Naturally, such versatility of these units is revealed thanks to the many pieces of attachments that allow both removing snow and plowing the ground. A flat cutter with a ripper for a walk-behind tractor is one of the most famous and widespread devices, so we will pay maximum attention to it today.

How does a walk-behind tractor gearbox work?

A gearbox, often called a converter, is a mechanism that processes the torque of the motor and transmits it to the power take-off shaft of the walk-behind tractor. This happens with the help of a set of gears located in a durable metal casing. The gearbox and the quality of its parts affect the service life of the unit for agricultural work. Therefore, when buying a walk-behind tractor in a store, you should pay great attention to its components, including the gearbox design.

The gearbox can be collapsible or non-dismountable. The latest models are installed on budget-type walk-behind tractors. The parts in them are cheap and cannot be repaired. In case of malfunctions, the gearbox must be replaced. During normal operation, their service life is measured in 1-2 seasons. On expensive equipment, the engine is equipped with a converter of a collapsible design. It serves well for several seasons. If individual parts break down, the failed part is simply replaced.

A converter of any type may include:

- housing (collapsible or not);

- gears and shafts;

- stars;

- belts or chains;

- bearings.

With the help of the listed parts, movements are transmitted from the motor to the mounted implements. The chain is put on the sprockets, the belt is put on the pulleys. The simplest mechanisms are equipped with a belt drive. They are also considered the weakest and most unreliable. When the torque is high, the belts slip and fly off the pulleys. But this design has a beneficial effect on the motor shaft. Belt slippage can be avoided by replacing them with toothed ones. With this replacement, the pulleys also need to be replaced.

The fastest models

First, let's find out which walk-behind tractors are considered the fastest? Do domestic manufacturers have advantages or does the palm unconditionally belong to foreign competitors?

By the way, it is quite difficult to determine the undisputed winner in terms of maximum speed, because not only are there a great many models of walk-behind tractors from various manufacturers today, but it is also possible to independently modernize this multifunctional agricultural unit.

For walk-behind tractors MTZ-05, MTZ-12

There are 4 speeds when moving forward and 2 in reverse. The minimum speeds correspond to the first gear; when switching to the next gear, it increases. For the above models, the minimum speed when moving forward is 2.15 km/h, when moving in reverse – 2.5 km/h; the maximum when driving forward is 9.6 km/h, when driving backwards – 4.46 km/h.

The walk-behind tractor "Mobil-K G85 D CH395" / Grillo

the maximum speed of forward movement is 11 km/h, reverse – 3 km/h. At the same time, the gearbox provides the ability to switch between three forward and two rear speeds. Don't forget that all these figures are true for unimproved models.

MTZ-05

MTZ-12

Mobile-K G85 D CH395" /Grillo

"Mobile-K Ghepard CH395"

– a Russian-made walk-behind tractor, has a 4 1 gearbox, can accelerate to 12 km/h.

Ukrainian walk-behind tractor "Motor Sich MB-6D"

can reach a speed of 16 km/h, six-speed gearbox (4 2).

Unit "Centaur MB 1081D"

Russian, but produced in Chinese factories. It is considered the fastest walk-behind tractor in the heavy class. Its maximum speed is as much as 25 km/h! Refers to diesel walk-behind tractors, unlike the models listed above - they run on gasoline.

Mobile-K Ghepard CH395

Motor Sich MB-6D

Centaur MB 1081D

What types of gearboxes are there for a walk-behind tractor?

Gearboxes are divided into types:

- angular;

- downward;

- gear;

- worm;

- chain;

- combined.

All of them find their application on walk-behind tractors of various types.

Angular

The angular gearbox for the walk-behind tractor ensures the coupling of the engine with the transmission and attachment mechanism. Another device is also used, if modified. The corner device consists of the following parts:

- flange;

- flange mounting;

- bearing;

- frame;

- pulley;

- belt;

- steel washer;

- pulley fastening;

- key;

- rotor shaft.

You can make this device yourself. Before work, it is necessary to take into account the conditions in which he will work. These are radial and axial loads at the ends of the shafts. The load depends on the type of lubricants and temperature. It is best to choose a factory-made case. Bearings of the required size are selected for the shaft.

Downward

A reduction gearbox for a walk-behind tractor, either self-made or industrially manufactured, is designed to increase the power of an agricultural unit. This may be necessary when operating the walk-behind tractor on sandy soil, when the wheels begin to slip. It is used on gasoline and diesel vehicles equipped with an air cooling system.

