Do-it-yourself mini tractor from a walk-behind tractor - manufacturing procedure

Before you start manufacturing a mini tractor based on a walk-behind tractor, you will need to prepare the materials necessary for the work. Conversion kit includes:

- welding machine;

- screwdrivers and wrenches;

- electric drill and a set of various drills;

- grinder and a set of discs for working with metal;

- set of nuts and bolts.

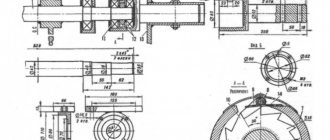

Suitable drawings will help you assemble a tractor from a walk-behind tractor correctly. In them you will find information about the order in which to connect the parts and which fastening method is suitable for their reliable installation.

Converting a walk-behind tractor into a mini tractor is carried out in the following order:

- A mini tractor based on a walk-behind tractor must be equipped with a strong, reliable frame. It must withstand an additional pair of wheels, plus the load carried in the tractor will put pressure on the supporting structure. To make a durable frame, metal pipes or angles are best suited. Be sure to keep in mind that the heavier the frame, the better the grip of the minitractor with the road, and the better the quality of plowing. The thickness of the frame walls is also not very important - the main thing is that they do not bend under the pressure of the cargo being transported. You can cut the blanks for making the frame using a grinder. Then all the parts are connected to each other first with bolts, after which they are finally welded to each other. To make the frame stronger and more reliable, equip it with a cross beam;

- Immediately after manufacturing the frame, it can be equipped with a hinged mechanism, through which the small tractor will be equipped with additional accessories. The hitch can be installed both in the front and in the rear of the supporting structure. If in the future the manufactured minitractor is planned to be used in tandem with a trailer, then a tow bar should be welded to the back of its frame;

- At the next stage, the homemade product is equipped with front wheels. To do this, it is best to equip the mini-tractor being manufactured with two ready-made hubs with brakes provided on them. Next you need to secure the wheels themselves. To do this, take a piece of steel pipe whose diameter fits the front axle. Next, attach the wheel hubs to the pipe. Drill a hole in the central part of the pipe, which is necessary for mounting the product to the front of the frame. Then install the tie rods and adjust them to the frame using a worm gear. After installing the gearbox, install the steering column. The axle at the rear of the tractor being manufactured is mounted through pressed bearing bushings. The wheels used must be no more than 15 inches in diameter. Smaller parts will lead to the front part of the unit “burying”, and larger wheels will significantly impair the maneuverability of the mini tractor;

- At the next stage, it is necessary to equip the minitractor with an engine from a walk-behind tractor. It is best to install the motor at the front of the unit, as this will improve the balance of the agricultural machine when operating with a loaded trailer. To install the motor, arrange a reliable mounting system. When installing the motor, do not forget that the power take-off shaft must be secured coaxially to the pulley located on the rear axle of the mini-tractor. The force on the wheels must be carried out using a belt drive. The video will tell you more about converting a walk-behind tractor into a mini tractor.

A self-made tractor will remain equipped with a reliable brake system and a high-quality hydraulic distributor, which is necessary for the proper operation of the unit with attachments.

What you need

Before you begin, you should make sure that you have all the necessary parts, materials, and tools.

So, what is required for work:

- Motoblock. It must be selected taking into account the above recommendations. It is this that will serve as the basis for a homemade mini tractor.

Motoblock Neva - the best option for remodeling

- Additional wheelset with axle. It is necessary to purchase bearings for the wheels, as well as a steering unit.

- Metal sheets, pipes and corners. The material is needed to create the body and frame of the structure.

- Elements for fixing parts and mechanical components. In this case, washers, bolts, nuts, and welding are used.

To carry out the assembly, in addition to the parts, you still need to prepare a number of tools:

- welder;

- drill-driver;

- a set of wrenches of different sizes;

- pliers;

- Bulgarian.

A homemade unit has a number of advantages. First of all, this is the cost. Even if a home craftsman needs to buy a cultivator, he will in any case spend less money. In addition, you can create special equipment of the required size, degree of adhesion to the ground, and performance.

As for the disadvantages, they are that equipment made by hand is much inferior to factory models in terms of reliability. Also, such equipment often requires repair work.

