A steam electric generator is something similar to a solar battery, but has much higher performance, not to mention the availability of this kind of devices. The very functioning of such units is to convert mechanical force into electrical force by heating water until it turns into steam. It is this force that sets the desired mechanism in motion.

What are the specifics of this equipment?

PGE is an independent type of equipment capable of converting energy of any type (mechanical, thermal, etc.) to electrical.

A characteristic feature of this equipment is the simplicity of its design and operating principle. Such an electricity generator, regardless of its variety, consists of a motor mounted on a structure frame that burns fuel and a generator. Through a mechanical transmission, torque is supplied from the motor to the generator.

A significant factor influencing the enormous popularity of similar installations is the high level of efficiency, close to 98%.

There are several types of installations, the classification of which is based on several main factors:

- Type of fuel. The equipment has the ability to operate on several types of fuel. This can be fuel oil, firewood, gas, diesel fuel, etc.

- Scope of application. These installations are widely used both for domestic purposes, but also in the manufacturing and processing industries.

- Design characteristics. Energy conversion can occur through two different systems: pipes with hot gas and containers with water.

In order for the equipment to perform all the functions assigned to it and its operation as a result to be expedient, it is very important to choose the right installation. In this case, experts advise considering the following factors:

- Power

- The speed at which the generator spins

- Type of current

- Indicator of the pressure of the generated steam on the turbine

Taking into account all the indicators, the steam installation will provide the room with the required amount of available eclectic energy.

Water container

Now you need to take another paint can, but of a smaller size. A hole with a diameter of 1 cm is drilled in the center of its lid. Two more holes are made on the side of the jar - one almost at the bottom, the second above, near the lid itself.

Take two crusts, in the center of which a hole is made with the diameter of a copper tube. 25 cm of plastic pipe is inserted into one cork, 10 cm into the other, so that their edge barely peeks out from the plugs. A korok with a long tube is inserted into the lower hole of a small jar, and a shorter tube into the upper hole. We place the smaller can on the larger can of paint so that the hole in the bottom is on the opposite side from the ventilation passages of the large can.

How to do it yourself

If a minimum amount of energy is required, you can make a steam electricity generator with your own hands from a minimum amount of materials that are always at hand.

To do this you will need:

- Canned food can

- Aluminum wire

- A small sheet of tin

- Fastening elements

The production process itself is very simple:

- Make two small holes in the tin can

- Solder a tube into one of them

- Take a sheet of tin and cut it into small strips so that the turbine impeller comes out

- Fix the finished impeller on a tin strip previously bent in the shape of the letter “P”

- Using fastening elements, secure the strip with the impeller to the second hole. It is necessary to carefully look at the fact that the impeller should be towards the tube

- All holes and seams made during the manufacture of the installation must be soldered. This is necessary to ensure the tightness of the structure

- Make a stand from wire on which the finished equipment is placed

- The system is filled with water using a syringe.

- Under the stand in a specialized box, set fire to dry fuel

A steam engine made according to these instructions cannot provide the house with the required amount of energy. Here you can easily and easily get acquainted with the working principle of a steam electricity generator.

The creative process of this installation, which could provide the house with the required amount of energy, is a little more complicated, but nothing is impossible.

To make it, you will need to take a base - a Peletier component. You can select it separately in the store, or you can remove it from a failed desktop PC.

Plus, to work you will need:

- Module equipped with USB output

- Metal sheet for the production of the installation housing. You can do it yourself, or you can take a ready-made PC case

- Cooling heating device with cooler

- Paste for coating joints with sealant

- Scissors for cutting metal

- Riveter

- Drill

- Soldering machine

- Rivets

At the beginning of the process, make a small container into which you can put very small firewood and light a fire. Construct the upper part of the container so that you can place a small saucepan of water on it and bring it to a boil.

Attach the Peletier component to one side of this container. On the second one, use pestles to secure the cooling radiator with the cooler.

Professionals point out that the heater and cooler must be quite strong. The speed and amount of electricity release depends on how large the temperature difference is.

If the equipment is used during cold weather, it can be left standing directly in the snow and the problem will almost be solved. If the installation is used in warm weather, it is hardly possible to do without a powerful cooler and cooler. We must not forget about diligently sealing all seams and fastenings.

Solder the electrical voltage stabilizer to the Peletier element. This device is needed in order to be able to set a specific indicator of electricity output.

