In recent years, the installation of electrical equipment for space heating has become popular among the population. This is due to saving money on natural energy resources. But the installation of such equipment requires significant material investments, so many home craftsmen are interested in how to make an electric boiler with their own hands.

You can make such an electric boiler yourself

Features and application of electric boilers

The reliability of electric heaters can be explained simply - they have no mechanical components, so in principle there is nothing to break. The design is complemented by temperature regulators, which allows you to quickly set the devices to warm-up mode - reduce or increase power depending on the weather outside the window.

As for efficiency, a properly made homemade electric boiler can heat rooms of 30 m3 in just 4 kW/day. This is a very good and low indicator. Another way to save money is to install two-tariff meters and put equipment into operation at night, when the price of energy is much lower.

A little about the advantages:

- No harmful emissions. Electrical appliances do not emit gas, combustion products or other toxic substances, so there are no restrictions on the installation area.

- To form a heating network you will not have to obtain permission. The only thing that is required is the presence of a powerful electrical network or wiring of a separate power cable from the panel.

- Versatility. Depending on the power and performance indicators, the units are used as the main or backup heat source.

- Compactness. On average, a boiler powered from a 220 V outlet and weighing up to 22 kg can easily warm a room up to 400 m3.

The disadvantages are that the device is completely dependent on energy – if there is a power outage, the equipment will not start working. But this drawback is offset by the presence of a generator.

Where can I buy

You can purchase a water heater as quickly as possible at your nearest specialty store. A good option in terms of price-quality ratio is purchasing from the AliExpress online store. Mandatory long waits for parcels from China are a thing of the past, because now many goods are in intermediate warehouses in destination countries: for example, when ordering, you can select the “Delivery from the Russian Federation” option:

| HYUNDAI Instant Electric Water Heater | Electric water heater TINTON LIFE with temperature display | Stainless steel liquefied water heater |

| 2500W floating electric water heater, for bath, swimming pool | RX-21.3500W instantaneous electric water heater | Kitchen electric water heater HYUNDAI |

Main structural elements

In general, an electric boiler consists of the following components:

- Heat exchanger: This is a reservoir connected to the heating system in which the working medium flowing through it receives thermal energy.

- Heater: An element in a heat exchanger in which electrical energy is converted into thermal energy through resistance.

- Electrical circuit: a set of parts due to which electric current appears in the heater.

- Automation unit: monitors the temperature of the coolant using sensors and, if necessary, turns on or off the electric boiler.

All of the above is placed in a steel box with thermal insulation - the housing.

Difficulties during construction

The design of an electric boiler is simple and mistakes are difficult to make. The main thing is to choose a whole heating element that will be the size of the body. All welded joints must be performed by a professional, otherwise leaks may occur.

It is better to seal the joints with flax tow and a special paste. Winding a lot of flax can damage the joints.

For safe operation of the boiler, a limit thermostat is built into the system - when the coolant temperature reaches a high temperature, this device turns off the heating element.

For more efficient operation, the electric boiler is thermally insulated by placing it in an insulated foam casing.

Connecting the device to the heating system

Installation of the boiler is accompanied by its reliable fixation to the wall. Heating element devices should be suspended at a level of 1.5 m from the floor surface or more. If we are talking about the other two types of equipment, then they can be installed lower, as far as it will be convenient for tying. The last two types of heat generators are installed vertically.

Connecting a heating element boiler with a circulation pump and automatic safety system to the heating system is very simple. The outlet pipes must be connected to the pipelines using a ball valve, which is supplied with American fittings for convenience. A membrane expansion tank is connected to the return line, and a mesh filter, also called a mud filter, is installed on it. For easy cleaning, an additional ball valve should be installed in front of the mud trap. This will eliminate the need to empty the entire system.

Design

In essence, a homemade electric boiler is a piece of pipe with built-in electrical accessories. This is very convenient, especially if you make the unit removable: then the care and maintenance of the equipment will be significantly simplified.

If you place the unit not in a pipe, but in a separate housing, you can install additional sensors that will automate the operation of the heating system, increase efficiency and reduce energy consumption. In addition, when you need to replace the boiler with another one, this can be done without violating the integrity of the system circuit.

