Every owner, owner of a plot, always wants to process it in the best possible way, but for this he needs to have a good mechanism for processing; small tractor or walk-behind tractor. It can be purchased if sufficient funds are available. What if they don't exist yet? There is an exit!

You can design a mechanical unit yourself—a minitractor—to work in your garden, plot, or field. What is needed for this?

- ability to make a walk-behind tractor;

- machine parts;

- tools for work.

If you need help, then on the Internet you can find a lot of suggestions and tips on how to make a walk-behind tractor with your own hands.

Definition of a gearbox and its purpose

The most important part of the walk-behind tractor is the gearbox. This is the main drive of the entire mechanism with which the agricultural unit operates. It is important for the owner to know that the life of the walk-behind tractor depends on the gearbox, so you need to choose a high-quality, reliable mechanism.

The purpose of the gearbox is to convert and transmit torque, which is generated from a mechanical transmission and thereby makes the machine mechanism work.

What it is?

First you need to understand what a gearbox is. It is a mechanism that ensures the movement of the cultivator. The gearbox for a walk-behind tractor converts torque into driving force. The device is sometimes called a converter. The service life of walk-behind tractors depends on it, so it is very important to pay attention to the quality of parts when choosing .

The dimensions of the gearbox depend on the dimensions of the mechanized motor vehicle.

Angular reverse gear unit

This is one of the effective gearboxes. Its task is to ensure that the transmission is connected to the engine. The owner can improve the angular gearbox himself, which will help increase the power of the gearbox. The mechanism consists of:

- generator housing;

- flange;

- flange mounting;

- keys and steel washer;

- pulley fastening;

- a pulley that has a V-belt drive;

- rotor shaft;

- flange bearing.

To design a bevel gearbox, you don’t need a lot of knowledge. Even minimal skills in its manufacture are acceptable here.

Description of reduction and gear drive

The reduction gearbox serves to reduce the number of revolutions and maximize power. This type of gearbox is the most reliable and powerful because it has a special cooling system that is used to cool the air, so walk-behind tractors can withstand heavy loads and can perform a variety of functions. When plowing, even large blocks are not an obstacle for them.

The gear reducer has the simplest device. The transmission of this mechanism is the transmitter between the engine and the wheels. The advantage of the gear reducer is its simple and reliable operation.

Reverse mechanism

In a reverse drive, the clutch is located between bevel gears, which are located on the main shaft. This device has a name: a reversing circuit, which is not at all complicated.

The advantage of this equipment is to reverse, which is often very necessary for the car in various situations. Of course, this system does not provide the possibility of obtaining high speeds, but this is not a big drawback.

So, having examined the types, structure and operating principle of various gearboxes, we come to the conclusion that it is possible to make them yourself at home.

We recommend that you read

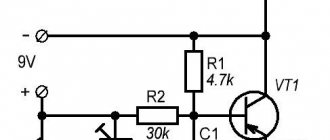

This circuit has a safety clutch. For the wheelbase value, see Chelyabinsk,

Gearbox with overdrive multiplier, providing 18 forward gears and 4 reverse gears. Net weight, excluding poured engine oil, is equal to kg.

The MTZ 92P tractor is designed for excavation work such as excavating soil, loading and unloading sand, crushed stone and other construction materials; cleaning of economic, construction and any work areas and areas; in the road construction industry; in the fleets of industrial enterprises. The transmission was divided into 17 gears: forward gear of 9 degrees with a speed range of 2.15...15.5 km per hour, reverse gear of 8 degrees with a speed range of 2...14.5 km per hour.

The MTZ 92P tractor is designed for excavation work such as excavating soil, loading and unloading sand, crushed stone and other construction materials; cleaning of economic, construction and any work areas and areas; in the road construction industry; in the fleets of industrial enterprises. The transmission was divided into 17 gears: forward gear of 9 degrees with a speed range of 2.15...15.5 km per hour, reverse gear of 8 degrees with a speed range of 2...14.5 km per hour. Magnitogorsk, city. The poor sound insulation is frustrating, there is not enough air conditioning - it’s quite hot to work in the summer, even opening windows can’t help.

You can purchase and install the following additional products from the factory dealer: Model D motor When installing tires The FDA consists of three parts and is detachable.