The stabilizer can be purchased ready-made in the store. Its advantage is that when the desired indicator is reached, the light bulb on the device lights up.

It is also of great importance that the already soldered stabilizer must be sealed in a similar way in order to completely prevent water from getting on it. The operation of this steam generator model can guarantee the heating of two coolers.

Tubular Type Heating Element for Steam Generator

You can also make a much more powerful model of a steam generator - a heating element.

It is based on a very high container in which tubular heaters (one or more) are installed.

This depends on the planned capacity of the subsequent installation.

Drill holes in the sides of the container to secure the tubular heating element.

Nuts with rubber gaskets are ideal as fastening elements.

If you intend to install two tubular-type heating elements, the main thing is to install them so that they do not touch each other. Place the second one next to the first container.

It will contain water, which, if necessary, moves into the first container. It is worth paying attention to the fact that during operation of the equipment it will not be possible to open the lid and look at the water level in the first vessel.

Because of this, experts advise to automate this process a little, by installing an ordinary float, like in a toilet flush cistern.

The two containers are connected to each other by a strong tube, which is placed in drilled holes located below the level at which the tubular heaters are installed. Carefully seal all seams.

In order for the water to quickly warm up, it is better to twist the tube through which the fresh part of the water will be supplied in the form of a spiral. Before permanent installation and operation of such an installation, it should be tested for leaks.

Plus, the valve must maintain the required pressure, otherwise the equipment will not be able to work. An installation created according to a similar rule achieves almost 100% efficiency. But it should be maintained in good condition.

To do this, you need to sometimes check the tubular heaters for the presence of scale on their walls. If there are a lot of them, they may not work at full capacity or get burned altogether.

In order for scale to form as little as possible, it is sometimes necessary to add citric or acetic acid to the water in the first container. Some people only fill the tank with specialized soft water.

There are often situations when a steam electricity generator for a home fails due to the reason that it was running dry. In order to avoid such a nuisance, it is recommended to set marks for a very small and maximum amount of water in the container.

In order to protect the finished installation from a power surge in the network, you can install a specialized voltage regulator, which automatically turns off the equipment when the voltage drops.

PGE is original equipment that is considered an independent source of electricity. His work at home has a number of positive qualities:

- The ability to operate on different fuels, which are considered the most profitable for any installation owner.

- High output power level.

- The power can be changed by the owner at his request in manual mode. This increases the operating efficiency of the installation.

- If solid fuel is selected as an energy source, for example, firewood, the ash that remains in the field of their use is a wonderful fertilizer for garden and vegetable plants.

The industry produces such installations in a wide variety. Plus, it is possible to make a steam generator yourself at home. To do this, you do not need to use very expensive materials and parts.

There are various options and schemes for manufacturing similar installations. Before you choose any particular method, you should first take into account the power of the steam generator that is needed at the output. In the process of creating a PGE at home, you need to follow safety rules and test the finished installation in advance.

You can take a look at the video on how to assemble a steam generator for a bathhouse yourself:

Did you see the error? Select it and press Ctrl+Enter to let us know.

Application of Steam Turbine

By pouring water into the kettle and putting it on the gas turned on, you can make sure that when it boils, the energy of the steam coming out of the tube is enough for an EMF to appear at the output of the electric motor. To do this, you should connect an LED flashlight to it. In addition to powering light bulbs, other uses for a steam turbine are possible, such as charging a cell phone battery.

In an apartment or private house, such a mini-power plant may seem like a simple toy. But if you find yourself on a hike and take with you a turbocharged kettle with an electric generator, you will be able to appreciate its functionality. Perhaps in the process you will be able to find some other purpose for the turbine. You can find out more information about making a camping generator from a kettle by watching the video:

Purpose

It makes sense to use units of this kind in those branches of modern industry or the domestic sphere where there is a very large number of vapor formations that can be used as a converter into electrical energy. Actually, backup steam-type power plants are widely used in boiler houses, where they create a kind of thermal power plant together with a boiler and a turbine.

Such units allow you to significantly save on your own operation, and also reduce the cost of generating electricity. This is why steam plants are very often one of the main operating units of many power plants.

Also, if you learn the working principle, as well as the design features of similar steam generators, you can try to implement them with your own hands, using specific means. However, this possibility will be discussed a little later.

Peculiarities

A wood-fired power plant is not a new invention, but modern technologies have made it possible to somewhat improve previously developed devices. Moreover, several different technologies are used to generate electricity.

