Hello to all do-it-yourselfers, as well as summer residents! Recently, when the snow melted and the ground began to dry out, I ran into one small problem. It consisted in the fact that at the very exit from the garden, next to the gate, a small tubercle came out of the ground. Moreover, the further it went, the higher it became and gradually began to interfere with the passage, and even later, the lower edge of the gate began to cling to it when opening.

When I dug up this bump with a shovel, it turned out that it was a wooden stump, or rather, the base of an old wooden post, apparently preserved from the days of an old wooden fence. Moreover, over the past few years, this stump did not show any signs of life, but this spring, for some reason, it began to actively crawl out of the ground.

This is what this stump looks like.

Naturally, there was nothing left to do but uproot this stump.

Moreover, I decided to do this, which is called “little blood”, and did not dig a large hole around the stump, but simply tapped it with a sledgehammer, shaking it from side to side.

And then, I tried to pull out this stump with a crowbar.

However, this was not the case. It turned out that the stump sits quite firmly in the ground. But most importantly, it seemed to me that when pulling it out with a crowbar, when the crowbar picks up the stump from only one side, it warps, which is why it actually becomes very difficult to pull it out. Moreover, this stump is quite long and sits quite deep, at least 60-70 cm.

As a result, it became obvious that in order to uproot this stump using a crowbar, you need to dig a deeper hole around it (30-40 centimeters deep). However, I really didn’t want to do this, since the ground around the stump is very compacted, and in addition, there are a lot of stones and fragments of bricks that were filled in and compacted when installing the wooden post.

And then another idea came to me. It seemed to me that if I made some kind of powerful metal hook and hammered it into this stump, then by applying a vertical force with a crowbar exactly in the center of the stump, it could be pulled out quite easily.

As a result, I rummaged through old pieces of iron and found this ancient door handle. Moreover, this handle is quite old, perhaps from the 19th century, since it is forged and quite durable.

How can you get a hose out of a well?

How to remove the hose and pump from the well:

- If, while removing the pump, the hose breaks and falls into the well, it can only be retrieved with special hooks attached to a cable or a special stick. ...

- If the cable sag, you need to lower the pump until you feel the slack, then slowly continue to rise.

Interesting materials:

How to view the list of extensions in Chrome? How to view VK account statistics? How to view your ID in sampa? How to view your rating in Yandex? How to view all gifts in OK? How to see all your reviews in the Play Store? How to see the winnings in 5 out of 36? How to view blocked calls on Android? How to salt mushrooms? How to put animation on the iPhone screen?

The easiest way to pull out a pole: an idea from an engineer

Fence posts that have become unusable due to time often need to be pulled out of the ground during reconstruction or rebuilding of fences. If they are small, without consolidating the underground part, problems do not arise. The pillars are dug up with a shovel, dumped on their side and dragged to the storage site.

If the supports are large or their stability was ensured by pouring concrete into the underground part, this method becomes labor-intensive and requires considerable time. To cope with the problem, several methods have been invented.

One of them allows you to cope with the task without greatly disturbing the soil near the support. Apply a long crowbar vertically to the stand. In the lower part, about 10 cm from the soil surface, wrap both objects with a thick rope, which is pre-wetted well in water.

A piece of log is placed next to the pillar - it is used as a support. They take the top of the crowbar and tilt it to the side until it stops with the last one. At the same time, the rope ring, compressed due to twisting with a crowbar, will tightly clamp the stand.

The crowbar, resting against a log, turns into a lever. Applying force to its free end, lift the pillar up a little. Next, the crowbar is returned to the stand in a vertical position, the rope ring is moved down and the lifting procedure is repeated again. Then, if necessary, several more times until the pillar falls to the side.

If the post is buried deep and tightly clamped with soil, you can try to pull it out using two crowbars, wrapping their ends with one rope ring. In this case, the stops are placed on both sides of the post, and the crowbars act together as levers in opposite directions.

You can pull out the pole using a car winch. It is installed not far from the stand, then a shovel is stuck into the ground along the entire bayonet in one straight line. If one is not enough, then follow it with one or two more.