You can purchase and install the following additional products from the factory dealer: Model D motor When installing tires The FDA consists of three parts and is detachable. The transmission has a self-locking differential. To drive the Belarus 92p rear mounted implement, there is a PTO with a two-speed independent drive. New MTZ 92P in our farm

Related article: Yamobur MTZ

Making a reverse gear manually

Now the main task: how to make your own gearbox for a walk-behind tractor so that the engine is powerful and reliable? To simplify the work in the manufacture of the mechanism, you can take a ready-made sample, for example, from Dnepr or Ural motorcycles. The following details must be present:

- ruler and calipers;

- straight and oblique screwdriver;

- metal file;

- pliers, wire cutters;

- hammers and vices of different sizes;

- rubber gaskets, preferably several different ones.

First you need to prepare the housing for the reverse gearbox. A two-inch fitting elbow works well for this. You can make it yourself; to do this you need to weld a body of metal plates.

They also use a generator shaft from a Ural motorcycle. It is simply masterfully refined. Gears for the gearbox can be used from the Druzhba chainsaw. Remove the end stop in one of the shafts, then drill a hole of the required diameter. It is important to remember that to perform this work you must have all the necessary tools, since the quality of the drive depends on this.

Mount the other gear shaft, along with bearings and its cage, into the gearbox housing on the opposite side. And already on the output shaft the owner must install a pulley that ensures rotation using a V-belt drive. Finally, bearings - fans - are attached to the hood frame using welding.

This is how you can design a small tractor for your household yourself with minimal investment.

Transmission

By type, transmission units (gearboxes and gearboxes) can be gear, belt, chain, or various combinations of both.

Classic gear transmission

, consisting only of cylindrical and bevel gears, is used mainly on heavy walk-behind tractors and some models of medium-sized machines. As a rule, it has a reverse and several lowering steps.

The figure below shows the gear transmission of the Ugra NMB-1 walk-behind tractor, consisting of cylindrical and bevel gears. The engine is rigidly attached to the gearbox, which in turn is rigidly connected to the bevel gear. The design of the NMB-1 walk-behind tractor does not have chain and belt drives, which, according to its developers, are an unreliable link in transmissions due to the tendency to breakage, damage and belt slippage.

The torque from the crankshaft is transmitted to the drive shaft 16 (Gearbox Diagram) of the gearbox and is removed from the bevel gear of the driven shaft 15 by the vertical shaft 6 of the angular gearbox (Angle Gearbox Diagram), which transmits rotation to the hexagonal shaft of the 8 drive wheels.

The design of the gearbox is a mechanical two-way with 3 forward gears and 1 reverse. The transmission has two power take-off shafts (A) and (B).

Gear-worm transmissions

, consisting of two gearboxes - an upper gear and a lower worm gear - are usually used on light walk-behind tractors. The engine crankshaft is vertical. Sometimes cars with a gear-worm transmission are equipped with a centrifugal automatic clutch. This design of the walk-behind tractor ensures increased compactness of the unit.

Belt-gear, belt-chain and belt-gear-chain transmissions

are quite common in light and medium-sized walk-behind tractors. The engine rotates the shaft of a gear or chain reducer using a belt drive, which is also a clutch. Gear-chain drives are often implemented in a single crankcase.

In a belt drive, to change the speed of movement of the walk-behind tractor and power take-off, the pulleys may have an additional groove. The advantages of such a transmission include simpler disassembly and assembly of the walk-behind tractor than in the case of a gear transmission.

The figure below shows the V-belt transmission of the GreenField walk-behind tractor model MB-6.5 (with a belt-gear transmission), which, along with transmitting torque and reducing the speed, also performs the functions of a clutch and gearbox (speed shifting).

The clutch function is realized using a tension roller and a control mechanism consisting of a rod and a system of levers that allow you to change the position of the roller, which tensions or loosens the belt and, accordingly, turns on or off the transmission of torque from the engine to the gearbox.

A similar scheme is implemented in the domestic walk-behind tractor Salyut 5, shown in the figure below. The V-belt drive transmits rotation to the gear reducer of the walk-behind tractor.