In addition, the concept of “wood-burning” is somewhat inaccurate, since any solid fuel (wood, wood chips, pallets, coal, coke), in general, anything that can burn, is suitable for the operation of such a station.

Let us immediately note that firewood, or rather the process of its combustion, acts only as an energy source that ensures the functioning of the device in which electricity is generated.

The main advantages of such power plants are:

- The ability to use a wide variety of solid fuels and their availability;

- Receive electricity anywhere;

- The use of different technologies makes it possible to obtain electricity with a variety of parameters (sufficient only for regular phone recharging and up to powering industrial equipment);

- It can also act as an alternative if power outages are common, as well as the main source of electricity.

Design and working principle

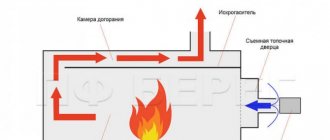

According to their own design features, boiler houses have a fairly similar structure. They include several working units, which in most cases are considered decisive - specifically the boiler itself, the electric generator and the turbine . The last two components create a kinetic connection between themselves, and one of the options for such systems is a steam-type turbine electric generator.

If we look more globally, then similar installations are full-fledged thermal power plants, albeit of smaller dimensions. Thanks to their own work, they are able to provide electricity not only to civilian facilities, but also to large industries.

The very working principle of steam electric generators comes down to the following key points:

- The necessary equipment creates water heating to good values, at which it evaporates, organizing steam.

- The resulting steam flows further onto the rotor blades of the steam turbine, which sets the rotor itself in motion.

- As a result, we acquire, first of all, kinetic energy converted from the resulting energy of compressed steam. Afterwards, the kinetic energy turns into mechanical energy, which leads to the start of operation of the turbine shaft.

The electric generator included in the design of such steam installations is considered decisive. This can be explained by the fact that it is electric generators that perform the transition of mechanical energy into electrical energy.

This is a description of one steam type installation. If the release of more energy is required, then a combination of several installations connected together is used.

A similar decision should be taken absolutely individually, depending on the types of object, and also the indicators of the required energy power. Only with such a competent approach will it be possible to avoid unprofitability in this matter.

Result

The result should be the following design. Water is poured into a small jar, which flows through a hole in the bottom into a copper tube. A fire is lit under the spiral, which heats the copper container. Hot steam rises up the tube.

In order for the mechanism to be completed, it is necessary to attach a piston and flywheel to the upper end of the copper tube. As a result, the thermal energy of combustion will be converted into mechanical forces of rotation of the wheel. There are a huge number of different schemes for creating such an external combustion engine, but in all of them two elements are always involved - fire and water.

In addition to this design, you can assemble a steam one, but this is material for a completely separate article.

A wood-fired power plant is one of the alternative ways to supply consumers with electricity.

Such a device is capable of generating electricity at minimal energy costs, even in places where there is no power supply at all.

A power plant using firewood can be an excellent option for owners of summer cottages and country houses.

There are also miniature versions that are suitable for lovers of long hikes and spending time in nature. But first things first.

Selection indicators

Nowadays there is a fairly wide selection of different steam-powered electric generators, so it is necessary to approach the selection issues very carefully.

To make this choice thoughtful and balanced, you need to look at the following indicators :

- Steam plant power (thermal and electrical).

- It is also necessary to look at the speed at which the generator and turbine rotors rotate.

- Type of current used - here we are talking about single-phase or three-phase installations. In many cases, the actual three-phase system is used.

- Indicators of steam pressure not only in compressed form, but also in a free state.

A sensitive attitude to these parameters will make it possible to significantly simplify the choice, thus helping the consumer get the device he needs. To make it more personal, let’s look at several models of steam electric generators that are in greatest demand.

Feasibility of operation

There is no need to talk about the advisability of purchasing a steam electric generator for personal needs, because its cost is very high for ordinary household use. In other words, such investments are unlikely to pay off during the life of the potential buyer. In addition, the overall dimensions of such installations mean that they must be placed over a very large area. That is why, at the household level, units with an engine running on gasoline or diesel are used, and for large enterprises, an engine running on steam is just suitable.

As for the use of steam-powered electric generators, their

use in boiler systems can bring certain benefits .

The fact is that upon reaching certain power indicators, these installations show very good performance characteristics, which distinguish them favorably from their analogues. Detailed story about the steam generator

Model overview

In our state there are several enterprises that produce steam electric generators. In particular, we are talking about turbogenerators and OJSC Roselectromash. Let's look at several models made by two companies.

