unlike a bell or horn, an electric horn breaks easily, and the probability of this happening is almost 100% if it falls;

- Not very reliable plastic fasteners.

And once again briefly on functionality. Electronic signals can be: “beep”, croaking intermittent sound, imitation of a car alarm. And there are also devices that have a whole collection of melodies built into them.

Types of electric bicycle wheels

Manufacturers offer beginners and experienced users bikes that have electric motors instead of conventional wheels. They resemble a large bicycle fork, wired into the wheel rim. The type of electric motor is selected according to the requirements for thrust and speed, and operating conditions. Motors that are installed in the wheel are divided into three types:

- gear;

- direct drive;

- carriage

The selected wheel models must comply with technical parameters (voltage, power, weight, moisture protection, etc.). For example, an electric wheel built into the carriage allows simultaneous rotation of the pedals.

The simple direct drive design consists of no auxiliary transmission parts; generates energy supplied to the electric bicycle battery; When braking, it operates in generator mode.

Geared

The main companies producing bicycle motors are located in China. The ranking of the best manufacturers includes the brands Bafang, MXUS, Golden Motor, Pasion eBike. Features of geared electric wheels:

- The light motor does not interfere with pedaling.

- The cyclist freely overcomes sharp climbs.

- The electric motor together with the planetary gear is installed in the wheel hub.

- The gears are made of plastic.

- An overrunning clutch is installed that transmits torque in only one direction (from the engine).

- When the gear is reversed, the electric motor is switched off and does not interfere with the rotation of the wheel.

Geared electric wheels come in two types. Speed cars reach their maximum performance with slow acceleration. Traction wheels are the opposite.

For example, the lightest Bafang bicycles (motor weight 2 kg) operate in 350-500W mode. The bike accelerates to 35 km/h in 10 seconds. The MAC bicycle wheel, designed to order from the Americans, weighs 4.4 kg. With a power of 1000W, the bike reaches speeds of up to 55 km/h.

Advantages and disadvantages

The positive characteristics of geared motor wheels include:

- better efficiency over a large speed range;

- light weight and size;

- free roll;

- low energy consumption;

- easy climbing;

- there is no resistance to movement when pedaling.

Minuses:

- the standard configuration does not allow you to develop high speed or obtain power of more than 1000W;

- insufficient reliability of the wheel motor;

- plastic gears whose teeth can be easily cut off;

- If the overrunning clutch is damaged, you will have to work only with the pedals.

Direct drive

A motor of this type can be easily installed on a wheel, turning an ordinary bike into an electric one. Expensive models are produced with built-in engines with a complete set. The direct drive motor wheel does not have a gear transmission and is characterized by an increased service life compared to other types. A simple device consisting of a rotor and a stator is installed on the front, rear or both wheels at the same time. Power is used to achieve high speeds. The indicator is related to the type of MK and battery, and has a range from 150 to 2000 W. For example, the dynamics of a 1500W electric motor are compared to a scooter. The wheel motor quickly accelerates to a speed of 50km/h, which is 50% faster than a 1000W motor. Hall sensors are installed on all models.

Top articles: Electrical bike conversion kits

Advantages and disadvantages

Pros of the wheel motor:

- simplified design;

- easy installation;

- discreet position on the bike;

- silent operation;

- increased efficiency;

- the ability to accelerate to 60 km/h on a flat road;

- reliable design does not require maintenance.

Disadvantages of MK:

- large weight (up to 6 kg and above) and size of the wheel motor;

- if at least one of the three sensors breaks down, the wheel motor stops working;

- poor efficiency at low speeds and when climbing;

- using a weak controller and charger reduces engine power;

- there is resistance to movement.

Device

There are three types of bicycle bells and they differ not only in the device, but also in the sound level.

Mechanical type. Surely everyone remembers this ringing “ding-ding” from childhood. A round steel base with a tongue, when we pulled it we heard a characteristic sound. Inside the device there is a hammer that hits the body, thereby ringing. An excellent and low-budget option for cycling on the sidewalks. However, on a highway such a sound signal is barely audible.