As a rule, walk-behind tractor transmissions have power take-off shafts

, ensuring the transmission of torque to the working parts of the machine. According to their type and location in the transmission, power take-off shafts can be independent, located before the clutch and rotating regardless of its state (disengaged or engaged), or dependent, located after the clutch, and synchronous with a specific gear. One walk-behind tractor can have several power take-off shafts - different in type and rotation speed.

Diagram of a gearbox assembled from parts of a decommissioned car

This gearbox is assembled from parts of the main drive of the GAZ-69 vehicle. The bevel gears rotate from the drive sprocket, which is mounted on the shank. The torque is then redirected to one of the two driven gears, which rotate in bearings numbered 206 on the spline shaft. At the right time, the gear that engages with the reverse sleeve on the central spline of the shaft works. Then the cardan transmits the movement to the differential or the drive wheel of a mechanical vehicle.

Read also: How to remove the chuck from an aeg screwdriver

And the final important point for owners of walk-behind tractors or mini tractors. When purchasing a mechanism, price also plays an important role, because cheap units are mostly equipped with non-separable gearboxes. Such mechanisms are unreliable for long-term operation. If necessary, this gearbox cannot be repaired, disassembled or reassembled, or parts replaced. It is made of low quality metal, its parts are not gelled.

Expensive units are equipped with gearboxes that can be disassembled, which allows for gearbox maintenance and repairs. Like any other mechanical vehicle, it needs constant rechecking, repair, and updating, and the gearbox must be constantly inspected and monitored. From time to time it is necessary to carry out diagnostics of the mechanism to prevent breakdowns in the future.

When purchasing, it is more profitable to buy a more expensive gearbox, because it will serve you longer.

The pride of many summer residents is a homemade walk-behind tractor, assembled with their own hands from parts that have served their age. Installing an electric motor or a small gasoline motor from an old scooter or motorcycle onto a frame with wheels is not difficult even for a novice amateur mechanic. But what you have to think about is the gearbox for the walk-behind tractor.

Walk-behind tractor design

Schemes for assembling homemade walk-behind tractors are as varied as the spare parts in each owner’s garage. Dimensions are also chosen for practical reasons.

With different compositions and dimensions, there are required elements:

- The frame is a durable structure for attaching other parts.

- Wheels - from homemade metal to factory-made rubber. The position of the wheel or wheelset axle is fixed relative to the frame by iron struts with pressed-in bearings.

- Engine - power from 5 to 10 horsepower. You can even use an electric motor with a battery, but the most popular are engines from a scooter or motorcycle. This choice is good because it has a ready-made speed control and even a transmission device.

- Gearbox is a unit for transmitting rotation from the engine to the actuator, converting speed and direction.

But the first gearbox you come across may not be suitable. You need to choose the type of structure, calculate the size of each part, so that the speed and power of movement of the mounted cultivator allows you to cultivate the land in a convenient mode - neither quickly nor slowly.

Types of gear units

The transmission of rotational motion from the motor shaft to the actuator shaft can be carried out by direct connection of the axes, if the speed and power of rotation of the engine are acceptable for operation, and the axes of the drive and driven shafts coincide. Such cases are extremely rare, and with several attachments for different purposes, direct transmission absolutely cannot be used. To match the speed and power of the drive and driven shafts, 4 types of mechanisms and their combinations are used. Main types of gears:

The worm gear is structurally limited by the speed-reducing function; the rest can be used in both downshifts and overdrives. In addition, such a gearbox always has a driven axis perpendicular to the drive shaft. This scheme is called an angular gearbox. In addition to the worm gear, you can change the direction of the axis using a spatial planetary mechanism. Belt and chain drives keep the driven axis parallel to the engine axis. In simple devices, reverse is possible only when the rotation of the engine changes.

Motoblocks use engines with a high number of revolutions per minute, which can be verified in the product data sheet. This means that you need to make a gearbox with your own hands to reduce the speed, and it is better to choose what type of homemade gearbox for a walk-behind tractor, knowing the characteristics of each type.

Belting

The pulley or belt that transmits rotation from shaft to shaft is familiar to every motorist who has looked under the hood of the engine compartment. The rotation speed reduction coefficient is determined by dividing the radius of the small driven wheel by the radius of the large driving wheel.