PT-40/50-8.8/1.3 is a steam turbine used in a variety of schemes for the recovery of heat energy and also industrial waste. Among the possible buyers of these products are large industrial enterprises and power plants.

- rated power indicators - from 12000 kW to 80000 kW;

- steam pressure indicator - from 3 to 12.8 MPa;

- steam temperature indicators - from 420 to 550 C;

- production pressure - from 0.5 to 1.75 MPa;

- heating pressure - from 0.07 to 0.25 MPa.

P-6-3.4/1.0 is a steam turbine with production steam extraction.

- rated power indicators - from 4000 kW to 55000 kW;

- steam pressure indicator - from 1.1 to 8.8 MPa;

- steam temperature indicators - from 260 to 445 C;

- production pressure - from 0.4 to 1.3 MPa.

PR-13/15.8-3.4/1.5/0.6 is used in many thermal power plants, and also in industrial companies where there is a need to supply steam of a given indicator.

- rated power indicators - from 2500 kW to 35000 kW;

- steam pressure indicator - from 1.2 to 9.3 MPa;

- steam temperature indicators - from 290 to 540 C;

- production pressure - from 0.4 to 1.75 MPa;

- pressure behind the turbine is from 0.07 to 0.9 kPa.

Main element

We make a spiral from a copper tube. You need to take about 6 meters of soft copper tubing with a diameter of 1/4-inch (0.64 cm). We measure 30 cm from one end. Starting from this point, it is necessary to make five turns of the spiral with a diameter of 12 cm each. The rest of the pipe is bent into 15 rings with a diameter of 8 cm. Thus, at the other end there should be 20 cm of free tube.

Both leads pass through vent holes in the lid of the jar. If it turns out that the length of the straight section is not enough for this, then you can unbend one turn of the spiral. Coal is placed on a pre-installed platform. In this case, the spiral should be placed just above this platform. The coal is carefully laid out between its turns. Now the jar can be closed. As a result, we got a firebox that will power the engine. The steam engine is almost made with your own hands. Left a little.

Mini-CHP with steam engines - a reality of the 21st century

I. S. Trokhin , engineer of the VIESKh of the Russian Agricultural Academy, teacher of MOPC NRNU "MEPhI"

Do we need to remember the first domestic steam engines (see help) in our age of new technologies? Undoubtedly. After all, steam engines are now being used in the energy sector.

Nowadays, in industry and housing and communal services, the correctness of the combined production of electricity and heat energy in steam mini-heat and power plants (mini-CHP) (Fig. 1), located very close to the consumer, is increasingly realized. This is due to the constant increase in the cost of electrical energy, the increasing incidence of abnormal strong winds and frosts, leading to a decrease in the reliability of power transmission lines (wire breaks) of the centralized electrical supply.

Fragment of a block diagram of a steam mini-CHP with a guarantee of operation in trigeneration mode

Heat generating plant as a source of heat and electricity

Consumers who have their own boiler systems sometimes supplement them with electric generating units (electric units) with steam engines (in most cases turbines) and electric generators with a capacity of several hundred kilowatts to several million watts. Similarly, boiler plants reconstructed into mini-CHPs become sources of both thermal and electrical (Fig. 1, three-phase line A–B–C) energy.

Depending on the thermal performance of a steam heat-generating plant, 17–40 kW (1.7–4%) of electrical energy is required to generate 1 MW (100%) of heat energy [1]. The unconditional steam pressure in boilers, permitted by Rostekhnadzor authorities, is usually no more than 0.7–1.0 MPa (hereinafter – unconditional).

Industrial consumers or for steam-water heat exchangers (storage water heaters for producing hot water) require steam with a lower pressure - 0.12–0.6 MPa. Thanks to this, electric units with steam turbines are switched on in parallel with reduction devices or instead of them (Fig. 1). Then, instead of the useless throttling of steam by turbines, the necessary work will be done to drive electric generators. In this case, the exhaust steam is sent to an indirect heating water heater, after which it is condensed, and the condensate is pumped through the cleaning system back to the boiler.

Similarly, a heat generating plant becomes a cost-effective source of heat and electricity with a high efficiency coefficient of fuel combustion heat (80–85% or more).

If the consumer does not need a decent amount of heat, but only hot water, for example, in the summer, then mini-CHPs are also equipped with absorption refrigeration machines operating on steam exhausted in the turbine. Machines of this type provide the necessary cooling of water, which enters the refrigeration system for conditioning the consumer’s premises.