List of necessary tools and stages of installation work

So, for high-quality installation you will need:

- hardware for mounting the boiler on the wall and mounting plate;

- diagram of the correct installation of an electric boiler;

- drill for mounting holes;

- pipes, flanges and couplings that meet the design parameters;

- cable with the required cross-section;

- instructions for the device you are going to install.

Having collected all the necessary tools, you can begin installation.

First make sure that the wall material can support the weight of the boiler. The location is selected so that there is some space on the sides and top of the device. This is necessary to ensure further access to the device if repair work is necessary.

Usually the required distance is specified in the instructions supplied with the heating boiler. The equipment, in turn, must be placed on the wall without any distortions, which is very easy to check using a building level.

A mandatory requirement is the material from which the wall is made. It must be non-flammable. To ensure the correct positioning of the device, a special mounting plate is used. Absolutely all pipelines connected to it must be calculated based on the characteristics of the pump.

There should not be any particular difficulties during the installation process.

However, pay attention to possible nuances. For example, devices with low power can operate from 220 V, but for more powerful analogues it is necessary to connect to a three-phase network

It is very important to correctly calculate the cable cross-section. This is necessary so that it can withstand the power of the unit and pass a current of a certain amount

After installing the boiler, pipelines are connected to it.

Safety regulations

When carrying out installation work, it is necessary to comply with safety requirements. Violations can cause damage to the installation and a short circuit. Errors can cause ignition during the startup phase of the device.

Laying the power cable of the device requires disconnecting the voltage to prevent electric shock. Electrical equipment used to heat a room must be grounded.

When connecting, it is necessary to lay new wiring with a cross-section corresponding to the power consumption. The equipment must be mounted on a substrate made of non-combustible material.

Air conditioners

An air conditioner is often perceived as a device for cooling air.

It is important to understand that any such device is a type of heat pump operating on an air-to-air cycle. If you start it for heating, it demonstrates no less efficiency than similar direct heating equipment

The ratio of thermal power to consumed energy for modern inverter air conditioners is in the range of 3.6 - 5.

Heating functions can be effectively performed at a lower operating temperature of -25 degrees. In regions located in central Russia, air conditioners often serve as an auxiliary heat source, regardless of the time of year. Installation of equipment can be carried out either independently or by numerous companies. The most convenient in this regard are considered to be window models, the installation location of which is often an open sash.

Electric boiler installation

It is possible to organize heating of a private house with an electric boiler yourself! Installation of an electric boiler, compared to gas or solid fuel boilers, is quite simple. But you must strictly follow all the rules and requirements.

- There is no need to allocate a special room for the equipment. Due to their minimal dimensions, most electric boilers can be installed anywhere. And the modern design of the equipment can fit perfectly into any room interior. If you wish, you can hide the boiler in a special niche.

- Special ventilation systems or chimneys may not be used. This equipment does not create waste that threatens human life and needs to be disposed of.

- Connecting the equipment is easy.

- The heating scheme with an electric boiler is quite simple, so the installation and connection of this type of heating does not require approval and approval from the relevant authorities. Also, in the future, systematic checks, which often bring discomfort and conflicts, will not be carried out.

Heating a private home with an electric boiler is an innovation, but it is gaining popularity every year. Thanks to the availability of various modifications of equipment for heating with electricity, you can find a suitable option for a particular structure. Before purchasing equipment, each home owner needs to calculate the power of the electric boiler for a specific room, taking into account all heat losses. Therefore, you should worry about insulating the building in advance. This will avoid troubles associated with the heating system.

11 Weird Signs That You're Good in Bed Do you also want to believe that you please your romantic partner in bed? At least you don't want to blush and apologize.

10 mysterious photographs that will shock Long before the advent of the Internet and the masters of Photoshop, the vast majority of photos taken were genuine. Sometimes the pictures captured were truly incredible.

Contrary to all stereotypes: a girl with a rare genetic disorder conquers the fashion world. This girl's name is Melanie Gaydos, and she burst into the fashion world quickly, shocking, inspiring and destroying stupid stereotypes.

Our ancestors slept differently than we do. What are we doing wrong? It’s hard to believe, but scientists and many historians are inclined to believe that modern man sleeps completely differently than his ancient ancestors. Initially.

What does your nose shape say about your personality? Many experts believe that you can tell a lot about a person's personality by looking at their nose.

Therefore, when you first meet, pay attention to the stranger’s nose

7 Body Parts You Shouldn't Touch with Your Hands Think of your body as a temple: you can use it, but there are some sacred places that you shouldn't touch with your hands. Research showing.

