A stool is a compact and very comfortable piece of furniture that has become familiar to many people. Wooden products purchased in a store do not always satisfy consumers in terms of cost, practicality and aesthetic qualities.

Therefore, the question of making stools with your own hands arises in the minds of many. On the one hand, such a product can be made based on your personal preferences (material, size, shape, etc.), but on the other hand, a do-it-yourself stool made of wood is a long and labor-intensive process.

DIY stool made of wood

Stool design features

To make a stool, different materials can be used, but most often craftsmen take ready-made timber, waste wood or ordinary plywood . These are cheaper and more reliable materials that are used in the furniture industry. Working with wood is not difficult, so if you have a ready-made drawing, you can easily make a kitchen stool.

Most often, stools are made of wood

In the classical sense, a stool is several elements securely connected to each other. These include:

- stool base , which has a square shape (sometimes the base of the structure is round);

- durable legs in the amount of 3 or 4 pieces;

- fasteners that connect the legs of the product. They are called kings;

- a seat with rounded edges.

Creative wooden stools

For convenience, the surface of the seat is covered with thick fabric or leather. Such stools will look more presentable.

Design features of the stool

Advantages and disadvantages

Chairs made from logs have many advantages:

- Affordability of the material;

- Environmental friendliness of the product;

- High strength and wear resistance of the structure;

- Ease of manufacture. The work of constructing a chair from a log can be done even by those who do not have carpentry experience. Moreover, the simplest design can be made in less than 1 hour;

- A broken structure can be easily repaired or disposed of;

- Ease of product care and restoration;

- Original appearance of the product. Having a developed imagination, you can build not only a practical, but also an unusual structure.

However, log chairs also have their disadvantages. The disadvantages of products include the following factors:

- High sensitivity to moisture. Even with careful treatment of the material with water-repellent solutions, a log may crack if exposed to moisture for a long time;

- The massiveness of the products and their heavy weight;

- Flammability of the material. Almost any wood is a highly flammable material. Therefore, it is not recommended to use such chairs near an open flame, even after treatment with a fire retardant solution.

Also, the disadvantages of chairs made of natural wood include the specificity of tactile sensations and associations that this type of furniture can provoke.

Product requirements

A stool is a universal piece of furniture, because if desired, it can be hidden in a closet, under a table, or taken to another room. A stool can also replace a coffee table or a small stand. But for a handmade product to be truly functional and of high quality, it must meet several requirements.

Product requirements

- Structural strength . In the process of making a stool, all wooden elements must be fixed using high-quality wood glue. A durable product will be able to withstand even the largest people and will not fall apart.

- Correct sizes and proportions . The design of the stools should correspond to the size and height of family members. For example, a stool for children should be ideally selected so that they can place their feet on the floor or on a special crossbar.

- Compactness and convenience of a wooden product . You need to seriously think about the choice of upholstery material. It is desirable that the seats be soft, so materials such as leatherette, leather or velor are better suited for upholstery.

Ladder stool

Note! If you are going to make a stool for the first time, then it is recommended to choose simple designs first. But after some time, after gaining the necessary experience, you can begin to manufacture more complex products.

Advantages of log furniture

At the dacha they often use old furniture that used to be in a city apartment, or they buy lightweight plastic, folding chairs made of wooden slats, metal pipes and thick fabric. Their main advantage is mobility, but at the same time they are not very stable, and budget models are also quite inconvenient. A durable, comfortable, reliable chair for a summer house or picnic will not be cheap. Chairs made from logs have a number of advantages:

- cheapness, availability of material. If an old, large tree has recently been cut down or uprooted on the site, the material for making a chair is already at hand, and you don’t even have to worry about transporting the log. You can find a log of suitable size in the forest. As a rule, you can make a chair from it without a single nail (screw), and no glue is needed;

- strength. Furniture made from logs is solid and much more reliable than factory chairs made of plastic or small-section timber and plywood. Such a chair will not loosen or break even under a massive rider;

- ease of manufacture. A wooden chair with a back, drawers, and legs is a rather complex design; you need to make calculations, draw a drawing, select grooves and cut tenons to connect the parts. A simple chair can be made from a log in just a couple of minutes, and this task can be done even by those who have no carpentry skills at all;

- appearance. If you give free rein to your imagination, you can make original furniture that no one else will have exactly the same.