The advantages of belt gearboxes are their ease of manufacture and repair, and a wide variety of parts. And the disadvantages of the belt:

- belt stretching, decreased adhesion to the pulley due to temperature and wear;

- slippage during sudden increases in torque;

- short service life.

Read also: Do-it-yourself Cnc on Arduino

The shortcomings are compensated by using a spring-loaded roller that presses on the surface of the belt between the wheels, and by using a toothed belt on pulleys with transverse chamfers. Belt gearboxes require the drive and driven pulleys to be in the same plane; bending or twisting the belt will quickly lead to it breaking.

Chain type

The operating principle of a chain drive is similar to a belt drive, but sprockets are installed instead of pulleys, and the belt is replaced by a chain. Such a homemade gearbox will not allow slipping, and under similar conditions it will work much longer.

Just like a belt gearbox, a chain gearbox must have drive and driven sprockets in the same plane, and its gear ratio is calculated by the ratio of their teeth. The weight of this design is greater than that of a belt design, but it is safer to install it on powerful walk-behind tractors.

Unlike a belt drive, a chain drive requires caution or additional protective measures. If a rotating implement collides with a thick root in the soil, its drag force will be transferred to the motor, possibly damaging it. Until the engine fails or switches off, it will try to rotate with maximum power along with the frame around the driven axis of the gearbox. The greater the engine power, the stronger the tipping torque will be.

The gear ratio of a chain gearbox can be higher than that of a belt gearbox of the same size, since the drive sprocket, even having a small size, will not allow the chain to slip.

In terms of cost, ease of assembly, and prevalence of parts, a chain drive is not inferior to a belt drive.

Using gears

A walk-behind tractor with a gear reducer is more reliable and durable than one with a chain or belt drive. Gear structures are installed on factory products, and not only on walk-behind tractors. The units are small in size as a result of combining two gears with different diameters on one axis. For a walk-behind tractor, for example, a gearbox from an Ant scooter is perfect. But you can make your own using gears from motor vehicle gearboxes.

The required gear ratio can be provided by a planetary mechanism, in which satellite gears are installed between the outer and sun gears, mounted on a fixed ring - the carrier:

For a reduction gearbox, the sun gear is mounted on the drive shaft. The planetary gear carrier is mounted on a stationary housing, and the outer gear is connected to the actuator, rotating in the direction opposite to the sun gear.

The gear ratio of such a gearbox can be calculated as the ratio of the number of teeth on the sun gear to the number of teeth on the external gear.

To change the direction of the axis of rotation in gearboxes, a spatial planetary mechanism is used, in which the gears, in order to change the direction by 90 degrees, must be beveled to a cone of 45 degrees each. The diameter of the gears can be different, which can be used to change the gear ratio.

For a walk-behind tractor, such an angular gearbox is rarely made by hand, since planetary gears of the required size still need to be looked for. Changing the axis of rotation is often done using ready-made factory gearboxes or a worm pair.

Worm-gear

To change the direction of the rotation axis perpendicularly and create a large gear ratio, contact of a flat gear with an Archimedean screw is used.

Transmission of rotation from the actuator to the motor is not possible. This is a unique feature of the worm gear; other types of gears do not have this property. The output rotation speed can be reduced by as many times as the number of teeth the gear has. This transmission is distinguished by its ease of assembly, high friction, small size, and great popularity.

In order to make a worm gearbox with your own hands, you need to select a gear with a number of teeth equal to the reduction in rotation speed in times, as well as with a pitch between the teeth equal to the pitch of the worm flange.

Reversing mechanism

The presence of a reversible transmission mechanism simplifies work in the fields, but an amateur can only do reverse at home with an electric motor. The difficulties lie in the inclusion of an additional transmission element in the circuit with the possibility of its precise movement and reliable fixation. To do this, you will need to break the existing connection with the engine, and insert a new element into the gap, be it another pulley with a belt, a sprocket with a chain, or a gear. Such restoration conversions require parts manufactured with the precision of professional machines.

In this case, it is more practical to install a factory reversible gearbox. For example, from a car with a manual transmission.

Controls

Some controls (carburetor air damper, power take-off shaft, etc.) are located on the corresponding components and assemblies.

