Can a homemade air cooler become an alternative to modern split systems? After all, refrigeration machines that create a comfortable microclimate in the house cost a lot of money along with installation and are not affordable for everyone. Therefore, home craftsmen are trying to solve the problem cheaply and cheerfully, coming up with all sorts of cooling installations. Our goal is to consider all design options, select the most viable ones and tell you how to make a working air conditioner with your own hands for your home or car. And in order to assess the complexity of the task, we suggest first analyzing...

Operating principle of a household split system

An air conditioner is a complex household appliance that operates on the principle of transferring heat from one place to another: in the summer - from the apartment to the street, in the winter - from the environment to the house. To move heat, an interesting substance is used - freon, which can boil and turn into gas at negative temperatures.

For reference. Freon circulating in the circuits of refrigeration machines is called a refrigerant or working fluid. The key point is its evaporation and condensation, during which thermal energy is respectively absorbed and released in large quantities.

Traditional units consist of 2 blocks - external and internal.

The home split system works according to a cyclic algorithm:

- First, the refrigerant in a liquid state enters the heat exchanger of the internal air conditioner module (evaporator), which is blown by a centrifugal fan. This is where freon evaporates, causing the flow of room air to cool sharply.

- The gas then flows through a copper tube into a compressor, which raises its pressure to a certain value. The task is to force the working fluid to condense outside, where the air temperature is even higher than indoors.

- After the compressor, gaseous freon passes through the radiator of the external unit (condenser). A large axial fan forces air flow through its fins, and the refrigerant turns into a liquid phase again, releasing the room heat outside.

- At the last stage, the pressure of the liquid working fluid is reduced by passing through the expansion (throttle) valve. Now the freon is again ready to absorb heat and moves into the indoor unit, the cycle repeats again.

Diagram of the factory air conditioner

Note. During operation, a lot of condensate appears on both heat exchangers and must be discharged to the street or to the sewer. In order for the split system to switch to heating the house, freon is started in the opposite direction, and the radiators are functionally swapped.

An electronic control unit (ECU), which receives signals from various sensors, is responsible for maintaining the room air temperature and refrigerant pressure in the system. A car air conditioner operates on the same principle: the evaporator is built into the interior ventilation system, and the condenser is installed near the standard radiator of the cooling system.

Now you understand that making an evaporative air conditioner yourself at home is not as easy as it might seem. But for a car this is even more difficult to implement; here you need to be a master refrigerator. As an example, we suggest watching a video where such a specialist installed a household split system in his VAZ 2104 car:

Next, let's look at the air conditioner designs invented by craftsmen and highlight the most efficient devices that can be recommended for production.

Fan + plastic container. Option 2

- cooler;

- plastic containers (three two-liter and three half-liter);

- foam tape.

Manufacturing:

- For two-liter containers you need to cut off the bottom and drill holes inside. In one case - from below, in the other - from the side.

- Wrap the cooler with foam tape (for fixation and vibration absorption).

- Place the mechanism between the cut parts so that at the bottom there is the bottom of the bottle with side holes.

- Remove the bottom from two container lids.

- Inside two half-liter bottles, make holes on the side with a diameter equal to the neck.

- Insert the neck of a large container inside the side hole of a small one, secure it inside with a cut-off lid (you can use a long knife or other tool).

- Fix the second, small one with the first in a similar way. Now the small bottles can rotate perpendicular to their bases.

- Attach a third half-liter container with ice to the plastic box with the cooler.

- Cover the whole thing with a two-liter bottle with two small ones attached.

Improvised homemade air conditioner made from plastic bottles is ready for use. The air flow is regulated by rotating half-liter containers in two directions. It will be useful for a small room, for individual use.

Repair of household air conditioners. Can it be avoided? >>>

Simple homemade air conditioner

The principle of operation of such coolers is to blow room air through objects with a negative temperature. This capacity is usually served by ice or cold accumulators intended for special bags used for summer transportation of products.

