The level of security of the building largely depends on which bolt or latch for the gate is chosen. As you know, a gate without them is useless and impractical. To reliably protect your home from uninvited guests, you need to take care of the quality of the deadbolt. Basically, the gate latch comes with a factory lock, but you can try and make a durable mechanism with your own hands.

Forged bolt

Types of constipation

Before buying a deadbolt, you need to study its functionality and methods of attaching it to the gate. Locking mechanisms differ in appearance, fasteners and the device itself.

Homemade structures are fixed on the gate in different ways.

The following fastening methods are distinguished:

- Locks that are located in the center or bottom of the gate are called horizontal. They are most often used in garages. Usually this is a so-called latch with a locking loop, a shell and a movable metal rod. Locks in the form of steel rods, which serve as a moving part and are mainly located at the top or bottom of the gate. Sometimes they are installed centrally, as in horizontal locks. This type of fastening is called vertical and is used for swing gates and wickets.

- Some bolts are installed as additional fasteners to the main lock or deadbolt. Such modules have an average level of protection, so it is better to fix them in pairs with other, more durable ones.

All these locks can be modified and supplemented depending on the type and quality of the gate and the wishes of the owner of the private property. For example, it is better to install two horizontal fasteners at the top and bottom, rather than fixing one in the center. The first option will be much more reliable.

Regular gate valve

Making different varieties

The main task of hickeys is to ensure the safety of the territory. With their help, it is possible to reduce the risk of intruders entering the site.

When making a latch for sliding or swing gates, it is worth paying attention to the reliability of the mechanism. The appearance of the mechanism is not so important, since the installation of the bolt occurs from the inside of the yard.

It’s worth taking a closer look at how to make the most common types of shutters with your own hands.

"Turntables"

Often found on garage doors and other buildings. A spinner is a device with a simple operating mechanism, the moving part of which is a wooden block. Main parameters of the part:

- length from 1.5 meters;

- thickness from 5 to 10 cm.

Wooden beams are mounted on channels, which are secured with bolts. This approach allows you to achieve maximum immobility of the structure. The work may require a welding machine or a drill if the first is not available. The beams are mounted on two channels, one of which is installed a little higher, the other a little lower.

The spinner should rotate counterclockwise.

Features of assembly and installation of the bolt.

- If there are no channels at hand, then the mechanism is made of iron strips up to 5 mm thick or bars. If a profile strip is used, its length should not exceed 2/3 of the width of the gate.

- The turntable is rotated using a bolt installed in the fixing flap. The mounting height of the bolt should be 60-70 cm from the ground in order to easily lock the doors.

- A groove profile must be welded onto each door leaf, where the strip will subsequently fall when the gate is closed. The height of the profiles is 60-70 cm.

- The pinwheel strip in the closed position should protrude slightly beyond the edges of the profile. This cunning approach will help extend the service life of the mechanism and ensure reliable fixation of the valves.

To avoid any problems while rotating the bolt, you should put two washers on it. It is also recommended to grind off the outside of the bolt head and paint it so that it becomes invisible.

"Barrier"

This is a type of turntable with a similar design. The only difference is that the steel strip is fixed using a channel welded along the short side of the sash.

Eyelets are also sometimes welded on the end of the channel in order to use a padlock in the future.

You can make a barrier for a street gate yourself; the mechanism is quickly assembled.

- A wooden beam or steel plate is used as a base. The length of the product must be less than 60 cm.

- The structure is attached to the sash using bolts as fasteners. The distance at which you need to screw in the bolt is 1/3 from the edge.

- Next, take two channels up to 10 cm long and weld them. The width of the profile should not be greater than the width of the beam. If a steel plate was used, the profile can be replaced with a cut corner. In this case, it is necessary to ensure that the part is tightly embedded between two elements - the corner and the sash.

Sometimes the barrier is reinforced with a lock. To do this, weld a loop to one of the sides of the plate, where the constipation will subsequently be attached. The second ring will need to be secured to the sash.

"Espagnolette"

There are two types of latches: vertical and horizontal. The latter are a simpler design, which is installed on one side of the fixed sash. Such bolts are made in the shape of the letter G. To assemble the mechanism, reinforcement with a diameter of 12-14 mm is used, the length of the rod is 70 cm. To assemble a vertical bolt, you will need the following.

