Hardening defects

Hardening defects include:

- cracks,

- leashes or warping,

- decarbonization.

The main reason for cracks and cracks is an uneven change in the volume of the part when heated and, especially, during sudden cooling. Another reason is the increase in volume during martensite quenching.

Cracks arise because stresses due to uneven changes in volume in individual places of the part exceed the strength of the metal in these places.

The best way to reduce stress is to cool slowly around the martensitic transformation temperature. When designing parts, it is necessary to take into account that the presence of sharp corners and sudden changes in cross-section increases internal stress during hardening.

Warping (or warping) also arises from stress as a result of uneven cooling and manifests itself in the curvature of parts. If these distortions are small, they can be corrected, for example, by grinding. Cracks and warping can be prevented by preliminary annealing of parts, uniform and gradual heating of them, as well as the use of stepwise and isothermal hardening.

Decarburization of steel from the surface is the result of carbon burnout during high and prolonged heating of the part in an oxidizing environment. To prevent decarburization, parts are heated in a reducing or neutral environment (reducing flame, muffle furnaces, heating in liquid media).

The formation of scale on the surface of the product leads to waste of the metal and deformation. This reduces thermal conductivity and, therefore, reduces the rate of heating of the product in the furnace and complicates mechanical processing. Scale is removed either mechanically or chemically (etching).

Carbon burned from the surface of the metal makes the product decarbonized with reduced strength characteristics and difficult machining. The intensity with which oxidation and decarburization occurs depends on the heating temperature, i.e., the greater the heating, the faster the processes occur.

The formation of scale during heating can be avoided if a paste is used for hardening, consisting of liquid glass - 100 g, refractory clay - 75 g, graphite - 25 g, borax - 14 g, carborundum - 30 g, water - 100 g. The paste is applied to the product and allow it to dry, then heat the product in the usual way. After hardening, it is washed in a hot soda solution. To prevent the formation of scale on high-speed steel tools, a borax coating is used. To do this, the instrument heated to 850°C is immersed in a saturated aqueous solution or borax powder.

Heat treatment: how best to harden iron at home

This is a heating process followed by further cooling to change properties. We place a regular alloy in the furnace, and take out a hardened one, which is less susceptible to external deformations. What is it for? During primary processing, for example during stamping, cutting or casting, internal stresses appear inside the alloy, which have a very negative effect on the strength characteristics and increase brittleness. There are four types of heat treatment:

- Annealing. Necessary for the formation of ferrite and pearlite. It consists of heating in a furnace to 680-740 degrees, when the recrystallization threshold has already passed. As a result, old molecular bonds break down and new ones form. Then follows some exposure at a temperature of 400-500, at the end - cooling, slow, together with the heating element and simply open doors.

- Normalization is similar to the procedure for relieving internal stress, but heating is higher and cooling is much faster.

- Hardening. The main process that occurs is a change in grain size, which leads to the desired results. Cooling is very rapid, often in water or oil.

- Vacation. It comes in several modes. Let's talk about it separately.

Properties of metal after processing

After carburization, the hardness of the carburized layer reaches: 58-61 HRC on alloy steels and 60-64 HRC on low-carbon steels. Prolonged exposure of steel to high temperatures causes a change in the structure of the metal.

Steel structure after carburization

To correct large grains of metal, parts after carburization are subjected to reheating and hardening, followed by tempering or normalization.

Hardening is carried out at a temperature not exceeding 900C. In the metal, grain refinement occurs due to the production of pearlite and ferrite.

Instead of hardening, alloy steels are subject to normalization. After through heating, martensite forms in the middle of the part. The heating of the part depends on the grade of steel from which it was made.

Heat treatment modes for steel after carburization

The final phase is low-temperature tempering, which eliminates surface stresses and deformations caused by high-temperature treatment.

Types of metal that can be processed

There are three main groups of metal used for hardening:

- Steel with non-hardening core. This group includes the following grades of steel suitable for cementing - 20, 15 and 10. These parts are small in size and are used for use in domestic conditions. During hardening, austenite is transformed into a ferrite-pearlite mixture.

