We have already published a translation of an article dedicated to a smoke eliminator for soldering. That article was about an Arduino-based sensor that automatically turns on the smoke eliminator when the soldering iron is removed from the holder. And today we will talk about making a smoke eliminator yourself.

Homemade Soldering Smoke Eliminator

Anyone who is into electronics knows that soldering plays a vital role in almost all of his projects. However, it is unlikely that anyone will like to inhale the smoke that is released when solder and flux are heated. This smoke has a terrible smell and can be harmful to your health, but the dangers associated with it can be reduced by using a smoke eliminator. This device, which captures toxic fumes, will be useful even to those who solder infrequently.

You can buy a good smoke extractor, but it will cost more than $70. Having learned about this, I made such a device myself, using a 120 mm computer fan and a 3D printed case.

Materials and tools

For this project you will need the following materials:

- 12V fan

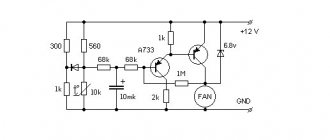

- Fan speed controller

- Power connector

- Key switch size 15×10 mm

- 5mm LED

- 580 ohm resistor

- Wires, 22 AWG

- Heat shrinkable tube

- Cage nuts M3

- Activated carbon filter

- Double-sided adhesive tape

- M3x12 screws

- M5x8 screws

- Rubber feet

Here is a list of necessary tools:

- Soldering iron

- 3D printer

- Wire cutters

- Wire stripping tool

- Hot air gun

Air purification methods

There are several options for protecting a room from the accumulation of toxic particles.

If the work is carried out in a kitchen where forced ventilation with a mounted unit is installed, it makes sense to place the soldering area directly below it.

Typically, fume hoods are hung above the stove. You can close the top panel of the oven and create a work space on it. Working this way is not very convenient, but it is safe for health.

A separate workshop in which soldering is carried out frequently should have special equipment for air purification. A good option is a hood for soldering work, which can work according to the principle implemented in professional or household equipment.

If you don’t have a workshop, and it’s inconvenient to work under a kitchen hood, then it’s advisable to buy a special device for home soldering. There are tabletop smoke eliminators on sale that have affordable prices and good performance. Their range is wide.

Homemade apparatus

Our smart people figured out how to make a smoke eliminator for soldering themselves. To do this you need a few main details. It's easy to purchase them. It is very likely that you already have them in your home storage.

The inventors recommend that as a basis for production, take 2 plastic bowls of different sizes, which need to be placed one inside the other. Cut a hole in the inner bowl.

A fan is installed on screws. A grid is cut out of the outer bowl, onto which a metal wire frame is attached.

The filter is fixed to the frame. A filter from a kitchen hood is suitable for soldering. Install the smoke extractor on legs made of thick wire. With this equipment, soldering at home will be a safe activity.

Finalization

What batteries are there, their types

solar battery

Since the body of the lamp is cone-shaped, I cut off such a part from it that it could be pushed into the hood without any problems. I cut a hole in the bottom of the jar for the body.

The joint area was filled with glue. I put the tube on and secured it with a metal clamp. A fan was installed at the outlet, which operates to blow out when power is applied. I planned to place the wires inside the tube first, but decided to press them with rubber bands from the outside.

The holes on the funnel were sealed with blue electrical tape.

Now the end of the tube can be brought out the window

The tube was long enough to fit flush

The height from the table to the edge of the funnel with the maximum curved bracket is about 37 cm

Those. The 8-arm holder fits quite well in terms of dimensions

Finally, an animation of what it looks like in action:

Video - “Do-it-yourself smoke absorber for soldering work”

When soldering any equipment, several chemical processes occur, each of which is accompanied by the release of harmful substances into the surrounding space.

Soldering acid, for example, evaporates even at room temperature. When heated, the release of acidic vapors increases sharply. Particles of solders, fluxes, hot metals and their oxides are sublimated into the atmosphere.

A smoke extractor for soldering can protect the craftsman's respiratory organs. It has sufficient power, the ability to capture harmful substances and return purified air to the space.

What is a soldering smoke eliminator?

During the board soldering process, toxic substances are released. Toxic substances have a strong destructive effect on human health. It is strongly recommended to carry out such operations using a soldering fume extractor or soldering hood.

