Brief overview of equipment for crushing grapes

Typically the device consists of a frame, a juice tray, a cylindrical container for raw materials, a filter, and a mechanical or mechanized squeezing device.

So, currently there are several types of presses:

- Mechanical manual. The design is quite simple, which allows you to independently manage the processing and pressing process.

- Mechanized with electric drive. Working with such a press is easy. I'm pleased with the performance and ease of control.

Among hand presses, there are 2 main types:

- Jacking type of equipment. The jack lever must be operated manually, raising and lowering it. To regulate the pressure on the pulp, additional bars are placed. The material is environmentally friendly;

- Screw wine press. The juice is squeezed out by rotating the screw handle, the rotational motion of which is transmitted to the rollers. Such designs are popular among winemakers.

Winemaking equipment for pressing grapes has a fairly simple principle of operation. The berry is placed in the housing, pressed on top by a working surface with a screw, the rotational movements of which continue until all the liquid comes out of the raw material. Next, the cake obtained during the pressing process is removed and, if necessary, reused.

Mechanized equipment is divided into two types:

- A hydraulic press that works under the influence of injection of working fluid into the chamber. As a result, pressure is created, with the help of which the juice is squeezed out of the berries/fruits.

- A pneumatic press is a mechanism where air exerts pressure on the working surface for pressing.

Homemade grape press: what is it?

The most popular option and easiest to use is a conventional mechanical press. It consists of a container with holes that acts as a filter, and a mechanism with a screw or lever. Operated by hand. This device is easy to use, simple in principle and cheap.

The raw material is poured into the container, and by rotating the screw or lever the piston is lowered. Under pressure, the juice from the berries flows out, passes through the holes and is collected in a tray, while the pulp remains in the container.

Types of grape squeezer: which one to choose

Absolutely all presses are made from environmentally friendly materials, without the use of chemicals for joining or processing parts. In this regard, there are two options for the material from which the press is designed: wood and metal. Devices are also classified by power and volume. Depending on the relevant characteristics required for crop processing, farmers choose one or another machine.

How to build trellises for grapes is described in this material.

Wooden: oak, apple, beech, linden, ash

In a wooden press, absolutely all the parts are made of natural material; as a rule, hard varieties are taken for production: apple, oak, linden, beech or ash. These presses require careful care and drying after each use. This is due to the fact that bacteria accumulate in the pores, which can adversely affect freshly prepared juice.

Before each use, farmers inspect the basket for damage to its integrity, the appearance of mold or other growths. And only after that he gets to work.

Homemade metal appliances: stainless steel, cast iron

For metal structures, choose non-corrosive metal: cast iron or stainless steel. These materials do not oxidize and, accordingly, do not react with aggressive juice due to the large amount of vitamin C and do not change the properties of the drink.

Such presses are durable and odor-neutral. They are produced in two formats: industrial use and household.

By volume and power (industrial, household)

Differences in power and volumes do not depend on the purpose of the press (domestic or industrial). Devices with a reinforced motor are successfully used both in private farms with large output and in factories.

Pressing units vary in volume, ranging from 1 liter of loading to 80 kg.

Press designs

DIY metal laser cutting machine: manufacturing process

It is unlikely that it is worth assembling a press to extract juice from two to three kilograms of grapes. A meat grinder or blender is quite suitable for this purpose; you can use it to grind the berries and then squeeze out the juice through cheesecloth. If we are talking about tens of kilograms, then you definitely can’t do without a press.

For high-quality pressing of berries for the purpose of making juice or wine, many home-made devices are used. Drawings of homemade presses for squeezing berries can be easily found. The most common types of press designs are:

- lever;

- screw.

The first ones are easier to manufacture. Their disadvantage is that even with the use of a lever, the squeezing force is not enough for high-quality pressing of the berries. And it will be almost impossible to get anything from the second or third spin.

Lever type crusher

It’s easy to crush one grape with your hands. It’s completely different when there are thousands of these berries. Together they create serious compression resistance, so the force must be appropriate. The simplest thing in this case is to use a lever.

To make such primitive crushers, you can use solid wood blocks. Of course, it will not be possible to squeeze out the pulp efficiently with such devices. And labor productivity will leave much to be desired. If you come to terms with increased losses and have nothing else in stock, then you can build such simple devices. The undoubted advantage of such homemade products is their ease of manufacture. In addition, by actually squeezing berries by hand, you can at the same time get yourself into good physical shape.

Screw squeezers

The principle of operation of a screw press is to create a constant pressure, regulated by tightening a screw with a thrust thread. The pressure of such a mechanical press is much higher than a lever press, and besides, the constant force of influence drives the juice out of the pulp better.

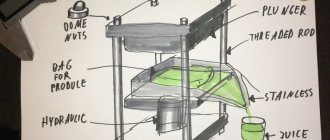

But greater effort also requires greater structural strength, so it is better to make it from metal. The screw press consists of the following parts:

- support frame;

- screw with handle;

- piston;

- pallet;

- separator basket.

