One can even exaggerately say that man came from a primitive state gradually to civilization, thanks to the preparation of summer products for future use. Monkeys, as you know, do not store anything in reserve.

In addition to preserving the harvest, dried fruits are also beneficial for health.

For example, one cook serving members of the Politburo of the CPSU Central Committee wrote in his memoirs that at all dinners it was mandatory to serve dried fruit compote.

Not juices, not fruit drinks, but dried fruit compote.

That is, proper drying of plant products is not only about preserving the harvest, but also about health benefits.

We have found out the need for drying, the main question is how best to do this? As it turns out, you don’t have to buy expensive branded dryers for this.

Using inexpensive materials (up to 1000 rubles), you can assemble a productive, economical and very convenient dryer on which it will be equally easy to dry greens, berries, mushrooms, pieces of fruit, fish, etc.

Many people are not satisfied with store-bought dryers either because of their quality or their price. And it happens that both at the same time.

But the most important inconvenience is their small size. What can you dry in a small saucepan with a 250-300W heating element?

In order to process a rich harvest, such a thing must function offline for days on end.

Meanwhile, homemade options are assembled in much larger sizes and at the same time cope with their task no worse than store-bought ones.

In a few hours, it is sometimes possible to dry a volume slightly smaller than a bucket! It all depends, of course, on the type of product. Compare this to factory pots and boxes.

At the same time, the cost of homemade ones will be 5 times lower than the price of the cheapest ones sold on the market.

And if compared with expensive and high-quality models, the difference will be more than tenfold.

Let's look at three popular ways to assemble such an electric dryer with your own hands, and you can choose the right option for yourself.

Assembly options for solar dehydrators

Solar dehydrators are dryers that use solar energy to operate. They are good for drying herbs, fruits or vegetables, even fish. Such designs are more economical, however, they can be used effectively only in hot sunny weather. You can make a very simple design in the form of an ordinary box, or you can make a more “advanced” device equipped with additional equipment.

Simple solar dryer

To make a simple solar dryer for your summer cottage you will need a minimum of materials, tools and time. The assembly of the housing is carried out using a method similar to the manufacture of a dehydrator in the form of a homemade cabinet. The exception is that there is no need to make holes for fans and in the dryer door.

Small slots for ventilation are made in the upper and lower walls of the structure and are equipped with mosquito nets. Another difference is that the bottom surface must be longer than the top, thus achieving an angular position for the door. The drying box must be placed on a stand made of wooden blocks, made like a stool.

The box door must be made of transparent material: glass, plastic, plastic film. It is mounted to the top like a frame.

The box contains slats for baking sheets. Their number is determined by the size of the manufactured box. You should not leave a small distance between the pallets - this has a bad effect on the circulation of air masses.

In the end, all that remains is to select or make suitable pallets. After which you can place the homemade dehydrator in a well-lit place.

Device with collector

A solar dryer with a collector is a more labor-intensive version of the product. The drying box is designed almost the same as a simple dryer. But there are a number of significant differences. This dehydrator consists of 2 parts: an air heating zone (collector) and a food drying zone. The front of both areas should be covered with transparent material.

Holes should be made at the bottom of the heating zone for free air flow. An aluminum plate painted black should be installed on the inner wall of the collector. Air passing along this plate will heat up and flow through an additional hole into the lower part of the drying zone. As it rises, it picks up moisture and exits through the exhaust pipe to the outside.

For a dryer with a collector to work effectively, it must be moved so that the collector is constantly facing the sun. To avoid this, you can improve the dehydrator with additional collector devices on each side.

Modification with fan and thermostat

To make a solar dryer with a fan and thermostat, you should prepare the following materials:

- glass or plastic;

- plywood;

- corners, bars, slats;

- wheels with a diameter of 40-80 mm (for ease of moving the unit);

- aluminum sheet;

- small fan (diameter 120 mm, 12 V);

- thermostat;

- voltage stabilizer with KR142EN8B microcircuit;

- 12 V solar battery;

- mosquito net.

For ease of assembly, you should be guided by the drawing indicating the dimensions of the product parts, which is presented below.

The first step is to assemble the body of the product from beams and plywood and seal it. Then, wheels are mounted on the bottom of the dryer. With their help, the product will easily turn towards the sun. The back door of the dryer is made of transparent material (glass or plastic).

If you follow the dimensions suggested in the drawing, then 7 pallets can be installed in this dryer at a distance of 7 cm from each other. For this purpose, wooden slats are mounted in the body. It is appropriate to make pallets for such a design from mesh material and support slats.

A black painted aluminum sheet is installed on the manifold. A fan is mounted in the upper part of the box and, in accordance with the diagram, an electrical circuit is assembled from a fan, a solar battery, a voltage stabilizer and a thermostat.

When connecting the elements of the electrical circuit, you should be guided by the diagram below.