During the melting of solder and rosin, substances such as antimony, cadmium, arsenic, zinc, lead and others are released into the air along with the smoke. During work, carcinogens and formaldehyde accumulate in the room. A smoke eliminator for soldering protects a person from the direct entry of poisons into the body. The hood sucks in the smoke and redirects it in another direction.

[contents]

A soldering smoke eliminator is a device that filters and extracts contaminated air. Thanks to this device, the air in the workroom remains clean and safe for humans.

Appearance

1)2)3)4)

Color grey. The material feels thick to the touch

Length at rest: slightly more than 1 meter

Diameter approximately 8 cm

The inside of the pipe smells like gouache paints. Over time this smell goes away

A steel rod (1mm) comes out from the edge of both ends, which runs in a spiral through the entire pipe

How it stretches

Now to the funnel on the bracket.

The bracket itself is flexible, but bends tightly. Its length is 60 cm, thickness 12 mm

At its end there is a screw fastening to the edge of the table

It is attached to the funnel using one nut through a plastic gasket

Rust is visible in the internal cavity of the bracket

The funnel is made of transparent ABS plastic

It has a ribbed surface along the perimeter of the wide part

Height 133.6mm, diameter at the narrow part - about 70mm, at the wide part ~14.5cm

On the outer side there is a rotary handle for rotating the damper. In theory, the damper is a useful thing, because... when closed, it will prevent drafts if the hood is installed through a hole in the wall or a drilled hole in the window.

Damper with two clamps

Funnel with installed damper

Animation demonstrating how the damper position changes

The bracket was later secured to the edge of the table, after placing a leather shoe tag.

The screw was tightened thoroughly, causing the bracket to begin to bend. The Chinese made it thin.

conclusions

The overall stability of the structure is quite enough so that it does not warp at the slightest touch.

There is still a noticeable reserve in the tripod's load-carrying capacity. In the future I’m going to attach several LED lights here. One of the discovered disadvantages is the fastening of the end of the bracket to the funnel. At least one more nylon washer was reported. Thin metal where it is attached to the table, holes in the funnel. The transparent plastic funnel gradually becomes clogged with dust, this is not surprising. What I liked was the overall flexibility of the design; you can turn and direct it as you wish, which makes it more convenient to use. By absorption. With a 12-volt cooler installed at the outlet of the tube, smoke begins to be sucked in at a distance of about 20 cm from the edge of the funnel, which is not much, but quite tolerable, and certainly better than soldering without a hood at all, therefore the assembly option is far from final. In addition to LEDs, I plan to buy a more powerful fan. Overall quite satisfied. The hood, which is the heaviest part, was purchased as part of a combined parcel (1.5 kg) through an intermediary, the total price with a $10/50 coupon was $40 + delivery with fees ~26 $.

The product was provided for writing a review by the store.

The review was published in accordance with clause 18 of the Site Rules. Planning to buy +23 Add to favorites Liked review +42 +70

Soldering iron hood - DIY Community on DRIVE2

I'm tired of blowing on the soldering iron again, so as not to breathe in the smoke from acid fluxes. I remembered that various smoke absorbers are available for sale. I decided to put together something similar myself.

I took polypropylene pipes as a basis.

In the plug of a sewer pipe with a diameter of 110 mm, I cut a hole for a 32 mm pipe. I inserted a piece of pipe at 32 and fixed it with hot glue. The continuation of the pipe will be a 32mm elbow at 45 degrees.

At first I wanted to install a 120mm cooler, but it showed worse results than an 80mm cooler

In order for the cooler to fit into the plug, I had to cut down the ribs a little.

I sealed the sides using regular cardboard and hot glue.

During assembly, I came up with the idea to also provide illumination for the workplace.

The base of the board holder with LEDs was made from a section of a 32 coupling.

I printed the drawing on magazine paper and cut out a piece of PCB.

I etched the board, ground it along the contour, tinned it and tried it on the coupling.

I soldered the LEDs and 150 ohm resistors, coated everything with clear acrylic varnish, and put on the lenses

I soldered the 2pin connector and glued the board to the coupling with hot glue.

I took two clips for attaching 32mm pipes and ground off the ears on the sides. In the plug for 32, I drilled two holes and cleaned the bottom. I screwed the clips to the plug and sealed them with hot glue.

I secured the wire from the cooler with hot glue. I drilled holes in the clips for the wires. The wire used is 2 wires from the IDE cable.

A diode bridge with a capacitor was soldered to the cooler and backlight. I glued all this to the plug with hot glue.

