Work associated with the formation of dust, the release of toxic gases, and fumes requires the installation of an exhaust system in the workplace and room. In most cases, do-it-yourself ventilation in the workshop is the most affordable way to solve the problem.

There are various options for constructing air exchange systems. We will help you navigate their diversity and consider the features of building ventilation for each type of workshop. Let's look at the most effective and affordable options for self-installation.

How does the chip pump work?

A flexible hose, preferably corrugated, of small diameter, is connected to the mechanism. The smaller the cross-section of the hose, the higher the speed of the sucked air, which means the quality of cleaning will be better. Along with large chips, small particles several microns in size will be removed from the room.

The air in the device is discharged due to the rotation of an impeller connected to an electric motor.

Description of the operating principle of the hood

The operating principle of this device is quite simple. The design is based on an engine with an impeller, during operation of which air flows move. The system is reminiscent of a vacuum cleaner, only instead of a narrow air intake pipe, a wide dome is used, covering the entire cooking surface. The air that is drawn into the hood through a special channel is discharged into the ventilation system.

Previously, hoods were dome-shaped, did not have any cleaning systems and were quite noisy with low efficiency. Modern hoods are a whole work of art. They can not only remove unpleasant odors, but also decorate the kitchen space. Also, modern hoods use filtration systems, a work area lighting system, and many other useful functions.

Selection of material

A hose, preferably with a fabric braid, from an old vacuum cleaner, is suitable for removing air with debris. You will need a plastic sewer pipe D = 50 mm and a length of 150 mm, a plastic corner bend of 45 degrees and a length of 200 mm, a plastic bucket from 10 to 25 liters with a lid, and a second bucket can be purchased in smaller sizes (5 - 10 liters).

You will also need 20 mm thick plywood, screws and sealant.

Device noise level

This parameter is also important, since the comfort of using the device depends on it. Therefore, it is also necessary to pay attention to it.

Noisy operation is a significant drawback of many models. In the product data sheet, the manufacturer usually indicates the noise level of the fan installed in the hood.

If the noise level is not higher than 45 dB, then the device is quite suitable for a standard-sized kitchen room. For a more spacious room, you can choose a model with 55 dB, but no more, otherwise you simply won’t want to turn on the hood because of the discomfort it causes.

The efficiency of the device, as well as the level of noise emitted, depends on the selected speed mode.

Most exhaust hoods are equipped with a three-speed operating mode, but there are models with five speeds. Accordingly, the higher the speed, the louder the noise of one or two fans running.

The lowest noise level is 40 dB, it will not cause discomfort to apartment residents, but when choosing this version of the device, you will have to sacrifice its performance.

And one more thing - noise can increase during operation due to vibration and resonance phenomena. As a rule, the reason for this is errors in the installation or assembly of the device. There should be nothing loose, rattling, etc.

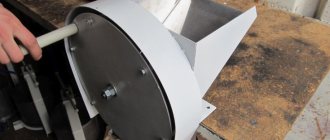

Cyclone assembly

The design of the chip ejector must include the use of a cyclone filter.

Cyclone assembly:

- Installation of a ring for fixation;

- Side pipe fastening;

- Assembling a figured insert;

- Making a cyclone.

Cost of devices for removal and collection of wood waste

The cost of both individual components and finished systems depends on many factors, the main of which is productivity, that is, the volume of air pumped per unit of time.

needle-punched fabric bags are the cheapest .

Such bags allow air to pass through, but retain shavings, sawdust and fine dust. After filling, the bag is thrown away and a new one is installed in its place.

More expensive filters operate on the cyclone effect, although modifications with bags are also found among them.

The most expensive are full-fledged plastic or metal cyclones with a large hopper, which allows them to be used for collecting wood processing waste for subsequent removal.

The distance from the treatment plant to the machine is also of great importance , because the further they are from each other, the longer the air duct should be.