This design allows you to squeeze out juice quite efficiently, and not only from grapes, but also from denser fruits. It can even be used on tough fruits like apples. The frame design is either fully welded or collapsible. This press works as follows. By rotating the handle, the screw is turned out completely. A stainless steel tray is installed on the frame, which acts as a bottom and at the same time collects juice. A basket with loaded berries is installed under the piston.

To reduce losses from splashes, it is advisable to make a continuous fence around the separator from a thin stainless steel sheet. By rotating the screw handle, the piston creates pressure, squeezing out the juice, which flows onto the tray and from there is discharged into another container.

Instead of a screw in such a frame structure, you can use a conventional manual screw or hydraulic jack. It is installed in the gap between the piston and the top edge of the frame.

By gradually raising the jack and placing thick blocks under it, you can achieve the same result as with a screw press.

Making a wine juicer with your own hands

The press is quite simple in nature, especially when it comes to the screw format. At home, it can be made almost from scrap materials.

- 2 pipes with a diameter of 18 or 25 mm in cross-section are welded to a metal profile in the shape of the letter P. Its height is arbitrary, but selected in such a way that the key nut on the screw fits freely.

- A compression mechanism is welded at the bottom, which will fix the required position. A clamp will help attach the finished press to a horizontal working surface.

- The frame is made from bars 5*10 mm or 4*10 mm and approximately 70 cm long.

- The width of the device depends on the length of the grooved rollers. It is best to count on a dimension of 20 cm, while the rollers and bars should protrude at the same distance, and the depth of the grooves should be at least 2.5 cm.

- The structure is directed helically with a shift of 2 cm to the rollers and secured every 10 cm to the frame using a bearing.

In addition to the main part, which crushes the berries, you need a ladle or bucket with a narrowed base. It is also installed on the frame, at a distance of 1 cm or more from the pressing mechanism.

A container for liquid is attached below and the process can begin. Thanks to the gaps between the rollers, the seeds slip into the filter compartment intact, so the drink turns out sweet, rich and without bitterness. Is it possible to eat grapes with seeds? This link will tell you.

The basket can also be made of metal. In this case, stainless steel gaskets are used to separate the juice into portions.

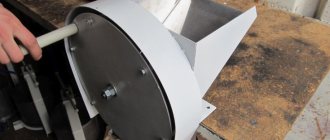

Materials for a drum press machine according to Italian drawings

Before you start work, you should understand what materials will be useful for the future press according to an Italian or other drawing. They need to be placed all at once on the desktop to speed up the design process.

- wooden beams 4*10 mm or 5*10 mm;

- rolls;

- 2 mm stainless steel discs;

- pipes with a diameter of about 25 mm;

- U-shaped profile;

- fastening tool, welding machine;

- bearings.

Rules of application

Once manufactured, the press can be placed and secured to any support. Before use, the grape crusher must be placed on a flat surface and secured well.

The manual crusher must be installed on a container to collect pulp. To do this, you can use barrels or tanks made of plastic or stainless steel. To obtain juice, berries are loaded into the loading ladle. From there they are poured onto windrows. A strong napkin must be placed at the bottom of the basket, from which the pulp is then removed.

When rotated, the berries are crushed and then turned into a mass like a puree, from which juice comes out. Before loading the berries into the receiving bucket, they are removed from the bunch and washed well. There is no need to remove the skin from the berries; thanks to it, the juice has a pleasant aroma.

After processing the crop, the device should be thoroughly washed and dried to avoid rotting. A homemade press greatly simplifies the work of processing berries, especially when the harvested crop is about 200 kg.

Video about the principle of operation of the grape press:

We bought it in Ukraine, according to an advertisement. It is popularly called a grape press. For ourselves, we defined it as a press for obtaining juice from grapes, or simply a press for grapes. The advertisement for the sale of the press was given by a man who, in Soviet times, did his own tinkering at the factory, like many in those days.

| The design is simple: a hand press, a stainless steel cylinder with holes and a tray with a groove through which the juice flows. |

| True, the press and cylinder turned out to be fairly smeared with some kind of technical lubricant - either grease or something else. And, of course, before pressing the juice, it was necessary to wash it thoroughly. We asked the seller what the press is smeared with and what is the best way to wash it off, since we want to use it to obtain a food product. The seller replied that he himself probably did not know what kind of lubricant was used. For cleaning, I advised taking “Galosha” technical gasoline for degreasing, “Fairy” type dishwashing detergent and alcohol. We didn’t take risks with gasoline; we were afraid that it would be difficult to wash later, so we washed it right away with Fairy, and then with industrial alcohol. The most difficult thing was to wash the threads on the press, which can only be done with a fine brush. |

| Washed and dried. Carefully secured it to the table. And they started squeezing the juice. And since we did not have instructions for its use, and, unfortunately, the Internet was not “at hand,” we mastered the nuances in practice. |

| The first problem was that the piston came off the press; it took a long time and with difficulty to strengthen it, because the hole in the piston for attaching it to the press was not centered. And how they put him on the press in the first place is unclear. |