You can reduce the number of revolutions and increase the power of the drive mechanism using reduction gearboxes, which are sometimes called creepers for a walk-behind tractor. They are considered the most reliable for operating a diesel or gasoline air-cooled walk-behind tractor. When the unit is operating, the number of revolutions decreases. This allows you to use the walk-behind tractor for particularly difficult work, for example, plowing heavy soil or harvesting potatoes using a potato digger.

Gear

A gear converter with a differential is used in heavy-duty walk-behind tractors. It is well suited to engines with a vertical crankshaft. The gearbox produces little noise during operation and has high performance. It is capable of functioning in straight and angular patterns. Gears are used both bevel and cylindrical. The device requires the constant presence of oil in the crankcase, but this feature is compensated by its high power.

On heavy units, the gear converter is often equipped with a gearbox. This transmission allows the walk-behind tractor to move in reverse. Reverse occurs during reverse rotation of the gears in the housing. This is achieved by changing the position of the lever outside the housing.

Gear reducer is the best choice for heavy agricultural machinery. An engine equipped with this mechanism runs longer than with a worm version.

Worm

Worm gearboxes are widely used in mini-tractors and walk-behind tractors. This model has gained popularity due to its long period of trouble-free operation and high reliability. The worm-type device has a reverse, allowing the unit to move in reverse. A distinctive feature of this converter is the presence of a special screw and worm wheel. The thread profile on the parts is trapezoidal. They are made from high-strength materials.

The screw can have a four-start thread or a two-start thread. It matches the thread on the gear. The teeth on high-quality parts are made of anti-friction steel. The efficiency of the device is high. Its advantages:

- the gearbox allows you to extend the service life of the engine;

- creates little noise during operation;

- The device consists of only 2 parts;

- has a large gear ratio;

- has a smooth ride;

- high self-braking effect.

All positive qualities appear with precise assembly and adjustment of the mechanism.

Chain

A chain device must have a chain in its design. Sometimes it occurs not just one, but in several pieces. The gear chain is put on the sprockets and ensures their rotation. The device is easy to use, has a reverse function and a high degree of reliability. The operating principle is similar to a belt mechanism. Changing the gear ratio is easy by changing the sprocket sizes. They work like a bicycle, but in reverse: the small one is the driving sprocket, and the large one is the driven sprocket.

Reliability of operation is ensured by the quality of the metal of the sprockets and the strength of the chain. When making your own gearbox, you should use motorcycle sprockets; they are much stronger than bicycle sprockets. The design of the product is simple and reliable, it has a reverse function. The chain requires constant lubrication and tightening. Its rupture is a common cause of gearbox failure. To repair, you need to change the chain.

Combined

The combined gearbox combines gear and worm, worm and cylindrical gears. It can be single-stage or multi-stage. The single-stage mechanism has a gear ratio of up to 7. The body is made of cast iron or welded aluminum. Two-stage devices have a gear ratio of up to 40, three-stage - up to 150.

All of them are designed to change the speed of rotation of the engine shafts and the power take-off shaft. All types of gears are placed in a single housing. The combined mechanism is the most practical. Despite its small size, it has high quality and low cost.

Modifications in the brait-135 line

The catalog of the official website of the Bright company currently offers 11 modifications of Bright-135 walk-behind tractors, two of them are diesel. Let's talk about them first.

- Brait-135DEA (diesel) – this option is equipped with a 4-stroke, single-cylinder diesel engine BR-178FE, vertical air-cooled, with direct injection, with electric start (battery included). The power of this engine is 7 horsepower, its working volume is 296 cm3. Cylinder diameter x stroke – 78 x 62. Output shaft: 25 (for splines). Milling cutter shaft: hexagon D=32. Engine oil capacity – 1.1 liters. Gearbox oil volume: 2.3 l. Fuel tank capacity – 3.5 liters. Walk-behind tractor weight: 138 kilograms.

- Brait-135DEB (diesel) – equipped with a 4-stroke, single-cylinder BR-186FAE diesel engine, vertical air-cooled, with direct injection, with electric start (battery included). The power of this engine is 10 horsepower, its working volume is 418 cm3. Cylinder diameter x stroke – 86 x 72. Output shaft: 25 (for splines). Milling cutter shaft: hexagon D=32. Fuel tank capacity – 5.5 liters. Engine oil volume – 1.65 l. Gearbox oil volume: 2 l. Walk-behind tractor weight: 148 kilograms.

Gasoline:

- Brait-135GA – with a 4-stroke, single-cylinder BR-170F engine. The working volume of this engine is 212 cm3, its power is 7 horsepower. The starter is manual. Output shaft: 20 (keyed). Milling cutter shaft: hexagon S32. Oil capacity 1.1 l. Gearbox oil volume – 2.0 l. The volume of the fuel tank is 3.6 liters. Walk-behind tractor weight: 136 kilograms.