To increase the performance of the assembled solar-powered dehydrator, it must be placed so that the collector and battery are facing the sun's rays.

Types of drying chambers

Do-it-yourself dryers are classified in the same way as their factory-made counterparts. First of all, they need to be divided into devices that use solar energy and electrical devices equipped with shades and fans . The first ones are different

Despite the variety of such devices, their design is generally the same. This is a cabinet of different sizes, usually made of wood, with ventilation holes, glass walls around the perimeter or on one side to allow heat to enter. Their counterparts using electricity have a more complex device. According to the principle of operation, they are divided into conventional electric dryers using convective or infrared heating methods and dehydrators, which provide a function for precise temperature adjustment, which leads to complete dehydration of the product.

Convective

In this option, drying occurs with a directed flow of heated air. The design provides a shadow that can be located above, below or in a horizontal plane.

The easiest way to make such a device is to assemble a chamber, install a heater and a fan heater in it. However, the quality of processing becomes a victim of design simplicity. The fruits are dried from the outside, retaining moisture in the core. They are not suitable for long-term storage because they quickly become moldy and pose a risk of botulism infection. This disadvantage can be minimized by longer drying times, but this leads to the loss of a significant part of the beneficial properties and increases energy consumption.

Infrared

These devices use infrared radiation, the effect of which is as close as possible to that of the sun. The effect occurs more evenly, vitamins and microelements are better preserved. Drying results are better suited for long shelf life.

A serious advantage in favor of this variety is low energy consumption. But here there is a higher risk of making mistakes, drying out the products and losing their beneficial properties.

It is more difficult to assemble such a device; you will have to select a suitable infrared emitter and choose a scheme for its correct placement.

Dehydrator

Translated into human language, installations of this type are called a dehydrator. The design of these devices is designed for maximum moisture removal. Despite the fact that the same term is often used to refer to conventional dryers, the difference between them lies in the presence of a thermostat that controls the temperature.

Thanks to such design improvements, drying occurs under optimal conditions in a tolerably short time. This device is better than others for drying beef, pork or fish . Result: maximum free from moisture, evenly dried, able to retain consumer properties until the next harvest and longer. But to assemble a dehydrator with your own hands, you cannot do it with improvised means; you will need additional equipment.

Types of fruit dryers

Currently, the consumer can independently produce three types of dryers:

- electrical;

- infrared;

- devices “powered” by the sun.

In the first device, moisture from the fruit will evaporate by exposure to hot air, which will be forcibly heated by the built-in fan. Such devices delight with efficiency, reliability and long service life.

Infrared models' drying method resembles a process involving sunlight. Only the role of the source will be performed by a special heater that transfers thermal energy to the products. Moisture will be removed from the fruits, and they will retain their color and presentable appearance.

Solar dryers are devices in which fruits are dried using a natural method under the influence of sunlight.

Useful tips

- Vegetables and fruits should be cut into small and not very thick pieces.

- If you are using a fan dryer, you do not need to turn on the air flow right away. It is necessary that the slices lie in the dryer for 2-3 days.

- Temperature is the main criterion for the correct drying process. 40-50C is the optimal temperature at which the maximum vitamins and nutrients will remain in dried products. Therefore, some summer residents cover the internal surfaces of the dryer with thermal insulation material. This is especially true if the device is made from an old refrigerator.

- Shelves should only be mesh. It’s just that air must constantly circulate in the internal space.

As you can see, making a dryer for drying vegetables and fruits with your own hands is not so difficult. Mostly used building materials are used, so production costs are low.

Harvesting difficulties

There are certain difficulties and inconveniences associated with the drying process. It often happens like this: you’ve just put the food out to dry, when suddenly the wind subsides or the sun disappears, or it even starts to rain, and all the work goes down the drain. But the greatest evil in the summer is associated with flies. They swarm around the exposed product and before you can blink an eye, they will lay their eggs in it. In this case, a DIY mushroom dryer will help.

Important! Flies are malicious carriers of infection. Contact of these insects with products is simply unacceptable. It is because of this that before hanging fish and meat preparations in the sun or wind, many wrap them in gauze; however, this does not always guarantee reliable isolation from flies, and in light winds it can complicate the drying process.

Particular difficulties arise for fishermen, because after a good catch and salting of the caught fish, it is simply unrealistic to wrap each fish in gauze to dry, and the likelihood of spoilage of the product by flies increases significantly, especially if the fish is layered. But still, there is a way out.

After many experiments, a wonderful solution was found - to make a dryer for mushrooms with your own hands, reminiscent in shape of matchboxes, or rather, the lid of this box, only several tens of times larger.