| The second problem is to secure it so that the press does not move during operation and does not fall. By the way, it weighs more than 10 kg. The cutouts for the bolts on the base are very small. Well, these problems have been solved. We drilled a hole in the center of the piston and secured it to the press. We attached the press to the table, placing washers under the screws. True, they had to make holes in the table, but they didn’t come up with another option. |

| And they began to squeeze the juice from the grapes. The effort, as it turned out, needs to be made unfeminine. At the same time, juice splashes through the holes in the press cylinder when the grapes are crushed, and even grape seeds shoot out, falling into the pan with juice. As we found out later, to prevent this from happening, you need to put the grapes in a canvas bag and then squeeze the juice out of it. |

| Lowering the piston to the very end, when the handle of the press touches the body, you realize that this is not the very bottom. That is, what remains is a “pancake” of grapes 4.5 cm high. And in these 4.5 cm there are even whole berries. |

In what cases is a crusher used, how to make it yourself?

It is necessary to leave a gap between the rollers of the crusher, otherwise the seeds will be crushed along with the berries and lead to excessive astringency of the juice.

Assembling the crusher yourself is not difficult. Any production begins with a drawing. The Internet will help you find the image of the crushing structure you like. And you can make it if you find all the elements:

- Oak boards.

- Two rollers.

- Two identical gears.

- Bars for frame size 50x50.

- Lever.

- The reservoir into which the pulp is loaded.

The loading hopper is made of oak wood in the form of an inverted pyramid.

You need to draw 6 lines on the roller. Drill holes along the length of each with a diameter of 10 mm and a depth of 50 mm at a distance of 50 mm.

Gears are installed on the outside.

The frame together with the rollers is mounted on the pulp reservoir. A bunker is installed on top.

A handle is placed on the axis of one of the rolls, and when rotated, the mechanism begins to move.

How to make basic press parts

Initially, you need to prepare a metal base, then form the upper half of the frame, positioned horizontally. A very durable material with thick walls is selected for it, which will eliminate the deformation of the components under load. Corrosion can be prevented by treating the surface of the frame with paint. Then plywood is laid on the base, and a tank with a tray is installed on top. The plywood is varnished.

Pallet

If you make the press yourself, it is important to make the pallet correctly. Here they sometimes use a large pot, where a round hole is cut out near the side and a tube is secured

Through this tube, the juice will flow from the tray into the receiver. When working with the structure, you need to be careful. The tray may break if the tube, tray gets caught, or something is accidentally dropped on it. If you are not careful, you can tear out the tube. For this reason, it is preferable to choose a tray made of stainless steel, and weld a metal tube to the hole.

The tray can be made from a large plate or from a stand for a flower pot

Filters

Filters are bags in which the pulp is placed. The scraps of fabric that are needed to make bags of fruit must be durable. Suitable for this purpose: calico, cotton or burlap. Some people use linen. The density of the fabric should not reduce its filtration qualities, but it should not be fleecy.

To filter juice, you should use a durable cloth with a fine mesh, such as lavsan or polyester.

Drainage grate

A grid for drainage function in the form of a basket can be made from oak, birch or beech planks. Choose those whose thickness is 20 mm or more. To do this, take several identical planks, two steel strips, and self-tapping screws that have a special coating. The planks are screwed to the strips, the strips are bent in a circle, and secured with bolts. The basket is ready. The distance between the slats is about 10 mm. You should not take chipboard plates; such material will release resin, sawdust and other harmful substances into the juice.

To sew bags, use any durable fabric that will not tear under the pressure of the raw material. In addition, the fabric must have filtering properties.

Chopper

This part is a mandatory part of the presses, since their models work in conjunction with such a component of any pressing structure. The simplest among such grinding mechanisms is considered to be a steel grater drum, which is placed in a homemade casing with a hole for loading pulp. When you turn the handle, the chopper is set in motion, turning the fruits into pulp.

It is made from a sheet of moisture-resistant plywood, a sheet of anti-corrosion steel or wooden planks. The resulting hopper is mounted on a circular shaft. Two blocks are attached to the bottom of the bunker for stability. At the bottom of the resulting container, a roller of wooden material is inserted onto which self-tapping screws are screwed in a spiral. The axis of rotation of the element is brought out, and the drill is inserted into it. It will act as a chopping drum. To do this, you can use a regular rolling pin, which is found in every kitchen.

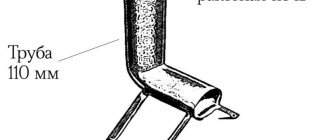

When making a model of a device for obtaining juice, you should pay attention to its stability. To cope with this problem, three pieces of square pipe are welded at the bottom of the frame.

Instead of legs, they will give the unit stability. At the top of the improvised legs, a stand made of boards or a wooden slab is placed, where the pallet is placed.

You can independently make a press for high-quality extraction to obtain any juice without spending a lot of money or special skills, abilities or knowledge. The use of complex equipment is also not required.

Power element of the structure

Piston

Containers for must and wine

The first thing you need to start equipping a home distillery is purchasing containers in which the wort will ferment, as well as strain and store the wine. It can be:

- Glass bottles,

- Oak barrels and tubs,

- Stainless steel tanks.

