If you are a fan of cooking dishes in an unconventional way (in the oven, on the stove), then we can offer you a very interesting option. No, this is not a grill. This thing came to us from Asia. Tandoor is a brazier oven, a special spherical or jug-shaped grill for preparing a variety of food. They were also used for heating rooms, since the tandoor can be called a heat accumulator. Today we will make a tandoor from a barrel with our own hands. We found this to be the easiest way to make it at home. There is already an initial form from which we will build in the future.

Our design will be used only for cooking, but not for heating the room. It's not the time to do this at home anymore. Our tandoor from a 200 liter barrel will stand on the street, and thanks to its mobility, it can be moved to different places. True, for this you will need at least 4 people of average physical shape, since the weight of the entire structure will be close to 250 kilograms. Making a tandoor is very simple, everything we need can be bought for pennies, and some of it can even be at home. Let’s not torment you with long conversations, and let’s start making the tandoor.

Making a tandoor from a barrel

It is best to do the work in the summer, then the clay body will dry out best. Any barrel can be used in the process; a metal version is best. If a metal structure is not found, you can use plastic.

The construction of a tandoor, where the base is a barrel, will differ little from the traditional version, but there are still a number of differences. The structure itself will consist of the following elements:

- A solid base (a reinforced concrete slab is best);

- The firebox is clay, without a bottom, with a metal or wooden lid on top;

- The outer walls are brick, the bottom part;

- A filler made of a material that has a different heat capacity (sand or fine gravel is best);

- There is an iron grate, as well as an ash chamber and a blower door.

The design is not complicated; it looks like a jug. According to the principle of operation, an Asian stove is in many ways reminiscent of an ordinary Russian stove; an open fire from the stove creates heat, which is stored in the walls made of heat-intensive material. Ready-made tandoor ovens in Ukraine from the manufacturer in a large assortment are presented on the website https://pech-tandyr.in.ua/.

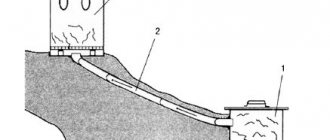

tandoor diagram

Tandoor in the Uzbek way: step by step progress

The optimal way to make an overseas stove with your own hands involves the use of improvised means - a wooden barrel. It will allow you to easily achieve the required cylindrical shape of the product. It’s good if you can choose an option made of oak.

To use it in construction, the barrel will have to be prepared. The item selected is slightly larger than the expected finished oven. It is convenient to do the preparation while the clay mixture is “ripening”.

A barrel with pre-loosened iron rings is filled to the top with water. In this way, the wooden frame lasts up to 5 days. During this period, the necessary swelling of the wood occurs. After the scheduled period, the barrel is emptied. The noticeably heavier object turns upside down.

Next, you should dry the product a little. 1 day is enough for this. The next step will be treating the inner surface of the barrel with sunflower oil.

No need to skimp on consumables. The quality of the finished tandoor for the dacha depends on the thoroughness of processing. The oiled base is left to soak for another 1 day.

After all the preparatory work, the crucial moment of sculpting the tandoor comes. To do this, it is necessary to roll sausages from the matured clay mixture, approximately 7 cm in diameter and about 50 cm long. The resulting blanks are rolled into ribbons and cut according to the dimensions of the wooden base.

The finished strips fill the entire interior space of the barrel. They should be placed in such a way that the working material overlaps. At the same time, in the upper region of the product, not just an overlap is made, but a narrowing is simulated. This will be required for the oven to function properly. The appearance of the finished tandoor resembles a jug.

When the barrel is completely lined with clay strips, the inner surface is smoothed. The presence of unevenness is ultimately reduced to a minimum.

The final stage of making the oven base is drying the clay walls. This process will take approximately 1 month (subject to weather conditions). To do this, the barrel with clay interior is placed in a dry place with good air circulation.

Growth mirrorInstallation of a lawn watering system

- Lawn laying

The drying process is periodically monitored: the clay should gradually peel off from the wooden walls. After the drying period, the barrel is freed from the steel hoops, the wooden layer is removed, releasing the clay oven.

The finished tandoor is installed on a pre-built foundation. A fire-resistant barrier is created around the stove: brickwork is made. The tandoor itself is coated with fireproof clay or covered with a special heat-resistant solution.

The working chamber of the furnace is equipped with a grate. This will improve the airflow and functionality of the product. Installing a chimney pipe will ensure draft stabilization.

Before the first heating, the inner walls of the furnace are treated with cotton oil. The initial heating of the furnace is carried out within 24 hours. Only a combination of actions will ensure reliable operation of the structure in the future.

Scheme and drawing, dimensions

How can you make a tandoor from a 200 liter barrel with your own hands? You need to create drawings using any graphic editor, or use ready-made ones on the Internet. Provided that the base is a metal barrel of a standard size, you will get a design with the following parameters:

- Cement-sand screed 50 mm thick - 1030 mm.

- The height of the brickwork is 1040 mm.

- The radius of the resulting circle inside the structure is 350 mm.

- Inner diameter 700 mm.

- Removable metal rods – 16 mm.

- Cover made of metal 5 mm thick.

We recommend: Do-it-yourself tandoor

The parameters may differ slightly in each specific case, so you need to focus on the source material.

Necessary materials

When starting to make your own tandoor from a barrel, you will need to prepare all the consumables. The main materials are:

- Solid ceramic brick.

- The barrel itself (made of plastic or metal).

- Wooden handle.