For a year-round continuous supply of electricity to consumers, including mini-CHP equipment (pumps, smoke exhausters, lighting, automation systems, etc.), its continuous operation is necessary. This is possible, for example, if electrical energy is generated simultaneously with the generation of heat needed to supply consumers with hot water.

At the sites of existing heat-generating installations, mini-CHPs with increased heating capacity are also being built. For example, old boilers with a lush steam pressure of 1.4 MPa are being replaced with boilers with a superheated steam pressure of 4.0 MPa and a temperature of 440 °C. With the same dimensions of the boilers, the electrical power of such a mini-CHP becomes much greater.

But it is necessary to look at the type of steam engine used in modern mini-CHPs 1. This is a low-power steam turbine, which usually has a single-stage design, because it does not stop operating at low pressure drops. The rotor, as the rotating part of a turbine, consists of a hub that sits on a shaft and a set of profiled blades (blade crown). Blades are made of specialized alloys and are critical and expensive elements of the turbine. Steam screw turbines also have a profiled rotor, exclusively like an Archimedes screw.

Even in the days of steam engines, a piston was considered a very simple and inexpensive productive organ, when compared with a turbine blade.

The first domestic steam engine, which turned 75 years old in 2011, was intended for an aircraft power plant and was designed at the Moscow Aviation College to operate on superheated steam with a pressure of 6.1 MPa and a temperature of 380 °C. It was made at one of the Moscow factories and could reach up to 1800 rpm.

The characteristic features of steam engines from traditional steam engines are not only their high-speed qualities, but also a completely different type of steam distribution. The motors are designed to operate with single steam expansion. Steam from the boiler enters all cylinders in parallel, similar to how the fuel-air mixture enters the cylinders of an internal combustion engine. In traditional steam engines, steam flows through all the cylinders gradually, expanding in a similar way, repeatedly.

With the advent of piston technology, the mechanisms for a one-time increase in steam became much more advanced than the mechanisms for its repeated increase. This made it possible to reduce the inevitable and useless drop in steam pressure from inside the steam distribution elements and, therefore, to obtain a higher-speed steam piston motor at the same steam pressure at the inlet.

Comparison of parameters of electric generator sets with a steam turbine and a steam engine

Some designs of steam engines and engines of the past century were not very imperfect, as is believed. Let's imagine an electric generating plant with a steam engine or motor and a modern electric generator. Because steam engines generally had very low shaft rotation speeds (up to 300 rpm), and modern electric generators operate at frequencies of 1000–3000 rpm, an imaginary installation also requires a multiplier.

Let's compare this installation with the most modern steam turbine. Let's do this correctly: at commensurate pressures and temperatures of steam at the entrance to such engines and commensurate back pressure of steam at the exit. Then it becomes clear (Table 1) that the specific steam consumption per unit of generated electrical energy, and therefore the efficiency of specific steam engine or steam engine installations, is quite comparable with the specific steam consumption in modern turbine plants, the power of which is even 5 times greater!

Representatives of factory-made power plants

Let us note that the indicated options – a thermoelectric generator and a gas generator – are now a priority, therefore ready-made stations are produced for use, both domestic and industrial.

Below are a few of them:

- “Indigirka” stove;

- Tourist stove “BioLite CampStove”;

- Power plant "BioKIBOR";

- Power station "Eco" with gas generator "Cube".

Stove "Indigirka".

An ordinary household solid fuel stove (made like a Burzhaika stove), equipped with a Peltier thermoelectric generator.

Perfect for summer cottages and small houses, as it is quite compact and can be transported in a car.

The main energy from burning wood is used for heating, but the available generator also allows you to obtain electricity with a voltage of 12 V and a power of 60 W.

BioLite CampStove stove.

It also uses the Peltier principle, but it is even more compact (weighs only 1 kg), which allows you to take it on hiking trips, but the amount of energy generated by the generator is even less, but it will be enough to charge a flashlight or phone.

Power plant "BioKIBOR".

A thermoelectric generator is also used, but this is an industrial version.

The manufacturer, upon request, can produce a device that provides output electricity with a power of 5 kW to 1 MW. But this affects the size of the station, as well as the amount of fuel consumed.

For example, an installation that produces 100 kW consumes 200 kg of wood per hour.

"Eco".

