The process of smoking at home has always been a rather labor-intensive undertaking, especially when it comes to the most delicious form - cold smoke processing. It was necessary to monitor the temperature and quality of the process for long hours, maintain the proper operation of the smoke generator and, most importantly, control how accurately the flow of smoke was directed towards the meat or fish filling. The process can be seriously simplified if you make your own electrostatic smokehouse. The quality of processing will remain virtually unchanged, and worries and problems will noticeably decrease.

The secret of live smoking

It’s worth making a reservation right away - making an electric smokehouse with your own hands only makes sense for cold smoking. Despite the fact that enthusiasts are actively experimenting with hot smoking and even trying to cook kebabs using electrostatic devices, the best quality indicators are still obtained with smoke with a smokehouse temperature of no more than 45-50°C.

In this case, the electrostatic amplifier provides two additional factors that are practically useless when processing food in a hot smokehouse:

- The electrostatic field accelerates both predominantly charged water molecules and existing polar organic compounds into smoke, including acids and lower alcohols. Thanks to this, the process of saturation of products occurs many times faster than in the absence of an electrostatic field;

- When a cold electrostatic smokehouse operates, there is no degradation or destruction of animal protein and fats, those basic building blocks that make up meat, lard or fish. In this sense, the process of smoking in an electrostatic field is very similar to drying, but with a higher processing speed.

- In hot smoking, moisture is intensively removed from the surface of the product, and even if the electrostatic field “throws” water vapor and acids from the smoke, all this is swept away by streams of hot air. Essentially, it is the process of frying meat or lard in hot air with the addition of smoke.

There are more than enough fans of both smoking methods, cold and hot, so every year more and more new methods and designs of electrostatic smokehouses appear. There are even schemes for smokehouses with a built-in unit for monitoring the temperature of the meat surface using a remote infrared thermometer and with an adjustable electrostatic field voltage. It is clear that such smokehouses are made mainly for processing large volumes of products; for yourself, you can make a small electric smokehouse with your own hands (photo).

Unlike large chambers with powerful electrostatic units, which require a barn, garage or at least a summer house, small-sized electric smokehouses can be used even in a city apartment. Naturally, the productivity of an electrostatic smokehouse is less, but the taste and quality of the product is noticeably higher.

Design Features

The main feature of a cold smoking cabinet is the need to cool the smoke, since the temperature of food processing should be no more than 30-40°C degrees. Several main elements of the smoking cabinet should be highlighted:

- chamber for smoking products;

- chimney;

- smoke generator.

Electric smokehouse device

The circuit diagram of the apparatus for electrostatic smoking is very simple and quite easy to assemble with your own hands. The design of the smokehouse consists of the following parts:

- Housings made of dielectric material, possibly wood, plastic or even paper;

- Electrostatic “radiating” mesh suspension made of steel, copper or brass wire;

- Smoke generating unit of a smokehouse or smoke generator;

- Flue flow cooling systems.

The main module on which the quality and performance of the smokehouse depends is the electrostatic field generator. There are a huge number of designs and different circuits of the electrostatic unit, but not all of them work equally successfully and provide a high quality product.

A removable wire hanger is mounted in the center of the body, onto which the products are directly attached. The radiating mesh is installed on the walls of the electrostatic smokehouse, and a smoke generator is installed in the lower part of the body. In powerful smokehouses, the smoke generating unit is removed together with the cooler as a separate structure outside the housing.

Manufacturing process

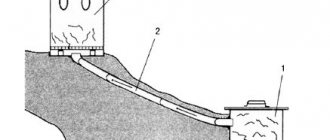

A pipe is laid and buried in the ditch.

Following step-by-step instructions, any master is able to build a high-quality, beautiful and durable smokehouse.

The collapsible structure is erected in the following sequence:

- The terrain is being marked.

- A ditch is made for the chimney. The pipe is laid and buried in it.