- Steel with a weakly hardened core. This group includes metals of such grades as 20Х, 15Х (low-alloy chromium steels). In this case, an additional ligation procedure is performed using small doses of vanadium. This ensures a fine grain, which results in a more ductile and ductile metal.

- Steel with a highly hardened core. This type of metal is used for the manufacture of parts with complex configurations or large cross-sections that can withstand various shock loads and are exposed to alternating current. During the hardening process, nickel is introduced or, if it is deficient, manganese is used, while small doses of titanium or vanadium are added to crush the grain.

In general, the process of carburizing steel is necessary to improve the wear resistance and strength of parts.

The most common parts that are carburized are shafts, axles, knife blades, bearing parts and gears.

Steel cementation at home: what it is and how to do it

The carburization process is based on the principle of chemical and thermal treatment of metal. The whole point of the procedure is to saturate the steel surface with the required amount of carbon under certain temperature conditions.

Several years ago, this procedure was almost impossible to implement at home. Today this is possible using graphite media or their analogues. The main thing is desire and some knowledge.

The first step is to understand the basics of heat treating steel.

The features of metal carburization include the following factors:

Thanks to the procedure, case-hardened steels become stronger, which increases the wear resistance and strength of the material; The operating properties of the metal are changed by heating the products in a liquid, gas or solid medium, which improves its characteristics; Parts can be heated to different temperatures; there is no limited constant or exact recommendations. At home, the cementation process takes place at a temperature of 500 degrees Celsius. In industrial conditions using professional equipment, the heating temperature in the furnace reaches more than 1300 degrees Celsius. You should know that the temperature is chosen taking into account the concentration of impurities and carbon. Professionals recommend cementing low-carbon types of steel (approximately 0.2%) at home. For example, a blade from an inexpensive kitchen knife made of steel or small parts. Carbon penetrates into the structure of steel rather slowly. Therefore, cementation of the knife blade in a home procedure occurs at a rate of no more than 0.1 ml per hour. In order for the same blade to withstand heavier loads, it is necessary to strengthen the layer with a thickness of up to 0.8 ml per hour

It is also important to understand that carburizing a knife or small shaft in a home workshop will take at least eight hours. In this case, you should maintain a certain temperature in the oven so as not to disturb the temperature regime. During the process of carburization, not only the property of the metal changes, but also its phase composition and atomic lattice

In general, the surface obtains the same characteristics as when hardened, but it is possible to control it over a narrow temperature range in order to avoid various material defects.

Carburizing stainless steel is a little more difficult, but at the same time it will qualitatively improve the characteristics of this type of metal.

Case hardened steels using gas

For the first time, steel cementation with gas was carried out at the Zlatousovsky plant under the vigilant leadership of P. Anosov. This effective method was developed by V. Prosvirin, S. Ilyinsky and N. Minkevich.

The essence of the process is quite simple - the metal is cemented under the influence of carbon-containing gas (natural, artificial or generator) in a hermetically sealed furnace.

The most accessible and frequently used gas is a composition obtained from the decomposition of petroleum products.

It is made in the following way:

- Kerosene is poured into a special steel container and heated until the process of pyrolysis occurs - the decomposition of kerosene into a mixture of several gases;

- approximately 60% of this gas is modified and made suitable for cementation.

A mixture of modified gas and pure pyrolysis gas is used for cementation. The need to modify part of the gas is due to the fact that the use of pure pyrolysis gas on steel results in insufficient carburization, and a little soot may settle on some parts, which is difficult to remove.

The process of carburizing steel with gas is carried out in special continuous conveyor furnaces. Or they use unique stationary units.

First, the part is placed in the furnace, its muffle. The installation is closed and the furnace is heated to 950 degrees. Then pre-prepared gas is supplied.

It is almost impossible to carry out this procedure at home.

