How to make heating from the stove?

There are several options for arranging a bathhouse with hot water supply. To ensure that the chosen method meets your personal needs, you should talk about the pros and cons of each in more detail.

Samovar tank type

The most common modification, placed on the chimney outlet. The reservoir can have a rectangular, cylindrical, or oval shape.

The water is heated using high-temperature flue gases escaping through the pipe.

There is a fitting at the bottom of the container; some models have two pieces to connect the supply and discharge lines. The tank is equipped with a convenient hole for filling water with a removable lid.

The volume of a samovar-type tank is usually small ; its maximum dimensions do not exceed 80 liters. This option is ideal for medium-sized baths.

The simplest solution when filling the tank with water is to use a regular hose, since the height to the filler neck will be at least 1.5 meters.

Advantages of the samovar type design:

- fast water heating;

- good heat dissipation;

- compactness and ergonomics;

- selection of containers of any volume;

- the ability to carry out installation yourself;

- savings on additional elements, such as heating elements or pumps.

Flaws:

- lack of visual control of water level and heating temperature;

- the large volume and high location of the container above the stove make the process of filling the tank difficult;

- impossibility of obtaining dry steam.

When buying a samovar tank, you need to pay attention to the individual serial number, passport and instruction manual. Their presence indicates compliance with all technical regulations during manufacturing.

The step-by-step installation of the tank to the chimney is carried out according to a certain scheme:

- Dismantle the pipe segment up to the ceiling passage assembly.

- Weld a pipe 8-10 cm long to the outlet of the furnace.

- Connect the pipe outlet running inside the tank to the pipe.

- Use an adapter for joining if the diameter of the pipes does not match.

- Use metal clamps to secure pipes at connection areas.

- Install the tank so that the distance between the top surface of the tank and the ceiling is at least 250 mm.

- If necessary, use an adapter for the main chimney pipe or the remaining section of the stove pipe with the same size in the upper part.

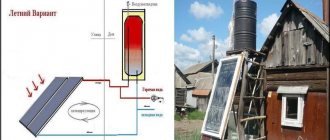

Installation diagram of a water heating system using a “samovar” type heat exchanger:

Remote tank

This product is considered the optimal solution when it is possible to remove the storage tank to other rooms in the bathhouse. In this case, the water will already be heated from the heat exchanger and flow through copper pipes into a remote reservoir.

However, when choosing in which room the tank will be located, it is necessary to take into account that the maximum length of the pipes should not exceed 3 m. The working mechanism of such a device is quite simple and fully copes with the task. Cold water falls into the furnace heat exchanger, and heated water rises into the reservoir.

The container has two main elements - the body and the bottom, connected by welding. The tank itself is equipped with two outlets, a lid and fasteners.

The tank can be selected:

- rectangular;

- oval;

- triangular shape.

Do-it-yourself water heater: choosing the type of device

Despite the fact that it is much easier to make a storage device at home, you should first of all consider the option of assembling an instantaneous water heater. Such household appliances will allow you to instantly heat water, and electricity will be consumed only when the device is turned on. Unlike boilers, installing a flow-through device does not require much space, and you also do not need to insulate the device.

To heat water, both options use a heating element, but to make a flow-through device you will need to purchase a more powerful element.

Powerful water heating element

Of the additional parts, you cannot do without the use of an RCD. This device will automatically disconnect the contacts if an electrical leak occurs. You should also stock up on large-section copper wires and tools for the job.

Heating from heat exchanger

Units operating on the principle of heat exchange are the most effective and simple way to maintain optimal temperature in all rooms of the bath. Let's look at the most popular options.

Gas water heater

The best heater in terms of system efficiency and fuel consumption are natural gas heaters.

What you need to know about security

Do not forget that we are dealing with a source of increased danger - an electric heating device, therefore, when assembling and using it, you must follow some rules:

Be sure to use a separate electrical line to connect the induction boiler, and also equip it with a safety group.

- If water circulates naturally in the boiler, be sure to equip it with a temperature sensor so that if it overheats, the device turns off automatically.

- Do not connect a homemade water heater to an outlet; it is better to draw a separate line for this with a larger cable cross-section.

- All exposed sections of wires must be insulated to protect people from electric shock or burns.

- Never turn on the inductor if the pipe is not filled with water. Otherwise, the pipe will melt and the device will short out or it may even catch fire.

- The device must be mounted at a height of 80 cm from the floor, but so that about 30 cm remains from the ceiling. Also, you should not install it in a residential area, since the electromagnetic field has a bad effect on people’s health.

- Don't forget to ground the inductor.

- Be sure to connect the device through an automatic circuit breaker so that in the event of an accident, the latter will cut off the power from the water heater.

- A safety valve must be installed in the pipeline system, which will automatically reduce the pressure in the system.

Large storage systems

When making it yourself, it is recommended to use a stainless steel tank and a copper coil. The additional costs will be offset by the high efficiency of the system.