Assembling an infrared dryer

An infrared dryer is suitable for mushrooms, vegetables, nuts and fruits. It’s quite easy to make it yourself. To do this you will need the following materials:

- iron wire with a diameter of 5 to 8 mm;

- a cardboard box, for example, from a vacuum cleaner;

- aluminium foil;

- metal mesh;

- light bulb socket;

- awl;

- screwdriver;

- self-tapping screws;

- socket for a regular light bulb with fasteners;

- thermometer;

- infrared lamp;

- aluminum tape or glue.

The installation is created in the following sequence.

The insides of the box are covered with aluminum foil using tape or glue. Shelves are made from mesh according to the size of the box. On any wall near the bottom, make a hole for the supply wire and secure the cartridge with self-tapping screws. Screw in the infrared bulb. A thermometer is attached to any sidewall. Cut the wire into pieces that are approximately 5 mm longer than the width of the box. Punch holes in the sides for the rods for the shelving. They insert a wire into them and seal its protruding ends with tape on the outside. Stack the shelves.

As a result, after all the manipulations, you will get an installation similar to that shown in the photo below.

The lid can be the side parts of the box, or it can be made separately from the same cardboard. If you want to automate the design, you should use a temperature sensor. Under his control, the light will turn on automatically.

Also in the created design you can use an incandescent lamp (its sufficient power is 60 W) or a heating film used to create heated floors. In the latter case, at home, a piece of 50 by 100 cm with a power of 110 W is sufficient. In general, the length of the fragment is selected based on the box used.

When using film you will also need:

- insulation, for example, bitumen, used to create heated floors;

- a set consisting of 2 clamps, two eyelets and the same number of terminal rings, which is intended for connecting power to the film.

PVC tape is laid on top of the bitumen insulation. To connect the film, you will need to solder wires and contacts.

This dryer allows you to reach temperatures of almost 60 degrees. It can be rolled up and placed on the bottom of a box made using the previously indicated method.

General device design

It should be noted that today gardeners use three types of dryers, which are based on different drying principles.

- Using air flow movement. In principle, the structure of this device is a box, inside of which grids are laid one above the other, and chopped fruits or vegetables are placed on them. One or two holes are made on the side of the box into which fans are inserted. With their help, airflow occurs.

- Using the sun. This is a chamber in the form of a box, installed at an angle so that the sun's rays always fall on the pallets where fruits and vegetables are placed. The front part of the device is often covered with glass or mesh. Experts recommend not using a metal body in this type of dryer. It becomes very hot under the influence of sunlight and begins to emit a lot of thermal energy, which negatively affects the quality of dried fruits.

- Dryer with infrared heating element. In principle, this is all the same as the solar variety. Only instead of sun rays (free), ultraviolet rays are used here, which are emitted, for example, by a special film connected to a transformer. A very effective design that dries quickly and efficiently. But of all those described above, it is the most expensive. True, one of the advantages is the fact that the design of the dryer itself can be simplified to a minimum. There is no need for a drawer or chamber, you just need to install mesh shelves and direct the UV rays from the heating element onto them.

Use of air flow movement for drying

How to inexpensively equip grain storage warehouses

Just as with old equipment for working with grain, which is given a second life, the same is done with warehouses. Old warehouses are renovated and used for their own needs. On farms, old premises that were originally built for other purposes are also being converted for grain storage. As Vasily Znaydyuk said, in his practice there was a case of converting an old cowshed into a grain warehouse.

But metal warehouses can be transported —farmers also use this.

“Such structures are easy to dismantle, transport and reassemble. They require a foundation for columns, a hard surface, or a floor in the form of corrugated sheets or slate. Ideal for the small farmer. You can save money on the cost of metal, construction work and construction time,” said Yaroslav Shtyka.

For a farm, such a warehouse will cost a little more than the price of scrap metal, plus dismantling, transportation and installation. But the most economical option is to rent a warehouse, renovate it and use it.

What can you cook with a dehydrator?

Dried fruits. Do you like prunes, dried apricots, dried berries and pieces of fruit? A dehydrator is what you need! Homemade dried fruits are more natural, healthy and economical compared to store-bought ones (expensive and unknown how they are prepared).

Paste. The taste of fruit and berry marshmallows from the store is incomparable to the taste of homemade natural marshmallows prepared with your own hands. Treat yourself and your family with a simple, but tasty and healthy treat!

Eco-chips. With the help of a dehydrator, you can enjoy the only chips in the world that will bring nothing but goodness! Banana, orange, strawberry and any other fruit slices of your choice.

Raw food breads, kozinaki, sweets, cookies and cakes.

Healthy snacks are a reality! Of course, if you have a dehydrator at home. With it you can dry not only fruits and vegetables - even sweets such as candies, cookies and kozinaki can be easily obtained in a raw food version.

Crusts for raw food pizza, cake or pie.

To make pizza or pie, you don't have to bake the dough. You can dry it in a dehydrator at temperatures up to 40°C and get the basis for a raw food pizza or pie - all you have to do is put the filling on it according to your taste.