At the same time, it has several advantages over the solid processing method:

- less time is spent on preparing raw materials for cementation;

- more favorable and safe working conditions for workers;

- acceleration of the hardening process by reducing the holding time of products.

The most important thing when carburizing steel is a well-organized process and high-quality equipment and raw materials. The solid method can be implemented at home if you have a stove, carburizer and metal molds

As well as certain skills and abilities associated with this steel hardening process.

Do-it-yourself steel cementation process

When setting up a chemical-thermal treatment process at home, the method of cementation in a solid medium is chosen. This is due to a significant simplification of the task of equipping the premises. Typically, a solid carburizer is made using a mixture of barium or calcium with charcoal, as well as sodium carbonate. The salt is ground to a powder and then passed through a sieve.

Cementation of steel in a solid carburizer

Recommendations for creating a solid mixture are as follows:

- The first method is to use salt and charcoal, which are mixed thoroughly. If you do not use a homogeneous mixture, then there is a possibility of the formation of stains with a low carbon concentration.

- The second method involves the use of charcoal, which is poured on top with salt dissolved in water. After this, the coal is dried to obtain a mixture with a moisture content of about 7%.

For knives and other products, the second method of producing carburizer is most suitable, since it allows you to obtain a uniform mixture. Cementing steel at home with graphite also involves creating a mixture using several technologies.

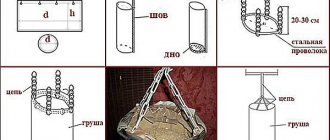

Cementation is carried out in special boxes, which are filled with prepared carburizers. The structure must be airtight, for which the cracks are sealed with clay. It is recommended to achieve high tightness due to the fact that when the carburizer is heated, gases are released that should not enter the environment. The box itself should be made of heat-resistant steel that will withstand high temperatures.

The process of carburizing steel in a box at home has the following features:

- The part is placed in a box with the mixture. The thickness of the solid carburizer layer is selected depending on the size of the workpiece.

- The stove is being installed.

- The initial heating of the furnace is carried out to a temperature of 700 degrees Celsius. This heating is called through heating. The uniform color of the steel from which the box is made indicates the possibility of moving on to the next stage.

- The next step is to heat the medium to the required temperature. It is important to ensure uniform heating of the surface of parts with complex shapes, since significant problems may arise if the atomic structure is unevenly rearranged.

Cementing steel in a box at home

Today it is possible to carry out a similar procedure at home, but difficulties arise in achieving the required temperature.

The lack of necessary equipment leads to a significant decrease in the quality of the resulting products, as well as an increase in holding time.

Structural changes in metal

When nitrogen and carbon atoms are introduced into the surface layer of the metal, some changes occur. During nitrocyanation, the ratio of the residual amount of austenites and fine-crystalline martensites in the surface layer changes, a small amount of a solid solution of carbonitrides is added, which affects the mechanical properties - hardness and wear resistance.

At the same time, fragility increases slightly and fatigue and contact strength decreases. This quality is especially evident in alloy steel with a nickel content of more than 1.2%. Thus, not all brands can be processed using this method. Reducing the grain size of the structure is achieved by additional hardening and tempering immediately after the nitrocarburization process. Steel treated in this way has a smaller grain size than cemented steel, which increases its bending strength while reducing the thickness of the treated layer.

Nitrocarburization significantly changes the characteristics of the thin outer layer of metal, its hardness and wear resistance. After additional heat treatment - hardening, the hardness of the surface layer on the Rockwell scale is 58-64 HRC or 500 - 1000 HV according to the Vickers method. Using low-temperature carburization, it is possible to obtain a thin surface layer with a hardness of 5000 – 11000 HV.