The cost of the air duct is also affected by the material from which it is made, so the cheapest hoses are made of PVC, while the more expensive and flexible ones are made of polyurethane. We have prepared a table in which we have included various options for ready-made devices and fans, some of which are also used in industrial facilities, so that you can roughly estimate their cost:

| Model | Purpose | Description and characteristics | Price rubles | Seller or manufacturer website |

| Ancord VU-5000 | Chip suction | The basis of the device is a dust fan, to which 1-4 filter units are connected, consisting of a “Cyclone” and a fine filter. The chip pump pumps 5900 m3 per hour, while the air speed at the device inlet is 66 meters. Suitable for servicing several machines of small productivity. | 52000 | vacuum-press.ru |

| UVS-7000 | Aspiration unit | The basis of the installation is a 5.5 kW centrifugal fan pumping 7000 m3 per hour. The installation includes 4 filter devices, consisting of a cyclone and paper filters. Due to the large inlet diameter of the air duct, the air speed at the inlet is 28 m/s. | 66000 | scperun.ru |

| VR 01-4.5 | High Pressure Centrifugal Fan | High-pressure centrifugal fan, weight 65 kg, electric motor power 5.5 kW, capacity 7000 m3 per hour, can be used with any filter elements. The diameter of the pipe is 280 mm. | 50000 | www.eventa-k.ru |

| PUA-M-1500 | Chip suction | The device is of low power, pumps 1500 m3 of air per hour and can serve 1-3 machines. It is standardly equipped with a filter bag; you can additionally connect 2 more of the same filters. | 37000 | www.ekovent.ru |

| JCDC-3 | Cyclone treatment plant | The purification unit consists of a high-pressure fan and a multifunctional Cyclone type filter. A filter of this design purifies the air better than its counterparts with bags, and also separates pollution by fraction size, so small sawdust and dust are collected in one container, and large sawdust and shavings in another. | 140000 | jet-online.ru |

| Corvette 60 | Vacuum cleaner for collecting chips | The vacuum cleaner has a power of 750 W and is equipped with one filter bag. Can serve a low-capacity machine operating for a short time. Most often, this vacuum cleaner is used in home workshops, connecting it alternately to various machines. | 7920 | enkor.ru |

| PO50 | Ventilation hose | Polyophene hose for aspiration systems, reinforced with a metal spiral, length 10 m, diameter 50 mm. | 1970 | bi-teh.ru |

| Uniflex PUR.05.90.10 | Ventilation hose | Polyurethane hose for chip extraction, diameter 90 mm, length 10 m | 5240 | cmt-shop.ru |

Making a ring and insert

- Cut off the side of a small plastic bucket.

- Having placed the container on the plywood, you need to circle its bottom and determine the center of the resulting circle. To find the center, it is enough to draw 2 perpendiculars to the drawn tangents.

- Another circle is drawn 30 mm larger than the first.

- Using a jigsaw, cut out a ring along the drawn circles.

Dimensions

In this case, everything is much simpler. To select the correct dimensions, you must have information about the exact width of the electric or gas stove over which the equipment is suspended. In this case, you should buy an exhaust panel with a width slightly larger than the slab, so that the remains of dirty air do not spread throughout the apartment, passing by the fan.

Now in online stores there are various devices available to choose from, the width of which starts from 45 and ends with 90 centimeters, so it will not be difficult to determine the optimal dimensions. For a studio kitchen, 50 centimeters would be a good option.

Ring retainer installation steps

The ring is attached to the cut out side of the plastic container.

- Screw the side using self-tapping screws.

- To prevent the plywood from bursting from the screws, you need to drill holes at the fastening points of a smaller diameter than the thickness of the screws.

- On the lid of a large container, a circle is marked equal to the diameter of the bottom of the container itself.

- Cut out the resulting circle, securing it to the side of a small container with screws.

Kinds

Portable

These are small-sized products that are quickly installed and disassembled. The tools are lightweight. They can be placed on the table for ease of use.

Portable chip ejectors are recommended for use in cases where it is not possible to use other units. Most often this happens if the machine is installed in a small room and for technical reasons.

They have a large number of disadvantages, namely:

- Low power.

- Poor performance.

- Poor waste disposal.

Expert opinion Dmitry Konstantinovich Levin

If it is possible to use other types of chip ejectors, then the use of portable devices is abandoned.

Mobile

Such devices are placed near the machine. To move the device from place to place, you will need a cart or other similar device. These tools can be used to service two machines, but only in turn and the equipment must operate at different times.

Advantages:

- Small dimensions.

- Good performance.

- Quick assembly and dismantling.

Flaws:

It is not always convenient to use, since sometimes there is no space for the unit near the machine.

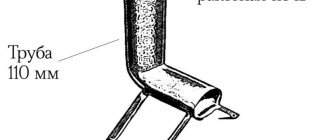

Installation of the pipe

Before installation, you need to make a hole in the bottom (not in the center) of a small container, and insert a 45-degree elbow into it. The outlet is attached with self-tapping screws and sealant to ensure tightness and strength of the joints.