Klaxon. Also a kind of “hello” from the past. A pipe with a pear at the end, which, when pressed, produces a drawn-out and “quacking” beep. Ideal for rare low-speed bikes. For more modern bicycles, a pneumatic horn was developed. The principle of operation is the same, but inside there is a container with compressed air.

Such a call can produce up to 100 dB, which is similar to the whistle of a locomotive!

Electronic call. A modern portable device that allows you to give signals to drivers and pedestrians with different sound levels - it will delight cycling enthusiasts with a variety of melodies.

What voltage should I choose for the wheel motor of an electric bicycle?

When assembling an electric bicycle or other types of personal electric transport, you need to decide on the characteristics that suit you. The motor is selected depending on how much power the electric bike needs, taking into account the required speed and traction qualities. When choosing a battery, its capacity, voltage and weight play a primary role. As the battery capacity increases, so does its weight and range on a single charge. The voltage of an electric bicycle can be different - 36, 48, 60, 72, 96 V. We will tell you further what it affects and how not to make a mistake with your choice.

Electric bike battery voltage

The stored energy is equal to the product of power and time: E=W·t. Its unit of measurement is joule or watt-hour. Since the power of electric current is the product of current and voltage (W=I·U), then E=I·U·t. The product I·t is the capacitance (C). This means that the stored energy of the battery is equal to the product of voltage and capacity: E=U·C.

Conclusion: To increase the value of stored energy, you need to either increase the capacity of the electric bicycle battery, or choose a battery with a higher voltage. The main thing is that the voltage of all components, including the electric motor, battery, controller and charger, is the same.

The most common components on sale are 36 and 48 V. Other components are less common, which can become a problem when replacing them later. Also, when using higher voltage components, larger cross-section wires and powerful BMS boards are needed. As current increases, the load on the electronics increases. Therefore, you need to choose elements with a power reserve to avoid their frequent burnout.

Electric bike battery power and capacity

For internal combustion engines, the main characteristic that determines the driving force is horsepower. This parameter is responsible for acceleration and ensures driving at a given speed. For electric vehicles, power is measured in watts (W). To convert to horsepower, you need to divide kW by 0.736, i.e. 10 kW≈13.6 hp

Electrical power (designation - W, unit of measurement - W) is defined as the product of current (I, measured in A) and voltage (U, measured in V). We get the formula: W= I·U.

For example, if an electric motor with a rated power of 1000 W is supplied with a voltage of 48 V from a battery through the controller, and the BMS board and controller support a current of 35 A, we obtain the value of the output power: 48 V x 35 A = 1680 W. As a result, an electric motor with a rated power of 1000 W produces 1600 W

It is important to take into account that additional losses occur in the controller, and the wiring and phase wires must have a sufficient cross-section to support large current values

The battery capacity of an electric bicycle is the accumulated energy on which the mileage depends. Its unit of measurement is watt-hour (ampere-hour). Formula: C=U·I·t, where C is capacitance, U is voltage, I is current, t is time. Chemical energy of the battery E=U·C. For example, a battery with an operating voltage of 48 V and a capacity of 12 Ah has a chemical energy reserve of 48·12 = 576 Wh. It is enough for 1 hour of operation of a 500 W electric motor.

Recommendations for choosing battery voltage

36 or 48 V components provide a high level of electrical safety. They are indispensable when creating electric vehicles for children and teenagers. Such components are also suitable for most electric bicycles for adult riders. If the power of the electric motor used does not exceed 5 kW, the optimal voltage is considered to be 48 V. Components of a different voltage can be used if there is a BMS, a controller and a charger with a high current for the required voltage.

It makes sense to use higher voltage electrical components when you need a powerful e-bike that reaches speeds of over 50 km/h. In such cases, a powerful wheel motor, a battery of 60 V or higher, and a controller with the same operating voltage are used. As the voltage of electrical components increases, the maximum speed also increases. How much it will increase depends on the power of the electric motor and the load experienced by the vehicle.

There is a simple rule - choose a voltage of the same value as the desired speed. For example, to get an e-bike with a maximum speed of 50–60 km/h, you need to use a wheel motor (power 1500–2000 W), an energy-intensive battery and a controller with an operating voltage of 60 V. You also need to compare the capacity of the electric bike and the driving distance on one charge (with reserve). The controller power should not exceed the permissible load for the electric motor