The winch is attached to the first shovel at the very bottom of the handle. The end of the cable covers the rack at the same level. The winch is activated and the pole is tilted. Then the cable enclosing it is moved down and the operation is repeated again. And so on until they complete the task.

If one shovel cannot withstand the force and turns out, then a second one is stuck into the ground behind it, and if necessary, a third one. Each is attached to the one located in front.

The method is more expensive than the previous one, and the more it leads to damage to the integrity of the soil - especially near the pillar. But they do without crowbars and rope, which may not be at hand.

Preparation and calculations

You cannot install poles without first making calculations. Also, the future location of the fence must be indicated on the site plan. After this, you need to calculate the number of pillars, and then purchase the material.

Before you drill a hole in the ground for fence posts, you need to familiarize yourself with certain rules:

- During calculations, it is necessary to correctly determine the distance from one pillar to another. It will depend on the area of the site, as well as on the weight and size of the canvas that will be used as a fence and attached to the support. Often this distance is no more than 3 m

- The hole must be made wider than the cross section of the pillar. But it also should not be too wide, otherwise the soil will be too loose. If the hole is made narrow, then concreting will be impossible.

The post must be carefully aligned Source mahis.ru

See also: Catalog of companies that specialize in the construction of fences and enclosures.

- To determine the number of holes, you also need to make calculations. The length of the fence perimeter is divided by the distance between two posts that stand next to each other. These calculations must be made to ensure that the number of pillars is optimal. With a smaller quantity and a larger distance between them, the canvas may sag, and if you purchase a larger quantity, it will be too expensive.

- It is important to remember that the higher the fence, the closer to each other the posts should be installed.

- The depth of the holes depends on the soil. The harder it is, the smaller the hole can be made. But if there is sand or clay in the soil, then the depressions should be larger, since such soil is not very stable. And if with solid soil the depth of the hole can be made up to 1 m, then with sand or clay it is advisable to dig more than 1.5 m.

- Before digging holes, you need to find out if there are underground communications in that place.

It is also important to remember that the calculations must be made accurately, without the slightest errors, otherwise the fence may warp or fall.

Fence after incorrectly installed poles Source khersondaily.com

How to dig a hole for a post

Before you dig a hole for a post without a drill, you also need to mark the places where the recesses will be. The best way to do this is with signal tape or any other bright thread or fabric. This way the master will not crawl out of the frame and the hole will not be too wide. If you don’t have fabric or tape, you can simply place stones in the corners, which will also serve as a kind of limiter.

If it is not possible to make a hole with a drill, then you can use a shovel or digger:

- When all the lines are marked, you can start digging. The top layer of soil is often removed without problems. But the lower it is, the more difficult it is to insert a shovel into the soil. In this case, you can begin to loosen the soil with a bayonet shovel, then it will be easier to remove the soil. Such actions must be performed until the recess reaches the desired size.

Drilling holes for poles

If you need to make a lot of holes, then it is better to choose a garden auger and sharpen its edges and tips. Before quickly drilling a hole for a post, you need to mark the places where the recesses will be, and then start working. The drill is installed vertically and rotated by pressing the handle. On clay soil at a depth of 0.3 - 0.4 m, it is more difficult to turn the drill. To make the task easier, you can pour half a bucket of water into the hole, which will soak the soil in less than 5 minutes. After these steps, the handle turns without problems.

If the drill is firmly stuck in the soil and cannot be removed, then it is necessary to loosen it in different directions. This will loosen the soil a little, making it easy to get the tool out. Adhered dirt can be easily removed with a knife. To minimize time costs, you can make several small holes and fill them with water, then the ground will be well soaked and the work will be easier.

The drill makes a neat hole for the post Source onlypatriot.ru.com

Why is pile extraction necessary?

When laying the foundation and its further construction, pile structures are often used. They are pressed or driven deep into the ground, due to which the foundation will be able to more easily bear increased loads in the future.