Liquid cementation

Liquid cementation is performed in molten salts, usually salts consisting of alkali metal carbonates. This mixture is melted in a bath and carburization is carried out by immersing the parts in the melt. The process is carried out at 850°C for 0.5 - 3.0 hours, while the milking depth is within 0.2 - 0.5 mm. The main advantage of the process is the possibility of direct hardening from a carburization bath and small deformations of the processed products. In conditions of individual and small-scale production, cementation from pastes has found some application. In this case, a coating containing soot (33–70%), wood dust (20–60%), yellow blood salt (5–20%) and other components is applied to the treated surface. Organic, organomineral and inorganic adhesives are used as binding materials. The thickness of the coating should be 6–8 times greater than the required thickness of the cemented layer.

Currently, the most promising cementation method is carburization in an endothermic atmosphere with controlled carbon potential. During gas cementation in an endothermic atmosphere, at the beginning of the process (during the active period of saturation), a high carbon potential of the atmosphere is maintained by adding unprocessed hydrocarbon gas (methane or propane-butane) to the endothermic atmosphere. During the diffusion period, the carbon potential of the atmosphere is set to 0.8 - 1.0% and the amount of added hydrocarbon gas decreases sharply.

Nitriding of steel

When nitriding, the surface layer of a steel part is saturated with oxygen. This method received industrial application almost 100 years ago, in the 20s of the 20th century. Nitriding a part is an excellent way to increase not only the hardness of the product, but also its corrosion resistance.

Nitriding of steel is carried out by immersing the part in furnaces, which are hermetically sealed. Ammonia is supplied there, which, when heated, breaks down into nitrogen and hydrogen. During this reaction, nitrogen atoms are absorbed by the steel surface layer and penetrate into the part.

It is difficult to say how deep and durable the layer subject to nitriding will be. This factor depends on many details:

- temperature at which nitriding was carried out;

- duration of part processing;

- composition of steel that has been nitrided.

Chemical-thermal treatment method

The described procedure does not allow achieving several goals simultaneously, unlike cementation. There are two types of nitriding.

Increasing the strength of the surface layer of a steel part. The process temperature is up to 560 °C, the average layer thickness is 0.5 mm. The duration of the operation can reach one day.

Increased corrosion resistance. The optimal temperature is from 650 to 700 °C. Anti-corrosion nitriding can continue for up to 10 hours. The thickness of the layer formed in the process is 0.3 mm.

The steel nitriding process can only be carried out on fully finished products that have gone through the stages of heat and mechanical treatment. The structure of sorbitol inside the product is completely preserved, which increases the strength and toughness of the part.

Gas cementation

In mechanical engineering, the technology of saturating the top layer of steel products with carbon in an atmosphere of carbon-containing gases is widespread. It is known that such production is convenient for mass processing of parts, since:

- Adjustment of gas density is allowed; thereby forming a carbon layer with the desired properties.

- The full heat treatment cycle (cementation, hardening, washing and tempering) takes place in one place - in a shaft (cementation) furnace.

- The process is economical, mechanized and automated.

- Boxes with a carburizer do not require heating, which reduces the time of carburization.

- The rate of carburization of parts increases by 2–3 times (compared with other methods), and the uniformity of the layer is higher.

- The temperature of the gas mixture of hydrocarbons (methane and carbon monoxide) is adjusted to 900-950°C.

- After carburization, the technological chain is completed by tempering (hardening).

In what environment is steel carburization possible?

The hardening process takes place under various environmental conditions:

- in solid;

- in gaseous;

- in an electrolyte solution;

- in the form of a special paste;

- in a fluidized bed.

steel is carburized with graphite in a home workshop .

This greatly simplifies the process, since there is no additional need to worry about the strong seal of the oven. In industrial production, gas is most often used, since this method reduces the time spent on hardening.

Hardening the cutting edge of a knife

We take a knife.

We go along the edge with a file, while paying attention to the dull sound and slight grinding of the metal. Everything indicates that the knife is made of ordinary steel and has not been previously hardened

For hardening you need graphite. It is best to obtain graphite from graphite brushes of a generator or brushed electric motor. Of course, I haven’t tried it, but you can also get graphite rods from AA batteries or simple pencils. In general, we grind this graphite into powder in any way. There is no need to grind it too much, without fanaticism.