- A pit is dug for the base slab. The bottom of the ditch is compacted, and a cushion of sand and crushed stone is poured onto it.

- Slabs, bricks are installed or concrete is poured.

- The firebox is installed and the chimney pipe is led into it.

All that remains is to make a camera, place it on a pedestal and connect the pipes.

Smokehouse with a smoke generator in the ground

A smoke generator is a metal vessel with holes for air. The product is filled with small chips, branches and sawdust. This solution allows you to achieve fuel savings with acceptable device performance.

The structure is being erected in the following order:

- Digging a trench at least 300 cm long. Laying bricks at the bottom to form a channel.

- Filling the ditch with steel or concrete slabs. Backfilling on top of the ground.

- An excerpt from the far edge of the pit, installing a smoke generator in it.

- Construction of a house starting from laying the foundation and ending with laying the roof.

In all cases, the final stage is decorating the structures.

Electronic generator using spare parts from a TV

Most cold smoking enthusiasts believe that the easiest way to make an electrostatic smoker with your own hands is from a TV scanner. Indeed, old transistor televisions used a frame scanning board. In modern TVs, its functions are performed by several chips and keys, so getting hold of such a board will not be easy, and the device will cost a lot.

In fact, the use of a board is not very suitable for such utilitarian purposes; it is important not only to obtain an electrostatic field for the smokehouse, but also to control its power. Otherwise, the smokehouse will work like a Russian stove, so most often a separate circuit is made, which uses only a high-voltage transformer.

You can assemble an electrostatic smokehouse with your own hands from an ignition coil from an internal combustion engine of a car. There is not much difference, but if in the previous case the maximum potential of the electrostatic field in the smokehouse is only 20 kV, then in a system with an ignition coil the total is 40 kV.

The currents are very small; if the insulation is broken, the trans from the TV can noticeably hit your hands, while the impact of a high-voltage generator on a coil from a Lada car will be equal in strength to the discharge of a powerful stun gun, as in the video

Therefore, if you plan to build a small smokehouse, then it is best to make its electronic part using a TDS17 transformer.

Tools and materials

Cold smoking cabinets are usually made of wood. Laminated material with adhesive impregnation is not suitable.

Wood will inevitably impart a special aroma to products. It is better to make a smoking cabinet from alder, linden, aspen or other hardwood. It is undesirable to use coniferous wood due to the resin it produces, but spruce is allowed. After several uses, the wood smell will gradually go away.

In addition to wood, you will need the following tools and materials:

- hacksaw;

- hammer or screwdriver;

- nails or screws;

- bars for the frame, internal crossbars;

- hinges for fastening the door;

- door handle;

- a bolt or bolt - a regular latch will do;

- hemp rope or tow;

- roofing material if the cabinet will be installed outdoors;

- thermometer to control the temperature inside the cabinet;

- grates for food, rods with hooks;

- chimney pipe.

Electrostatic smokehouse for yourself, the simplest option

You can smoke lard and meat quite simply even in a city apartment, where there is no way to install and run a smoke generator, and even more so there is no way to get rid of the combustion products of wood chips. Therefore, home models of electrostatic smokers are made compact and low-power.

The main advantages of the electric smoking chamber option below are as follows:

- Very simple design;

- The minimum amount of materials and parts required for the manufacture of a smokehouse;

- Easy maintenance.

For your information!

To obtain high-quality processing of products with smoke in a smokehouse, it is necessary to use an adjustable electrostatic field. The basic provisions and operating principle of a smokehouse with a controlled electrostatic field are outlined in the video

Camera design

The smokehouse is a body with a diameter of 300-350 mm and a height of 600-700 mm; you can use a plastic or cardboard pipe of the appropriate diameter. At the bottom of the body, a metal base is made - a sleeve, preferably from an aluminum or steel container.