I found a 12 volt transformer. The task became to attach it to the block, because... the mounting ears were in the middle. To do this, I took two self-tapping screws and two brass anchors. I covered the anchors with heat shrink and, using self-tapping screws, pulled the trans to the block through them.

An ordinary wooden block 150*100*25 was taken and painted in 2 layers of varnish. Fixed the transformer. The wire was wrapped in heat shrink. I took the second plug for 32, made holes for the wire and secured it to the block with three self-tapping screws.

I soldered the power cord and secured it with a plastic bracket.

As a leg, I took a 32 coupling and drilled a hole in it for the toggle switch. I soldered and assembled everything.

The finished result.

At work.

The light ring is easy to remove. This was done specifically so that the knee could be changed from 45 to 90 degrees. Practice has shown that the use of 60-degree lenses is not justified. Although it was brighter with them, when the smoke exhauster approached closer to the soldering site, it did not fall under the beam of light from the lenses. Therefore, it was decided to operate without lenses.

Link to lenses, took here

www.drive2.ru

Varieties

Soldering happens

- low temperature (heating solder to 450 °C);

- high temperature (heating the solder over 450 °C).

Accordingly, there are solders

- fusible;

- refractory.

For low-temperature soldering, mainly electric heating is used, for high-temperature soldering, mainly heating with a torch is used. Alloys are used as solder

- tin-lead (Sn - 90%, Pb - 10%, temperature pl. 220 °C);

- copper-silver (Ag - 72%, Cu - 28%, temperature pl. 779 °C);

- copper-zinc (Cu - 48%, Zn - 52%, temperature pl. 865 °C);

- gallium (t° pl. ~50°C);

- bismuth (Wood's alloy with a temperature of 70 °C, Rose's alloy with a temperature of 96 °C)

- etc.

Soldering is a highly productive process, provides a reliable electrical connection, allows you to join dissimilar materials (in various combinations of metals and non-metals), and lacks significant temperature distortion (compared to welding). Soldered joints allow repeated separation and connection of the parts being connected (unlike welding). Disadvantages include relatively low mechanical strength.

Based on the physicochemical nature of the process, soldering can be defined as follows. The process of joining metals in a solid state by introducing solder into the gap, interacting with the base metal and forming a liquid metal layer, the crystallization of which leads to the formation of a solder seam. At the boundary between the solder and the base metal, transition layers are formed, consisting of the products of their interaction - solid solutions and intermetallic compounds. They provide adhesion between the solder and the base metal, but too thick layers of intermetallic compounds are brittle and lead to solder failure.

Types of soldering:

- capillary (wetting of parts and flow of solder into the gap between them occurs due to capillary forces): horizontal;

- vertical;

- atomic diffusion;

- with the formation of eutectic;

- no solder;

- without reflow;

Analyzing the essence of the physical and chemical processes occurring at the boundary of the base metal - molten solder (when forming a joint in existing types of soldering), one can see that the differences between capillary soldering, diffusion soldering and soldering-welding are not fundamental. Capillarity is a common feature of soldering. A distinctive feature of diffusion soldering is a long exposure at the soldering temperature and isothermal crystallization of the weld metal during the soldering process. This method has no other characteristic features; its main purpose is to increase the temperature of the seam and the strength of the soldered joint. Diffusion soldering can be a development of any type of soldering, including capillary, reaction-flux or contact-reaction. In the latter case, diffusion soldering is possible if the second metal of the interacting pair is introduced as a layer between the metals being joined. During reaction-flux soldering, the processes of displacement of the metal serving as solder from the flux and its interaction with the base metal are combined. Finally, soldering-welding differs from other soldering methods in the amount of solder introduced and the nature of the formation of the seam, making this soldering method similar to fusion welding. When connecting dissimilar metals during soldering and welding, the edge of one of the parts made of a lower melting metal may melt.

Ventilation device

The operating principle of all models for home soldering is similar. The main structural elements of the smoke eliminator are as follows:

- a grille through which dirty air enters the device;

- fan;

- filter with adsorbents;

- back panel with holes for the purified stream to exit.

Activated carbons are usually used as adsorbents for soldering. The smoke extractor is located on the table using legs. The angle of inclination relative to the working plane can be varied.

If desired, the device can be directed strictly vertically or parallel to the table surface, horizontally.

The power of smoke eliminators usually varies from 15 to 19 W. More powerful models are used in industrial soldering equipment.