Regarding the use of plastic containers and utensils made of other metals for wine production, you need to take into account that wine alcohol tends to acquire the taste of the material from which the container for storing it is made.

Raw material grinding

For this operation there are special crushers for grapes and fruits. These devices can

be

- Manual - for delicate chopping of small volumes of fruits,

- Mechanical - for intensive work and speeding up the process.

Grape crushers can be equipped with a destemmer to separate the branches (ridges) from the grapes.

Pulp pressing

No home wine production can do without separating the juice from the pulp. A press can handle this operation perfectly; it can be manual or mechanical.

- A manual press is a basket for pressed mass with holes, equipped with a mechanical head with handles.

- A mechanical (hydraulic) press is a basket for crushed pulp with a membrane in the center that expands when it is filled with air.

Under the basket of any press there is a tray with a spout for draining the squeezed liquid. After collecting the valuable juice by gravity, the remaining mass is pressed until it is completely squeezed out.

Fermentation and filtration

Wine in fermentation containers should not come into contact with oxygen. Special fermentation tanks

for wort they must be equipped with water seals. They allow carbon dioxide to be removed and protect the wort from air, and also allow you to control the end of the fermentation process. Hydrometers are used to measure the alcohol content of young wine.

Fermentation is followed by a stage of filtration and removal from sediment. The purpose of this stage is to separate the wine from the yeast that has sunk to the bottom of the container, so as not to degrade its quality. For this purpose, such equipment for wine as a filter press equipped with a pump has been created. Passing through the filter board of this apparatus, the wine is cleaned of colloids, microorganisms, mechanical and adsorption particles. The device is equipped with a pressure gauge that controls the fluid pressure. After such filtration, the wine becomes significantly brighter.

Maturing and capping wine

Aging young wine gives it a special taste and aroma, especially if it takes place in oak barrels. Tannins and oak tannins add a unique accent to the overall bouquet of the drink. If the maturation of wine is planned to be carried out directly in bottles, then in-line and vacuum bottling machines have been created for the production of the drink. Their advantage is that during bottling, the contact of the drink with oxygen is minimized, which guarantees its quality.

It is convenient to cap bottles using a special device for securely placing the cork in the neck. These devices, mechanisms and devices greatly facilitate the work of a winemaker in preparing wine at home.

Attention, TODAY only!

Tips for use

The quality of the resulting juice depends on how the grape press is made and how it is operated. Before starting work, the grapes must be washed, sorted, and the berries separated from the bunches; they do not need to be peeled. It gives juice and wine a pleasant bouquet.

Raw materials for pressing:

- whole berries, used for juice production;

- pulp, allows you to fully reveal the aroma of grapes, recommended for obtaining wine materials.

Sequence of actions when working with the press:

- Fix the device motionless on a horizontal, flat surface to avoid displacement.

- Prepare a container for collecting the pulp. This could be a bucket, tank, pan.

- Place a container under the outlet hose or chute into which the juice will drain.

- Place a plastic bag over the piston plate to prevent the piston from rubbing against solid pulp particles. Rotate the handle to set the screw to the top position.

- Cover the inner surface of the press basket with a clean, cold-water-washed, white, coarsely woven cloth (you can use material from flour or sugar sacks). The edges of the fabric should hang over the sides of the basket. This will make it easier to remove the pulp.

- Place pulp or berries in the basket, cover with the hanging corners of the fabric. Place the basket under the piston.

- Tighten the press screw until juice appears. Slowly turn the screw with the handle until significant resistance is felt.

- Stop the rotation of the screw. After a break of 30-60 seconds, start turning the screw again. This technology allows you to most fully open the cell membranes of grapes.

- After the juice stops flowing, use the handle to turn the screw to the top position.

- To better squeeze the grapes, repeat the process of rotating and stopping the screw 2-3 times.

- After the spin is completed, the press screw should be returned to its original position, turning it in the opposite direction.

- Remove the contents of the fabric from the basket. Transfer the pulp into a previously prepared container. Add a small amount of water so that it covers the cake by 1-2 cm. After 3-4 hours, warm the mixture to 65 degrees. This will allow you to extract as much juice as possible. Spin again. It is not recommended to squeeze the pulp more than three times; this leads to the accumulation of suspension in the wort.

- After completing the process, disassemble the device, clean all parts, rinse well, wipe and dry. To wash the basket, regardless of whether it is made of wood or metal, synthetic detergents should not be used. You can use soda or table salt.

- The press should be stored in a dry, ventilated area.

If a wooden basket becomes moldy, it should be washed with cold water and thoroughly brushed. Then you can prepare a solution of sulfuric acid (100 g per 2 liters of water) and wipe the entire surface of the basket with it, using a brush or piece of cloth. After two days, rinse with lye (an aqueous solution of wood ash) to neutralize the acid, then with clean water.

Read also: Simple landscape design for a small area in front of the house

Another way to get rid of mold is to coat the surface of the basket with lime. After two days, clean everything and rinse with water. Then treat the basket with sand and rinse with a solution of ammonia (3 tablespoons per 5 liters of water). If the mold is not old, you can scrape it off with a knife, then steam the basket with oak sawdust. Moldy parts of the press basket should not be washed with boiling water. This will cause the mold to eat into the wood surface.

