The presence of a summer cottage simply obliges you to have space and equipment for a “delicious” holiday. One of the most popular of them is a barbecue grill and a barbecue roaster, or both, combined into one unit. You can, of course, if possible and the space allows, arrange a whole recreation complex with a stove and a gazebo. But, unfortunately, not everyone can afford this, and therefore resort to more affordable methods of manufacturing useful devices for relaxing in the countryside. One of them is a barbecue made from a metal barrel. It is quite possible to make a barbecue from a barrel with your own hands.

Barbecue from a barrel, made by yourself

This design can be of two types: open, without a lid, or having a lid-door.

The first of them, thanks to its design, allows you to prepare not only shish kebab and barbecue, but can also have a grill function if additional skewer stands are attached to it.

To know how to build this work of engineering, and what is needed for this, you need to understand it in detail.

Types and features of barrels

Typically, steel drums have become widespread in the liquid transport industry. For example, oil, resin or gasoline.

Such barrels have a welded structure, this is done to impart corrugation and rigidity to the product.

By design, metal containers can be:

- open, in which the upper bottom is removed;

- closed, with two necks.

Reference! More detailed characteristics can be studied in the tables. The displacement and diameter of metal products are written there.

Advantages and disadvantages of a metal barrel barbecue design

Like any design, a barbecue made from a welded metal barrel has its strengths and weaknesses. The advantages of such a device include the availability of primary manufacturing material. Metal barrels can be easily found and purchased. Such barrels can be found on notice boards.

Important! When purchasing a barrel, you should pay attention to the thickness of the container walls. This is a very important characteristic that requires special attention.

As a rule, 200 liter barrels do not have thick walls; their maximum thickness is 1.5 mm. Although, the optimal thickness is 1.8 mm

Disadvantages of a barbecue installation from a barrel:

- The previous point is the main drawback. The fact is that too thin walls cannot ensure the durability of the structure. It will quickly rust or become thin, especially if the grill is lit with wood rather than coal.

- Uneven cooking of food. Of course, if you cook vegetables on the grill, then their uneven cooking is not critical, but unevenly cooked meat is a drawback;

- High fuel consumption.

This is what refers to the positive and negative sides of a barbecue made from a metal barrel.

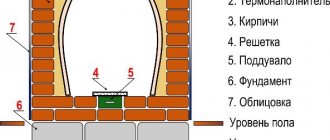

Construction of a fireplace inside a gazebo

A wood-burning fireplace covered by a gazebo is a stationary structure that cannot be moved and disassembled for storage during the cold season. Therefore, its construction must be approached with maximum responsibility.

Particular attention should be paid to the foundation, as it must withstand a heavy fire. Below is a detailed plan that will help you create a cozy corner where you can cook your favorite dishes in the fresh air at any time of the year.

Here you can read how to make a 3x4 gazebo out of wood.

Laying the foundation

Dig a pit no more than 0.5 m deep under the base. Fill the hole with gravel approximately halfway. Then compact the gravel thoroughly. As a result, you will end up with a kind of pillow.

3cd4f5f601d75faff7d74a36f634b678.jpeThen you need to install formwork around its perimeter. Next, install reinforcement, which can be iron rods or steel mesh. Next, you need to pour concrete into the formwork. After about three days, as soon as the concrete has hardened and dried, you can remove the restrictive elements.

Important! Make sure that the reinforcement under no circumstances protrudes beyond the upper edges of the formwork.

Masonry of woodshed and portal

A stationary fireplace is usually a two-level design. The first tier is the woodshed, which is placed directly on the base under the stove. Dry logs should be stored here. The bricks and concrete base must be cleaned of dirt before laying. This measure guarantees reliable fastening of the bricks to the concrete plane.

Wet the base with water, then apply a setting agent and lay the initial row of bricks. Carry out the laying using the proven method: on edge and in a run, approximately 10-11 tiers.

After completing the construction of the firewood storage area, isolate its upper border from the second row. A steel corner and an iron grate can serve as a delimiter. The dividers should be flush against the top bricks.

Important! It is unacceptable to use sand-cement mixture as a connecting solution. It does not resist high temperatures when in contact with an open flame.

The second level of the building is the portal

To lay the bottom of the portal, use fire-resistant material, placing it on a metal grate. Fill the seams between the bricks thoroughly with fireclay clay. The result should be a completely flat, stable surface. Next, lay the first tiers of the back and two side walls of the portal.

We suggest you familiarize yourself with information on how to build a 4x4 wooden gazebo.

fireplace tooth

Having completed the first two rows, proceed to laying the fireplace tooth. This element is the rear wall of the portal, assembled at a slope of approximately 60°. Its presence is necessary for the complete removal of volatile carbon dioxide.

For this purpose, treat the fireplace tooth with a grinder. From each building element of the first level, cut off a certain part at the required angle. The geometry of the side walls must correspond to the slope of the tooth and form a single whole with it. Place the top row just above the portal arch. In this position, it will ensure that volatile combustion products escape into the chimney.