But the Eco power plant is a gas generator. Its design uses a “Cube” gas generator, a gasoline internal combustion engine and a 15 kW electric generator.

In addition to ready-made industrial solutions, you can separately buy the same Peltier thermoelectric generators, but without a stove, and use it with any heat source.

Thermoelectric generators

Power plants with generators built according to the Peltier principle are quite an interesting option.

Physicist Peltier discovered an effect that boils down to the fact that when electricity is passed through conductors consisting of two dissimilar materials, heat is absorbed at one of the contacts, and heat is released at the other.

Moreover, this effect is the opposite - if the conductor is heated on one side and cooled on the other, then electricity will be generated in it.

It is the opposite effect that is used in wood-fired power plants. When burned, they heat up one half of the plate (it is a thermoelectric generator), consisting of cubes made of different metals, and the second part is cooled (for which heat exchangers are used), as a result of which electricity appears at the terminals of the plate.

But such a generator has several nuances. One of them is that the parameters of the released energy directly depend on the temperature difference at the ends of the plate, therefore, to equalize and stabilize them, it is necessary to use a voltage regulator.

The second nuance is that the energy released is just a side effect; most of the energy when burning wood is simply converted into heat. Because of this, the efficiency of this type of station is not very high.

The advantages of power plants with thermoelectric generators include:

- Long service life (no moving parts);

- At the same time, not only energy is generated, but also heat, which can be used for heating or cooking;

- Quiet operation.

Wood-burning power plants using the Peltier principle are a fairly common option, and they produce both portable devices that can only release electricity to charge low-power consumers (phones, flashlights), and industrial ones that can power powerful units.

Rotor with neodymium magnets

The end rotor with encapsulated epoxy resin magnet is a three phase 12katushek 3.3 ohm resistance. Therefore I have a magnet to rotor of 24polyus, so the ratio of magnets on coils in a three-phase system is 2/3, where there are two magnets on three coils, for example if the coils have 18 poles. First attached to the rotor magnet 24 with the same distance and filled with epoxy resin.

The assembled generator, connected to the star phase and twisted, spinning at a hand counting speed per second, turned into a 200rpm 13 volt and 2A koe generator at 300rpm 20 volts and 1A for the batteries. The result was pleasant, but the generator stuck the magnets to the stator teeth, which prevents the propeller from starting in light winds, and I decided that the tilt of the magnets would be on the rotor.

Homemade stations

Also, many craftsmen create homemade stations (usually based on a gas generator), which they then sell.

All this indicates that you can independently make a power plant from available materials and use it for your own purposes.

Next, let's look at how you can make the device yourself.

Based on a thermoelectric generator.

The first option is a power plant based on a Peltier plate. Let us immediately note that a device made at home is only suitable for charging a phone, a flashlight, or for lighting using LED lamps.

For production you will need:

- A metal body that will play the role of a furnace;

- Peltier plate (purchased separately);

- Voltage regulator with installed USB output;

- A heat exchanger or just a fan to provide cooling (you can take a computer cooler).

Making a power plant is very simple:

- We make a stove. We take a metal box (for example, a computer case) and unfold it so that the oven does not have a bottom. We make holes in the walls below for air supply. At the top you can install a grate on which you can place a kettle, etc.

- We mount the plate on the back wall;

- We mount the cooler on top of the plate;

- We connect a voltage regulator to the terminals from the plate, from which we power the cooler, and also draw terminals for connecting consumers.

POPULAR WITH READERS: GSM alarm system - security of your home, cottage, garage under your control

It works simply: we light the wood, and as the plate heats up, electricity will begin to be generated at its terminals, which will be supplied to the voltage regulator. The cooler will start working from it, providing cooling of the plate.

All that remains is to connect the consumers and monitor the combustion process in the stove (add firewood in a timely manner).

Based on a gas generator.

The second way to make a power plant is to make a gas generator. Such a device is much more difficult to manufacture, but the energy output is much greater.

To make it you will need:

- Cylindrical container (for example, a disassembled gas cylinder). It will play the role of a stove, so hatches should be provided for loading fuel and cleaning solid combustion products, as well as an air supply (a fan will be required for forced supply to ensure a better combustion process) and an outlet for gas;

- A cooling radiator (can be made in the form of a coil) in which the gas will be cooled;

- Container for creating a “Cyclone” type filter;

- Container for creating a fine gas filter;

- Gasoline generator set (but you can just take any gasoline engine, as well as a regular 220 V asynchronous electric motor).