Moreover, materials are not in short supply. The tank will fit from an old activator-type washing machine. A copper tube is sold at any plumbing store.

The internal container (in which indirect heating will occur) is selected with corrugated walls (preferably). This means there is a larger heat exchange area. And the primary heating water flows through an external point. If you cooled a pan of hot compote in a bowl of cold water, the principle of operation of the heater is clear.

Of course, such a system is more difficult to implement, but the efficiency will be higher.

The law is what the drawbar is, where it is turned there and out

The design on YouTube is not illegal, but it is not very convenient. There is even less chance of setting it up correctly for use. Here are a couple of tips to help you do this somehow:

The radiator in the video resembles something from a car hood. There was no time to figure out what exactly it was, but the point is that you will need not just a coil, but just such a corrugated surface. This will significantly increase the efficiency of the device, on which both efficiency and gas fees (if there is a meter) ultimately depend.

This device is a gas instantaneous water heater, which should produce about 4 liters of warm water per minute. It’s easy to calculate how much power it should have for this:

N = A / t = (4200 x 4 (45 - 8)) / 60 = 10.36 kW, this is the power achievable for a factory gas water heater. You can only find out if you can make an appropriate heat exchanger at home by trying it.

The device itself is a coil, which is connected at one end to a cold riser, and at the other to a shower head or mixer. The flow is regulated by a valve. In this sense, you will have to use an old cast-iron tap at the inlet or a bronze tap at the outlet of the coil. The radiator is placed on the hob grate and heated by one or two burners. It is clear that the hose must be heat-resistant, otherwise various unpleasant consequences are possible.

An adult must supervise the operation of the device and, in case of danger, turn off the supply of blue fuel while someone is washing or doing the dishes. A gas water heater or an electric water heater is much safer from this point of view. I would also like to add that even purchased equipment needs to be configured, which means that the intervention of a qualified technician will be required. Sometimes a set of jets (injectors) needs to be replaced, in other cases a reducer is installed in the gas supply path. In the latter case, the system resembles traditional propane-butane power supply.

Will need

- Before starting work, we need to find and purchase:

- old gas cylinder;

- door hinges and awnings;

- plastic pipe and corrugated elbow;

- copper tubes and elbows;

- hoses, connectors and adapters;

- solder and flux for soldering copper pipes;

- perforated mounting tape;

- screws with washers;

- steel corner.

The tools we will need are: grinder, semi-automatic welding machine, gas torch, drill, hammer, dremel, etc.

Installation methods and shapes of boilers

Boilers come in wall-mounted and floor-mounted versions, horizontal or vertical models. The capacity of the product, which is mounted on the wall, is naturally lower: it does not exceed 200 liters. Floor-standing devices can hold one and a half thousand liters. Boilers are mounted on the wall using standard brackets and suitable dowels. The most common boilers are cylindrical in shape.

Working pipes for connecting the system are located at the rear of the unit for convenience and aesthetic purposes. There is a temperature sensor and a thermostat on the front panel. There are models with the possibility of additional connection of heating elements if the power of the main heat source is not enough.

Main types of breakdowns

Modern manufacturers have learned to create excellent luxury water heating equipment. It uses gas to operate efficiently and rarely fails. However, even the best gas heaters cannot avoid breakdowns. The list of inevitable malfunctions includes:

- water leaks;

- poor heating of the liquid;

- discharge of power elements;

- weak water pressure;

- lack of gas.

Owners of gas boilers can repair some faults themselves. Anyone can change the batteries in the power supply. It is also easy to eliminate weak water pressure - perhaps excess scale has simply formed in the heat exchanger. To remove it, remove the heat exchanger and rinse thoroughly. For these purposes, you can also use special descaling liquids.

It is not difficult to solve the problem of poor water heating on your own. The main reason for such a malfunction is often contamination of the heat exchanger with soot. The solution to this problem is to remove the mentioned element and remove plaque. If more significant problems occur, you should contact a professional.

Those who have seen enough of the video on YouTube about a homemade gas water heater, which consisted of a coil placed directly on the hob in the kitchen, have probably already dreamed of how they can get a lot of boiling water cheaply. Actually this is not true. Today we will talk about why you should not make a gas water heater with your own hands.

The construction pricing reform should have been completed 1065 days ago.

Good afternoon In the standards of the GESN-2001 collection No. 12 “Roofs” 12-01-002-08, 09, 10 propane gas consumption is 11.8; 6.9; 3.4 kg accordingly are indicated erroneously. The most commonly used burners have an average propane consumption of 6 kg/hour. Based on this, propane consumption (code 542-0042) should be taken at the specified standards in the following amounts: standard GESN-12-01-002-08 - 41.4 kg, 09 - 27.6 kg, 10 - 14.4 kg. QUESTION: is there official confirmation of these figures?