Next, I need a metal base on which the graphite powder will lie. I took a piece of galvanized drywall profile.

The knife edge hardening process also requires a power source. Ideally, this is a pulsed DC welding machine set to minimum. You can also try to repeat the process using another source, 30-60 volts AC or DC. There is another dangerous option: using a 220 V network directly, in series with an incandescent lamp, but this is already fraught, so I do not recommend it.

Pour in graphite. We connect the plus of the welding machine to the base of the substrate, and the minus to the knife. We set the inverter to minimum settings and turn it on. We begin the process of hardening the edge. To do this, very carefully run the edge of the knife along the graphite pile. Our task is: first, to prevent the blade from touching the base. And the second thing is to prevent the graphite from burning. In both cases the blade will be damaged.

Ideally, the blade should be moved slowly, and the graphite should sparkle and flicker. Naturally, you don’t need to lower the knife too much. As soon as you notice the contact area heating up, immediately lift the knife.

The whole process does not last long, about 5 minutes. During this time I managed to walk along the entire length of the blade several times.

Hardening a knife - description of the technological process and sequence of actions

There is no need to talk about the indispensability of a knife. It is in every home, and we use this item every day. It is also interesting that this device has been an integral part of human life for thousands of years, despite this, the need for it does not decrease.

Both then and now, people were worried about the same issue - metal processing. Nowadays this is done more when creating blades, but knife hardening is also of interest to owners, although not many.

Brief contents of the article:

Peculiarities

The classical process of steel hardening has always been accompanied by high temperatures, in which polymorphic transformation of the steel occurs. At the same time, heating was always accompanied by sudden changes in temperature, because at a certain stage, the steel was always cooled in water.

Temperatures affected the structure of the metal, since when it increased strongly, the structure of the crystal lattice on its surface changed, and the sharp temperature change produced by water strengthened it. In this regard, the technology for hardening knives today is not much different from that which was used for swords and blades a thousand years ago.

This technology has always had one serious drawback. With a sharp change in temperature, the metal became much harder, but at the same time, it suffered greatly in terms of strength.

If this is a problem, you need to still heat the metal, but then gradually reduce its temperature. In this case, the steel will not become brittle enough.

Subtleties

If you have started hardening knives at home, then you should know that not every knife that comes into your hands is suitable for temperature testing.

This method is optimally suited for products in the production of which stainless steel was used. This may be a high content, or it may be an alloy containing stainless steel or nickel, for example. These knives are much stronger than their high carbon steel counterparts.

In addition, hardening can be carried out over the entire area of the blade, or can be used in a separate area that needs increased strength. The first type is called global, the second was called local.

General information about the process

The first step is to understand the basics of heat treating steel.

The features of metal carburization include the following factors:

Thanks to the procedure, case-hardened steels become stronger, which increases the wear resistance and strength of the material; The operating properties of the metal are changed by heating the products in a liquid, gas or solid medium, which improves its characteristics; Parts can be heated to different temperatures; there is no limited constant or exact recommendations. At home, the cementation process takes place at a temperature of 500 degrees Celsius. In industrial conditions using professional equipment, the heating temperature in the furnace reaches more than 1300 degrees Celsius. You should know that the temperature is chosen taking into account the concentration of impurities and carbon. Professionals recommend cementing low-carbon types of steel (approximately 0.2%) at home. For example, a blade from an inexpensive kitchen knife made of steel or small parts. Carbon penetrates into the structure of steel rather slowly. Therefore, cementation of the knife blade in a home procedure occurs at a rate of no more than 0.1 ml per hour. In order for the same blade to withstand heavier loads, it is necessary to strengthen the layer with a thickness of up to 0.8 ml per hour

It is also important to understand that carburizing a knife or small shaft in a home workshop will take at least eight hours. In this case, you should maintain a certain temperature in the oven so as not to disturb the temperature regime. During the process of carburization, not only the property of the metal changes, but also its phase composition and atomic lattice

In general, the surface obtains the same characteristics as when hardened, but it is possible to control it over a narrow temperature range in order to avoid various material defects.