Professional winemakers distinguish two types of juice used as wine material:

- obtained by gravity;

- isolated by pressing grapes.

Working principle of a grape crusher

Provides 3 technological operations at once:

- separation of juice from the cake through crushing the berries;

- thorough cleaning of twigs and seeds;

- if necessary, separating other parts of the plant.

Such a unit will be useful in a personal plot for making wine from grapes at home. Regardless of the type, the unit consists of the following components:

- receiving hopper (the product is loaded into it);

- movable rollers of various shapes or a rotor (carry out the process of squeezing juice and producing grounds);

The berries are crushed by rollers, the juice and cake end up in a container for the finished raw materials.

A separate category includes destemming presses: roller or impact-centrifugal. They produce additional peeling from grape combs. These parts of the bunch are also needed because they add a hint of brightness and astringency to the finished wine. For the production of red wine varieties, such as Moldavian and Monarch, the use of pulp with ridges is allowed. Read about the Moldavian wine grape variety here. When making white wines, such impurities are not allowed; you will need a type with a separator for enhanced purification.

Read about Monarch wine grapes in this material.

Purpose and principle of operation

A grape crusher is a device with a simple mechanism designed for processing berries. The design consists of a loading hopper, a container for collecting cake and two parallel crushing rollers. Grape crushers are used both in wine production on an industrial scale and in home winemaking.

The grapes intended for processing are poured into the loading hopper and crushed using crushing rollers driven by motion. The drive can be mechanical or electrical. Processed raw materials are discharged from a pulp collection container.

An important feature of a grape crusher is the presence of a gap between the crushing rollers. This allows you to leave grape seeds intact, which in a crushed state affect the taste of the finished product. The tannins contained in the seeds give bitterness to the wine.

Recommendations for obtaining high-quality juice from berries

One of the main recommendations for working with a press is the need to wash the berries before loading. Only after removing them from the bunch and thoroughly washing them in running water, the material is loaded into the apparatus (drum).

Winemakers who are professionally involved in grape cultivation divide it into 2 levels:

- fruit juice obtained by gravity;

- using a press.

In the first case, the liquid is the most valuable, as it is rich in taste and useful substances. In the second option, you can squeeze out the juice in 2 stages, that is, recycle the pulp. For varieties such as Chardonnay, white Muscat, Pinot Noir, secondary processing is not recommended, since the taste characteristics are significantly affected.

Mechanism components

- frame;

- a tray into which liquid flows;

- the pressing element itself;

- barrel;

- fine mesh;

- spin-intensifying screw.

The principle of operation of the device is simple: berries are loaded in portions, then the screw is turned and juice with pulp is obtained, which passes through the filter mechanism and is separated from the pulp.

In addition to the fact that the crusher squeezes juice, it can also be used to ferment various drinks. Also, the part that presses and the food material are practically not in contact; therefore, heating is minimal, which ensures the safety of all vitamins and nutrients in the drink.

Advantages and disadvantages

A press juicer greatly facilitates the processing of grapes and other soft berries. The unit has the following advantages:

- simple design;

- low noise level during operation;

- obtaining the maximum amount of high-quality juice or must, thanks to the features of the unit, which allows you not to crush the skins, ridges, and seeds of grapes;

- processing of various berries and fruits by adjusting the gaps in the pressing element;

- no foaming;

- accelerating the process of squeezing juice, reducing labor intensity.

There are only two shortcomings in the operation of the device: leaky design, due to which the juice comes into contact with the environment; the possibility of mold formation due to insufficient cleaning and drying of the press after spinning.

Step-by-step manufacturing instructions

Design development

You can make a crusher yourself

To make a grape crusher with your own hands, you need to develop a sketch or drawing of the future product.

Of all the variety of designs, the easiest to make is a roller device: it actively crushes the bunches.

In advanced designs, the distance between the rollers is adjustable.

Bunker

Crushers must have a hopper for 10-20 kg of grape mass. For manufacturing you will have to use plastic, wooden panels or stainless steel sheets.

The hopper has a wide part at the top and narrows at the bottom: this shape makes it possible to compress the product directed to the active working element.

Drive unit

A small homemade grape crusher is equipped with a handle: its axis is a continuation of one of the rollers.

Large-scale processing requires an electric drive. However, it should be taken into account that the shaft rotation speed should be no more than 3-4 rpm. A gear motor with a speed of 180-240 rpm is used. A power of about 1-2 kW will be required.

Container for berries

A homemade press can be tabletop, or it can be located on its own frame.

The container for the pulp is placed under the product. Plastic buckets are used for food products; they make it easier to transfer the semi-finished product into the fermentation container.

Manufacturing of elements

Wooden rollers are installed inside. Dough rolling pins made of birch or linden are used as a base.

For the protrusions of the grape crusher, slats (beads) are used.

- The length of the rolling pins is measured.

- 6 glazing beads are sawn off (12 in total).