Find out also how to build a gazebo with your own hands in one day.

Installation of a chimney

Also lay out the combustion product exhaust channel from refractory bricks. When installing, avoid gaps and cracks - seal them with clay in time.

By following this technology, you will provide the stove with excellent traction and protect the surrounding area from exposure to smoke. Another important point is the height of the chimney - it should be enough to ensure that corrosive gases do not penetrate the windows of neighboring buildings.

What types of metal containers can be used to create a grill?

The best option that is worth considering is containers of 50-60 liters. But, they have a significant drawback in the form of a thin wall. They can serve as a portable or disposable barbecue.

If a durable and reusable design is required, then it is best to consider the option with a 200 liter barrel. They have fairly thick walls; if the choice concerns a container for making a homemade grill, then you need to pay attention to the following items:

- options for which the bottom cannot be removed. With such barrels, a lot of work will not be required and there will be no need to mount the bottom (which will then serve as the side wall of the barbecue);

- those in which edible oil was previously stored. Since such barrels are intended for transportation of both food and chemical liquids, it is better to give preference to those in which chemicals were not transported.

Reference! The last point should be given special attention, since cooking in a chemical barrel can pose a health hazard.

Painting

To paint, you must first prepare the surface - clean, degrease, sand it. Some of this work is done before cutting the barrel, others just before painting.

a0559b107ce82bce0aff6b879f3389b3.jpe

Paint can be applied either by spraying or manually using a brush.

What paint should I use?

Given the specifics of the grill, you will need matte black paint that is resistant to high temperatures. The best option would be special paint for car mufflers. A regular coating will not work, since when the case heats up, the paint layer will bubble and peel off.

What are the features of a barbecue made from a metal barrel?

Before starting work, it is important to become familiar with the metal structure and its main design features. The requirements for the primary material from which the barrel will be made depend on this. These features include the following indicators:

- the main feature will be considered that a 200-liter barrel is the best option for cooking;

- in order to quickly clean the inner surface, the two halves of the barrel will be folded together;

- the lower part of the fryer consists of a pair of elements intended for combustible fuel and the cooking product;

- the upper part of the grill will serve as a lid that protects the product from a gust of wind;

- For greater convenience, a stand and handles are attached to the barbecue.

The metal from the barrel should not come into contact with food or melt easily.

Coloring rules

After all welding and assembly work has been completed, we can move on to the appearance of the unit. Considering that the grill will be exposed to fire and smoke during operation, we will choose a dark color for the entire structure. Usually black color is used. So that the paint can prevent corrosion for a long time, we carefully degrease all surfaces of the grill. Only heat-resistant paint should be used. It is best applied using a pressurized spray bottle.

It is important to know: what paint is best for a barbecue.

To ensure the quality of the surfaces being painted, three layers should be applied.

After the paint has dried, the unit is ready for use. All that remains is to fill it with food, firewood or coal.

Preparatory work

Before using the barrel, you need to thoroughly clean it of various contaminants and rust. It is necessary to pay attention to the fact that no chemicals or harmful substances should have been transported in the barrel. The barrel will be in fairly close contact with the food, so if the harmful fumes heat up, the food will not only acquire an unpleasant taste and smell, but may also be dangerous for further consumption.

Reference! Metal tends to absorb odors and harmful substances upon prolonged contact with some kind of chemical.

You also need to prepare all fastening elements: screws and nuts. This is very important for assembly. In addition, do not forget to draw up a drawing of the future barrel for frying shish kebab. The user must understand what result to strive for.

Container cutting

According to the drawn up drawing, the metal barrel is cut. Typically there are two options:

- some part is cut out of the barrel;

- the metal barrel is cut into two parts;

To ensure that the products are not traumatic, the cut edges must be processed.

Where to place it?

Proper placement of a barbecue is a matter of not only convenience and beauty, but primarily safety.

The basic requirements for the location of the barbecue are the same for all models, namely:

- Smooth surface;

- there should be no flammable objects (buildings, plants, cars, etc.) nearby;

- distance from a residential building by 5–15 meters;

- providing protection from rain under a canopy or roof;

- wind rose (the direction of the smoke should be in the opposite direction from the residential building).

Don’t also forget that the intense heat from a barbecue can damage any vegetation, so you shouldn’t place it surrounded by flower beds or garden beds. Not only the appearance of the landscape will suffer, but also the crop. It’s also better to think in advance about the path to the barbecue from the house and the recreation area.

Making barbecue installations

Any user can independently make a barbecue installation and choose one option from several.

Barbecue installation with cutout

The design is a solid metal barrel with a cutout on one of the parts.