Carburizing stainless steel is a little more difficult, but at the same time it will qualitatively improve the characteristics of this type of metal.

Classification of the environment in which steel carburization takes place

Carburization of a knife or other product can take place in the following environments:

- Solid.

- Gas.

- In the form of a paste.

- Electrolyte solution.

- Fluidized bed.

Cementation of metal at home with graphite is most often carried out. The most widespread is the solid medium due to the fact that it is not necessary to ensure high tightness of the furnace.

Gas is used primarily in industrial production, as it allows achieving the required results in a minimum period.

Uniform heating

Using this technique will require repeated use of coolant, so you need not one container, but several. The whole process is based on uniform heating of the workpiece in the furnace. If you periodically dip a part into oil, it will heat up over time, so you will have to change the container. After completely heating to the required temperature, you need to suddenly place the product in the oil to cool it as quickly as possible.

It was repeatedly noticed that during the heating process, the hardened workpiece noticeably changes color; temperatures were measured during the process, which led to certain conclusions. The longer the workpiece is heated, the higher its temperature, and in the color scheme this was expressed as the acquisition of a lighter shade. At the moment when the metal had a red-brown color, the temperature of the workpiece was approximately 530-580 degrees, then its shade turned into burgundy, and the temperature readings were 650-720 degrees. Over time, the burgundy turned into red; measurements already show results of 720-950 degrees. And only after the 950 mark did the metal begin to acquire a bright orange hue.

These measurements help to extract another trick that will undoubtedly help the home craftsman during hardening, especially if he has not had such experience before.

It is also worth noting that when using steel containing chromium, the heating temperature changes more slowly. Therefore, to achieve the same results, you will have to spend a little more effort and time.

Cyanidation of steel

This process is somewhat different from carburization and consists in the fact that the surface layer of the steel element is saturated not only with carbon, but also with nitrogen. In industry, high- and low-temperature cyanidation is used, while carburization does not allow several types of operations.

High temperature cyanidation

The main objective of this process is to make the part harder and more wear-resistant. The manipulation is carried out in baths that are filled with neutral salts: BaCl2, NaCl, Na2CO3 and some others. The role of carburizers is performed by KCN and NaCN salts, the active ingredient of which is cyanogen. It contributes to the fact that the steel part is saturated with nitrogen and carbon. The process is carried out at temperatures up to 900 °C.

In order for the cyanidated layer to become as durable as possible, the parts are hardened either in oil or in water for one and a half hours. To prevent the amount of cyanide from decreasing (it gradually burns out), small portions of cyanide salts are added to the bath.

Low temperature cyanidation

This process is appropriate if the part must meet the criteria of increased strength and wear resistance. The temperature required to achieve these goals ranges from 550 to 570 °C (high-speed steel) and 510–520 °C (high-chromium steel).

The procedure is carried out in a salt bath, the contents of which are equal parts of NaCN and KCN. The depth of the resulting layer is from 0.01 mm (with a cyanidation duration of 10 minutes) to 0.06 mm (with a process duration of up to 60 minutes).

Basic processes

Usually, homemade blades made of steel or available improvised means that have lost their relevance (files, valves, etc.) are subjected to home hardening.

It is important to understand that only a blade that has undergone the correct hardening process will be as strong and wear-resistant as possible.

Weak hardening is fraught not only with the appearance of cracks on the blade, but also with its rapid dulling. If the knife has been hardened according to all the rules, then it will break only when deformed, the angle of which exceeds 45 degrees. In this case, the key to success is the correctly selected temperature regime, which must correspond to the selected steel grade.

Temperature selection

You should not assume that in order for a knife to be properly hardened, it must be kept at maximum heat, because more does not always mean better. The optimal temperature range for hardening can be determined using special summary tables that indicate the markings of the alloys. There is a simpler method of determination that does not require knowledge of the exact characteristics of the metal being processed:

- Temperatures from 757 to 950 degrees Celsius are suitable for hardening blades made of low-carbon steel.