But what to do if something doesn't go according to plan? For example, was the pile driven in crookedly or damaged in the process? In this case, the only solution is to remove the pile to further correct the problem.

Thus, the need for extraction may arise for the following reasons:

- there was a deviation from the specified direction for the pile during the introduction of the structure into the ground;

- when immersed in the ground, the pile is bent or broken, which means its use is unacceptable.

Another is the reuse of piles. In this case, the pile is removed from the old foundation and driven into the ground a second time, but in a new structure. However, piles are most often removed after their temporary use as enclosing structures. In any case, if it is necessary to remove the pile structure from the soil, there are several ways to do this.

How are piles removed?

To remove an already driven or depressed pile from the soil, different methods are used. They can be divided into two main groups:

- statistical efforts;

- dynamic forces.

The first option is the most common: the piles are pulled out by cranes, jacks or winches. Of course, this method is quite labor-intensive and does not always allow maintaining the integrity of the extracted material.

In the case of dynamic forces, either piling equipment operating in both directions or pile pullers are used. Such equipment operates due to vibration.

The vibration extraction method of piles is considered the most effective and efficient. It allows you to keep the extracted piles intact, making the process faster and safer. The high productivity of the method makes the work more cost-effective.

- This method is versatile: it can be used on any type of soil without restrictions.

- The equipment used in such work is quite mobile and accessible for transportation.

- Modern vibratory hammers accomplish their task quickly and efficiently.

By creating vibration, the friction between the pile and the soil is sharply reduced, making extraction easier and faster. However, the force of influence is not always the same. It can be determined individually, taking into account the length of the pile, its mass, immersion depth, and soil characteristics. It also takes into account how long the pile has been underground, whether there are new layers of soil on the surface, and whether the structure has been deformed under the influence of time.

This method is effective even when other options fail. When using a vibratory pile driver, a less powerful crane is required to remove the pile from the soil, which can significantly reduce the cost of the job.

If you need to remove the piles, leave it to the professionals. At IntelStroy at https://vibrorent.ru/izvlechenie-svay/ you can order the rental of drilling rigs and vibratory loaders with personnel at the best price on the market.

We pull out the pillar along with the concrete base

We cut down the pillar, leaving it about a meter high.

This, of course, is not necessary, but in the future it will be more convenient to work with the part that will be removed from the ground. Cut a block from the sawn part and drill two holes in it. Use a clamp to temporarily attach the block to the post. We will continue to drill the pillar itself through the same holes. Of course, everything can be drilled at once, but it may not be entirely convenient. Next, we hammer in wood studs or long bolts. We prepare a base for supporting the jacks from a thick board. The support should rest on free ground, at some distance from the concrete base. We lay down the timber. It must be reliable and withstand significant forces without severe deflection. We place the jack and rest it against the screwed block. As the pillar comes out of the ground, we place blocks, since the jack's stroke at one time is not enough. We bring the jack together and repeat the procedure. You can see the pillar coming out. Next we add more bars. As soon as more than half of the concrete base has come out of the ground, the pillar can be tilted on its side. That's all. It didn’t take a lot of time or effort. After the post, there was only one fairly equal groove left, which, by the way, can be reused.

I personally really liked this simple method for uprooting fence posts without any extra effort. As for steel structures, the steps are the same, except that welding can be used instead of drilling and bolts. As you can see in this example, the concrete base has the shape of a cone, which greatly simplified the task. If the base is made as a step with an increase towards the bottom, then this method is also quite suitable. Except that in this case the pole will have to be pulled out to the very end.

Hello to all do-it-yourselfers, as well as summer residents!

Recently, when the snow melted and the ground began to dry out, I ran into one small problem. It consisted in the fact that at the very exit from the garden, next to the gate, a small tubercle came out of the ground. Moreover, the further it went, the higher it became and gradually began to interfere with the passage, and even later, the lower edge of the gate began to cling to it when opening.

When I dug up this bump with a shovel, it turned out that it was a wooden stump, or rather, the base of an old wooden post, apparently preserved from the days of an old wooden fence. Moreover, over the past few years, this stump did not show any signs of life, but this spring, for some reason, it began to actively crawl out of the ground.