Manufacturing technology. Instructions

After familiarizing yourself with the structure of the boiler, you can try to make a similar device at home

This process is not as difficult as it may seem, but it requires utmost care and attention. Otherwise the finished product may be unsafe

Stage 1. Preparing everything you need

To work you will need the following equipment:

- welding machine;

- electrodes;

- iron tee;

- electrode insulation (polyamide);

- neutral wire;

- coupling;

- ground terminals;

- steel pipe of appropriate dimensions;

- insulation for terminals.

Stage 2. Assembling the ion boiler

Assembling the boiler

First, let's clarify a few important aspects. So, the ion boiler needs grounding, as mentioned above, and the neutral cable must be supplied exclusively to the outer pipe. It is also worth remembering that the phase should only be supplied to the electrodes.

Assembling the boiler

With proper preparation, the assembly procedure should not cause any difficulties.

Assembling the boiler

Step 1. First, take a pre-prepared pipe (optimal dimensions - length 25 cm, diameter 8-10 cm). On one side, a set of electrodes is placed in the pipe, and on the other, a coupling is installed for connection to the heating main.

Ion boiler drawing

Step 2. An insulator is installed near the electrode, which, in addition to its direct function, will also serve for additional tightness of the boiler.

Step 3. High quality heat-resistant plastic is used to make the insulator. But not only tightness is important for the device, but also the possibility of threaded connection of the electrode with a tee. That is why it is recommended to entrust the manufacture of the insulator to an experienced specialist who will make the part in accordance with the required dimensions.

Parts for boiler assembly

Step 4. A large bolt is welded to the body. Next, the neutral cable and grounding terminals are attached to the bolt.

Step 5. After connecting to the heating system (this is done using a coupling), all that remains is to hide the finished boiler with a decorative coating. Such a coating is necessary not so much for aesthetic purposes, but for safety and protection from electric shock. This should not be neglected, since it is necessary to limit access to the heat generator as much as possible.

Stage 3. Installation work

Boiler connection diagram Boiler connection diagram

- air vents;

- pressure gauge;

- fuse.

In this case, the shut-off valves are installed after the expansion tank. The above diagram will help you get acquainted with the connection features in more detail.

Installation of an electrode boilerInstallation of an electrode boilerConnection diagramAssembling a heating systemAssembling a heating systemAssembling a heating systemPolyphosphate filterAdjusting an electrode boiler

Video - DIY ion boiler

Other important installation points.

- The boiler is installed exclusively vertically, which can only be explained by its operating features. Fasteners must be separate.

- Before installing the device, the entire heating system is thoroughly washed. To do this, take clean water diluted with an appropriate product (such as Rothenberger). If a contaminated coolant is used or the line has not been properly flushed, the performance of the ion boiler will decrease significantly.

- For grounding, you can only use a copper cable ø4 mm (or larger) with a resistance of no more than four ohms. The cable is connected to the zero terminal, which, accordingly, is located in the lower part of the unit body.

- Heating devices (batteries) are selected in accordance with the volume of the system. The best option is that a kilowatt of device power corresponds to 8 liters of total volume. If this figure is exceeded, the boiler will operate longer than required, resulting in increased energy costs.

- In addition, when arranging a heating system, preference should be given to bimetallic alloys or aluminum. The use of other alloys is unacceptable, since they contain many different impurities that affect the electrical conductivity of the working fluid.

- If an open system is installed, then the batteries used must in any case have a polymer coating on the inner surface, which will prevent air from entering and, as a result, prevent corrosion. Closed systems do not have this disadvantage.

- Cast iron products should be abandoned altogether, because the impurities they contain in large quantities will reduce the performance of the ion boiler. Also, such batteries are too large, which will increase energy consumption.

A little more complicated

Drawing of a homemade boiler

Despite the availability of alternative ways to use electricity in heating systems, the best option is still a full-fledged boiler. The boiler body is best made of steel. This choice is justified from the point of view of safety, durability of the structure, and ease of manufacture. You can create a housing using a conventional welding machine. Such work will not require any serious special skills.

You should not make the case large. The more compact the dimensions of the boiler, the more efficiently it works. What to do if the house is large and you need a unit whose power will allow you to heat a large amount of water? Refuse the electric boiler in favor of another type of equipment. Electric appliances are suitable for heating a small country house, but when heating large cottages they will not be the best choice.