Cold sources are placed inside a closed box, and an axial fan is built into its wall. On the other side, a hole is made to allow the cooled flow to exit. What is not used to make the case:

- an old car refrigerator with insulated walls;

- capacious plastic bottles designed for 5 liters of water or more;

- cardboard or plastic boxes with lids;

- canisters made of polymer materials.

This is what a simple cooler design looks like

Note. The air supply is provided by any small-sized fan, for example, a computer cooler.

This mini-air conditioner is also suitable for cooling the car interior; you just need to correctly connect the air blower to the on-board power supply and stock up on the required amount of ice in advance.

Advantages and disadvantages of the design

It is noteworthy that such devices actually drive cold air flow into the room. In addition, simple air conditioners are actually made from scrap materials, whose price tends to zero. The most you will have to spend on is an axial fan if you don’t have one in your household.

Installing and connecting the device in the car

Unfortunately, the disadvantages cancel out all the advantages of the cooler:

- No matter how much ice you put in the chamber, in hot weather it won’t last long, so you need to constantly freeze new water.

- While you are cooling one room, the next room is being heated by the refrigerator, where ice is being prepared. Plus, energy consumption increases.

- The duration of operation of the unit in the car depends on the supply of ice taken with you.

- The air passing through the ice is partially humidified. After some time, the room will become oversaturated with moisture, making you feel even worse than from exposure to heat.

Advice. Over-watering can be avoided if, instead of ice, you use cold accumulators that do not melt and do not turn into water. And to control and maintain optimal moisture levels, there are other household appliances.

Conclusion. The above-described air conditioners, made by yourself, can be considered operational. They can help you out in a hopeless situation, but operating the cooler is quite a troublesome task.

Types of cold accumulators

How long will the ice in the chamber last?

To answer this question, let’s calculate how much cold 1 kg of ice will release when heated from a freezing temperature of -6 °C to +20 °C. To do this, we will use the formula for calculating heat depending on heat capacity.

You need to perform 4 steps:

- We calculate the return of cold when ice melts: Q = 1 kg x 2.06 kJ/kg °C x (0 °C - 6 °C) = -12.36 kJ.

- We find the reference value of the energy released when ice melts - 335 kJ.

- We calculate how much cold the water will transfer when heated: Q = 1 kg x 4.187 kJ/kg °C x (0 °C - 20 °C) = -83.74 kJ.

- We add up the results and get -431.1 kJ or 119.75 W.

Note. The results of cold calculations in physics are also obtained with a minus sign, this is natural.

Even if you freeze ice to a temperature of minus 15 °C, you are unlikely to get more than 150 W of cold from 1 kg. This means that to intensively cool a 3 x 3 m room in heat over 30 degrees, you will have to add 1 kg of ice to your homemade air conditioner every 20-30 minutes and freeze the same amount. In practice, the consumption will be less if you are satisfied with a tolerable air temperature - 25-28 ° C.

How to assemble an air cooler

A mini air conditioner for a home or car is made as follows:

- Cut a hole in the side wall of the container equal in size to the working cross-section of the fan.

- Screw the cooler with self-tapping screws or place it on small bolts.

- Make a second hole to allow the cooled stream to exit. Another option is to attach a corrugated plastic tube to the neck of the bottle or canister. The device is ready.

Advice. From an operational point of view, it is better to use a box with a removable lid, since it is more convenient to load ice or cold accumulators into it.

All that remains is to install and connect the improvised car air conditioner. The wires from the cooler can be connected to the cigarette lighter connector, which has a powerful fuse in the circuit. The manufacturing and connection process is shown in detail in the video:

Simplified designs for the home

One of these designs is a water heat exchanger combined with a conventional floor fan. To make such a primitive cooler, you need to take a copper tube and roll it into a spiral, attaching it to the fan protective grille. For installation, you can use plastic clamps used to secure wiring in cars. The ends of the tube are connected to the water supply, and the fan is connected to the network.

The copper tube is attached directly to the fan grille

Note. The described design is ineffective because the tap water is not cold enough and the usable area of the copper heat exchanger is too small. The air flow from the impeller will cool slightly and nothing more.