- Processing high-carbon steel grades requires lower temperatures, ranging from 680 to 850 degrees.

- If the knife blade was made of an alloy containing alloying components, then the optimal range in this case would be from 850 to 1150 degrees.

To determine the degree of heating of the blade, a special measuring device called a pyrometer is used. But even if a novice craftsman does not have such an auxiliary device, this is not at all a reason to abandon the idea of hardening the metal for a knife, because the degree of heating can be determined using a regular magnet.

So, according to physical laws, a steel blade stops attracting a magnet if it is heated to the so-called Curie point - the peak point when high-quality hardening of the metal occurs. If you neglect this rule and overexpose the blade to the fire, then it will become too fragile and the chances of breaking or pricking it when used in everyday life will be much higher.

Technology and features of home heating

In order to harden a knife correctly, not only without damaging its blade, but also making it stronger and sharper, it is recommended that you familiarize yourself with the basic rules and nuances of this process. And the first recommendation is that instead of a blade, it is necessary to process another fragment made of the same alloy, conducting all kinds of experiments on it. This simple technique will help you choose the optimal temperature regime for heating and cooling without damaging the blade of your kitchen or hunting knife.

Gas Application

In mass production, a gaseous environment is used. Surface saturation with carbon can only be carried out using a sealed oven. The most common composition of the gas environment is the substances obtained from the decomposition of petroleum products.

Gas carburization of steel

The procedure has the following features:

- Continuous conveyor ovens with increased isolation of the working environment should be used. They are very rarely installed at home due to their high cost.

- The workpieces are placed in the furnace, after which the medium is heated to the required temperature.

- After heating the furnace to the required temperature, gas is supplied.

There are quite a lot of advantages of this technology:

- There is no need for lengthy preparation of the gas environment.

- The process involves short holding times, which reduces the cost of maintaining temperature.

- The equipment is compact and does not take up much space.

However, there is a significant drawback, which is the inability to install equipment and set up the process at home. The profitability of cementation at home when installing such equipment is ensured only with a significant increase in the batches processed.

If you find an error, please select a piece of text and press Ctrl+Enter.

Topic: how to harden a knife yourself using electric current.

It is known that metal can be hardened, this gives it additional strength. Hardening involves heating the metal to a certain temperature and then cooling it. This process changes the internal structure of the metal, making it stronger. Although at the same time the metal loses another of its properties, namely flexibility and ductility. Here the choice is yours: what do you need from the metal, its increased strength (but at the same time fragility increases) or flexibility (stiffness decreases).

The classic method of hardening metals is conventional heat treatment in flames, hot coals, gas furnaces, etc. But the temperature can also be increased due to electric current. Hardening is done uniformly. To ensure this, there is one interesting way using graphite powder. As you know, graphite conducts electricity quite well, in addition to this it is resistant to high temperatures. It is these two qualities of graphite that make it possible to harden metal with electric current using graphite powder.

I decided to try electrically hardening a small metal knife (homemade) and organized the following. So, I needed a power source, graphite powder, wires of sufficient cross-section, a metal substrate, and a small knife itself. As a power supply, I used a regular step-down transformer taken from an old color TV. Its primary winding is designed for a voltage of 220 volts, and I rewound the secondary winding to a voltage of 80 volts (in the end this turned out to be not enough, about 100 volts are needed).

To harden metal with electric current, sufficient current is needed. The cross-section of the secondary winding on my transformer was about 1.5 mm. But for larger knives it is better to have a larger cross-section. Next, I took a metal substrate onto which I poured graphite powder. You can make the powder yourself from a piece of graphite (grind off any graphite brush from an electric motor with a large file). I connected one of the wires coming from the secondary winding of the transformer to this substrate. I connected the second wire to the knife itself, which I hardened. The cross-section of these wires must also be at least 1.5 mm.