This design does not have a separate remote smoke generator; instead, a built-in model is used. Essentially, this is a tray with a built-in electric heater. Since the volume of the electrostatic chamber is small, no more than 70 ml of fine sawdust from beech or alder is used for one session. As a heater, you can use a Chinese soldering iron with the handle removed; instead of a tip, a copper wire bent in a spiral is laid.

The main amount of smoke in the smokehouse is formed due to the sublimation of dry chips upon contact with a heater coil heated to 350-400°C. As a result, the smoke produced for electrostatic smoking is colder, more humid and richer than that produced by thermal decomposition of wood. Most of the smoke is cooled on a cone plate at the bottom of the smoker.

In order to avoid smoke leakage, a tee pipe is installed in the upper part of the lid, onto which a container for collecting condensate and a miniature fan are placed. Some of the air and smoke from the electrostatic chamber is pumped out through a PVC tube in order to create a vacuum and prevent the leakage of odors and smoke.

Electrostatic unit design

The electrical part of the smokehouse consists of three parts:

- Electrostatic high voltage generator;

- Pendants for meat and fish;

- Grid guide.

In the upper part of the smokehouse, a grate is installed on ceramic insulators, on which a pendant with products is placed. The negative electrode of the electrostatic generator is connected to the grid. Whatman paper with glued wire is placed along the walls of the smokehouse; this is a positive electrode. Sharpened pieces of the same wire are soldered onto the wire; they direct the flow of charged molecules towards the products.

Generator circuit

The most complex part of an electrostatic smokehouse is the electronic circuit of the high-voltage constant voltage generator. The electrostatic generator circuit is shown below.

The circuit is based on a TDS17 high-voltage transformer. To form rectangular pulses, a circuit assembled on NE555 from a powerful field-effect transistor IRF3205 is used; the operating frequency of the driving circuits is about 10 kHz, but it can be adjusted using a variable resistor R5. As a result, the potential of the electrostatic field on the smokehouse grid can vary within 10%. To power the circuit, an EN 8 142 series assembly is used.

A stranded copper wire with a diameter of 1 mm is used as the primary winding; ten turns are wound directly onto the magnetic core. When setting up a high-voltage field generator, you may have to swap the connections so that the output produces the polarity required for the smokehouse.

Smokehouse in the form of a house with a pitched roof

Stationary and portable smokehouse

If the smokehouse will be used regularly throughout the year, it is advisable to choose a permanent, capital-type structure. As a base for the house, you can use supports made of brick, pipes or timber. It is advisable to choose materials that are resistant to natural factors. The supports themselves are left as is, sheathed or used as the basis for a small cabinet. The box can be used to store smoking equipment, firewood, and various small items needed in the household.

If a portable model is chosen, it should be made compact, lightweight and collapsible with grooves, hinges and locks. To make the hut look good, the pitched roof is made solid, and the exhaust pipe is attached to the back or side. This will not affect the quality of the drying process. The flooring itself is made of thick boards with grooves that fit tightly together. As a decorative element, you can cover the roof with copper tiles. It weighs a little and looks appropriate.

Schemes, drawings and dimensions

The dimensions of the firebox and chamber are selected based on the volume of food that is planned to be dried at the same time. If the owners expect to smoke fish, meat and vegetables occasionally, at picnics or before entertaining guests, a small box with a volume of 30-50 liters is sufficient. It should be borne in mind that the food will not be prepared in a few hours.

To prepare large batches of pickles, you need to build chambers with a volume of 100 liters or more. To create the required quantity and concentration of smoke, a lot of firewood will be required, which means effort, time and money.

The owner can easily design a smokehouse and make a drawing on his own; there is nothing complicated here, the calculations are simple, errors are acceptable. To save time, you can use ready-made projects, which, after implementation, have proven themselves well in practice.

Necessary materials

The list of materials for construction is small:

- pipes for chimneys with a diameter of 100 mm;

- planed boards 20-30 mm thick;

- beam 40-50 mm;

- accessories - handles, hinges, thermometer;

- self-tapping screws;

- roofing;

- metal grill;

- wire for hooks;

- pallet of their iron.