What is the difference between inclined hoods?

Inclined hoods are distinguished by the fact that, unlike dome hoods installed parallel to the slab, they are located at an angle of about 60 degrees. Thus, without hanging over the user and creating a feeling of free space. Technically, they are not much different from ordinary horizontal ones. To remove air, an electric motor is still used, thanks to which the air is discharged into the ventilation system. But thanks to this arrangement of the dome, as well as thanks to the perimeter suction system, the performance of this hood increases by 20-30%.

Top outlet mounting

- The entries are drilled in the center of the bottom of the small bucket.

- The plastic pipe is attached to a sheet of plywood with a prepared hole equal to the thickness of the pipe.

- The structure is screwed from below with four screws.

- Fill all formed joints with sealant. In addition to tightness, it gives the assembly additional strength.

The insert is attached to the outer wall of the filter using self-tapping screws.

How does a cyclone chip pump work?

The air purified by the cyclone along with the garbage from the room is thrown outside. The filter involves the use of an electric motor with a power of 3.5 kW.

It sets into rotation the impeller, which can withstand a fairly large load and create the necessary air vacuum. Filtration in such a chip ejector is carried out in several stages.

Large debris, after passing through the filter, is collected in a special bag. The installation housing must be sealed. To reduce noise, the housing can be covered with absorbent material.

It is possible to make such a device yourself.

Features of ventilation in the workshop

Working in a workshop is associated with the presence of toxic and harmful substances in the air. The design and construction of ventilation in such premises depends on the type of work and the nature of the harmful factors.

Let's consider the main features that influence the configuration and parameters of ventilation systems for different types of workshops.

#1. Dust removal in a carpentry workshop

Fine dust is the main problem in woodworking workshops. Such a suspension of particles can remain in the air for 24 hours, although it is not noticeable to the eye, but is inhaled by the lungs. In addition, it settles on all surfaces. Whenever there is a draft or the engines of machines or tools are started, it ends up in the air again.

The organization of a dust removal (aspiration) system is complicated by the presence of a large number of dust sources and different fractions of chips. For this reason, it is necessary to connect suction hoses with individual filtration to each machine.

Dust removal systems operate on the principle of a cyclone. Polluted air is sucked in by the rotational movement of the fan and, under the influence of centrifugal force, heavier dust particles fall to the bottom of the container. Purified air rises. Additionally, the flow can be humidified for better cleaning

But, in addition to the harmful effects on breathing, wood dust also has fire and explosive properties. Which places increased demands on ventilation systems in terms of eliminating electrostatics and grounding structures.

#2. Air purification in a car service center

A car service workshop belongs to premises with increased air pollution. The constant presence of exhaust gases, carbon and nitrogen monoxide, aerosols, gasoline vapors, paint and other technical fluids places special demands on the performance of the ventilation system. The power of the supply and exhaust unit is selected with a reserve to ensure pumping of the entire volume of the room with the recommended multiplicity of 20 - 30.

In addition, contaminated air must be filtered and discharged through a pipe separate from the general ventilation.

#3. Ventilation of repair and forging workshops

The combustion products of electrodes, smoke, fumes and dust released during welding and metalworking operations when cutting and processing metal require removal using local exhaust hoods. What is regulated by GOST 12.3.003, SP 49.13330, POT R M 020-2001 [22], STO 221 NOSTROY 2.10.64-2013 and safety rules for construction, installation, gas welding and electric welding work.

For manual electric welding, their approximate productivity is selected based on the provision of air exchange from 1500 to 4500 thousand m3*h/kg, divided by the weight of the electrodes burned in 1 hour.

With semi-automatic welding, the volume is increased to 1700 - 2000 thousand m3*h/kg.

Ventilation of the welder's workplace is of paramount importance. Vapors of metals and slag contain harmful manganese oxides, compounds of silicon, titanium and other chemical elements that lead to diseases of the nervous system, lungs, and can accumulate in the body

The general air circulation is distributed in an inflow to exhaust ratio of 1:3 for the upper tier, and 2:3 for the lower.

A feature of the ventilation of a forge workshop is the need to remove excess heat and toxic gases. For this purpose, local suction above the furnaces and natural ventilation are used.