The body can have any shape, but it must be hermetically sealed on both sides. There are two holes on both sides. Through one, the coolant is supplied to the system, through the other, cooled water enters the boiler.

heating element

Types of heating elements

The biggest difficulty in making an electric heating boiler is choosing the right heating element. Its power should be enough to heat the coolant and water in the hot water system (if necessary, its arrangement). The power is selected based on the calculations performed. When designing a hot water supply system, it is better to choose a heating element with high power ratings.

The heating element is installed in the housing on the bottom cover, opposite the hole through which cooled coolant is supplied to the heater. It is worth installing shut-off valves in the pipeline next to the boiler to ensure the maintainability of the device. Shut-off valves will allow you to turn off the boiler if necessary without draining water from the system. As a rule, heating systems with an electric boiler are made with forced circulation, which will also require connecting pumping equipment.

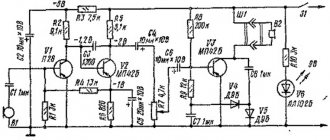

Electrical panel

The operation of electrical equipment is ensured by energy from the electrical network. To connect a homemade device to the latter, you will need to construct an electrical panel. You will definitely need to connect a three-phase input. It is better to entrust this part of the work to a qualified electrician, since the cost of an error is disproportionately high.

A starter, automation, relays, and electrical appliance control elements are installed in a metal panel. The system must be grounded. The effectiveness of grounding should be checked annually by employees of specialized organizations. The data obtained by measurements must be recorded in the protocol. The simplest way to perform grounding is as follows. Under the floor there is a structure made of a bolt welded to a metal pin. An electrical wire coming from the switchboard is screwed to the bolt. As you can see, everything is simple.

Factory electrical panel

The electrical circuit of the device will include the following elements:

- Machine.

- Magnetic switch.

- Control buttons.

- Toggle switch and relay.

- Circuit breakers.

- Thermal sensors.

- Additional automation (if necessary).

After connecting to the power supply, you can start the boiler for the first time and test the system.

The procedure for assembling a boiler with heating elements with its own rivers

Before you make an electric boiler with your own hands, you should make sure that you have a reliable power supply line. Only equipment with a power of no more than 6 kW can be connected to ordinary networks with a voltage of 220 V and a frequency of 50 Hz. If a more powerful boiler is required, it needs a three-phase wiring and a separate input.

So, we begin assembling a homemade electric heating boiler from a pipe with a cross-section of 159 mm and a wall thickness of 10 mm. This pipe will serve as the boiler body. It will require either a factory-made hemisphere with a cross-section of 159 mm and a thickness of 10 mm, or sheet metal with a thickness of 8 mm or more of a similar section.

The boiler roof, into which the heating elements will subsequently be embedded, can be made from an 8 mm thick channel.

We cut a ¾-inch coupling into the boiler dome. We will screw the drain valve into this coupling. In addition, you will need 2 pipes with a cross-section of 1 inch for inflow and return. The threads on the pipes can be made both internal and external. It all depends on which one you are more comfortable working with.

Please note that it is advisable to cut the threads on the pipes and adapters immediately. Prepared pipes with threads, the same as on heating elements, must be immediately screwed into the adapters

This is necessary so that the threads are not damaged during welding to the arch. To mark the insertion points of the heating elements, the outer diameter of the pipe must be divided into 6 equal sectors according to the radius size. Then we draw three identical sectors strictly at an angle of 120°

Prepared pipes with threads, the same as on heating elements, must be immediately screwed into the adapters. This is necessary so that the threads are not damaged during welding to the arch. To mark the insertion points of the heating elements, the outer diameter of the pipe must be divided into 6 equal sectors according to the radius size. Then we draw three identical sectors strictly at an angle of 120°.

The next step is to start cutting. Having finished with the markings, using a plasma cutter we cut out holes for the pipes for the heating elements. They should be cut only along the outer contour. With all other pipes this is not of fundamental importance.

Let's start welding work. First we intercept the pipes at several points so that they do not lead. Then we check the accuracy of the location, if necessary, lightly tap with a hammer, and then make a continuous seam

It is important that the adapters for heating elements in an electric boiler for heating with your own hands protrude 1 cm above the surface of the boiler roof

Next, you need to make sure that the heating elements fit completely inside the body of the electric boiler. Therefore, after applying a continuous seam, it is necessary to screw the heating elements into the adapters.