To make the smoking chamber, you should use wood that does not contain resins:

- cedar;

- oak;

- alder;

- Linden;

- birch;

- aspen.

Waterproof plywood is suitable as an alternative.

When buying boards, you need to pay attention that they do not have knots. Over time, they shrink and fall out. You should categorically avoid chipboards. When heated, they release harmful substances and soon delaminate.

Tools for building a smokehouse

The master will need the following tools:

- hacksaw;

- jigsaw;

- drill;

- screwdriver;

- level;

- roulette;

- square;

- pencil.

It is mandatory to use protective glasses and gloves.

Operation of an electrostatic mini smokehouse

Before starting, the products are hung on the smokehouse suspension for a relatively short time, 5-7 minutes. turn on the blower fan. To avoid breakdown of the electric field, the meat and lard must be dried, and even the excess moisture must be blotted with a napkin.

Sawdust is loaded into the smoke generator box, a “soldering iron” is inserted and the electrostatic system terminals are secured. Next, the smokehouse is closed with a lid and the heating is turned on; after the lower part of the body is filled with smoke, the power generating system is turned on. In order for the smoke to concentrate on meat products, it is necessary to adjust the level of the electric field potential, otherwise most of the decomposition products will settle on the walls of the smokehouse.

Useful improvements

In order to make a wooden smokehouse more convenient to use, you can additionally make several more elements.

Drovnitsa

In order to store firewood next to the structure, it is enough to make a firewood shed. To do this, one of the sides of the roof is stretched and placed on special supports. Additionally, the place for firewood can be fenced off.

Temperature sensor with thermometer

With their help, you can easily control the smoke temperature and cook smoked meats, exactly following the chosen recipe.

Universal smoking chamber made of clapboard

The following will provide instructions for making a cabinet suitable for both hot and cold smoking.

We make the frame from planed bars with a section of 40x40. Vertical length - 140 cm; horizontal (internal size) - 60 cm. We connect the corners with self-tapping screws. The height of the legs is 30 cm.

We make a groove in the front of the frame into which the door will be inserted (also from forty bars assembled into corners). We select the groove using a milling machine.

Inside, we nail foil onto all the walls, then sew it up with clapboard.

To nail the foil onto the back wall, we additionally screw bars to it.

We cover the door with foil, put insulation inside, then cover it with clapboard on both sides.

Window fittings can be used as handles.

We seal the door opening with a rubber seal.

At the bottom of the cabinet we drill two holes to connect the heating element.

In the side wall we mark a hole for the fan (diameter 100 mm) and cut it out with a jigsaw.

From above we drill a hole with a diameter of 50 mm for the exhaust pipe.

We insulate the outside with mineral wool (to the thickness of the timber), attach a hydraulic barrier and fill it with clapboard.

On the wall opposite the fan we mark a hole for the smoke generator.

We make a blank for the roof: four bars, sawn at 45 degrees. Each length is 65 cm.

We assemble the roof from blank bars

We assemble the roof into corners and cover the gables with clapboard.

We also put clapboard on top; one side can be made opening.

Result:

Ready-made smokehouse made of clapboard

Safety precautions

Since the future smokehouse will have an electrical circuit, it is extremely important to know and follow safety rules when working with it.

- First, the unit must be placed on a rubber mat (or some other dielectric base).

- The cooking process can only be started if the humidity level in the room does not exceed 80%.

- Ingredients for smoking must only be hung; contact with the mesh or body is unacceptable.

- All components of the electrical circuit must be reliably isolated from the structure itself, which is additionally recommended to be grounded.

- You can remove smoked food only after disconnecting the device from the network.

Any sign of a malfunction - the appearance of a spark or a static charge on the case - is sufficient reason to immediately turn off the device.