After this, everything must be connected into a single structure. From the boiler, gas should flow to the cooling radiator, and then to the “Cyclone” and a fine filter. And only after that the resulting gas is supplied to the engine.

This is a schematic diagram of the manufacture of a gas generator. Execution can be very different.

For example, it is possible to install a mechanism for forced supply of solid fuel from a bunker, which, by the way, will also be powered by a generator, as well as all kinds of control devices.

When creating a power plant based on the Peltier effect, no special problems will arise, since the circuit is simple. The only thing is that you should take some safety measures, since the fire in such a stove is almost open.

But when creating a gas generator, many nuances should be taken into account, among them is ensuring tightness at all connections of the system through which gas passes.

In order for the internal combustion engine to operate normally, you should take care of high-quality gas purification (the presence of impurities in it is unacceptable).

The gas generator is a bulky design, so it is necessary to choose the right place for it, as well as ensure normal ventilation if it is installed indoors.

Since such power plants are not new, and they have been manufactured by amateurs for a relatively long time, a lot of reviews have accumulated about them.

Basically, they are all positive. Even a homemade stove with a Peltier element is noted to completely cope with the task. As for gas generators, a clear example here is the installation of such devices even on modern cars, which indicates their effectiveness.

Electricity-generating stove "Indigirka" for firewood

Engineers from the Russian plant Termofor, in collaboration with the company producing electric generators Kryotherm, combined a wood-burning stove and a thermal electric generator to create a stove that generates electricity from ordinary firewood.

Indigirka is a fairly compact solid fuel heating and cooking stove, which includes a built-in electric generator in its design, which converts heat from burning wood into electricity.

The stove is convenient, it can be used for its intended purpose, cook soup, other dishes, brew tea, etc. In general, a stove is much more practical than a fire in terms of the environment or saving firewood if there is not much of it at the vacation spot. It is known that the efficiency of a fire is only 5-7 percent. The rest of the energy is lost, since many combustible particles of firewood go into smoke. While the efficiency of stoves is ten times higher than that of a fire. For example, look at the description of an efficient miniature forced-air stove.

But in the context of our topic, its ability to generate an electric current of 12 volts and a total output power of 60 watts is interesting. Such a stove is indispensable in field conditions, for example, on a fishing trip, on a picnic, especially if the trip is for a long time and it is impossible to stock up on energy-intensive batteries. This current is enough to illuminate two or three energy-saving light bulbs, enough to charge laptop batteries and to operate a portable TV and devices of equal power consumption. By the way, if you wish, you can connect a 12 volt-220 volt converter to the output.

How the Indigirka stove works

The furnace operates on the basis of the Peltier Effect - a thermoelectric phenomenon in which heat is released or absorbed when an electric current passes at the point of contact (junction) of two dissimilar conductors. You can purchase these items in this Chinese store. There is also a special cooling cooler.

Due to the temperature difference on one surface and with forced cooling due to fans installed in the generator structure on the other side, an electric current occurs.

During operation, the stove's electric generator reaches a reliable mode of generating electricity 10-15 minutes after igniting the wood in the stove. This electricity-generating wood-burning stove is of interest to fishermen, hunters, tourists, gardeners whose gardens cannot be connected to power grids, and military structures. The stove is in demand and is supplied to dozens of countries around the world.

Other oven characteristics

The solid fuel stove is designed for a heated room volume of up to 50 cubic meters.

The furnace material is heat-resistant steel. The Indigirka comes with two connecting cables for connecting portable devices, one with cigarette lighter and USB connectors (5 volts), the second with alligator clips.

In the video, look at the description of the device (the video mentions the power of the feather model - 50 watts, currently available in a nominal 60 watts).

Testing a solid fuel power generator in a tent and describing the operation of the device.

Thermoelectric stove “Indigirka” and reviews of it during the hike.

https://youtube.com/watch?v=DKm9xEkYAi4%23t%3D67

The principle of operation of a wood-fired thermal power plant: pros and cons

Ecology of consumption. Estate: A modern wood-burning power plant is a very efficient and at the same time relatively inexpensive equipment, the main fuel in which is firewood.

A modern wood-burning power plant is very efficient and at the same time relatively inexpensive equipment, the main fuel in which is firewood. Now this equipment is quite widely used in the private residential sector, as well as in small production areas and in field conditions.