Typically, the clutch control lever and the engine emergency stop lever are located on the left steering rod, and the gas handle, wheel drive lever and brake lever (if equipped) are located on the right steering rod. The design of the steering column of walk-behind tractors, as a rule, provides for adjustment of the position of the handles in the horizontal and vertical planes. The figure shows the controls of the SunGarden MF360 walk-behind tractor.

Additional information about the operating hours of the online store on holidays and weekends. Main news and events that are relevant to the work of the store. Brief, necessary information about simple issues related to the work procedure.

Choosing the right cultivator is a simple process, even if you are going to buy a cultivator for the first time and have never used it before. The first thing you need to pay attention to when choosing a cultivator is the power of its engine.

The power of the cultivator engine should be related to the area of your cultivated area. The larger the plot of land you have, the greater the engine power of your cultivator should be. So, to cultivate a plot of land of 10 acres, a cultivator with an engine power of 4-5 hp is sufficient.

Cultivators such as Sungarden T 250 OHV6.0, CAIMAN COMPACT 50C S. Craftsman 29802 and other cultivator models will cope with this task. Of course, a plot of 10 acres can be cultivated with a cultivator with a lower power engine of 3 hp.

In this case, you will have to make stops so as not to overload the cultivator engine. It should also be noted that the greater the engine power of the cultivator, the greater the width of plowing with the cultivator in one pass, the faster it will be possible to cultivate the entire plot of land.

In addition, more powerful cultivators also have a greater depth of plowing of the soil. Cultivators with an engine power of 3 hp. suitable for processing plots of 3-6 acres. For plots with an area of 12-15 acres, it is better to select a cultivator with an engine power of 6-7 hp.

The second thing you need to pay attention to when choosing a cultivator is the number of speeds at which the machine can operate. The cultivator can have one forward speed. Such cultivators are designed for cultivating ordinary soils in garden plots that are regularly cultivated.

These include middle-class cultivators: Sungarden T 250 OHV6.0, Sungarden T340 OHV7.0. Sungarden 345 OHV7.0, CAIMAN COMPACT 50C S. Craftsman 29802, etc. Thus, these cultivators are suitable for regular cultivation of an ordinary garden plot.

The cultivator can have two forward speeds. In this case, the cultivator has an additional gear with reduced speed, designed for cultivating heavy soils or soils that are not regularly cultivated (for virgin soil). These include heavy class cultivators:

Sungarden T390 OHV7.0, Sungarden T360 OHV7.0.. Saturn HSD1G-80, etc. The third thing you need to pay attention to when choosing a cultivator is the presence of reverse or reverse gear. Middle-class cultivators may or may not have reverse.

Such cultivators, as a rule, weigh 40-50 kg, so control can be done without reverse. But the presence of reverse or reverse makes the work more comfortable and easier. This is especially noticeable when working near various obstacles (fences, for example) or in some narrow, limited areas when it is constantly necessary to make efforts to rearrange the cultivator.

Buying a cultivator with or without reverse in this case is a personal choice. Heavy class cultivators weigh more than 60 kg and have a reverse as standard. When choosing a cultivator, you also need to pay attention to some technical features of its design.

The cultivator may have a worm or chain type gearbox. The worm gearbox is easier to maintain. Such gearboxes are used only on middle-class cultivators. Worm gear cultivators are Champion BC 5602 Sungarden T 250 OHV6.

0, Viking HB 585, Viking HB 445, etc. Cultivators with a worm gearbox have a motor with a vertical shaft. Such cultivators can have a modular layout; the engine can be easily detached from the cutters. This is convenient when transporting the cultivator.

The chain gearbox is more resistant to overloads, has a slightly more complex design and is a little more difficult to operate. The chain-type gearbox can be used on both medium and heavy class cultivators. Thus, the medium-class cultivator CAIMAN COMPACT 50C S and the heavy-duty cultivator Sungarden T390 OHV7.0 have chain-type gearboxes.

DIY gearbox assembly

The operation of walk-behind tractors, and with them gearboxes, means dust, off-road conditions, heat when plowing or cold when clearing snow, uneven loads. You can extend the life of the transmission mechanism by using a closed housing.

Read also: DIY airplane weather vane photo drawings

ST-40 steel is used for the base on which pulleys, gears, and other parts are mounted. The cover can be made from less durable steel if torque transmission elements are not attached to it.