When calculating the performance of ventilation systems for all types of workshops according to the recommended multiplicity, it is necessary to take into account heat losses during the cold season. Choosing the maximum parameters will guarantee the rapid removal of harmful substances, but at the same time, will require costs for heating the supply air. If heat recovery is not provided, it is better to opt for the lower permissible expansion limits.

Filter from plastic buckets

To make a garbage disposal, you will need a cutting tool, a tool for drilling, surface treatment, a heat gun, a pencil, a ruler, and a knife.

The material you can use is laminated chipboard, a plastic thirty-liter tank, a PVC pipe, hot melt adhesive, silicone sealant, bolts, nuts, and screws. You will also need a vacuum cleaner with a hose.

Air suction power

Another important parameter is power. It refers to the extraction capacity in cubic meters per hour

- the volume of air that it can draw in per hour of operation. Performance, in turn, depends on the characteristics of the motor and fan speed.

350 m³/hour - optimal value

for small kitchens (up to 10 m²). For kitchens of 10–15 m², it is better to choose hoods with a capacity of up to 600 m³/hour. For larger rooms, look for devices from 700 m³/hour. Haier has HVX-W692GB and HVX-W692GW with a capacity of 1000 m³/hour.

Some experts associate the required hood power not only with the size of the kitchen, but also with the type of dishes that you are used to preparing. For example, if you often fry at high temperatures or use oils with a low burning point (linseed, unrefined sunflower, butter), choose hoods with a capacity of 700 m³/hour.

Manufacturing procedure

- A partition is cut from a sheet of laminated chipboard to connect plastic containers.

- Grooves are cut on it for a tight connection with the edge of the bucket.

- A plate is cut to cover the cyclone filter.

- The jumper is attached to the buckets using sealant, then a hole is drilled that connects both vessels.

- The bottom of the container is cut out to create a cone.

- The assembled structure is tightened using clamps and left alone until the sealant dries.

- The recess on the hopper lid is filled with hot melt adhesive.

- Using a drill, you need to make a hole with a diameter of 50 mm. A 120 mm long pipe with sealant is installed into it.

- A PVC corner outlet is inserted into the side hole. It is secured with bolts and nuts.

The cover is put on the mechanism and the vacuum cleaner is connected. The connected hose can be wrapped with electrical tape for better tightness.

Criterias of choice

It is necessary to select a hood based on the balance of needs, the concept of the interior of the room, the technical capabilities of installation and costs.

- When using the stove intensively for cooking first and second courses, you should pay attention to the air purification resource of the system. The criterion is important for assessing the frequency of filter replacement. If you often cook fried and baked dishes, various soups and borscht on the stove, then it is advisable to buy a resource-intensive appliance. It costs more, but will not require frequent additional costs for replacing filters.

- An important criterion for selecting a recirculating hood is the style of kitchen design. You should choose a model that fits harmoniously into the interior so that the device does not stand out from the overall style.

- Some kitchen furniture sets provide space for installing built-in appliances, including an extractor hood. In this case, you should choose a suitable built-in model.

Making a cyclone from a traffic cone

A very simple and quick way to make is to use a traffic cone.

- You need to cut off the bottom and top of the cone and, turning it over, place it in any container to accumulate waste.

- Make a round lid approximately equal to the top of the chip by drilling a 40 mm hole in it.

- Secure the corner bend into the opening made in the side wall with glue.

- Glue all connections with a heat gun for tightness and strength. The waste collector is connected to the vacuum cleaner through a corrugated hose.

The chip ejector can be made from a wide variety of available materials with your own hands.

The importance of preliminary calculations

Ventilation of the shower is necessary if it is installed in a concrete building or in a wooden house. It prevents the negative impact of high humidity on the integrity of plumbing equipment and building materials.

It is necessary to follow SNiP standards, which will serve for the safe operation of the room in the future. Before equipping a room with ventilation with your own hands, you must have a drawing of the shower stall, as well as the dressing rooms available in the room.

Removing excess moisture helps increase the life of all metal plumbing fixtures and some building materials. For normal human well-being, humidity should not exceed 65%. If this indicator is too high, staying in the shower can negatively affect the health of its visitor.

SNiP standards introduce the concept of “air exchange rate”. It represents the ratio of the volume of air entering or leaving a room to the volume of the room itself. The minimum indicator according to SNiP is 50 m3/hour. For public showers – 75 m3/hour.

The minimum “air exchange rate” according to SNiP in a public shower is 75 m3/hour