This is what this stump looks like.

Naturally, there was nothing left to do but uproot this stump.

Moreover, I decided to do this, which is called “little blood”, and did not dig a large hole around the stump, but simply tapped it with a sledgehammer, shaking it from side to side.

And then, I tried to pull out this stump with a crowbar.

However, this was not the case. It turned out that the stump sits quite firmly in the ground. But most importantly, it seemed to me that when pulling it out with a crowbar, when the crowbar picks up the stump from only one side, it warps, which is why it actually becomes very difficult to pull it out. Moreover, this stump is quite long and sits quite deep, at least 60-70 cm.

As a result, it became obvious that in order to uproot this stump using a crowbar, you need to dig a deeper hole around it (30-40 centimeters deep). However, I really didn’t want to do this, since the ground around the stump is very compacted, and in addition, there are a lot of stones and fragments of bricks that were filled in and compacted when installing the wooden post.

And then another idea came to me. It seemed to me that if I made some kind of powerful metal hook and hammered it into this stump, then by applying a vertical force with a crowbar exactly in the center of the stump, it could be pulled out quite easily.

As a result, I rummaged through old pieces of iron and found this ancient door handle. Moreover, this handle is quite old, perhaps from the 19th century, since it is forged and quite durable.

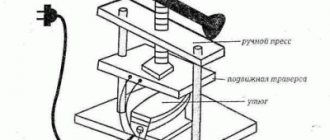

Attaching the stop to a concrete pillar

The fastening of the thrust structure to the support must be strong and reliable. Drilling concrete is a labor-intensive task; it is better to use overhead parts. There are three such options:

- wooden beams are placed on both sides of the rack and tightened together with long bolts;

- metal plates are fixed on the pole in the same way;

- a piece of chain is wrapped around the support in its lower part, leaving a loop for the lever, and fastened with bolts.

For placing under the jack, wooden blocks measuring 50x150 mm in diameter are prepared. A 3–4 m pipe or a log of the same length is used as a lever; the support for the lifting mechanism is a meter block.

Unscrewing method

This option is more complex. After all, to implement it you will need a special drill. Removing casing pipes from the well in this particular case means applying simultaneous tension and rotation forces. This will provide an opportunity to pull the pipeline to the surface.

What do we have to do:

- First of all, you need to run a bit into the well.

- The top of the object is clamped in a fixed position.

- The crown rotates counterclockwise, after which the pipe can be removed.

During the work, every action must be very clearly controlled. If you apply too much force, the object will be damaged. Details can be seen in the video.

How can I dig a hole for a post?

You can make a hole for a post with a shovel, drill or digger. Each method has its own advantages and disadvantages:

- Shovel. One of the advantages is that with its help, shovels can easily dig wide holes, which are mainly needed for installing pillars. The disadvantages include the fact that people with poor physical fitness will not always be able to dig a hole of the required size without any problems.

- Boer. There are two options for this design: a manual drill and a motorized drill, the rental of which is not affordable for everyone. It is also necessary to apply force to a hand drill, but much less than to a shovel. Therefore, most often masters give preference to it. There is also a special technique that is used if it is necessary to make a depression in a short time. Since it is impossible to quickly dig a hole for a post without it.

Hand drill Source rozetka.ua

- Digger. This tool is designed for digging holes manually, without using a shovel. The advantages: no need to use much effort, minimizes time consumption. The disadvantages include the fact that it is difficult to use on hard ground, problems arise with dry soil, and also, if you need a hole of 1.5 m, then only 1.1 m can be made with diggers, which is not suitable for such a case.

But it is important to remember that before you dig a hole for fence posts, you need to make calculations and preparations.

Digger for digging holes Source alicdn.com

Extraction technique

In order to remove the pillar from the ground along with the base, you first need to cut it down so that its height does not exceed 1 meter. Now, to the remaining clean we need to attach a block against which our jack will rest. It must be securely fixed. It's best to use two hefty bolts.