Main details

Frame

To make a tractor with your own hands, you need to start with a support. In this case it is the frame. It should be strong and light in weight. They are made from channels (metal products with a U-shaped cross-section, with a wall size of 5-14 millimeters) or from a profile using metal corners.

There is another type of frame - a breaking one. Made for 4x4 mini tractors - they have both front and rear axles driven. They make two half-frames, an assembly from the driveshaft of any car, for example, GAZ-52.

Engine

The only selection criteria are the purpose of use and the total weight. All-wheel drive vehicles will work better with 30-40 hp, single-wheel drive vehicles - 15-20 hp.

The most popular option is the internal combustion engine from the VAZ 2101-2107. The cost is low, does not require modification and fits any configuration, but fuel consumption is high (11 l/h).

Low-power models are equipped with ZID-4.5 engines. Simple service, low consumption (1.5 l/h), built-in gearbox. But at the same time the power is low – 4.5 hp.

Transmission

The ideal option is the GAZ-51, UAZ gearbox. For all-wheel drive models, the UAZ transfer case is suitable. To transfer power to the gearbox, it is necessary to use shorter driveshafts of the same type.

Helmsman

To create it, the front axle must be equipped with king pins. Trunnions are attached to them from below, turning levers from above, and a transverse rod is placed between them.

The transverse slope should be from 6 to 10 degrees, longitudinal - 1-3. This will ensure proper operation of the steering complex. After all, you need to connect the longitudinal rod to the steering gear. A rack is suitable for this.

Rear axle

Taken from any car, the length of the stockings and axle shafts is reduced to the required values. At relatively low speeds, you can only leave the handbrake on. You can make a pedal with locks for better controllability.

Wheels are chosen with a radius of 14-24. Tires are taken with lugs.

Design features

A homemade walk-behind tractor is most often used to perform simple but labor-intensive work:

- plowing of land;

- hilling up plantings;

- mowing grass or tops;

- application of organic fertilizers.

You can upgrade any walk-behind tractor with a ZiD engine or any other, make it on large wheels, with a belt drive.

Often, craftsmen prefer to reassemble such units using old spare parts from such mechanical devices:

- chain saws of the “Friendship” type;

- scooter;

- motorcycle;

- washing machine.

If a person owns a tool and understands the structure of equipment, then making a walk-behind tractor is not difficult. In terms of material costs, this can cost a minimal amount, while prices for a good unit start at $300. If everything is done correctly, a new device created by yourself can be in no way inferior in reliability and performance to imported models such as Cayman walk-behind tractors.

Often craftsmen use old units from the Druzhba saw as engines. At the same time, the walk-behind tractor is easy to operate; even a non-professional or a minor can work with it. The power plant is able to withstand significant loads without stalling even at low speeds.

This indicator is important for the following work:

Safety precautions

Regardless of which mechanism was the main one when assembling the mini-tractor, you must understand that this is a rather dangerous device. There are no instructions for homemade equipment, and therefore the first safety measure is careful selection of the design. It is recommended to read the comments on the drawings and descriptions, and the reviews of those who have already tried to use them. The mini-tractor should be refueled only with the fuel for which the engine is designed. A similar rule applies to lubricating oils.

Important How to independently diagnose and repair a chainsaw Partner

If the unit has a gasoline engine, do not allow oil to get into the fuel. It is also impossible to fill fuel to the very edge. If it spills out while moving, serious problems can occur. It is strictly forbidden to use open fire when refueling a mini-tractor, and ideally at any time when people are near it.

If the canister becomes leaky, it should be thrown away. There is no need to create fuel reserves in excess of the required volumes. The refueling and engine starting points must be at least 3 m apart from each other. To avoid a fire, do not start the engine in the immediate vicinity of trees, bushes, or dry grass. If the engine starts poorly or starts with strange sounds, it is better to postpone work and look for the problem.

You cannot drive a mini-tractor over garden equipment or allow it to collide with walls, branches and stones. Only people who understand it should operate the mechanism. Even if headlights are installed, it is advisable to work mainly during the day.

You can learn how to assemble the transmission and brakes on a mini-tractor by watching the video below.

First spec sheet

At first, he achieved, as it seemed then, the ultimate dream. Using a crankshaft from a Niva and shortened connecting rods, I modified the standard 1300 cc engine 21011 to a volume of 1700, installed injection instead of a carburetor, removed the door handles and installed sports seats. Over time, he modified the car more and more.