Let's start cutting out the vault from the channel. In its center we make a hole for the air valve pipe, after which we weld the pipe itself. We make a hole on the side for the temperature sensor and also weld a pipe under it.

All protrusions, burrs and welding residues must be thoroughly cleaned using a grinder. The inner surface of the arch platform must be perfectly flat. The pipes for installing heating elements will protrude only 1 cm from the outside.

We got a fairly powerful electric boiler with our own hands with 3 heating elements. If you need a simpler unit, using the same principle it can be assembled using 1 or 2 heating elements.

Vegetable cutter from a barrel

How to make a root vegetable chopper with your own hands from a tank or barrel:

- If the working container is welded independently, then it is better to use steel 1.5 mm thick,

- The walls are given rigidity by flanging the edges with rubber tubes,

- The bottom is made of 5-6 mm steel sheet,

- A hole is drilled in the center of the bottom to install the motor. For this model, a conventional single-phase motor is suitable,

- An unloading hole is cut out at the bottom of the barrel, under which a tray or box is placed,

- The body is mounted on four legs made from a piece of pipe or angle,

- Two knives are installed inside the working container,

- The upper knife is made double-edged with the edges bent down,

- The lower knife is made in the shape of a propeller with one cutting edge,

- The shaft is connected to the engine using a chain drive.

- The dimensions of a homemade barrel depend on the thickness of the steel used. If you use a 1.5 mm sheet, then the maximum wall height should not exceed 60 cm.

Crusher knives are made from a hand saw blade - the size should be one centimeter smaller than the diameter of the working chamber.

Installation rules and requirements

Electric boilers are compact in size, require a minimum of wiring and have a modern design, which allows them to be installed anywhere.

All general requirements are described in the PUE (7th edition). Electric boilers with a power of up to 10 kW do not require approval from the Energonadzor services. However, if you want to install a meter that differentiates electricity consumption by zone of the day, which we recommend doing in order to save money, you will still have to coordinate the installation. For boilers with a power of more than 6 kW, three-phase power supply (380 V) is required; 8-12 kW models can operate from a single-phase (220 V) network, but it will not provide operation at full power.

The choice of installation location for an electric boiler is more extensive than for gas or solid fuel boilers. Electric boilers can be installed in a residential area, for example, a corridor, hallway or kitchen, but keep in mind that in any case you need to run pipelines, wiring, grounding and other communications to it. The installation of an electric boiler in the bathroom and toilet is prohibited.

The requirements for the installation surface are also minimal, it can also be a wooden wall, but in this case it is necessary to insulate the installation site with a layer of non-combustible material (basalt cardboard, xylolite sheet).

Fireproof protective plate when installing an electric boiler on a wooden surface.

Manufacturers also impose requirements on the space around the electric boiler necessary to ensure maintenance and repair. The values differ depending on the model, so before planning the installation location and wiring, you should find them in the operating instructions. Usually this:

- from 0.7 m from above the boiler;

- from 0.5 m on the sides (including to the pipeline) and below;

- from 0.7 m in front of the boiler unit;

- at least 3 cm between the wall and the boiler.

Gas heating

Traditionally, the most economical heating method is gas. Considering that Russia is one of the leaders in the production of blue fuel, this method is considered the most inexpensive for the population. Moreover, modern equipment, provided it is connected by specialists, is absolutely safe to operate - if the flame dies out for any reason, the gas supply is immediately stopped.

The model range is very extensive - units differ in size, power, modifications and price. So, for example, a RINNAI boiler with a power of 11.6 kW costs from 33,000 rubles, and a BaltGaz 11 kW boiler costs from 25,000 rubles.

Rinnai RB 107 EMF, 11.6 kW, dual-circuit, closed chamber

When choosing this method, it is necessary to take into account a number of nuances:

- In the absence of a centralized gas pipeline, you will have to use liquefied (ballooned) gas, which will immediately increase the cost of operation by at least 30%.

- To install such a unit, you need a special separate room with good ventilation and a chimney.

- Before installing any gas equipment, approval is required from the relevant authorities, in particular, from Gaztekhnadzor.

- Installation and connection work must be carried out by a specialist, which is also an additional expense.