“Behind the wheel” of a light petrol walk-behind tractor Brait-135GA.

- Brait-135GB – equipped with a 4-stroke, single-cylinder BR-177F engine with a working volume of 270 cm3, 9 horsepower, with a manual starter. The weight of the walk-behind tractor in this modification is 143 kilograms. The volume of the fuel tank is 6 liters. Oil capacity: 1.1 l. Gearbox oil volume – 2.3 l. The cutter shaft is a hexagon D=32.

- Brait-135GBD is a walk-behind tractor with technical characteristics similar to the Brait-135GB model, but also equipped with a differential. The weight of this walk-behind tractor is 150 kilograms.

- Brait-135GBE – equipped with a 4-stroke, single-cylinder BR-177FD engine. Its working volume is 270 cm3, power – 9 horsepower. Starter with electric start (battery included). Output shaft: 25 (keyed). Milling cutter shaft: hexagon S32. The volume of the fuel tank is 6 liters. Engine oil volume: 1.1 l. Gearbox oil volume: 2 liters exactly. The weight of such a walk-behind tractor is 156 kg.

- Brait-135GC - with a 4-stroke, single-cylinder engine with a power of 13 horsepower and a displacement of 389 cm3. The starter in this modification is manual. The volume of the fuel tank is 6.5 liters. The weight of the walk-behind tractor is 150 kilograms. Milling cutter shaft: hexagon S32.

- Brait-135GCE - also with a 4-stroke, single-cylinder engine with a power of 13 horsepower and a displacement of 389 cm3. But with electric start (battery included). The volume of the fuel tank is 6.5 liters. The weight of the equipment in this modification is 163 kilograms.

- Brait-135GD - equipped with a 15-horsepower 4-stroke, single-cylinder engine with a working volume of 420 cm3. The starter is manual. The volume of the fuel tank is 6.5 liters. The weight of the walk-behind tractor is 148 kilograms.

- Brait-135GDE – also with a 4-stroke, single-cylinder gasoline engine with a displacement of 420 cm3 and a power of 15 horsepower. But equipped with electric start (battery included). The weight of the walk-behind tractor in this modification is 163 kilograms.

- Brait-135GDD is a walk-behind tractor, similar in its technical characteristics to the Brait-135GD modification, but equipped with a differential. The weight of the walk-behind tractor in this version is 153 kilograms.

Creeper

The traction of the wheels of a tillage machine with the soil can be enhanced if you use lugs or a creeper for a walk-behind tractor. The creeper is one of the mounted devices. It makes it possible to reduce the speed of the agricultural unit and increase traction force along with torque. An analogue of a gearbox operates using a chain and sprockets on the shafts. If desired, this device can be made by hand. Parts are used from other equipment.

Each considered converter has its own disadvantages. To reduce their number to a minimum, you should try to make the device yourself. A homemade item can be of higher quality and easier to use than a purchased item.

Design features of the device

By its design, the creeper is a kind of reduction gearbox. By using a chain, it converts the driving force of the cultivator into the work of the attachment. This device can be purchased at many agricultural equipment stores.

- Whole generator housing;

- Rotor shaft;

- Flange bearing;

- Bevel gear;

- Steel parts;

- Screws;

- Pulley.

Making a stroke reducer for a motor cultivator with your own hands is quite simple.

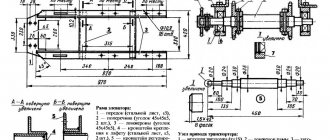

To avoid common mistakes, be sure to make drawings in which you will need to indicate the dimensions and material of the parts and the sequence of their fastening.

How to make a gearbox for a walk-behind tractor with your own hands

A homemade gearbox for a walk-behind tractor requires preparation of tools for manufacturing. For fruitful work you will need:

- screwdrivers of different sizes;

- hacksaw for metal;

- pliers;

- bench vice;

- welding machine;

- hammers of different weights;

- rubber for gaskets;

- drill with drills.

Some other tools may be required as you work. From the materials you need to prepare shafts and bearings, sprockets and chains, belts and gears. You can use a caliper to measure parts. Before work you need to complete the simplest drawings.

Preparation

So, the tools and sketches are ready, you need to prepare the material for welding the body or take a ready-made one. You can weld from pieces of stainless steel. The prepared gears should fit freely into the finished housing. They can be borrowed from an old chainsaw. The Friendship brand or any other is suitable. The saw must be carefully disassembled and the entire gears along with the shafts removed. They are cleaned and washed, then sized according to the gear ratio.