6 kg/hour - what kind of consumption is this, where did it come from? According to the passport or something? Excuse me, have you ever been on a roof or waved a torch? I was and waved a lot... The operating mode in the summer is this: 30% at idle (while you are preparing the next roll, cutting it, trying it on, moving on) and with connections - all 50%. In winter, however, the consumption increases sharply - 1.5 or 2 times (you have to warm and dry the base and warm the freezing cylinders). Try to negotiate with the Customer for compensation for gas, but in practice, during roofing work, the cost of gas is a small part of the cost of the work, so you shouldn’t push too hard.

The customer, as a rule, agrees, and then the switchgear comes and says: “Who are you to add gas to the state price?” That's how it was for me. And I read about such an expense in Grand Stroy-Info in the “Consultations and Explanations” magazine. It was all written there, however, without reference to an official source. So I’m wondering how the inspectors will react to this?

And there is no official source. Even in the standard database, propane butane costs are left unchanged. So refer to “Consultations and Clarifications” No. 2-2004, pp. 12-13.

Stages of work on creating a boiler

The boiler drawing may look like this.

Creating a Heat Exchanger

When choosing the diameter of the future coil, it is important that the water in the tank comes into maximum contact with such a pipe. To do this, leave free space between the turns of the pipe.

To make the work easier, you can use a log or pipe around which the heat exchanger tube will be wrapped. One end of this tube is fixed, and then turns are smoothly created, controlling the density of the resulting spiral.

Preparing the boiler tank.

Having chosen a suitable container, you need to make two holes in it for cold water in and hot water out. Ball valves should be built into each of them for ease of operation. You also need two holes for mounting the heat exchanger. Another hole will be needed for the drain valve, which is located at the bottom of the device.

Improved design

How to improve heat transfer? That's right, it is necessary to increase the contact area. Of course, the material of the inner pipe is also important; a copper pipe transfers heat much more efficiently. But in this design, the emphasis is on saving, so we make an indirect heating boiler with our own hands from steel.

To improve the heat transfer coefficient, several schemes can be used:

Important according to paragraphs 2 and 3:

Available materials

We have already talked about stainless steel tanks from old washing machines. However, finding such a blank is not easy. A discarded 100 liter propane tank can be an excellent donor. It doesn’t hold pressure (that’s why it was written off), but it will still serve as a water tank. Of course, a gas cylinder boiler must be thoroughly cleaned (especially from the inside) and painted with high-quality waterproof enamel.

If you have free access to other materials, you can make the heater even from stainless steel sheets. You can see how to make an indirect heating boiler with your own hands in the video (watch below).

Perhaps the aesthetics suffer, but the quality and durability of the manufactured heater is no worse than the factory one.

- We already know that in the warm season, when the heating boiler is not working, indirect heaters remain out of business. In this case, an electric heating element built into the tank as a backup element will help.

- Another option for obtaining hot water in the summer is to install a second heat exchange circuit connected to solar heating systems.

- As a result, you can assemble a 3 in 1 heating system. From a heating boiler (regardless of the type of fuel), from an electric heating element and from solar energy. If two of the three energy sources disappear, you will still be able to provide your home with hot water.

Thermal insulation

To minimize heat loss, the tank should be wrapped in a layer of thermal insulation.

For this purpose, use:

- construction foam;

- isolon;

- polyurethane foam;

- foam;

- mineral wool.

Some craftsmen use a foil-based backing for the laminate. The water heater is wrapped in this case like a thermos. The insulation is attached using wire, glue or strip ties. We recommend insulating the entire building.

The lining will not only ensure long-term preservation of hot water, but will also shorten the duration of heating of the tank, which will reduce coolant consumption. Without well-equipped thermal insulation, the water in the device will quickly cool down.

Often they resort to the construction of a double tank: a small tank is placed inside a large one. The space created between them also performs a heat-insulating function.

To secure the container, hinges are welded to the top of its body, and a metal corner is installed on the wall to which they are attached.

Main types of breakdowns

Modern manufacturers have learned to create excellent luxury water heating equipment. It uses gas to operate efficiently and rarely fails. However, even the best gas heaters cannot avoid breakdowns. The list of inevitable malfunctions includes:

- water leaks;

- poor heating of the liquid;

- discharge of power elements;

- weak water pressure;

- lack of gas.

Owners of gas boilers can repair some faults themselves. Anyone can change the batteries in the power supply. It is also easy to eliminate weak water pressure - perhaps excess scale has simply formed in the heat exchanger. To remove it, remove the heat exchanger and rinse thoroughly. For these purposes, you can also use special descaling liquids.

It is not difficult to solve the problem of poor water heating on your own. The main reason for such a malfunction is often contamination of the heat exchanger with soot. The solution to this problem is to remove the mentioned element and remove plaque. If more significant problems occur, you should contact a professional.