Now you need to prepare the support for the jack. It must rest on free ground and be at some distance from the concrete base. To create it, you can use several bars. You should take it with a reserve, since you will gradually need to increase the height of the base.

Otherwise, the technology for removing the pillar is extremely simple. We place the jack on the base and place it under the support, and begin to lift. After some time, when the upward movement of the pillar becomes too difficult, we remove the jack and increase the height of our stand. We put the jack on and turn it. This procedure should be repeated until the bitter end.

This is a great way to remove the post along with the concrete base without much effort. This method can be quite suitable not only for wooden but also for steel poles. To save your strength and create a powerful pulling force, a car jack will be used.

YAP19 › Blog › How to pull a reinforced concrete pole out of a hole without equipment.

Now he is very actively involved in construction, and at a certain moment a problem arose in the form of a reinforced concrete pillar sticking out of the ground. It once served as a side support for a main power line pole. Over time, it (the line) was removed, but a “legacy” remained, which sticks out of the ground “not according to Feng Shui” in a place where it is not needed. Perhaps someone will encounter a similar situation, but under more “extreme” conditions for solving it (a swampy, viscous place that does not allow digging a deep hole and the impossibility of access for equipment) ... It is for such cases that I want to share how to solve such a problem (if you don’t want to dig a deep hole to remove the “splinter”). To do this, you will need to choose something strong that can be strung on a pole and a strong and long lever (in my case, an “L”-shaped two-meter channel). The most suitable thing that I found in my garage (not yet very “systematically” littered with all sorts of rubbish) was a welded frame (the basis for mounting a water pump with an electric motor in water supply systems). Usually such “pieces of iron” are located in boiler rooms and circulate water through the system... but you can also pick up something similar “frame-like” (as long as it is durable and has the ability to be hooked with a lever). Almost everything can be understood if you look at the photo... It turned out very effective( I didn’t even expect it myself) it works on the principle of “Jeeper” Hi-Jack jacks (or on the same principle as all sorts of viscous (sealant, glue, etc.) “autochemicals” are squeezed out of tubes with a “syringe gun”) ...I pulled it out myself without anyone’s help (you just needed to first put a bunch of something solid near the hole, which, at the moment of raising the pillar, was thrown into the hole under the lower part of the pillar for its “cyclic fixation” in the raised position...

Ways to solve the problem

The simplest option that suggests itself is to dig out the concrete base with a shovel, hook it with a cable or rope, and pull the post out of the hole manually or using a traction winch. This option cannot be called easy, but you can use it.

Other methods are offered:

- Dig up the foundation of the support from two opposite sides, then swing it until it is completely free, and then remove it using the same winch or manually.

- Do without excavation work. Attach a stop to the outside of the concrete pillar, pave the jack stand and use it to press the support out of the ground.

- Apply the previous method, adjusted for the device to create force: use the Archimedes lever if there is suddenly no jack.

The last two methods seem more attractive, from the point of view of ease of pulling out. When implementing them, it is necessary to secure the emphasis on a concrete support.

Important! For better exit from the ground, the soil at the work site is watered through several depressions around the circumference, punched with a crowbar.

Walking method

It is mainly used to pull out narrow pipes and posts. But, again, there is no guarantee that they will be kept safe and sound. On the other hand, if the dimensions are large enough to fit a circular pump inside, then there is a chance to pull them out intact.

To implement this method, you need to:

- Install the pump on the upper edge of the pipe or immerse it inside.

- Having started the pump, you need to gradually walk the pipe - that is, swing and twist from side to side.

- As a result, the density of the connection between the pipe and the ground will decrease, and the object will crawl to the surface.

It is also suitable for those who are wondering how to remove a small pole in a simpler and easier way. Or a similar metal structure.

An object that sticks out of the ground is not the most pleasant sight on a personal plot. But it turned out that it’s not at all difficult to figure out how to pull a pipe out of the ground with your own hands, especially since the best way, step-by-step instructions and photos are attached. And it will no longer seem like an impossible task.