- Weld pieces of pipe of the same size to the lower edges of the sashes. The diameter of the fixed pipe must be selected so that the reinforcement rod can fit into the hole.

- Cement two more pieces of pipe on both sides of the garage floor. They will act as clamps for shut-off valves.

The last stage involves cutting the reinforcing bars to the required length and then using the bolts. To make opening the gate more convenient, it is recommended to weld fixing grooves on both sides of the gates. Horizontal bolts are considered more functional.

To make such a constipation, you will need a metal pipe with a diameter of 10 mm or more. The material will subsequently need to be cut into three pieces.

The length of one should be 10 cm, the rest - 5 cm.

The latch is assembled as follows.

- First, the longest pipe is welded to the bottom of the door leaf. The piece is placed horizontally.

- Next, take short pieces. One is also welded to the edge, installed opposite to the first tube.

- The third stage involves threading a latch assembled from a T-shaped pin into both pieces. For assembly, a rod is used, the diameter of which is selected so that it can easily enter the pipe.

- Then the latch is moved until it stops. The remaining section of metal pipe is welded to the edge of the finished mechanism.

Mechanism selection

If this is your first homemade design, then it is better to start with the simplest elements. This experience will undoubtedly be useful for performing more complex deadbolts.

Simple deadbolt

This is the lightest device for mounting on gates. To secure it, you need to stock up on three metal staples, a latch and a base for it. Then the brackets must be welded to the inside of the gate and the latch must be secured to them. Next, for strength, a limiter is screwed to the brackets perpendicular to the floor. The main thing is that it is slightly higher than the staples.

Very easy to make

Locking lugs

This design will not take much time to assemble. Any amateur can easily cope with this task. You will need eyelets purchased in a store or made from metal plates.

Latch-trap

This device has a rather complex design, since the fixation occurs automatically. All you need to do is bring the canvas to the fixer, and he, in turn, will do the job.

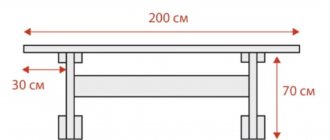

For manufacturing you will need a 50/30 mm profile pipe, a metal plate about 30 cm long and 5 cm wide.

1. To begin with, the profile pipe is buried in the ground. To make the structure more reliable, it is better to concrete it to a depth of about 40 cm. A hole is first made in the pipe for a metal plate, which will later act as a retainer.

2. Next, one edge of the plate is made into a cone, a small plate is welded to it, which protrudes 20 mm beyond its edge and makes the element look like a hook. Then holes are drilled on the other side and in the middle, one of them will serve for its fastening, and the other for the spring.

3. When the profile pipe is completely installed, the prepared clamp is screwed to it using a bolt. Then a ring is welded to the pipe at the bottom, onto which the second end of the spring clings, which, in turn, returns the latch to its original position.

4. To keep it in a horizontal position, a stopper is welded to the pipe on the spring side, which can be made from scraps of metal. To fix the garage door, it is enough to press it to the manufactured structure.

https://youtube.com/watch?v=oVd1Fmw-GSA

Modern market of locking mechanisms

Progressive methods for developing reliable models of locks for gates and gates allow owners of suburban areas to purchase electromechanical and electromagnetic locks.

The reliability of the second type is explained by the supply of voltage force, which actuates the gate leaves. A magnet has the property of literally sticking to a metal surface, and it is in principle impossible to open it without using a set of special tools.

This kit is expensive, but, according to experts in this field, the costs are completely justified. The latest models are opened after confirming the fingerprint of the owner of the estate. It is impossible to make such a mechanism with your own hands without special skills.

Conventional gate latch design

Board spinner

A wooden pinwheel is a simple and original solution for gates in the country. To make it, you need a long board, and the second one needs to be cut into 4 pieces.

A board is bolted to the edge of the sash. It should rotate freely around its axis. It should be placed in a horizontal position and places for fastening the staples should be marked. The easiest way to make them is from the second board. At the fastening points, gaskets are installed according to the thickness of the main lock.