The installation algorithm is quite simple:

- the metal barrel is placed on one side;

- on the side part where the cutout will be, markings are made along which the hole will be cut;

- on one side of the barrel, when cutting out, you need to leave 3 centimeters from the edge;

- on the second side the cutout must be at least 2.5 centimeters;

- using a grinder, cut out the lid in the barrel;

- where the loops are installed, a cut is made and the loop is mounted;

- try to minimize unevenness during cutting;

- hinges are installed;

- a metal profile is welded inside;

- hinges are installed to secure the lid.

At this stage, installation work can be considered complete.

By cutting into two halves

To do this you need:

- cut the barrel into two parts, you need to ensure that the cut is not completed completely.

- the loops are welded in order to connect the two parts;

- two halves are cut to the end;

- holes are made for mounting handles;

- the internal surface is cleaned of dirt and plaque;

- the body and supporting structure are combined;

- Several holes are drilled in the bottom of the structure for air circulation.

If desired, you can make a grill from one half and not install the lid.

Varieties

All barbecue models are divided into two options.

- Mobile models can be folded and easily carried, they are small in size and light in weight;

- Stationary models are barbecue ovens made of brick or stone. They are large in size, and almost all models require installation on a foundation.

Mobile barbecues are made of brick, laid without the use of mortar. These outdoor models are easy to assemble, take apart and put back together again. Design in such structures is not very difficult. Stationary barbecues are usually made of brick or stone. The functionality of such a barbecue is limited only by its design.

The simplest model of mobile barbecues is a disposable one. Its design consists of a coal tray and a thin grate. Since it is made of a thin type of tin, the tray burns out after the first use. There are a wide variety of folding models that fit into a small plastic suitcase, making them easy to transport. Their design is very simple, consisting of a roasting pan and a grate.

A more complex model is a barbecue boiler. This original American version is made of chrome-nickel. In appearance, it looks like a cauldron or deep frying pan, is presented on three stable legs and is complemented by a dome-shaped lid. At the bottom there is a round tray that is suitable for plates and other utensils. Thanks to this device and the presence of a lid, it can be easily used as an oven or smokehouse.

The barbecue trolley has a fixed or folding surface.

An electric barbecue is convenient for use indoors in the kitchen. A gas barbecue is a whole complex that contains the basic functions of a barbecue and grill. Such models are more suitable for use in the catering industry. They are very massive, weighing about 60 kilograms, which classifies them more as stationary models.

Any model has many additional elements, which gives more comfort in use.

These include the following:

- built-in mechanical and automatic spit;

- an open firebox area of increased dimensions, due to which a variation of a garden fireplace can be easily created;

- a grill designed for frying foods;

- space for installing a cauldron, which allows you to prepare a large variety of culinary masterpieces in the fresh air;

- separate barbecue area;

- structure for preparing barbecue;

- hob and work surfaces;

- smoking chamber and more.

How to make a barbecue smokehouse

Manufacturing algorithm:

- additional containers are being prepared that will serve as a firebox;

- a hole is made into it so that firewood can be placed there;

- holes are made so that there is traction;

- connection holes are installed, a chimney must be installed.

- the firebox and grill are connected using a welding machine;

- the cover is drilled;

- Holes are drilled at the bottom so that fat and juice can drain out.

At this point the installation can be considered complete.

Briefly about the main thing

Assembling a barbecue from an old barrel on your own allows you to acquire a convenient device with minimal investment of money and time and at the same time give a second life to unnecessary containers. The design of the device has a simple structure; you can choose the dimensions yourself or use the diagrams abundantly presented on specialized resources.

To work, you will need a welding machine plus a standard set of tools that are available in every home. Assembly will take several hours, after which all surfaces are coated with heat-resistant paint.

Question

Write in the comments what you think - is it worth making holes for ventilation in a homemade grill, and why?

Barbecue from a metal barrel 200 liters

How to make a roaster yourself from a 200 liter barrel.

Marking and making the cover

The principle of operation is no different from previous works.

- the surface is thoroughly cleaned of paint;

- the inside is also processed;

- markings are made on the proposed cover;

- use a grinder to cut out the lid (the cut is also not completed completely);

- hinges are installed;

- The corners are trimmed using a hacksaw.

This completes the process of cutting out the lid.

Surface cleaning

It will depend on what substances were transported in the container. If these were edible oils, then you can use the usual singing agent and warm water.

If heavier substances were used, the surface firing method should be used. You can move on to the next stage.

Installation of the brazier

To prevent the lid from falling through, two metal elements are attached that will serve as fastening. At the same stage, the grate is installed.

Reference! For convenience, a handle is built into the lid for more convenient use of the fryer.

Rack construction

I needed to make a base, and all I had around me were a few old chain-link fencing posts that I never got around to throwing out, and pieces of used plywood.

I cut the columns as follows: 2 along the length of the barrel and 4 for the legs. I wanted my grill to take up less space, so placing the barrel on top of the rack was the best option. Two columns are provided to hold the barrel and 4 legs are attached to them through holes using button head bolts. To make the legs more secure, I made a tie out of plywood. Now you can place the barrel on top so it stands tall and proud.