- The cylinders (rolling pins) are marked into 6 parts.

- Using copper or brass nails, parts of the glazing beads are nailed into place - the rollers are ready.

Bunker elements are cut out of plywood 4-6 mm thick. The fragments are fastened together with copper screws or nails. The finished parts are impregnated with hot drying oil or primer for exterior use (double coating).

For a homemade grape crusher and installation of rollers, closed bearings are selected, which are fixed on the outside of the hopper. Housings made of stainless steel or bronze are used.

Classification

The grape press must be made from environmentally friendly materials. In this regard, only wood and steel are used for the production of units. In addition, devices for pressing juice are classified according to their method of operation, design, and performance.

By way of working

Depending on the type of power supply and method of operation, the following types of equipment are used:

- mechanical and manual grape press - suitable for use in private households, you can do it yourself, but squeezing requires physical effort;

- electric unit - can be screw, pneumatic or hydraulic, characterized by high productivity, low physical labor costs, but expensive (about 30 thousand rubles);

- universal press - the peculiarity is that it can process any vegetables, berries and fruits; such a device operates from the mains.

Electric

Universal

Manual

By material

Equipment for pressing grapes is made of wood or metal:

- Press with a wooden barrel or basket. If it is possible to make a wine press with your own hands, then linden, beech or oak should be used as the material for the basket. These types of wood are durable, dry quickly, and do not crack or warp when dried.

- Metal unit. Structural elements are made of stainless steel, which increases the cost. This press is durable, hygienic, easy to clean and maintain. The contact of grapes with the working elements of the press does not add extraneous odors to the juice.

Made of metal

Made of wood

By volume and power

The productivity of the press is determined by its type, the power of the electric motor and the volume of processed raw materials.

- High-performance units – continuous electric screw presses. They can squeeze up to 5 tons of grapes per hour, their dimensions are: length - 2.2 m, width - 1 m, height - 1.5 m. Motor power 2.2 kW. Such equipment is appropriate for industrial enterprises or winegrowing farms with large volumes of processed material.

- Hydraulic and pneumatic presses are intermittent units. Productivity reaches up to 40 liters of juice from one bookmark. They are used if you plan to make wine regularly or organize craft production.

- For small volumes in the household, it is advisable to use a self-assembled screw grape press. Its performance is determined by individual needs. Devices with basket volumes from 2.5 to 25 liters are manufactured industrially, allowing you to get from 1 to 25 liters of juice in one batch, respectively.

By design

According to their design features, presses are divided into:

- Screw presses are mechanical presses for squeezing grapes with your own hands. The working container is a wooden basket or a perforated metal barrel, into which crushed pulp or whole grapes are placed. The spinning process is carried out by rotating the handle of a pressing element mounted on a screw auger or rod. Screw presses are simple and trouble-free; productivity depends on the size of the basket.

- Jacking – pressing is carried out using a piston (jack). It can be fixed from above, the pressing force, in this case, is supplied to the pressure plate. If the jack is secured from below, then the basket rises to the fixed pressure plate. In either case, the grapes are compressed between the bottom of the basket and the plate. It is convenient to work with such a press without exerting significant physical effort. They are manual, hydraulic or pneumatic.

- Screw - divided into manual and electric. The principle of operation is similar to a meat grinder and lies in the fact that, thanks to the auger, the pulp is mixed relative to the drainage perforated surface and is subjected to active mechanical action. This treatment can crush the seeds and grind the skins of the grapes. Phenolic and nitrogenous substances pass into the wort. A suspension may form in it.

- Lever ones are the most primitive type. A bag of grapes will be placed between the board and the lever hinged to it. Due to the force applied to the lever, the berries are squeezed between the pressing surfaces. Such presses are leaky, labor-intensive, and low-productive compared to jacking and screw machines.

Lever

Jacking

Screw

Screw

Types of devices

Before purchasing a press for squeezing grape juice or other fruits and vegetables, you need to carefully study all the varieties of these devices.

All industrial squeezing presses can be divided into the following categories.

Mechanical press

Such a device is a stationary cast-iron base on which a special basket made of wood is installed. This solution has good performance, reasonable price and small dimensions. Many winemakers consider a mechanical device for squeezing fruits and vegetables to be the ideal solution for creating juice at home.

Electric press

This subgroup includes two more types of press: hydraulic and pneumatic. Such devices are made of excellent quality stainless steel, so the press will not rust. This solution will not add any off-flavors to your juice. A hydraulic press operates using water, while a pneumatic press operates using high air pressure, which is created by a special pump. Both the hydraulic and pneumatic versions of the pump operate only on electric current.

The main advantage of this solution is the high performance of the device.

Universal press

Many people want their device to be able to squeeze juice not only from grapes, but also from any other fruits and vegetables. Universal presses have long established themselves on the market and are in great demand because they can be used to squeeze juice from apples, cherries, oranges and other crops. This significantly expands the possibilities for making juices and wines.

Every winemaker can buy a five-liter device for pressing grapes and use it at home. All press options are similar in function, however, the material from which the structure is made often differs. The most popular are 2 types of devices: a press made of wood and metal.