Bottled air conditioner is placed in the window opening

The original design was invented in one of the African countries, where it is traditionally hot and, in addition, there is no electricity supply. The device works based on a law of physics that states that the temperature of a gas passing through a sudden contraction and expansion drops by several degrees (up to 5 ° C). The neck of the same plastic bottle acts as such a narrowing, and to get more cooled air, you need to use a dozen of these necks.

To make it you need to drill through the plywood and cut the bottles

A non-volatile air conditioner is done like this:

- Cut a piece of plywood or fiberboard the size of the window opening to be opened. Check how many bottles can be placed on it close to each other.

- Cut off the necks of all bottles and twist the caps. Then place them on a sheet of plywood and mark the centers of the holes with a pencil.

- Make holes with a core drill whose diameter matches the neck. Insert the cut bottles into them.

- Attach plywood to the outside of the window opening so that the bottles stick out into the street.

Assembly is simple - bottles are inserted into the holes

The device is suitable for a country house where other options cannot be used due to lack of the required amount of water or power outages.

Water cooling unit

The idea is simple and at the same time effective: cold water is pumped through a heat exchanger with a fan located indoors. Since its temperature lies in the range of 5-10 ° C, the air flow cools and the room becomes cooler. The source of water is a well or borehole, and the heat exchanger is a radiator from a car or an old air conditioner.

Important note. Unlike other home-made units, a water installation operates on the principle of a heater and can not only cool the air in the house, but also heat it. It all depends on the temperature of the water supplied inside the radiator.

An original idea is to insert a radiator with a fan into the case from an old TV.

The flow cooling system consists of 3 elements:

- the heat exchanger itself;

- submersible or well pump;

- insulated water supply and discharge pipelines.

Manufacturing of water conditioner

The cooler assembly procedure is as follows:

- Place and secure the car radiator in a convenient place in the room.

- Lay a supply and return line to it. To connect to the element pipes, use adapters and clamps.

- Mount the pump in a well or borehole and connect the coolant supply pipeline to the heat exchanger to it.

- Insulate the section of the supply pipe so that the water does not heat up ahead of time. It is not necessary to insulate the return line.

You can use a car heater radiator for the cooler.

To make a water conditioner and run it successfully, you need to solve 2 problems: where to put the water and how to regulate its flow rate, because the pump’s performance usually exceeds the need. We propose to solve the problem of water discharge in the following ways:

- collect in a storage container from where the garden is watered;

- transfer to another well, as a water-to-water heat pump does;

- organize a closed circulation loop with a second heat exchanger submerged at the bottom of the well.

Water circulation can be organized according to a heat pump scheme

For reference. It is not recommended to water cultivated plants with cold water. Therefore, you will kill two birds with one stone if you first heat the well water in a radiator - an air cooler.

To reduce the pump's performance, you need to control the engine speed, which is impossible without a frequency converter (aka inverter), which will cost you a pretty penny. All sorts of autotransformers and other ideas are not suitable - so you simply “put down” the electric motor of the pumping unit. Without purchasing expensive equipment, the issue can be resolved as follows:

- for a well up to 10 m deep, you can use a circulation pump for heating of the appropriate power;

- You can limit the flow of water to the radiator using a bypass valve that discharges part of it back into the well. An example of the operation of a water conditioner is shown in the next video:

Pros and cons of a flow system

Briefly about the positive aspects:

- The air conditioner is capable of both heating and cooling the room;

- the design is simple compared to a factory split system;

- even if you have to buy a pump and pipes, the manufacturing costs will be low.

We have already listed some of the negative aspects and ways to eliminate them - difficulties in regulating the supply and the problem of water discharge. There is another drawback: the system cannot be used in an apartment (there is no source of cold water) or in a car for obvious reasons.

For reference. The simplest version of a cooler can still be installed in an apartment. It is a household fan, on whose grille there is a coil made of a copper tube through which water flows. The only question is where to get such cold water and how much to pay for it according to the meter, if you take it from a water tap.

Conclusion. A homemade air conditioner - a water heater - is a completely viable design. If you wish, you can make a decent cooler for a private house, provided that there is a well on the site with groundwater of an acceptable temperature.