PRINCIPLE OF THE CLASSICAL SCHEME

The very concept of “wood-fired”, according to which a wood-fired thermal power plant operates, you need to understand that as fuel, it is possible to use a variety of materials that can burn. At the same time, the most common and frequently used resource is firewood. You can buy wood-burning power plants from a large assortment on the market at a relatively low cost. The main structure of these types of power plants is as follows:

- Bake.

- Special boiler.

- Turbine.

With the help of a furnace, a boiler is heated in which there is water or there may be a gas special for this purpose. The water is then sent through a pipeline to the turbine. It rotates and with the help of this, electricity is converted in a specially mounted generator. It’s quite easy to make wood-burning power plants with your own hands and it won’t take a lot of time or significant financial investments.

MAIN FEATURES OF THE WORK

When the power plant is operating, the water will not immediately evaporate, but will constantly flow along the circuit. The exhaust steam cools and then becomes water again, and so on in a circle. Some of the disadvantages of this type of operation of a mini power plant using solid fuel is the rather high risk of explosion. If suddenly the water in the circuit overheats greatly, then the boiler may not be able to withstand it and will burst under pressure. To prevent this, modern systems and automatic valves are used. You can always buy a camping wood-burning power station, which has high efficiency and safety indicators at very low cost.

Also, in the standard steam generator circuit there are some requirements for the water used. It is not recommended to pour ordinary tap water into this equipment. Because it contains a large amount of salts, which over time will become the main cause of plaque on the walls of the boiler used and in the pipes of the power plant, which uses wood as the main fuel.

DIFFERENT OPTIONS FOR WOOD-FIRED POWER PLANTS

Nowadays, a solid fuel tourist mini power station is very popular and inexpensive, which can be purchased from a large assortment. Such power plants are highly popular and in demand among a large number of tourists and travelers. This equipment uses special solid fuel, which provides high levels of efficiency, reliability, and safety in operation.

A mini-power plant using firewood as fuel is a fairly successful and long-used piece of equipment that can be used in various fields of human activity. These types of power plants are very popular among summer residents, where there may be frequent problems with power outages, as well as in hard-to-reach regions where there are no power lines. In addition, camping versions of power plants that use wood or any other solid fuel elements are now becoming increasingly popular. published econet.ru

Engineering capabilities

The technical characteristics of power generating equipment speak for themselves:

- the optimal amount of fuel for loading is 30 liters;

- external dimensions have the following parameters: height – 652 mm, depth – 427 mm, width – 540 mm;

- unit weight – 54 kg;

- the maximum size of a heated structure is 50 m³;

- chimney diameter – 80.0 mm;

- the smallest chimney height is 3.0 meters;

- number of chimney pipes - 9 pieces per set;

- combustion compartment – 41 dm³;

- thermal power – 4 kW;

- output power – 50 W (min);

- output voltage – approximately 12 Volts;

- firebox door size – 178 mm in diameter;

- heating surface – 0.6 sq. m;

- type of fuel - brown coal, peat, firewood from deciduous trees, fuel briquettes, pallets.

It is important to know: it is strictly forbidden to use coal as a combustible material.

Classic version

As noted, a wood-fired power plant uses several technologies to produce electricity. The classic one among them is steam power, or simply the steam engine.

Everything is simple here - wood or any other fuel, when burned, heats up the water, as a result of which it turns into a gaseous state - steam.

The resulting steam is supplied to the turbine of the generating set, and due to rotation, the generator generates electricity.

Since the steam engine and generator set are connected in a single closed circuit, after passing through the turbine the steam is cooled, fed back into the boiler, and the whole process is repeated.

This power plant scheme is one of the simplest, but it has a number of significant disadvantages, one of which is the danger of explosion.

After water passes into a gaseous state, the pressure in the circuit increases significantly, and if it is not regulated, there is a high probability of rupture of the pipelines.

And although modern systems use a whole set of valves that regulate pressure, the operation of a steam engine still requires constant monitoring.

In addition, ordinary water used in this engine can cause scale to form on the walls of the pipes, which reduces the efficiency of the station (scale impairs heat transfer and reduces the throughput of the pipes).

But now this problem is solved by using distilled water, liquids, purified impurities that precipitate, or special gases.

But on the other hand, this power plant can perform another function - to heat the room.

Everything is simple here - after performing its function (rotation of the turbine), the steam must be cooled so that it turns into a liquid state again, which requires a cooling system or, simply, a radiator.

And if you place this radiator indoors, then in the end we will receive not only electricity from such a station, but also heat.