- The wooden version

is environmentally friendly and does not cause any harm to human health. However, it is very difficult to care for such a device, since after each use you will have to rinse the device very thoroughly and disinfect it. - The metal version

of the device is an alloy of cast iron and stainless steel. If the design is based on metal, then this device will be durable. The press, made of metal, is very easy to use and is hygienic, as it does not impart any unnecessary tastes or odors to the resulting grape juice.

Requirements for a juice press when making wine at home

All types of juicers are practical and have their own advantages. Your choice should depend on preferences, harvest volume and financial capabilities.

In addition to the principle of operation of the device, it is important to choose the right materials from which the equipment is made

Environmentally friendly materials for the manufacture of presses are the key to long service life and a high-quality final product (juice). Stainless steel will ensure long years of operation for the device. This is a reliable metal that does not corrode, which means it will not only last a long time, but also will not spoil the juice, which can be consumed in its pure form or fermented into wine. Aluminum is also a good choice. This material is capable of many years of service; one of the advantages compared to stainless steel is its low specific gravity.

A high-quality press is also made of cast iron. This material has high strength over many decades and does not lose its physical properties. The basket is made of wood. The best option is beech. The advantages of this material are naturalness, strength, durability. In addition, such a press looks very impressive and presentable.

How to make basic press parts

You can do everything yourself. Materials and tools are prepared in advance, this material is read, and then done in one go. It won't take long to do this, and the instructions will tell you where to expect surprises.

Pallet

If parts of a washing machine drum are used to make the press, then the outer drum casing is used for the tray:

- It is cut to the required height.

- All holes are blocked from below.

- Only one hole is made to drain the fruit drink. This hole should be on the side at the bottom.

Either a barrel or a plastic or metal basin can also be used as a pallet. There is also a hole in it to drain the juice.

Filters

This element of the apple press is made by hand from wooden dies or a washing machine drum. If wood is taken, then dense varieties are selected that do not absorb moisture, do not have resins and a strong odor of their own. If made from metal, all parts, including bolts and nuts, must be made of stainless steel.

In the drum of the washing machine, all unnecessary, large holes are plugged using a rubber gasket secured with a metal plate. If necessary, additional thin holes with a diameter of 1 mm are punched in the drum.

It is not difficult to assemble such a unit from wooden slats. The amount of material will depend on the volume requirement:

- The required volume of a barrel for processing the harvest from your own garden will be obtained from 20 wooden dies with a height of 40 to 50 cm, a width of 50-60 mm, and a thickness of 20 mm.

- You will need 3 metal strips 2-3 cm wide and 1 mm thick to attach the boards. These will make tightening hoops.

- To fix the boards, 60 screws and 3 pairs of stainless steel bolts and nuts are used.

Tools you will need:

- screwdriver or screwdriver;

- sandpaper;

- hacksaw for metal or wood.

The result will be a leaky barrel without a bottom. Let's look at it step by step:

- All wooden planks are leveled in height using a hacksaw and processed with sandpaper to remove burrs, roughness and sand them.

- Two metal strips are placed parallel to each other at a distance of 5 cm from the top and bottom of the resulting knot, and a third in the middle.

- The dies are laid out across the tapes with a gap of 10-12 mm between each other.

- The boards are attached to the strips with screws.

- The resulting structure is rolled up, and the tapes are fastened at the ends with bolts.

It will be better if the apple mass is placed in mesh bags. Or they take pieces of fabric and wrap the fruits in them, like in an envelope. All the pulp will remain in the fabric, and will flow into pure juice into the prepared dishes. The fabric acts as an additional filter.

Drainage grate

In such a unit, drainage gaskets are required; they help distribute the load of the press and better squeeze out the juice. They are usually made of wood:

- Either a fairly wide and thick board is taken, or from several dies, in 2-3 layers with transverse laying.

- The dies are tightened with screws or nails. Connection with screws is more reliable.

- Holes are drilled in the resulting gasket to allow juice to drain. This drainage design is made taking into account the possible high pressure on it.

- Fabric bags with chopped apples or apple mass are placed in the tank, sometimes the apples are placed whole. If these are cut or whole apples, then it is recommended to lay one layer of a bag with fruits, a second layer, a drainage grid, and so on.

If there is grated mass in the bag, then you can put 2-3 bags in one layer, depending on how finely the fruit is grated.

Chopper

If the press is powerful and the apples are small and not very hard, then you can crush them whole. If they are hard and large and the press is medium in power, then you need to cut the fruits or grind them.

As an option, a screw mechanism is used for grinding or a screw press is made directly.

OTHER

Maturation and aging of wine

The end of the preparation of any wine is marked by its transparency (or there is turbidity that no longer descends), which...

Wine production - what a novice winemaker should know

Experienced winemakers have their own tricks and secrets that allow them to produce tasty and aromatic homemade wine year after year...

Wine production

Video: Winemaking, wine production in Spain (part 2) wine juice Wine is a fermentation product prepared in advance…

Preparing to make wine

Preparing grape wine starter 7–8 days before the start of the grape harvest, in dry weather, selectively harvest...