Within one minute, the devices can purify from 0.9 m3 to 1.1 m3 of air. Smoke extractors are easily portable, their weight does not exceed 1.5 kg. The slots on the back panel are made so that the purified flow rushes upward. It's a smart decision.

If the air was directed in a horizontal plane, it would fall on the nearest wall. With this design option, air exchange during soldering cannot be effective.

High-quality smoke extractors operate silently. After the period of operation specified in the instructions, the filters should be replaced. This is done very simply.

Additional filters must be purchased from a supplier that offers solder smoke eliminators for this model. This minimizes the likelihood of the filter not matching the device.

Security measures

Even low-temperature soldering work is still accompanied by serious heating of the material and tool

Therefore, it is imperative to take precautions. Before starting work, it is necessary to check the serviceability of the equipment itself, wires and their insulation, and the quality of lighting

Overheating of the soldering iron is unacceptable, also because the efficiency of manipulation is lost.

When working, the soldering iron is placed on a special stand. If you place it in an unprepared area, the tool may roll and cause a burn or land on a flammable surface. Holders are made of metal or wood. You can buy them or make them yourself. In the room where they work with a soldering machine, you will have to carefully take care of ventilation.

The soldering iron is held strictly by the handle. The standard labor protection instructions also mention:

- electrical safety group of workers not lower than 2nd;

- use of special clothing and safety footwear;

- use of general and local exhaust ventilation;

- carrying out tests and tests of the soldering iron at established intervals;

- protection of the soldering machine cable from heat and mechanical impact;

- use only closed wiring;

- using only smooth and easy-to-clean materials to cover work surfaces.

Overview of species

Selective soldering allows you to form reliable joints on the terminals of pin components of radio electronics. This technology differs from traditional wave solder joining. Soldering is carried out at single points of the processed boards. Tight installation, location of pins under the housing, small spacing cease to be a serious problem. The basic processes and steps, however, are the same as with the classical method.

The term "curvilinear weld" refers primarily to the connection of suspended ceilings. With strict adherence to technology, it is possible to achieve an almost invisible seam.

A curved connection, however, is very difficult to create and the work is very expensive.

Low temperature

This type of work became very popular in the second half of the twentieth century. Its spread is associated with the emergence of the radio-electronic industry and especially computer engineering. Only manipulations at a relatively low temperature can ensure the safety of thin electronic boards and individual microcircuits. But you should not assume that soft soldering is only possible in well-equipped production facilities with sophisticated equipment. There are separate options available to almost any radio amateur.

The role of solder is not the main one, but only strengthening the connections being created. Soft solders can also be used in current-carrying joints. A variety of metals can be soldered with such compounds, but you will have to carefully consider the preparation parameters.

High temperature

This term refers to compounds produced at temperatures of at least 450 degrees. High temperature solder joint is tighter. But we must take into account that this results in significant changes in the structure of the material. Many problems arise when high-temperature soldering of cast iron. In some cases, heating occurs up to 1000 degrees and even higher, but such a need rarely arises.

Filtration and ventilation qualities

What types of LEDs are there?

The unit housing contains two turbines and filter elements. It is used with one or two exhaust devices. The radius of the working area can be up to 74 centimeters. The purified air is removed using a ventilation grille. The mini-exhaust device can have a tube diameter of 5 centimeters made of anodized aluminum.

Air ducts or flexible hoses supply air through the inlet pipe into the filter chamber. It performs preliminary cleaning. There is also a two-stage filter element here. Soldering suction means complete workplace safety. The filtration process is carried out in three stages:

- Preliminary filtration (the largest particles in mechanical impurities are captured, replaceable filter material needs to be periodically replaced).

- Main cleaning from impurities containing particles up to 0.01 centimeters.

- Retention of gases and odors.

The service life of the filter elements is determined by the intensity of operation of the filter-ventilation unit. The built-in control system controls the accumulation of substances hazardous to humans. The smoke extractor has an audible and optical warning signal about filter contamination or other problems.

The suction power can be adjusted using the built-in rotor speed setting in the motor. The device, having removed smoke from the soldering area, performs subsequent highly efficient filtration of combustion products. The use of the device allows you to make the air clean not only in the workplace, but also in the room as a whole.

Contaminated air particles are sucked out using a nozzle, exhaust hood or other intake device. The filter catches the smallest particles, the smell is adsorbed by activated carbon. After passing through three stages of purification, the air is drawn in by two turbines and discharged out through the exhaust opening.