The use of bearings for installing shafts, pulleys, sprockets, gears is mandatory, otherwise friction will dampen the rotational force, and the unit will either quickly fail or not work immediately.

Any rotating mechanism requires lubrication. Worm gear especially. Frequent replacement of lubricant will help extend the life of the device, for which the gearbox cover must be openable.

Gasoline and diesel engines have regulation of fuel supply and engine speed. It is optimal to move the so-called gas handle to the handle of the walk-behind tractor.

When all the necessary parts have been found, plumbing tools will be required to assemble the walk-behind tractor. You can’t do without a welding machine, grinder, drill, metal drill bits.

The time spent on making a walk-behind tractor will pay for itself completely in the first summer season.

Equipment

The converter can be collapsible or non-dismountable. As a rule, budget modifications of walk-behind tractors are equipped with the latter option. Their difference is in less expensive parts that cannot be replaced. If it breaks, you will have to replace the entire gearbox. Manufacturers determine the service life of such models from one to two seasons, no more, provided that the device is used correctly.

More expensive equipment is equipped with a collapsible gearbox, which can be repaired by replacing failed components. Therefore, the service life increases significantly.

The converter package includes the following items.

- Frame . Depending on the type of gearbox, it may be dismountable or not.

- Rotor shaft , which provides torque.

- Gears of different sizes.

- Chain or belt depending on the type of gearbox.

- With chain transmission, movement is carried out using sprockets - toothed disks .

- With a belt drive, the mechanism is equipped with pulleys onto which the belt is placed.

- Bearings . Since all the parts rotate, it is necessary to reduce friction and ensure that the elements rotate freely. The bearing is designed to cope with this task.

All parts are located inside the case. In addition to the standard set of components, elements for lubricating bearings, for example, an oil pump or a cooling device, can be added inside the device.

The principle of operation of a homemade walk-behind tractor gearbox

The simplest design of a two-shaft reversible gearbox for a homemade walk-behind tractor consists of two shafts on one of which (this is the driven shaft) a gear and a sprocket for a chain drive are permanently installed, and the second shaft (the drive shaft of a homemade walk-behind tractor gearbox) consists of two parts connected by a gear coupling with rectangular teeth . A gear is also installed on one part, and a chain sprocket is installed on the second. The upper shaft in the photo is the lever for engaging the gear coupling of the gearbox reverse. The principle of operation of the reverse gearbox of a homemade walk-behind tractor: rotation of the drive shaft (the longest shaft in the photo, sticking out towards us) is transmitted through the gear to the driven shaft, the clutch is turned off, the chain drive is idling, the driven shaft rotates in the opposite driving direction. To transmit unidirectional rotational motion, a chain drive is used; for this, the lever pushes the drive shaft gear out of engagement and moves it to the left until the rectangular teeth of the coupling engage, which connects the two parts of the drive shaft to reverse the gearbox of a homemade walk-behind tractor and then the rotation is transmitted through a chain drive to the driven shaft (the closest see us in the photo)

Clutch

Structurally, the clutch can be designed in different ways. In the form of a V-belt drive (see above), tensioning or loosening the belt of which using the clutch lever leads to the transmission or cessation of transmission of torque from the engine to the gearbox.

Or in the form of a single-disc or multi-disc friction dry or wet (oil) clutch, which is more reliable and is used in most models of walk-behind tractors. Some cars use a much rarer bevel clutch.

The already discussed Ugra walk-behind tractor from Kadvi LLC is equipped with a clutch that is the most traditional in design - a multi-disc friction with a pressure spring, operating in an oil bath. The design of a walk-behind tractor with such a clutch must include a clutch housing into which transmission oil is poured.

The clutch consists of a drive half-clutch 2 (Motoblock clutch diagram), a driven half-clutch 3, a disc spring 4, drive 5 and driven 6 disks, a thrust ring 7. It works as follows. When the clutch lever is released, the disc spring compresses the driven and driven discs, assembled in a package alternately.

Due to friction between the disks, torque is transmitted from the engine to the gearbox. When the clutch lever is depressed, the force is transmitted via a cable to clutch release lever 4 (Clutch lever). In this case, clutch fork 2 compresses the spring through the driven coupling half and release bearings, separating the driven disks from the drive ones and stopping the transmission of torque.