By the third year of the MAMI Institute, where, by the way, he received a specialty as a design engineer, Denis rolled out of the garage a 2106 with a 250-horsepower turbo engine, a steering rack from the IZh "Oda", relatively good brakes and a welded safety cage. The young engineer immediately realized that such equipment for the Lada was not the limit. And every winter he began to modify both the engine and the chassis. The components for the spec list were selected based on personal experience, studying online forums and advice from friends.

The engine is the heart of the unit

It is the engine that is the main component of any equipment. Basically, craftsmen take classic engines from VAZ 2101 - 2107. And all because they are ideal in terms of parameters, the main ones being:

- availability;

- price;

- traction indicators;

- light weight;

- budget repairs and maintenance.

The motor is an important component of the tractor

Ideally, just one classic VAZ car will become a real donor for your homemade tractor, because the main part of the parts can be borrowed from there.

The motor, together with the gearbox and clutch, acts as a single unit; they are attached together. Such a pleasant nuance will facilitate the process of assembling a homemade product.

It is important to place the fan impeller on the pump shaft. This is a mandatory condition (regardless of the design), because the tractor will operate in the same mode as a car feels in a traffic jam - the speed is low, but the load is considerable

So the radiator will have to be forced to blow.

Beginning of work

First, the engine is removed and rebuilt. If you do everything wisely, then the VAZ engine even with two gearboxes will last a very long time. Then it’s the turn of the transmission and chassis. After all components have been cleaned and repaired, a detailed layout diagram of the future device with a VAZ engine should be prepared. The engine must be located in front of the driver, as is the case on factory tractors.

The casing can be “borrowed” from an old tractor, accordingly converting it to the required format. To reduce weight and size, you can trim the frame, then you may have to move the bridge. A very important issue is the layout of gasoline tanks.

Most often they are located behind the driver's seat. The front suspension must be strengthened, because it will bear a large load. The wheels are installed with a larger diameter, then it will be easier to move along arable land and country roads.

And of course, you should clean all spare parts from rust, then coat them with primer.

Homemade mini tractor with a breaking frame: photos, videos, drawings

A mini tractor with a breakable frame is a great helper for those who like to work on the land. This tractor is distinguished by a special frame design, consisting of two semi-frames (front and rear), connected by a flexible hinge joint

The tractor is turned not by the angle of the wheels, as with a conventional design, but by bending (breaking) the tractor twice, which allows the tractor to turn literally “on its heels,” which is especially important for agricultural machinery intended for processing small areas

Homemade mini tractor

This device is not difficult to purchase at any specialized retail outlet. However, this operation has a significant drawback - such a mini tractor is quite expensive.

This situation provokes many summer residents to engage in individual production of such equipment. This article will tell you how to create a mini tractor equipped with a breakable frame. (As in the existing photo.)

The first stage is the project

Before you begin directly creating the device, you need to sketch out the appropriate drawings. This equipment is a rather complex set of mechanisms and systems that are closely interconnected. It is the location of all these elements that should be taken into account when making drawings of a mini tractor with a breaking frame. Moreover, the specified scheme should also include a driver’s seat, as well as the placement of a gearbox.

Drawing

Stage two - installation of the main parts

After the drawings are ready, you can begin to assemble the device

It is important to remember here that a homemade mini tractor with a breakable frame must be equipped with the following parts, which must be taken from one source:

- engine;

- Transmission;

- chassis elements.

All of these units must be related to one vehicle; this will eliminate problems with their compatibility.

As for the breaking frame for a homemade mini tractor, it is done independently. In the manufacturing process of the breaking frame, a metal channel is used. In order to ensure reliable fastening of all these parts of the future mini tractor, you will need a welding machine.

The rear axle axle shafts need to be shortened somewhat. They must have a strictly defined length. To carry out such an operation, a conventional lathe is used.

Stage three - articulation

Often, 4x4 mini tractors with a breakable frame have a hinged connection to the semi-frames, which can be the driveshaft of a GAZ truck. The model of the car, in this case, does not matter much, since the required element is made in the same way.

The steering of a minitractor with a tipping frame should be equipped with hydraulic cylinders. In this case, a homemade mini tractor will be easier to control

This circumstance is especially important when plowing the land is carried out using a mini tractor equipped with a breakable frame.