Required materials and tools

For the simplest air conditioner that anyone can assemble in a car, let’s consider a cooler made from a domestic heating radiator (a standard radiator for a stove will do). To assemble a fully functioning air conditioner you will need the following materials:

- a container from an old thermal bag or refrigerator;

- stove radiator from classic VAZ models;

- so-called “bilge” pump for bleeding;

- ties and other fastening elements for all air conditioning lines;

- computer cooling coolers;

- wire with a USB plug for connecting the assembled cooler to the cigarette lighter.

To collect all materials and devices into a single whole, a standard set of tools consisting of pliers, keys, scissors, electrical tape and a marker is suitable. Such a modest set of tools will be quite enough to assemble a working air conditioner. Next, we will consider the step-by-step process of assembling the interior cooler.

Is it possible to make an air conditioner from an old refrigerator?

An absolutely utopian idea. All materials published on the Russian-language Internet describe the same video, where a man tries to build a freezer for mushrooms from two refrigerators. Moreover, the result of this action is unknown, because the video material is incomplete. Let's imagine what it should look like:

- Both heat exchangers are carefully cut out of the refrigerator without disconnecting from the compressor, otherwise the freon will evaporate and you will have to pay for refilling.

- The compressor with condenser is taken outside the room, and the evaporator (former freezer) is installed in the room. You need to attach a fan to it for ventilation.

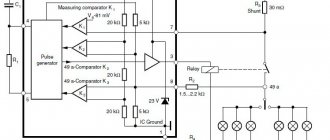

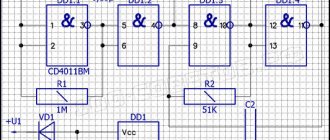

- The standard sensor and control unit, configured for a compressor shutdown temperature of minus 3-6 ° C, will have to be discarded and replaced with other elements, connecting the units via a relay. Otherwise, the compressor will never stop and will break down after 100-200 hours of continuous operation.

Organization of room cooling using two refrigerators built into the wall.

The results of the work are unknown. Let's discard all the technical subtleties (not the same operating mode, different brand of freon, etc.) and imagine that you managed to assemble this circuit. The maximum refrigerating power of such units is no more than 400 W or 0.4 kW. A rough calculation shows that this is enough for a room of 4 m². This is in theory, but in practice it will be even less.

Conclusion. If you belong to the noble tribe of enthusiasts and experimenters, you can try to make an air conditioner out of a refrigerator. But you will spend much more labor than you get cold weather.

Using cardboard box

The basis of this cooling system is a regular fan and ice. In this case, everything used during the installation process can be easily returned to its original position without any damage.

In the process of manufacturing a home split system, you will need the following parts:

- Box made of thick cardboard. Its dimensions should easily accommodate a large pan;

- Aluminum pan;

- Table fan;

- Scotch;

- Needle and thick thread;

- Sharp knife;

- Ruler;

- Simple pencil;

- Pieces of ice.

- At the first stage, a structure is built from the prepared box that will correspond to the size of the pan. To do this, cut the box with a knife, cut out its bottom and lid (they should be equal to the diameter of the pan);

- The box can be reassembled; to do this, it is assembled in the cut places and treated with glue in several layers;

- From the remaining part of the cardboard you need to cut out a square box lid;

- A circle should be marked in its center; its diameter should be 3 cm larger than the span of the impeller of the table fan;

- The cut circle needs to be set aside; the rest of the sheet will need to be covered with the prepared structure;

- The entire box must be carefully sealed with tape or glue so that the structure does not collapse during operation;

- You will also have to seal small holes if there were any on the side walls of the box (for example, for fingers);

- On one side of the box, cut a rectangular hole 10 cm long and 4 cm wide. It is from this rectangle that cool air will flow into the room;

- Now you will need to cut two identical strips from the remaining cardboard, their length should be 3 mm less than the cutout on the box, and their width should be 5-6 mm larger;

- Connect two rectangles together using a large needle and stiff, dense threads (all corners of the cardboards should be connected with threads, but so that they can be separated by 4 cm from each other);