Fermentation of yoghurt and soy cheese.

With removable trays, the Dream Vitamin dehydrator can accommodate large jars of yogurt or soy cheese to speed up their fermentation.

Herbal preparations for storage.

A dehydrator is an ideal device for preparing herbs for tea or infusions. Fireweed, mint, lemon balm, lavender, chamomile and many other aromatic and healthy plants will be carefully dried and will retain their benefits and natural taste for you. And to make drying herbs even more convenient, the Dream Vitamin kit includes 9 sheets for bulk products.

Drying papier-mâché and other crafts made from plaster, dough or clay.

The dehydrator will be useful not only for lovers of tasty snacks, but also for handicrafts: with its help you can dry crafts made from clay, plaster, dough and papier-mâché.

A dehydrator is an indispensable technique in the arsenal of a raw foodist and anyone who cares about their health and strives to eat healthy. With a homemade dehydrator for fruits and vegetables, you will enjoy delicious and healthy delicacies: raw food breads and kozinaki, dried fruits, marshmallows, eco-fruit chips. The main features of dishes prepared in a dehydrator are natural taste, benefits, simplicity and economy.

As the most optimal model in terms of price/quality ratio, we recommend the Dream Vitamin DDV-10 horizontal dehydrator from RawMid.

This model can dry food at temperatures up to 40°C, has a built-in timer, and 10 removable steel trays. The device comes with 9 pallets for marshmallows and 9 grids for bulk products.

With this dehydrator, preparing your favorite dishes will be a pleasure!

Solar dehydrator with collector

A more complex version of the solar dryer (shown in the photo below) consists of two sections:

- air heating zone consisting of a collector;

- drying zones where products are placed.

The front parts of both zones are covered with transparent material, for example, glass, polycarbonate.

The collector is a box, the bottom of which is covered with a thin sheet of metal painted black. A heat insulator (mineral wool or sawdust) is placed under it to minimize heat loss. Air enters the heating zone through the ventilation holes. Then it goes up through the food shelves and out.

For the device to work effectively, it must be constantly kept with the collector directed towards the sun. If the collectors are installed on three sides, then there is no need for rotation, and such a drying unit will work all day. All cracks are sealed with sealant.

Necessary materials

You need to start making your own drying unit with a drawing and preparing the necessary tools. For the simplest designs, an approximate diagram is sufficient; more complex ones will require detailed elaboration of individual elements of the device. The set of tools also depends on the complexity of the project, but most likely the required items on the list will be:

Materials are also selected based on the project and the selected type of device. For the convective model you will need:

The same materials are suitable for the body of the infrared device, but instead of shadows or lamps with fans you will need to purchase:

The simplest designs are assembled from a minimal set of components. These are the same wooden materials for the body, in addition to which you will need glass or polycarbonate.

How to make an electric fruit dryer with your own hands

A device operating from an electrical network has a number of characteristic features. The operating mode is as follows: moisture is removed by means of heated air masses penetrating 1 cm inside the fruit. At the same time, the fruit retains all its qualities and vitamins, which is why it will be stored for a long time. But before manufacturing such a unit, you will need to prepare tools and understand its structure.

Electric dryer device

Structurally presented devices have a body where shelves for fruits are located. Each shelf holds approximately 1 kg of food. In addition, the unit has a heating element. The top of the device is covered with a lid with slots. It ensures unhindered air movement inside the device.

What you need for work

Electric apparatus for drying fruits consist of the following parts:

- body (plywood sheets measuring 60 by 80 cm or an old refrigerator);

- mesh made of metal;

- shelves for arranging vegetables and fruits;

- a fan with a motor or two incandescent lamps with a power rating of 150 W;

- screws for fastening.

Accordingly, to make our own drying unit we will need the presented parts.

Making a Dryer: A Step-by-Step Guide

Step 1. If using sheets of plywood, the first step will be to connect them. And when preference is given to the refrigerator, you need to remove the compressor, freezer and remove the glass wool.

Step 2. You need to make holes at the top and bottom of the dryer for unhindered air movement.

Step 3. Make the bottom. The role of the bottom can be assigned to a grid with small cells. A grill grate can also fulfill this role.

Step 4. The interior of the dryer should be lined with insulating materials.

Step 5. Then slats are attached inside to arrange the pallets. They can be made from wooden beams or mosquito net edging.

Step 6. At the last stage, install the fan on the case and check the functionality of the device.

Principle of operation

All dryers run on electricity. Thanks to it, optimal conditions are created for drying products - the temperature rises and air flow is ensured. The air flow is generated using a fan, which can be located at the bottom, less often on the side and top of the device. The fan performs the function of wind. But, unlike natural conditions, it blows constantly and evenly, which improves the dehydration process.