Gear ratios

You should also select the gear ratio of the gearbox. This value is set in such a way that during an hour of plowing, performed at a speed of 2 thousand per minute, a homemade mini tractor with a turning frame moves at a speed of three, maximum three and a half kilometers per hour.

A few words directly about the frame

The frame of a homemade mini tractor is made of channel material, since it is this design that gives it sufficient rigidity. Thus, a mini tractor, which includes such a breakable frame, is capable of withstanding quite considerable loads.

Important Truck KamAZ-4308: technical characteristics, reviews

But it is worth noting that the use of the specified profile is not always a mandatory component when designing a mini tractor. Wings, seat frame and some other elements that do not require the use of particularly strong material can be freely made from other profiles.

Eventually

A tractor with a breakable frame is very convenient for installing a variety of attachments. These components will help to carry out all kinds of agricultural, municipal and even construction operations using such a device.

The video that complements this article will tell you more about the individual production of a mini tractor with a breaking frame.

Layout

The relative arrangement of the units of any tractor has historically developed a long time ago. The classic layout of a self-propelled vehicle is as follows: the engine is located in front, longitudinally, above the front axle. A gearbox is connected to it through the clutch, followed by a transfer case and followed by a drive axle. The shafts of the units are connected to each other using cardans and (or) couplings.

Following this scheme will be the best option when creating a mini tractor, because... will allow you to use existing units without changing them. According to the experience of many creators of homemade tractors, it is better to assemble the units “in place”, without doing unnecessary drawings and calculations. The best option is to place all the main components and homemade mechanisms on the finished frame, installing them on temporary supports (conveniently, on wooden blocks), and, having found the best mutual position, make mounting brackets. But we must not forget that all components on self-assembled tractors must be mounted through supports that dampen vibrations (rubber cushions). It is best to borrow them from the same equipment from which the unit was taken. Another important factor needs to be taken into account. This is weight distribution, i.e. distribution of the total weight of the minitractor along the front and rear axles. The most acceptable option is that 60% of the weight falls on the drive wheels, 40% on the steering wheels.

Manufacturing a three-point hitch

The hitch is used to connect additional equipment, such as a plow, to the tractor.

We suggest you familiarize yourself with How to sew a knitted hat with your own hands and patterns for it

The hitch must be movable both in the horizontal and vertical planes. In the first case, mobility helps to reduce the overhang of the nozzle when taxiing. Vertical movement of the suspension is required to lower the equipment into a working position or raise it into a transport position.

The hitch on a mini tractor is made from various parts removed from old agricultural machinery. It is quite difficult to describe how to make a three-point hitch at home. Therefore, it would be more correct to use the following video, which shows the dimensions of all parts of the device.

If you decide to make a mounted loader, then you can use T-25 and T-40 in tandem with this equipment. This option will be simpler compared to a front loader, which is true in matters of installation on a tractor and calculation of dimensions. At the first stage, you need to find or independently make a drawing, in which you should indicate the dimensions and proportions of the metal parts.

Important points

If you decide to make a homemade mini tractor from a Zhiguli, you should know some important points. This technique will be a great help, and you won’t have to spend a lot on its production. But you should consider some legal important points:

- If you buy an old Lada for homemade purposes, then a re-registration procedure must be carried out;

- After this procedure, you must notify the traffic police about the planned work. An act of surrender of the rooms will be drawn up there;

- After you create a mini tractor from a Zhiguli, you need to register it and get new license plates. But most often, farmers use such transport exclusively within their own area or between fields, so such registration can be avoided.

As you can see, making a mini tractor from a Zhiguli is quite simple

It is only important to think through every moment, prepare all the necessary parts and tools. Many owners of such homemade products note the excellent performance of the machine and its capabilities in working in the fields

But the important thing is that you assembled it yourself, and therefore, if a breakdown occurs, you can easily find and fix it.

Mini tractor equipment

As for the placement of mini-tractor units, this is a well-known fact. If we talk about the classic layout, it looks like this:

- the motor is located in front of the structure (above the front axle, in a longitudinal position);

- the gearbox is attached to the engine via the clutch;

- behind the transmission is a transfer case;

- the drive axle closes the sequence of units;

- the connection is achieved by installing couplings (cardans).