When calculating the gear ratio, you should take the number of idle revolutions of the engine crankshaft as a basis and add 10% to it.

With any design of the product, distortions between the parts of the driven and driving parts must not be allowed.

Bearings should also not be replaced with bushings. When disassembling an old saw, you need to remember this.

Assembly

When assembling the product, the parts are carefully inserted into place in the body and rotated. The housing must be sealed tightly. This will protect the parts from dust and dirt. Oil seals are installed on the shafts. Lubricant is poured inside the housing. The homemade device is connected in the same way as a standard gearbox. To test it, start the engine and roll it on the ground. The parts need to get used to each other a little.

Functions

The flat cutter for walk-behind tractors is very popular for a reason. Previously, gardeners used manual models, but when walk-behind tractors and attachments appeared, work in the garden became easier. Less effort was required and productivity increased.

Is used for:

- thinning plantings;

- hilling;

- weeding;

- ground leveling;

- deep loosening;

- preparing beds for planting;

- saturation of the soil with oxygen;

- crust destruction after rain;

- filling holes;

- inter-row processing.

The flat cutter does not turn over the soil, so it retains as much nutrients and moisture as possible.

At the same time, many gardeners note only one drawback: models of different sizes are required, because each crop has its own width between the rows.

You can easily buy a factory-made, branded flat cutter for a walk-behind tractor. But you can make it yourself, and the unit will turn out no worse.

How much oil to pour into the walk-behind tractor gearbox

When operating the walk-behind tractor, it is necessary to maintain a constant oil level in the gearbox. If this simple rule is not followed, lubricant residues may boil and jam the parts. Only high-quality oil is poured. Even with constant maintenance of the level, breakdowns occur. During chain transmission, the chain breaks or is pulled out. If traces of oil appear on the outside, this is a sign of leaking seals. Worn parts require replacement with similar ones. It is better to purchase them from a reputable manufacturer.

The gearbox ensures uninterrupted operation of the walk-behind tractor, extends its service life and increases the efficiency of use of the unit. A good helper in this matter is to lubricate its parts. Transmission oil is poured in for lubrication. Its possible brand is ZIC 10W40, Super T-3. The oil level is determined in this way:

- you need to take a wire approximately 70 cm long instead of a probe and bend it into an arc;

- insert into the filling hole until it stops;

- pull the homemade dipstick back;

- the wire should be oiled to a length of about 30 cm.

This level is considered to be the norm. If there is little oil, you need to add it to the norm. In a purchased gearbox, the level must be indicated in the instructions. A Chinese walk-behind tractor can be sold without oil.

Proper work

To work with a flat cutter as efficiently as possible, you should understand the basic principles of using attachments.

In general, there is nothing complicated about this. The algorithm of actions is as follows:

- If weeding and high-quality loosening are required, the blades of the flat cutter are directed to the left. So that they lie flat on the ground.

- If the weeds are thick, tall, or large thickets, then the blades also move to the left, but slightly lifting them above the ground.

- When arranging a bed, the blades point downwards. This will make the site neater.

- To form a backfill of seeds and rolls of soil, the blades are directed to the right and placed flat.

Even if you are a beginner farmer, these tips will help you achieve better results. And it will not depend on the type of flat cutter or the brand of the walk-behind tractor itself. Even with budget models you can achieve good results and get rid of weeds.

Sharpening

You only need to sharpen from the outside. On the inside, it is enough to remove the burrs at the end of sharpening.

First, the workpiece is sharpened on a sharpening machine, and then finished using a whetstone or a fine file.

If you bought a flat cutter and did not make it, then you do not need to sharpen it on a sharpening machine. The new original flat cutter has been sharpened; in the future you will sharpen it as needed.

The bulk of the work is done. All we have to do is make a handle for it and learn how to use it correctly.

Best DIY Equipment

Homemade products with an engine from a walk-behind tractor (read do-it-yourself harrow for a walk-behind tractor) are also of some interest. Among them, the greatest interest is in the manufacture of a snowmobile. As a running gear, you can use a transport tape on which you need to attach snow hooks.

In addition, interesting are the options for manufacturing other various types of equipment from a walk-behind tractor:

- All-terrain vehicles. The design resembles a mini tractor, but has wheels of a higher diameter. This is necessary so that the unit can pass through the most difficult terrain.

- Mini tractors. We have already considered this design, which includes an additional part of the frame for a second pair of wheels, as well as steering wheels and the driver’s seat.