The heating element (heating element or infrared) makes the flow of artificial wind hot or warm. Products are cut into small pieces or slices and placed on removable trays. The dryer body helps maintain the necessary microclimate inside the device and protect products from insects that can spoil them.

How to stick a thermal sticker on clothes? Check out the step-by-step instructions.

Find out how to care for home jasmine, how to water and propagate the plant from this article.

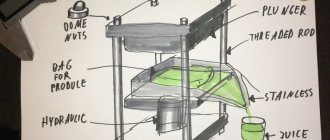

Do-it-yourself dehydrator for meat and fish

A dryer for meat and fish can be easily made from a plastic container. For this you will need:

- fan;

- plastic container equipped with a lid;

- steel rods with a cross section of 5 mm or studs with threads, washers and nuts;

- pipe cut or coupling.

The entire process of making a dehydrator for drying fish, meat and drying other products from a plastic container is demonstrated in the video:

It’s easy to assemble a dehydrator for fish, meat, vegetables, fruits and other products from scrap materials: plywood, boxes, a refrigerator. Various working old fans are suitable for blowing. In each case, you will, of course, need to think over a way to secure them, but the economic costs will be reduced. In small installations, you can use a fan from a computer, having previously provided the required supply voltage. If you automate the dryer, then in terms of functionality it will be able to compete with factory analogues. When drying meat and fish, it is imperative to prevent flies from entering the interior of the installation so that they do not spoil the products.

Step-by-step construction of a drying cabinet

Since the solar and electric varieties of the dryer have quite a few design nuances, the assembly sequence of each of them needs to be considered separately.

Solar

The simplest version of such a structure consists of a plywood body with glass doors and shelves inside. It is installed on the sunny side at an angle, so that the heat has maximum effect on the inner chamber.

Electric

To assemble the electric version, you do not have to assemble the cabinet from scratch. An old cabinet or small cabinet of sufficient size will do just fine. Some craftsmen adapt old refrigerators for these purposes. Let's consider the option from a cabinet, as the simplest in terms of labor costs.

As you can see, in order to build a dryer with your own hands you don’t need to make any special efforts, and there are many benefits from this device. You can make a dryer yourself from scrap materials without spending a lot of money. Use our tips and instructions and enjoy your vitamins at any time of the year.

Source

How to prepare boxes

Place a fan heater in the lowest row so that the warm air moves upward. To do this, a hole is cut in the box with a diameter slightly smaller than the fan. It is necessary that it fits tightly in the hole made.

The resulting structure must be installed on the same box. This must be done so that the wire does not get pinched (it will be located freely in the lowest drawer), and there will be constant air access to the fan heater. You need to install another one on the box with the fan, and make holes in it for access to the power and temperature regulators.

Ventilation and release of moist air

Warm, moist air must escape somewhere from the cabinet during the heating process. To do this, a hole (d-100mm) is cut from the top and a plastic pipe is inserted there.

If you want to do without plastic and pipes, make not one, but three holes of a smaller diameter (35mm) around the perimeter.

It is only advisable not to leave all these holes open, but to install some kind of protective grille or mesh there to prevent flies and insects.

But still, as operating experience shows, with one hole in the form of a pipe it is possible to maintain a more stable temperature regime than with three.

All dampness, smell and steam will go outside through this hood. During the drying process, do not forget to swap the trays, because the bottom row dries much faster due to the close proximity of the fan heater.

With a large harvest, processing it with a relatively small factory dryer is a very non-trivial and tedious task. And with the help of such a large cabinet you will do it quickly and with pleasure.

Expert recommendations

Using three strips of thin steel, the gables should be made. At the bottom of each strip it is necessary to make longitudinal bends that will not allow rain to penetrate inside. Such useful homemade products necessarily include a roof, which is made of two sheets of polycarbonate. The principle of operation of the device is ventilation; for this, a box should be installed. Air will penetrate through the mesh pan, removing moisture. Through the roof, where there are gable and side gaps, excess moisture will evaporate. To increase the intensity of traction, the back wall should be covered with black film.

How to make an infrared fruit dryer yourself

An infrared dryer is an alternative to electrical devices. They are quite similar in their method of operation. And fortunately, any consumer can make the presented device with his own hands at home. This does not require any special knowledge or skills. All you need to do is follow the instructions below.

What does an infrared dryer consist of?

The design of these devices includes a cable with a switch and plug, a 100 by 50 cm film intended for heated floors, as well as 2 terminals, a similar number of eyelets and clamps. Everything is extremely simple.

Required tools and materials

The materials described in the previous paragraph will definitely be needed to make your own dryer. But besides them, we need to prepare several tools to successfully complete the work, namely:

- soldering iron;

- bitumen and PVC insulation;

- metal block.

Step-by-step production of an infrared dryer

The process will not take much time and you will only need to follow a few simple steps.