- Clay for masonry.

- Pure water.

- Sand (preferably cleaned).

- Metal grate and door for ash pan.

- Material for making the lid.

- Gravel or other material to fill the walls.

- Cement, reinforcement and crushed stone.

Only after everything necessary is available, do they begin the work itself.

Required Tools

To make an Asian oven, where the base is a barrel, you do not need technically complex equipment. Usually all the items listed below are already present in the master's kit. Before starting work you need to prepare:

- Bulgarian;

- Drill;

- Putty knife;

- Chisel;

- Metal scissors;

- Master OK;

- Kelma;

- Ruler with level.

This will be quite enough to quickly and, most importantly, efficiently cope with the task.

Step-by-step manufacturing instructions

How to make a tandoor from a 200 liter barrel with your own hands? It is necessary to strictly follow the instructions, as well as the recommendations of the masters who have already managed to bring the idea to life. A simple step-by-step plan will help you avoid mistakes.

Stage 1. Preparing the base

Before starting work, a suitable flat area is selected where the device will be used directly in the future. You need to dig a hole with a diameter not much larger than the size of the future structure. A sand “cushion” is lined at the bottom; 10 centimeters thick will be enough. Reinforcing mesh or metal rods are laid on top; even fairly thick wire will do.

It is best to fill the hole with concrete mixture and let it dry. It is very important to level the surface. To obtain sufficient strength, you should wait at least a day.

Stage 2. Preparing the barrel

First, you should find a suitable 200 liter barrel for the job. They are usually used as containers for flammable material or lubricating liquids. Therefore, it is imperative to thoroughly wash the surfaces with warm or hot water (even steam will do), and also make sure that there are no life-threatening materials left inside.

We recommend: Base for the stove

It is necessary to cut out the end part of the barrel, preferably the one where the neck part was located. They do this using a grinder. The smoother the edges are, the easier it will be to process them later.

Stage 3. Laying the walls inside the barrel

Before laying out the brick, you need to use a grinder to cut out a small rectangular hole in the bottom part. It will then be used to supply oxygen to the combustion area.

After this, a laying of refractory material is done, always on a clay mortar. The blower area requires special attention; here the brick is cut with a grinder. It is given the desired shape, or one of them is placed vertically.

The lid for the blower is made from the same brick; for this, a handle from a wooden handle is attached to it.

You can drill the product with a drill with an impact mechanism or a hammer drill.

Stage 4. Bricklaying from the outside

The external masonry is made of red brick, and the void between the barrel and the masonry material is filled with insulation. Clay is used as a bonding solution.

The work is completed by installing the finished tandoor on the prepared base and making the lid. To preserve heat, it is advisable to make two of them: wooden and metal. One will be located on the lower level, and made of wood on top.

In this case, the heat will not evaporate during the cooking process.

What can you cook?

The main purpose of a simple tandoor is to prepare a delicious dish in a short period of time.

Such designs are most often used for family evenings outside the city. It is used for:

- Baking;

- Meat dishes;

- Cooking fish;

- Vegetable barbecue;

- First courses.

Thanks to such products, it is possible to quickly boil water for brewing aromatic tea. As noted above, large-sized models allow you to cook several dishes at the same time.

Despite this structure of the tandoor oven, the smells inside do not mix with each other. Each product acquires a golden crust and a juicy structure.

Operating rules

Once the tandoor has been installed on the prepared foundation, you can try it in operation. The first ignition requires increased care, as well as a gradual increase in heat. Dry firewood is placed inside, and both the top and bottom should be open. The volume of stored raw materials should not exceed 2/3 of the furnace volume. It is better to use branches of fruit trees for ignition; they provide more heat and aroma.

Sufficient heat inside is achieved approximately 1 hour after igniting the wood. In many ways, the time depends on the selected raw materials and the volume of material used. Features of operation of the resulting furnace:

- After the combustion of the wood is completed, and the temperature rises to operating temperature, all burnt residues, twigs, firewood, and coals are removed;

- The ashpit is closed, and the cooking itself is carried out without fire or coals, only due to the heat stored in the walls;

- It is allowed to maintain a thin layer of coals at the bottom if you plan to work with the furnace for a long time;

- Flatbreads or other dishes are placed on the walls with one quick slap. Once a bright golden crust has appeared, you can consider everything ready.

We recommend: How to lay bricks

When the walls are heated to maximum temperatures, hairline cracks may appear on the inner walls or a characteristic cracking noise may be heard, but there is no need to worry about the efficiency; this does not affect the service life of the structure in any way.

In the tandoor they prepare shish kebab with various meats, vegetables, flatbreads, using skewers or a barbecue. The most popular dishes are flatbreads, lavash and samsa. If a cauldron is placed inside, first courses, as well as pilaf, are prepared in it. A special hook is used to roast a leg of lamb. Cooking in this design takes from 15 minutes to half an hour, but it all depends on the dish itself and the temperature inside the tandoor.

Temperature conditions in tandoor

It was already mentioned above in the article that the temperature inside the structure is maintained quite high. But some people think that this temperature can be maintained using a regular barbecue. But this is a common misconception.

Inside the tandoor the temperature reaches 400 degrees. No barbecue can guarantee such a high temperature, since this is due to significant heat loss that cannot be minimized.

It is noteworthy that a horizontal tandoor in the shape of a barrel is more suitable for industrial baking. Because it is more convenient to bake different cakes in it. The temperature in them is also quite high.