History of the creation of a flat cutter

As the name suggests, the idea of creating and using a flat cutter belongs to Vladimir Vasilyevich Fokin. He was not a scientist and did not sit days and nights in the laboratory, inventing, testing and improving his brainchild. Vladimir Vasilyevich did not devote his life to the idea of creating a tool that combines a shovel, rake and hoe, allowing you to easily loosen and weed the beds. After serving in the army, he went to work as a designer at a machine-building plant, then worked for the benefit of the collective farm. Throughout his life, Fokin was many things: a fire safety engineer, chairman of a comrades' court and assessor of a district court, deputy, lecturer, chief of staff of the Civil Defense, journalist for the Leninets newspaper - a total of 18 public duties. But it was the work of a journalist that gave him the opportunity to come into contact with agricultural issues, to learn from ordinary peasants about the then pressing problems in this area.

Hard work does not go unnoticed. In 1987, Vladimir Vasilyevich suffered a severe heart attack and disability. I had to give up active physical work. But a person like Fokin, who was accustomed to work and could not imagine himself without it, could not just give up. “Twice (three months) we were nursed in the hospital: an extensive, as they later said, transmural infarction. Disability. Pension - “they push it through the door... Home - at work and at school. Silence - even the howl of a wolf. I tried to read about spies - that’s not it.” The awakened love for farming prompted the idea that I needed to come up with something that would allow me to work at least in my own garden without unnecessary stress. Elena Nikolaevna, Fokin’s wife, recalls in her memoirs: “Volodya worked on a flat cutter for a long time. Various drawings and diagrams often lay on his desk. At first he did it just for fun, but then ordinary curiosity grew into a serious matter.” And the author of the invention himself describes this process in his notes as follows: “The search for a manual flat cutter was long. I made dozens of structures, starting with a plow... It’s not the same. I've been thinking about it for years. I did it in 3 days.” Patent for the invention of a flat cutter and its author Vladimir Vasilyevich Fokin. Photos from the sites: www.offokin.ru, blagodatmir.ru But one way or another, the flat cutter became the work of the entire Fokin family, and its first test can rightfully be called a birthday: “I will never forget that day. We joked and laughed a lot. We really liked the flat cutter, it was our brainchild.” Vladimir Vasilyevich decided to apply for a patent for the invention only after he gave it to all his friends “to try.” They really liked the flat cutter. Well, his future path was predictable. The positive assessment of strangers and wide popularity among gardening lovers made it possible to open production and even supply flat cutters to other countries: Lithuania, Estonia, Belarus, etc. The invention outlived its creator, who unfortunately passed away in 2002.

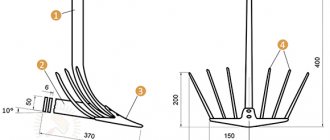

Drawing with dimensions

The drawing is made according to the dimensions of the original Fokin flat cutter. The more accurately the work is done according to the sample, the better quality tool you will receive.

Drawing with dimensions

Important! The Fokina flat cutter is protected by a patent. Mass production of replicas for sale is a violation of copyright. Single production for personal use is permitted.

WHAT IS A WEEDER AND WHY IS IT NEEDED?

A weeder, also known as a frame flat cutter, is an agricultural tool used for weeding, loosening soil, fluffing up rows, etc. Several types of hand weeders and special attachments for motor cultivators are common in agriculture:

- Weeder "Swift".

- Fokina flat cutter.

- Weeding "razor".

- Weeding pads for motor cultivators.

PRINCIPLE OF USING THE TOOL

Let's start with a word of caution: weeders are NOT used as a hoe! This is fundamentally wrong. His task is to trim the top layer of soil 1.5 - 3 cm, the resulting crust and young weeds. This is both weeding and loosening, which is very useful for plants.

Various types of weed weeds

Desirable rules for working with weeder:

- Work with young weeds. Don't delay or grow pests higher than the corn. Then even a shovel won’t help – the vegetables won’t be of any use.

- Adjust to row spacing. Standard row spacing is processed in one or two movements.

- When working with a tool, pull it towards you or push it away from you. Tilt the handle and make sure that the blade goes 1-2 cm deep into the soil. In one motion, cut a strip of soil 50-80 cm.

- Work on bare soil.

- After rain, loosen the slightly dry (0.5 - 1 cm) soil.

General information about cultivators

Many people associate the concept of “cultivators” with mini tractors and walk-behind tractors that perform soil cultivation functions. However, if you delve deeper into the terminology, it turns out that the cultivator is only a part of the technical means directly involved in processing. Depending on the design, homemade cultivators can perform several work operations. They can be universal both in processing and in combination with additional equipment. Before you begin manufacturing such a tool, you should evaluate the nature of the work and the need to connect it to a tractor or other equipment.