Step 1. Support corners and walls must be trimmed so as to prevent their contact with the heater.

Step 2. Three bases for IR element holders should be cut out of cardboard.

Step 3. To direct the radiation to vegetables and fruits, you will need to use foil, which will serve as a reflector.

Step 4. At this stage, we cover the inside of the case with foil and connect the heaters to the transformer.

Step 5. Afterwards, you should assemble the entire system and check the device for functionality.

Do-it-yourself electric dryer for fruits and vegetables

To do this, you need to make an electric dryer body, buy a fan, a heating element, a temperature sensor (thermostat), a time relay, and two chimney draft regulators.

Fan

For our purposes, household smoke exhausters for boilers are best suited.

Smoke exhausters for domestic boilers

Their distinctive feature is that they can pass through air at temperatures up to 150°C without damaging the electric motor. An ordinary axial fan is not suitable for these purposes. It is not able to work at a temperature of 50°C for a long time. The diameter of smoke exhausters starts from 150 mm. An electric heating element with an open spiral must be placed in the pipe coming from the smoke exhauster.

Electric heating element for dryer

For maximum heat extraction, the heating element must have an open coil. The power is calculated based on the permissible rated power for the house and is equal to 3 kW minus the power of the smoke exhaust fan and household appliances. If this norm is exceeded, the automation will work and turn off the lights in the house.

Electric heater with open coil

When choosing an electric heater, consider its dimensions. It must fit into a pipe that is connected to a smoke exhauster or fan that supplies air to the drying chamber.

Smooth thermostat

Thermostats with smooth temperature control from 0 to 300°C are a standard part of all household electric furnaces. It must be connected in series to the electrical circuit with heating elements and a fan. When the required temperature is reached, it will automatically turn off the heating and fan.

Household thermostat

You can use a thermocouple from ovens.

Where to buy a thermostat? There are several purchasing options:

It is quite possible to purchase a thermostat at a flea market.

Time relay

In order to fully automate a homemade dryer, you need to buy an electronic two-channel time relay with weekly programming.

There are many options for designing and programming time relays and everyone can choose the right one for themselves.

By connecting a fan and heating element to the time relay, you can adjust its operation experimentally. To do this, you need to set the turn-on time of the heating element and fan.

Chimney draft regulator

Draft regulators are installed in stainless steel chimneys. This automatic device consists of a precisely fitted valve on an axle. To ensure that it is always closed or open, a small weight is installed on one side.

Install these two valves in the inlet and outlet openings of the dryer. When the fan is turned off, they will close the inlet and outlet of warm air under the weight of the load.

Traction regulator

The use of these valves will allow you to automate air intake and supply without the use of actuators and expensive controllers.

For particularly advanced handymen, we recommend purchasing a programmable controller. This equipment is more complex, but it allows you to automate all drying processes, connecting humidity sensors, temperature sensors, motors, gate valves and other actuators. They are widely used for lumber drying kilns.

How to assemble a structure

The required number of boxes are placed on the constructed structure. Each box is a drying container. If the cells at the bottom of the box are large, then you can cover the bottom with a mosquito net with medium cells. The assembled pyramid must be wrapped with stretch film - at least 7 layers for packaging film and at least 10 for food film. This ensures overall sealing of the structure. It is necessary to wrap all the boxes except the bottom one (which is intended for air flow).

After the process of sealing the dryer is completed, it is necessary to make sure that the boxes can be used individually. To do this, use scissors or a sharp knife to carefully cut the film at the junction of the boxes with each other. To keep the film tightly, it must be glued to the box along the bottom edge with adhesive tape.

The mode suitable for drying is set on the fan heater as follows: the temperature is set to the maximum, and the power of the device is set to the average value. In this mode, the fan heater will not overheat too much, and, accordingly, will not turn off spontaneously. The optimal temperature for drying is +40-45 degrees.

That's it, the dryer is ready for use. The drying process in such a device takes from 8 to 12 hours.

How corn is dried on an industrial scale

Most often, on an industrial scale, corn is dried on the cob. For this purpose, a chamber grain dryer is used. The process occurs at temperatures from +35 to +50°C.

Removing 1 kg of moisture requires about 8.5 MJ of thermal energy. The efficiency of chamber dryers is approximately 35%, and that of shaft dryers is 60%.

At the first stage, they begin with preheating the raw materials. For this, elevated temperatures are used, since the embryo heats up more slowly. Based on scientific experiments, heating at a temperature of +50°C reduces the drying time of raw materials by 7 hours and increases moisture transfer by almost 11%. As a result, the productivity of the installation increases by 22% when compared with drying in normal mode.

Corn is first dried on the cob, since wet kernels are difficult to separate without damage. The cobs are dried to 18-20% moisture content, after which the grain is threshed. Then it is sent for final drying.