When rotating, the board should fit into the wooden half-loops. Therefore, one connector faces up, the second on the opposite side faces down. For gates made of corrugated sheets, you can use a strip of rolled sheet metal.

A reliable lock will be achieved if you weld hinges on one side and lock the turntable. By attaching a handle from the outside to the axial bolt, you can freely enter the yard from the street if the gate is located far away and you have enough strength to turn the beam. The longer the locking strip, the better the gate leaves are aligned and the more difficult it is to open from the outside.

How to make a deadbolt yourself

Yes, today you can buy a reliable lock that has several levels of protection. But some craftsmen continue to put their knowledge into practice and make simple mechanisms for the gate with their own hands.

So, to make the simplest lock using a rod and staples, you will need some materials and tools:

- welding machine;

- pipe with rod;

- electric drill;

- Bulgarian.

Diagram for making a bolt

Metal products (pipe and rod) must be selected so that the rod fits freely into the pipe. For example, for a thin pipe, regular fittings or a profile round tube are suitable.

Next, the pipe must be divided into two pieces, the length of which depends on the length of the valves. The cut pieces are welded at the same level and a movable rod is inserted into them, onto which the handle is attached. Also, one end can be bent in such a way that it is possible to easily turn the model in different directions.

Diagram of a valve made from pipe scraps

This design can be supplemented with various fasteners, springs and hinges, and you can carefully consider how to make the base of the lock more durable.

Installation of a gate valve

It is easy to build a gate valve of this type with your own hands. The main element of the design is a heavy latch with a set of accessories. Such a plate can be made either independently, or purchased ready-made with a set of consumables.

Video description

An idea for making a deadbolt yourself is shown in this video:

When the bolt is screwed into the door leaf, part of it will protrude from the outside of the gate. It is important to file down the protruding edge. This is necessary for two reasons. Firstly, then the outer surface will be smooth and easy to paint if desired. Secondly, a ground bolt cannot be unscrewed from the outside, which means it is impossible to open the protective structure.

Using a similar technique, you can make a latch in the form of a barrier. The bar must consist of two halves so that the security latch provides double protection for the gate.

Sliding gates: bolts and latches

If sliding gates are installed on the site, then you need to know how to make a latch for the gate with your own hands. The advantage of such gates is that they are perfectly compatible with other types of locks. For example, a locking bolt is a very effective design that prevents the gate from opening from the outside. For production you will need old spare parts from a domestic car. But even if they are not there, you can use available parts.

To make the bolts last a long time: advice

Without protection from external manifestations, any constipation is unlikely to last long. You will need a secret niche made of metal or other material to prevent moisture from entering the mechanism itself. The use of machine oil to lubricate working mechanisms will be useful.

To make a lock for a sliding gate with a wicket, you just need to accurately measure the future structure and draw the correct drawing. Only under such conditions will the latch be made by any craftsman who has a set of necessary tools for precise work.

Example of a wooden gate valve

If you couldn’t make the lock you like on your own, you can always contact a reliable company that will provide high-quality installation of the lock at an affordable price.

Peculiarities

The locking mechanism that secures the gate leaves in the closed state is commonly called a deadbolt. With a well-installed lock, the process of operating the gate is greatly simplified. At the same time, the entrance structure itself in the fence becomes much more reliable. Basically, gate deadbolt models are designed to open the doors only from the inside and do not require the use of keys. That is, it will not be possible to open the mechanism from the outside.

This means that you will not need to carry any additional keys with you. With a high-quality gate bolt, the risk of intruders entering private territory is minimized. This device is capable of keeping even very massive doors closed.

What else to pay attention to

A fence in the form of a wicket or gate cannot exist on its own, since it is initially designed for some type of lock.

Usually, at the request of the gate users, the lock is installed as a separate element that is in no way dependent on the gate.

Typical deadbolt model

The requirements for locking a gate must correspond to simple and practical solutions. In a word, it should open easily and without much effort. Also, all bolts, latches and latches on it must be combined with the general appearance of the fences, without violating the integrity of the architectural forms.

Latches with secret

These latches, the functioning of which is implemented in a similar way to the convenient push mechanism of door handles. Their device is like this:

- A hook is installed on the support post, which is made of a plate with a cut tooth with the tip facing upward. The plate is fixed horizontally to the gate support post on the side of the vestibule, perpendicular to the plane of the fence.