- To connect a separate branch from a centralized gas pipeline, the costs for technical specifications and other aspects amount to 50-100 thousand rubles.

The efficiency of a gas boiler is relatively high - 85-90%. In general, gas heating can be called economical and convenient, but there are many nuances that can become a hindrance.

VIDEO: The cheaper way to heat a house

Solid fuel equipment

An alternative to gas heating can be solid fuel boilers that burn coal, wood, pellets, briquettes, etc. Heating a house with solid fuel devices is very convenient if the house has neither gas nor electricity. Modern models are equipped with automation and require minimal maintenance.

Quite a wide selection of models according to the fuel used:

Solid fuel units are easy to install and do not require approval or standardized designs. In addition, the cost is lower than other options. For example, the Evan WARMOS-TK-12 kW device costs from 18,500 rubles.

Evan WARMOS-TK-12 kW

The main disadvantage of this type of equipment is the need to manually load fuel, low efficiency - only 70-75% - and the mandatory arrangement of a fuel storage area.

Water heating with electric boiler

Water heating systems for private houses are constructed according to a closed scheme and operate on the principle of forced coolant circulation. The construction of a complex with natural circulation is impractical - due to the low speed of the coolant in the system, fuel consumption is not rational - this will cause an increase in electricity bills.

The basic elements of electric autonomous water heating systems are the following types of boilers:

- heating elements;

- Electrode;

- Induction.

Heating element models are the most common version of the equipment - this is due to the simplicity of the design and reliability in operation. The heating element of the boiler is a tubular electric heater - its design consists of a conductor insulated in a dielectric with high thermal conductivity - both elements are placed in an outer metal or ceramic casing. Heating elements (or a group of heating elements) are placed in a tank with pipes through which the coolant circulates. The power of the equipment is controlled in steps or smoothly.

Heating element devices have a fairly high efficiency, but are inferior in this indicator to their counterparts (electrode and induction units). The decrease in efficiency is due to the need to overcome the thermal resistance of the dielectric and the shell of the heating element.

Electrode boilers carry out their work by using the conductivity properties of water - they can only work with it as a coolant, and the water must have certain parameters in terms of chemical composition and conductivity. When current passes from the electrode to the body, the water heats up due to resistance and transfers heat to the heating devices during circulation.

Electrode electric boilers have high efficiency (up to 98%), energy consumption is on average 15 - 20% lower than that of heating element analogues. But at the same time, electrode-type equipment also has disadvantages:

- Boilers only work with water of certain parameters;

- The power of the unit is unstable and largely depends on the conductivity of the water;

- There is virtually no quality regulation of productivity;

- Rapid wear of working elements - electrode and housing;

- The need to construct a high-quality grounding loop.

Induction electric boilers operate on the principle of using the properties of electromagnetic induction. The basic elements of the product design are the primary and secondary windings. The secondary winding (closed) is a tubular element - the coolant circulates through it, a current is passed through the outer primary winding and an electromagnetic field arises, under the influence of which the tubular element heats up and transfers heat to the water (coolant).

Induction equipment has the highest efficiency among electric boilers - its value is close to 99%. Energy savings compared to electrode and heating elements units can reach 30 - 40%. The following criteria are also significant advantages of the equipment:

- Versatility in terms of coolant type;

- Possibility of precise power control;

- No deposits due to microvibration;

- Safety, high heating rate.

At the same time, the equipment is very expensive and has a significant mass - this somewhat complicates its installation.

The main advantages of organizing an autonomous water boiler based on an electric boiler are:

- There is no need to build a smoke removal system;

- No separate room is required to place the boilers;

- No waste is generated during the operation of the equipment;

- Affordable cost of boilers;

- No fuel storage required;

- It is possible to reduce electricity bills by integrating a heat accumulator into the circuit (at a two-rate or three-rate tariff).

The main disadvantage of any electric heating configuration is the high cost of energy. In addition, it is often not possible to provide a limit on free power (by the electricity supply organization) and the construction of high-quality wiring of certain parameters is required.

Full glazing of the veranda

If you don’t have the necessary tools at your dacha or in a private house, and you simply don’t have the funds to buy expensive wooden blocks, then there is only one way out - solid window frames.