There is a differentiated regime. It allows you to increase the productivity of units by 20-30%. The principle is to gradually increase the temperature.

This is interesting:

What is a corn sheller and how to make it yourself

How to peel corn from grains at home: the best life hacks for quickly processing the vegetable

How to distinguish feed corn from food corn and the scope of application of both types

Technical characteristics and dimensions of the dryer

In recent years, mine grain dryers have been most often used. Technical characteristics of the installations are presented in the table.

| Characteristic | Minimum indicator | Maximum indicator |

| Removal of moisture from corn from 25% to 15%, t/h | 2,5 | 22 |

| Capacity, m³ | 16 | 78 |

| power, kWt | 12 | 60 |

| Natural gas consumption per ton, m³ | 1,1 | 1,1 |

| Height, m | 10,5 | 24,9 |

| Length, m | 5,35 | 6,5 |

| Width, m | 5 | 5,7 |

What types of dryers for vegetables and fruits are there?

There are several main parameters by which dryers differ from each other:

Airflow type.

Dryers come with vertical and horizontal airflow. Vertical dryers have a round shape, the fan is located at the bottom and directs the air flow upward. Such dryers, as a rule, are cheaper, but have a number of significant disadvantages: uneven drying of products on different levels, less capacity, inconvenient rearrangement of trays, mixing of odors of products from different shelves. Horizontal dehydrators are a little more expensive, but are distinguished by uniform drying, greater capacity, and convenient rearrangement of trays. These dryer models have a rectangular shape; the fan is located on the back wall and evenly blows food on all shelves, so that odors do not mix.

Choose horizontal dehydrators - they are characterized by more uniform drying and ease of use.

Capacity.

Among horizontal dehydrators there are models with 6, 7, 10 and even 20 trays - for any needs. The most popular are dryers with 7 or 10 trays - this capacity is sufficient for home use even in large families or for drying crops. One of the most compact models is the Dream Vitamin DDV-07 dehydrator with 7 trays. And for large volumes of products, there are super-capacity dryers with 20 trays. A 10-tray dehydrator is the golden mean, which is suitable for almost any need - city residents, summer residents, gardeners, large families with children.

Materials.

When choosing a dehydrator, you should pay attention to the material of the trays. To protect products as much as possible from the absorption of toxic substances, we do not recommend models with trays made of ordinary plastic

Dryers with steel racks, such as the Dream Vitamin DDV-10, are preferable. If the durability of the case is an important factor for you, then you can choose a model with a stainless steel case, for example, Dream Pro.

Give preference to dehydrators with steel trays - they are safer and more durable.

Time and temperature settings.

Modern dryers for vegetables and fruits allow you to set the drying time, after which the device will turn off automatically

Another important function is setting the drying temperature. For raw foodists, models with the ability to set the temperature no higher than 40°C are suitable.

This function is provided, for example, in the Dream Vitamin dehydrator. This means that with it you can naturally preserve vegetables, fruits, berries, herbs, and mushrooms for many years, while preserving the nutrients of the food - vitamins, enzymes and microelements.

Plus, the Dream Vitamin control panel contains useful tips for drying different foods.

Advantages and disadvantages of drum-type grain dryers

The advantages of this type of grain dryer include their following operational features:

- compact size;

- mobility in use;

- automated operation of the grain dryer;

- savings on construction and connection.

SwissCombi drum dryer

The disadvantages of this type of mechanism include:

- complex regulation of the duration of grain drying and the speed of its movement in the drum dryer during operation and stopping drying;

- the need for constant monitoring by a highly qualified specialist; the high possibility of a fire if safety precautions are not followed; uneven drying of grain, high possibility of crushing and abrasion;

- high operating costs, at least 1.5 liters of fuel and 4 kW per tone/% moisture removal (2 times higher than conveyor ones);

- low maximum performance;

- complex, maintenance-intensive design of grain dryer units (furnace unit, lubrication system, internal screw mechanisms, electronic control).

Drum grain dryers have been used for about ten years and during this time they have not proven themselves to be the best. They were used mainly by small and small farmers, but now they are already moving away from this technology. As for large and even medium-sized farms, those experiments that took place ended in failure.

Infrared dehydrator

A good dryer for herbs, nuts, mushrooms and fruits can be made using an infrared light bulb. For work you need the following materials and tools:

- wire with a diameter of 5-8 mm;

- small cardboard box;

- foil;

- metal grid;

- lamp holder with fasteners;

- thermometer;

- 60 W infrared lamp;

- screwdriver, knife and awl;

- screws, tape.

The inside of the box is covered with foil and mesh shelves are prepared according to its size. On one of the walls below, a hole is made for the wire and a socket with an infrared lamp is fixed there. A thermometer is attached to one of the inner walls of the box.