Diagram of tractor layout types

The masters say that you don’t need unnecessary calculations and drawings. It is best to make a frame and consistently bring everything to mind. For temporary supports, you can use ordinary wooden beams. When you find the ideal position and connection of all the structural components, then you can manufacture and assemble everything.

Also useful: How to make a hand cultivator.

The main thing is not to forget about rubber cushions that will dampen vibration. All components must be mounted on such supports. It is also necessary to properly distribute the total weight. The best division is: 60% (for driving wheels) by 40% (for steered wheels). This scheme will allow you to best control the equipment.

Standard layout of a homemade tractor

Minitractor from the Zubr walk-behind tractor

Motoblocks of this brand have a reliable and fairly powerful motor, the presence of which allows you to convert the unit into an all-wheel drive mini tractor. Before work, be sure to study the detailed drawings, and also buy steel sheets, pipes and angles. The procedure for making a mini tractor is as follows:

- When arranging the frame, you will need to expand the existing frame of the walk-behind tractor. This is necessary in order to install additional wheels. Cut the corners and pipes into suitable pieces, then weld them to each other;

- The front beam is mounted on a mini tractor using a ready-made hub equipped with brakes. The wheels in the front part of the unit must correspond to the size of the rear wheels, or be slightly larger than the latter - this will prevent the mini-tractor from “burrowing” when driving over rough terrain;

- Then install the walk-behind tractor motor. It is best to install it in the front to achieve the best balance of the entire structure;

- Weld a tow bar to the back of the finished mini tractor - it will be needed for mounting the trailer.

A homemade mini tractor, made on the basis of the Zubr walk-behind tractor, will be able to cope with a number of the most complex economic tasks: plowing the soil, cutting grass, collecting and transporting crops.

Advantages and disadvantages of homemade structures

When transporting small loads or cultivating areas of up to 10 hectares, it is better to use a mini-tractor for household use. It can be made with your own hands without any problems, and the design is much cheaper than a purchased product.

Important Review of technical characteristics of the Neva MB-1 walk-behind tractor

Assemblies from waste structures are often used as parts. If you have a used walk-behind tractor, the task is simplified. A big plus is the ability to improve a homemade design with found parts. This cannot be done with a purchased product.

The disadvantages include the following:

the difficulty of producing drawings that cannot be avoided; the installed components are initially worn out; The ability to work with metal and engineering knowledge are important.

How to assemble a walk-behind tractor yourself

Let's look at how to assemble a walk-behind tractor with your own hands. Parts that can be used for DIY are taken from old motorcycles and scrap metal. As an engine, which is often installed on homemade motor cultivators, you can use a motor from Druzhba - a chainsaw.

This engine has sufficient power to allow the use of various attachments. This significantly expands the functional use of motor cultivators. Many people install the engine from the Ant scooter on their walk-behind tractor, which has excellent characteristics and parameters for working in their summer cottage.

To create a walk-behind tractor at home, you will need the following spare parts and materials:

- Steel corners measuring 36x36 mm or pipes 60x50x2 mm. From these parts you can assemble a frame for a walk-behind tractor.

- Engine fully assembled.

- Fuel tank.

- Exhaust system.

- Air filter.

- Kickstarter.

- The steering wheel on which the clutch and gas handles should stand.

The following tools will help you make a walk-behind tractor with your own hands:

- Welding machine.

- Drill.

- Vise.

- A set of horns and spanners.

- A grinding machine on which a special disk must be installed for cutting metal.

How to make a homemade tractor with a walk-behind tractor engine. Advantages of a mini tractor

Among the main advantages of a homemade technical product, one should first of all note the lower cost in comparison with ready-made analogues. In addition, such a unit will not require much storage space. Now it’s clear why most owners of personal plots want to know how to make a mini tractor from a walk-behind tractor with their own hands.

At the same time, do not forget about the efficiency of a homemade device, because it does not require a lot of fuel

. The prices for spare parts are also quite attractive and they are easy to acquire

If you install tires with a deep tread on a homemade tractor from a walk-behind tractor, the unit will get good cross-country ability. An equally important characteristic of the device is its small dimensions.

To make a mini tractor with your own hands from a walk-behind tractor, you need to have some knowledge and be familiar with tools.

Before starting work on creating this technical tool, it is worth studying several drawings and reading the relevant literature. Units from various manufacturers have unique technical characteristics, which affects the list of necessary modernization work.