In order to create such a masterpiece, you need to prepare:

- Planks of wood from which the structure will have to be made. Small blocks of 50/50 mm are best suited. They must be cut in the required quantity, after which they are fastened to the frame, which is also made independently.

- It is recommended to fasten the glass to the frame using silicone sealant, but if this is not available, then you can do it the old fashioned way with glazing beads.

- The final stage is processing the joints with platbands.

Adjusting the water temperature

Besides security, we need one more element. A control element that will periodically turn it on and off to maintain the set water temperature.

This device is a working thermostat.

Don't confuse it with the ultimate. In the limit there is a manually reset button, which, when triggered, prevents the sensor from turning on independently.

That is, when it triggered once, you will need to inspect the entire system and circuit in order to understand the reason for the triggering. And only after that, by pressing this button, the heating can be started again.

This thermostat is installed after the limit, again in an open circuit.

Thus we received a security element and a control element. In principle, this is the most primitive scheme No. 1 for automatic electric heating.

DIY electric boiler for heating

(Last Updated On: 02/23/2018)

Homemade electric boiler for heating

In Russia, abnormally low cold weather occurs almost every year, so the question of insulating and heating your home always remains relevant, so that the family hearth does not turn into a cold cave. If your financial resources are limited, but the need for heating is higher than ever, and you can create miracles with your own hands, then homemade electric heating boilers are what you need.

Home-made electric boilers for heating require skills, extensive experience and high responsibility in their manufacture, because the cost of an error is very high - if a home-made boiler fails, a fire may occur, jeopardizing the entire house, since a home-made heating boiler with a power of 220 volts is quite dangerous .

Making a homemade electric boiler for heating

To successfully design and assemble a boiler, it is first of all important to clearly understand the principles of its operation, the structure and purpose of each part. To do this, it is best to draw up a drawing of a homemade heating boiler

After this stage, you will need to select the materials you will need:

- One steel pipe with a diameter of 10 to 12 cm.

- Two small pieces of pipe, approximately 5 to 15 cm long, with a diameter of 4 or 5 cm.

- Steel, preferably stainless, sheet with a minimum thickness of 2 mm (in this case, the more, the better).

- One tubular electric heater (abbreviated TEN), which must have three electrophases. The recommended power is 9 kilowatts.

Homemade electric boilers for heating are essentially an ordinary heater, since the heating element is a fundamental part in our future homemade boiler, we buy it first and, depending on the size of the heating element, we buy the remaining components (for example, the diameter of the steel pipe must correspond to the heating element so that it can fit into pipe).

Depending on the desired size and performance of a homemade electric boiler, a pipe is cut, and pre-prepared steel sheets must be welded to it at the ends, and bends with a diameter of 4-5 cm are attached to the remaining planes (sides, top and bottom) for inclusion in the heating system.

A nut is screwed into one of the end holes of the largest pipe, which is necessary for the subsequent attachment of the heating element to it.

Safety first!

The next very important point is safety.

To ensure this, it is important to observe three points:

- Grounding. We need to weld a bolt onto the body of our future boiler, to which the ground will be connected.

- For the boiler, you need to build a reliable casing that provides its reliable protection from external factors, including from children.

- Carefully consider the place where you plan to place your boiler. There should be no combustible or flammable materials nearby. A homemade electric boiler should not be accessible to children to avoid their contact with hot and live surfaces.

The heating element will be located depending on the type of heating you want to use:

- When installing a homemade electric boiler connected to a water heating system, the location of the electric heating element is not of fundamental importance (but preferably with the heating element facing up).

- If the heating element will heat the air, then for its uniform heating and, accordingly, long service, it is better to place it from top to bottom.

A programmable automatic control system is installed on ready-made homemade electric heating boilers, which allows you to control the temperature and operating mode of the device manually or automatically.

Advantages and disadvantages of homemade electric boilers for heating

Homemade electric boilers for heating have obvious advantages:

- Cheapness.

- Easy to assemble and operate.

- The ability to select individual characteristics suitable for your premises.

On the other hand, there are also disadvantages:

- Increased fire hazard.

- Low energy efficiency.

- The need to have the skills of an electrician and turner to produce a high-quality boiler.

Thus, homemade electric boilers for heating make sense to manufacture if you are in dire need of a means of heating the room and do not have the appropriate financial capabilities. In other cases, we recommend that you purchase domestically produced electric heating boilers that have the best price-quality ratio.