Mesh tray holders are made from pieces of wire. To do this, you need to pierce the walls of the box, thread pieces of wire and secure their ends with tape.

You can use a thermometer to monitor the temperature inside the device. It is recommended to dry plant products at a temperature of 40-50 degrees. If the temperature inside the dryer exceeds the norm, you can turn off the light bulb for a while or leave the drawer lid ajar. This product can be made more convenient to use by installing temperature sensors. Which will automatically turn off the lamp when it overheats.

Homemade dehydrator from an old refrigerator

To make a dryer at home, the main factor is the availability of suitable material for the body of the unit. An unnecessary refrigerator is well suited for these purposes.

Preparatory activities

The body of an old refrigerator is a good option for a homemade electric dryer. Spacious and stable, it will get a second life as the external frame of home drying equipment.

To make a dehydrator, you first need to get rid of unnecessary parts: freezer, compressor and radiator

Dismantling should be carried out very carefully so as not to spill the working substance of the refrigerator. The refrigerant can be used, for example, freon, ammonia, SF6

These substances are unsafe for the human body.

Dryer assembly

After preparatory measures have been carried out, a fan of suitable size is installed in the place where the compressor was installed. A device with a diameter of about 120-200 cm and a power of 18 W is suitable. It can be purchased specially or removed from the old exhaust system. A special feature of the installation is the fact that the fan must work to force air masses inside the dehydrator.

In the upper part of the refrigerator you need to cut a hole for a pipe with a diameter of 10 cm. This can be done using a tool available at home, for example, a crown or a jigsaw. This hole is designed as an outlet for moist air. On the roof of the refrigerator, a piece of metal pipe (with the appropriate diameter) or aluminum corrugation is installed into it. A sufficient pipe length is 2-3 m.

For faster drying, you can install a small hood at the upper end of the pipe. The top of the duct should be protected from insects using a mosquito net or gauze folded in several layers.

In order to be able to load products into the future dehydrator for drying, wooden slats are attached to the sides of the refrigeration chamber body. Pallets will be placed on them. The distance between the slats is chosen to be 10-20 cm. This is enough to place various vegetables, fruits, mushrooms and herbs, both chopped and some as a whole. If there is a need to dry larger pieces, then simply remove the extra trays from the refrigerator.

It should be noted that when using heating elements, it will be necessary to install an additional fan to speed up the exhaust. If these methods of accelerating drying are not required, then you can get by with a simple fan.

If desired, a homemade dryer can be improved with the help of temperature sensors. Also, with the proper skill, you can equip the equipment with a timer and other automated means for your convenience.

Pallet production

Trays for the dehydrator should be selected or made according to the size of the refrigerator, so that there is a gap of 2 cm between their edges and the door. The same gap should be provided between the trays and the rear wall of the case. This is necessary for complete airflow of products at all levels.

DIY drying cabinet

If you don’t have unnecessary equipment at home with a suitable housing, you can make a drying cabinet yourself. For work you will need the following materials:

- plywood sheets;

- slats;

- corners;

- foil;

- electric heating device;

- regular and fan heater;

- self-tapping screws

The first step is to install the frame of the cabinet, then it is sheathed with plywood or other wood on all sides except the door. You can pre-drill holes in the rear wall for mounting fans. The door is made separately from the same materials and is attached to the body using hinges. Previously, numerous holes with a diameter of 5-10 mm are drilled on the surface of the door.

The inside of the cabinet is lined with aluminum foil and wooden slats for pallets are attached to its side walls.

Baking trays for fruits and vegetables are selected in the same way as when making a refrigerator dryer. Their dimensions should not interfere with the free circulation of air inside the dehydrator.

Both fans are mounted on the rear wall of the cabinet: a fan heater in the lower part, and a regular fan in the upper part.

Parallel connection of devices is allowed, thanks to which they will operate from one switch. You can also equip your drying cabinet with lights that will serve as visual indicators of its operation.

Equipment for drying mushrooms

Written by Nikolay Budnik and Elena Mekk.

After many years of drying mushrooms, we have come to the conclusion that it is best to do this on grids over a heat source. Gradually we acquired different grids. But they are all easy to make and can last for many years.

We use a gas stove, stoves, a factory dryer, and a homemade drying cabinet as heat sources. The main thing is that the drying temperature is 50 - 70 degrees and remains stable for several hours.

1. This is one of our homemade meshes.

2. You can use it to dry not only mushrooms, but also berries, herbs, etc.

3. We have 8 such nets.

4. They are very easy to make. An ordinary rolled mesh is taken and cut into the required size.

5. Then the edges of the mesh are folded.

6. Then corners are made and folded inward.

7. And here the base is formed by wooden slats.

8. A metal mesh is stapled to them.

9. This is an example of how you can do without a metal mesh.

10. Willow twigs are used.

11. They are tied to a frame made of wooden slats with aluminum wire.