- The locking element is a plate that is loosely screwed to the sash. The fastening bolt is located at a distance of 20-30 cm from the gate post. In the closed position, the bar fits into the protrusion of the tooth. To open the bar, you need to lift it slightly so that it is released from the hook.

Since the bar is attached freely, to prevent it from falling or rotating around the axis of the bolt, two limiting pins are installed on the gate. In the simplest design, the bar closes under gravity. If you attach a handle to the bolt from the outside, the bar will be lifted by pressing the handle.

In order for the lock to latch when closing on its own, the bar is spring-loaded with a weak spring, which will hold it in the lower position. The spring is attached at one end to the bottom of the sash, and the top is fixed to the rail. Instead of a spring, you can use a counterweight, as in the photo:

Original design with counterweight

The bevel of the front side of the tooth on the strike plate is made more flat so that the door rail can slide freely along it when closing the gate.

DIY making

On a metal plate 200-250 mm long and 30-40 mm wide, a tooth is cut out at one end with a grinder, as in the photo. It is welded (or screwed) to the support post on the side of the vestibule. A long (30-50 cm) metal plate is screwed onto the gate. Check how it engages with the tooth when closing. Weld handles and stops.

This constipation is easy to make secret. A hidden latch is a mechanism with no obvious external signs from the outside, by which one can judge the method of opening it. In a rack and pinion valve, the secret opening method is implemented in two ways:

- Using a cable, which is connected to the free end of the locking strip and through a system of blocks and is brought out in a hidden place. In this case, the device must be spring-loaded.

- Secret latches are made by masking the head of the outer bolt that holds the rack in place. Instead of a turning handle, only the head of the bolt is visible on the outside of the gate.

- Cut a false opening for the key.

To better disguise the constipation, many owners screw several more “false bolts” onto the gate, among which the “working” head is hidden. To unlock the door from the outside, you need to have an open-end wrench and know which bolt to turn.

You usually buy locks for gates, but make them yourself for gates. What's the matter? There are several reasons:

- The gate is used more often; the mechanism should work like a clock. Can you do it yourself?

- The lock for the gate is always visible. It should have a beautiful appearance and at the same time some kind of secret opening mechanism or a regular mortise or rim lock.

- The gates are more or less standard and there is enough choice of locking devices to choose the right one.

- Gates are more individual: sizes, materials, design. Constipation is hidden. No one wants to give such wide access to their plot or garage. Beauty fades into the background, the main thing is reliability and safety. That's why we make gate bolts each in our own way. And what design we choose is already a secret.

Operating rules

Difficulties in operating gate latches are caused by exposure to natural phenomena. This is especially noticeable in the autumn-winter period. At high air humidity, the metal actively rusts, which can cause the mechanism to jam. In addition, rust forms streaks, worsening the appearance of the gate. To prevent corrosion in spring and autumn, the valves are removed, treated for rust and painted.

Some craftsmen burnish steel, making it resistant to moisture.

Night frosts after a thaw pose a danger. Accumulated moisture can freeze on the bolt, preventing its movement in the body. It is advisable to protect device parts from natural phenomena. For this purpose, various housings are made for hidden installation.

If there is evidence that severe frosts are possible at night, it is necessary to wipe the moving parts dry in the evening, removing moisture, then in the morning the bolt will be operational.

Source

Recommendations

Many people think about what is better: buying a valve or making it yourself? In the case of gates, it is recommended to buy a latch, but for gates you can make a lock yourself. The explanation for this decision is simple.

- The gate is used more often, and purchased mechanisms are more resistant to mechanical damage. Such deadbolts will last a long time and look beautiful at the same time.

- In most cases, gates have standard sizes, so choosing a purchased mechanism will be easier.

- Gates are individual; various designs and materials are used for their manufacture. The result of this approach is that beauty fades into the background. The functionality of the design and its safety are more valued. Therefore, homemade valves, barriers, latches and turntables are in greater demand in this case.

When making homemade deadbolts, you can use improvised means and secondary raw materials in the form of leftover scraps of pipes or other metal products. The final choice of type of constipation depends on the owner of the site.