The electric hardening of the knife itself was done as follows:

Having applied voltage to the transformer, I took a knife and carefully began to move its tip along the graphite powder. Many small sparks began to jump between the tip of the knife and the graphite powder, indicating electrical contact in the circuit

I also made sure that while driving the knife through the graphite powder, I did not have the knife in direct contact with the metal substrate. Such contact would create a short circuit. Nothing particularly terrible would happen here, but it’s better not to allow it. As a result, the tip of the knife gradually warmed up. This was proof that this method of hardening metal works fine if everything is done correctly.

https://youtube.com/watch?v=ss300MaHZXM

Features of the technology

At home, if you approach the matter correctly, you can qualitatively harden any knife. This could be a hunting or folding knife, a bayonet-knife or a product in the form of a hook, a blade made of a file or a bearing, a butterfly knife, etc. It is somewhat more difficult to harden products made from stainless steel at home, but this problem can be solved, if you carefully study the process technology and select the appropriate heating equipment.

Various materials are used as a cooling medium when performing hardening, both in production and at home. Thus, the most common cooling media - water and oil - provide the following cooling rates of a heated steel product:

- oil at room temperature – 150°/s;

- oil heated to a temperature of 200° – 300°/s;

- water, the temperature of which is slightly above 20°, – 450°/s;

- ice water – 600°/s.

In some cases, hardening is performed by cooling the product in an intermediate medium, which can be molten lead. This technique, in particular, is used when hardening knives that are made from files.

Annealing a knife over an open fire requires close attention.

The most important problem that you may encounter when trying to harden a knife at home is overheating the metal, which leads to a significant increase in its fragility. It is also necessary to very carefully monitor the uniform heating of the knife being hardened, so as not to encounter the formation of transverse cracks on its blade.

There is a simple rule that should be followed in order not to encounter such a problem: the part of the blade that will not be sharpened is heated three times to a purple color, which corresponds to a temperature of 285 °, and the cutting part is heated only once to a yellow color, after which the degree Its heating is checked using a magnet. You can learn more about this technique by watching the corresponding video.

Colors of heat and tarnish of carbon and low-alloy steels

On stainless steels, tarnish colors appear in the same sequence, but at higher temperatures

Different cooling media also provide different depths of the hardened layer (hardenability). Thus, when cooled with water, steel is calcined at a rate of 1 mm per second, and when oil is used as a cooling medium, this rate is almost halved. To harden a double-edged knife, obtaining hard cutting edges and an elastic core, you need to do the following: the blade, heated to the required temperature, is first dipped in water for two seconds and then placed in oil.

Another technology that allows you to qualitatively harden the cutting edge of a blade with significant thickness is hardening the knife in graphite. Using this technology, the details of which can also be easily studied in the video, you can qualitatively harden knives of various models and configurations (hunting knife, bayonet knife, butterfly knife, etc.). At the same time, such hardening can be performed efficiently at home.

Homemade knife after hardening in graphite

It is often necessary to carry out zone tempering of an already hardened knife in order to make its middle part more elastic, while maintaining the hardness of the cutting blades. At home, such a technological operation is performed according to the algorithm below.

- The middle part of the blade is heated using a metal rod with a diameter of 10 mm, heated to maximum.

- After heating the middle part of the blade, it is dipped in boiling water and kept in it for 2 hours.

- After soaking in boiling water, the blade is dipped into ice water.

After completing all the manipulations described above, you will receive a knife whose middle part of the blade has been subjected to low tempering.

You can determine the tempering temperature by the colors of tarnish - a rainbow film that appears when the cleaned surface of the knife is heated: from light yellow (item 1) to bluish (item 6)

If you are trying to harden your knife at home, you should follow two rules that will allow you to get high-quality results.

- The volume of coolant used must be large enough (minimum 20 liters). Otherwise, the liquid will become very hot, which will change the temperature regime and cooling rate, and this in turn will negatively affect the result of the entire technological operation.

- In order for the heat transfer from the heated knife to be uniform and not to lead during the hardening process, it cannot be moved in the cooling environment - it must be kept motionless.