Today on the market you can find models equipped with adapters with a seat. As a result, the process of creating a homemade mini tractor from a walk-behind tractor will be even simpler. However, if the adapter is missing, then making it yourself will not be so difficult. Many owners of personal plots prefer Salyut, Neva and some Chinese models. To make a tractor from a walk-behind tractor with your own hands, in addition to the basic device you will need:

- 2 wheels;

- stainless steel sheet, as well as metal corners and pipes;

- welding machine;

- drill;

- chair; attachments.

Preliminary design stage

The following parts are taken from the Oka car during construction:

- Motor;

- Transmission;

- Wheel axles;

- Steering.

If necessary, elements can be replaced with compatible ones and some connections can be modified.

A mini tractor from an Oka walk-behind tractor is constructed on the basis of a channel No. 6-8 or a corner 4x4 centimeters. The amount of necessary materials is determined according to prepared drawings with the exact dimensions of the elements.

You need to acquire the following tools and materials:

Do-it-yourself mini tractor from a walk-behind tractor

In order to make a miniature tractor from a walk-behind tractor with your own hands, you will need:

- Bulgarian;

- fastening parts;

- channels and pipes;

- drilling device;

- electric welding;

- measuring instruments (angle, tape measure, caliper);

- small hand tools (screwdriver, wrenches, hammer, etc.).

You also need to purchase a ready-made kit for converting a walk-behind tractor into a mini tractor. This will be the main expense item, but you should not save on this equipment, so as not to question the quality of the future product.

You also need to choose a comfortable and high-quality steering wheel, seat, wheels and pedals. When all the necessary components have been selected, you can begin to create a drawing. Do not neglect this stage - with clear drawings and diagrams it will be much easier and faster for you to work. The photo below shows examples of the simplest drawings for independently converting a walk-behind tractor into a mini tractor.

A good homemade mini tractor with an engine from a walk-behind tractor can only be obtained when the original unit has good power and performance. Heavy diesel walk-behind tractors are ideal for conversion. They are quite economical, heavy, have considerable power, are productive and durable. All these parameters will allow you to turn the walk-behind tractor into a full-fledged mini tractor, capable of plowing heavy soils and working for a long time without interruptions.

The conversion process as a whole is carried out according to the same algorithm, with minor differences for different models. The general scheme for converting a walk-behind tractor into a mini tractor is as follows.

Frame preparation

Since the mini tractor will need another pair of wheels, the frame design will have to be improved and strengthened. A metal profile or metal pipe is used to make a new frame. The thickness and size of the workpieces should be selected based on individual preferences, taking into account the power of the future unit. The components of the future frame are cut out with a grinder and connected by welding. It is advisable to strengthen the structure with a transverse crossbar. Also take care of the attachment point and the towbar if you plan to use a trailer.

Chassis system

The front wheels are mounted on a piece of pipe of suitable diameter. In turn, ready-made wheel hubs with brake pads are attached to it. A hole is made in the center of the structure through which it will be attached to the frame. Next, steering rods are mounted to the frame through a worm gearbox. Finally, the steering wheel itself is installed.

To install the rear axle, bearings are pressed into the bushings. The torque will be transmitted to the axis itself by a pulley. The wheels can be left from the previous unit, or you can choose new ones with a stronger tread and wider width. It is recommended to select the wheel diameter for a future mini tractor from 12 inches.

Engine installation

It is recommended to mount the engine on the front frame beam. This will improve the balancing of the unit

It is important to ensure that the power take-off shaft is parallel to the rear axle pulley. This will protect the belt drive from wear.

What is included in the factory DIY kit

The kit for converting a walk-behind tractor into a mini tractor includes all the necessary parts required for this process.

Kit for converting a walk-behind tractor into a mini tractor

This set includes:

- standard steering setup;

- reinforced prefabricated frame;

- chair base;

- mechanical lift lever;

- brake cylinder;

- protective system;

- seat back;

- brake mixture tank;

- set of hardware;

- brake drum with support disc;

- belt.

KIT kit for converting a walk-behind tractor. "Version 4x2"

This is a standard kit included in the Kit. In addition, each such product contains assembly instructions. Thanks to this, the owner of the set will not have any questions regarding the installation of the unit. The cost of such kits for converting garden equipment into a mini tractor varies between 40,000 rubles.