- Insert the connected cardboards into the cut-out side opening of the structure. Each of them should fit snugly into the top or bottom of the cut hole;

- Using the same large needle and thick threads, sew the cardboards located opposite each other to the structure itself. In this case, there is no need to tighten the threads; they are secured with knots;

- Lay a thick piece of cloth on the floor and place a pan on it;

- Remove the front mesh from the fan and place it on the pan;

- Place large pieces of ice on the grid. You can freeze it in medium-sized plastic cups. To operate a home air conditioner you will need 5-6 pieces;

- Cover the ice structure with the prepared box;

- Insert a fan into the cut-out space located on the lid of the structure so that its impellers point toward the floor (at the pan with the mesh and ice);

- Turn on the fan and start any cooling mode on it.

This design can cool a living space for up to 2-3 hours. After this, the ice will melt and the pan will fill with water. Owners will need to ensure timely replacement of water. Otherwise, the fan may fall into the structure and get into the water. This will cause a short circuit.

Cooling using Peltier elements

The use of these parts to assemble a homemade air conditioner is a controversial issue. It's all about the energy consumption of Peltier elements (otherwise known as thermoelectric converters), which is incomparable with the amount of cold produced. Outwardly, they look like plates with 2 wires; when electricity is connected, one surface of the element generates heat, and the other - cold.

What do home craftsmen and car enthusiasts who strive for comfort do:

- Buy from 4 to 8 Peltier elements and mount them with the “hot” side on a ribbed aluminum radiator.

- This radiator is installed in such a way that it is cooled by street air.

- A cooler from the computer is attached to the “cold” side of the converters so that it supplies room air to the plate.

Air cooling circuit using a Peltier converter

Note. For better heat transfer, the element is coated with thermal paste (“hot” edge) before installation on the radiator.

Peltier elements actually cool the air flow, but at the same time they simply consume electricity. After all, half of the energy is wasted because it is converted into heat and dissipated in the atmosphere. That is, for every Watt of electricity expended you will receive no more than 0.5 W of cold, while with a split system this ratio is completely different – 1:3. You can see how this works in practice in the next video:

Fan + plastic container. Option 1

The most common option for constructing an air conditioner from improvised means is a combination of a ventilation mechanism and plastic bottles with cold water or ice. You will need:

- ventilation mechanism;

- plastic or other containers;

- ice/chilled water.

Action plan:

- The container is filled with cold water and frozen.

- Cooled, mounted to the fan grille or placed in front of it. It is imperative to leave gaps of 1-2 cm for circulation and cooling of the air flow.

- Consider a way to collect condensation that will definitely appear.

The water needs to be changed periodically. You can make two sets at once, cooling them alternately.

How profitable is using a heat pump?

Theoretically, any person has a large choice of energy sources. In addition to natural gas, electricity, coal, it is also wind, sun, temperature difference between land and air, land and water.

In practice, the choice is limited, because it all depends on the cost of the equipment and its maintenance, as well as the stability of operation and the payback period of the installations.

Each energy source has both advantages and serious disadvantages that limit its use.

Installing a heating system with a heat pump is beneficial from the point of view of ease of use. During operation of the equipment there is no noise, no foreign odors, no installation of chimneys or other auxiliary structures is required.

The system is energy dependent, but the heat pump requires a minimal amount of electricity to operate.

A heat pump is a good alternative to conventional heating systems. To reduce the initial cost of equipment, you can assemble it yourself

Thermal installations themselves are extremely economical and require little maintenance, but their initial cost is very high.

Not every home or cottage owner can afford to purchase such expensive equipment. If you assemble it yourself and use parts from an old refrigerator, you can save a lot.

Industrial heat pumps are expensive. It is believed that their installation pays off in an average of 5-7 years of operation, but this period depends on the initial price of the structure and can be much longerHomemade installations cost literally pennies, and their use allows you to save significantly.

The only caveat: the productivity of homemade products is low, and they cannot be a full replacement for traditional heating systems. Therefore, they are often used as additional or alternative heating options.