Equipment for home winemaking

ContentsPreparation of raw materials for winemakingCrushing grapesPressing raw materialsFermentationUsing water seals in…

The best homemade apple wine

Fans of classical literature have often come across mentions of such a drink as...

What equipment is needed for winemaking?

What equipment is needed for winemaking and what grape varieties are suitable? Winemaking is popular in our country.…

How to make homemade wine?

Winemaking traditions, carefully preserved by humanity, date back several thousand years. Useful qualities of grape…

How best to store homemade wine

Owners of a home vineyard often face a problem: how to store homemade grape wine so that its taste...

Making dry wine

There is an opinion among people that it is impossible to make dry wine at home without adding sugar due to its low...

Making wine from rowan at home

Wine connoisseurs will appreciate the delicious homemade red rowan wine. It is characterized by a slight bitterness,…

Making cranberry wine at home

Cranberry wine retains most of the beneficial properties of this northern berry; it contains many acids, vitamins and…

Making homemade red wine

A classic of the genre is homemade red wine, a drink with centuries-old traditions of preparation and consumption. Wherever...

Choosing a container for wine fermentation

Home winemaking is impossible without special containers in which fermentation takes place. It largely depends on the capacity...

Winemaking at home

ContentsHistory of home winemakingSecrets and features of home winemakingRaw materials for winemakingEquipment…

Grape scallop tincture

This recipe for grape tincture appeared in Soviet times, when the people were subordinate to the party. The founder of anti-hangover products was Leonid Brezhnev, but his “brainchild” never appeared in stores. However, the technology has survived and taken root among those who like to make homemade alcohol.

Components:

- Dry ground grape scallops - 6 tsp.

- Alcohol base (alcohol 45%, moonshine or vodka) – 1 l.

- Glucose or fructose - half a teaspoon.

The recipe for making an anti-hangover tincture using grape scallops is the simplest:

- The dry ingredient is poured with alcoholic beverage and kept for 1 week. Shake the container daily.

- The composition is drained through a filter and a little glucose is added (can be replaced with fructose or sugar syrup).

- The product is infused for 2–3 days, then tasted.

The color of this tincture resembles cognac, and the taste is similar to chacha.

Purpose and description of the device

In the modern world, where they try to automate all work, it is impractical to use primitive manufacturing methods. Crushers are used to prepare grape juice.

They are designed to crush berries and form a mixture for further distillation of wine. These devices are used for processing grapes both on an industrial scale and at home.

The chopper has a fairly simple but effective design. The simplest device consists of a loading hopper, at the bottom of which there are two parallel rollers. The hopper is mounted on a wooden frame, and the rollers rotate using a gear system and a handle.

Some designs may also have a container for chopped berries. Although you can use a wooden vat or plastic barrel.

How does a crusher work?

After harvesting, grapes must be processed as soon as possible. Berries are poured into the loading hopper. The grinding rollers are located at some distance. Thus, when the grapes fall between them, the berries are crushed, but the seeds remain intact.

Important! If the gap between the rollers is minimal, then there is a possibility of crushing the grape seed. In this case, the tannins contained in it will get into the juice or wine and give them bitterness and viscosity.

By turning the handle, the rollers begin to move. The gear system is designed in such a way that when it starts to move, the rollers rotate in different directions. Grape berries that fall between them are crushed.

Their skin bursts and the pulp and juice are released, and the rotation of the rollers pushes them into the pulp vat.

Grape crusher (video)

Crushers with and without destemmer

Grape combs can give wine the astringency and richness characteristic of quality drinks. However, their excess amount very often causes the drink to taste bitter or unpleasant, and also negatively affects its color and transparency. And if, when making red wines, it is allowed not to remove the grape stems, then for white wines such a procedure is mandatory.

There are two main types of destemming crushers used for grape processing.

Roller crushers-comb separators

Such a unit best meets the requirements of the technology for preparing raw materials for wine and allows you to obtain high-quality must. Our country has launched the production of such crushers. The operating principle is based on the operation of rollers and a destemmer. A pair or more horizontal rollers are cylindrical in shape and rotate in opposite directions. The size of the gap between the rollers is regulated by a special device. Rolls have a grooved, smooth or bladed surface and can be four-, six- or eight-bladed. Preferably profile rolls are used.

Centrifugal impact crushers-stemmers

Centrifugal crushers, or CDGs, can be either vertical or horizontal. The process of crushing grapes occurs as a result of impacts of a rotor rotating at speeds of up to 500 rpm. The use of this type of crusher-stemmer is characterized by the most complete yield of wort with an increased amount of coloring and phenolic substances. As a rule, CDG is used in the production of wine from red grapes.

Mechanical and electric crushers

The operating principle of a standard electric crusher has minor differences from the operation of a mechanical apparatus. A special feature is the presence of a special comb separator, which is a horizontal cylinder with a shaft and helical blades. Such elements allow you to quickly and efficiently separate grapes from the ridges. As a result of the translational movement of the screw blades, the ridges are pushed outward. Only juice and clean grapes enter the crushing container.