The wood for making furniture should be selected dry, but not rotten, without traces of fungus or mold.

Material selection

If you do not take into account glass and plastic models made in designer style, then wooden stools are the best option. It is advisable to use oak, cedar or yew, but budget types of wood, such as alder or pine, are also suitable. Craftsmen from other countries successfully use jute, bamboo, hemp or even stones to make furniture. But if you choose the most pliable material, then it is, of course, wood. The finished pieces of furniture are convenient, comfortable and extremely beautiful.

Choosing material for the stool

If desired, you can combine different materials, for example, the upper part of the stool is made of wood, and the legs are made of metal. But to make beautiful and durable forged legs, you need to be a real master of hot forging. Such products will decorate a summer terrace, corridor or living room.

Chipboard, plywood and veneer

The upper part of the stool (seat) must be covered with high-quality and soft material, for example, faux fur, textiles or even sisal ropes. Although a more aristocratic and practical option is genuine leather. With it, the finished stool will look more expensive and attractive. If we talk about wicker, then this option will be most suitable for decorating a summer house.

How to make a three-legged stool

Types of stools

Despite their simplicity, stools can be made in different variations and used for different purposes. Therefore, before starting work, you need to decide on the type of stool you plan to make. Below are the main types of products.

Types of stools

Table. Popular types of stools.

| Type of stool, photo | Description |

| Children's stool | It can be used not only by children, but also by adults, so this option will never be out of place in the apartment. The children's stool has a compact design, it is lightweight and can be transported without problems. Even a child can carry the product. |

| Box stool | It functions not only as a stool, but also as a small storage box. The box stool is an ideal model for workshops, kitchens or other rooms with limited space. Such structures are made primarily of wood. |

| Folding stool | Such designs are mainly used in small country houses or apartments with small kitchens. If desired, the folding stool can be folded and hidden in a closet or under the bed. The folded product will not take up much space. |

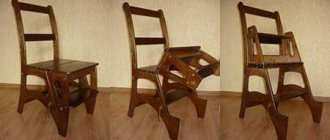

| Step stool | Another type of stools that you can make yourself. The product folds up and is used as a stepladder. A step stool can be used not only in private homes, but also in ordinary apartments, for example, during renovations or for screwing in a light bulb. |

| Dachny | An excellent option for a stool, made like a bench. The product is small, so it can be easily carried around the house. To make a country stool, you need to use only a wooden beam made of durable wood, because plywood is not suitable for such a design. |

On a note! When creating wooden furniture that will be used outdoors, it is necessary to make small gaps between the wooden elements. This is necessary to prevent moisture retention, which can harm the entire structure.

Simple round stool

Features of operation

Chairs made from pieces of logs can be used both in an apartment or private house, and outdoors as garden furniture. However, in order for the products to last a long time, when using them you must adhere to the following recommendations:

- Protect furniture items from moisture as much as possible. Do not place chairs on a wet surface and do not wash them with a stream of water;

- If cleaning is necessary, the product can be wiped with a dry or slightly damp cloth;

- It is not advisable to place hot items on chairs made from solid logs. This can cause damage to the wood.

When using the product as a piece of garden furniture, in autumn and winter, the chair should be stored in a dry and warm room. It is unacceptable to cover furniture with polyethylene for a long time, as this will lead to a greenhouse effect and damage to the wood.

A log chair should be periodically impregnated with stain

Periodically, the product must be updated by sanding it with sandpaper, impregnating it with stain and opening it with varnish. For home use, this will have to be done once every 3-4 years. For garden wooden chairs, the coating is renewed annually.

What do you need for work?

Regardless of the type of structure being manufactured, work must always begin with a drawing of the future project . It is advisable to consider several options so that you have something to compare with and ultimately choose one. The preparatory stage does not end here. You also need to take care of the tools.

Woodworking tools

So, to make a stool you need to prepare the following:

- softwood boards;

- furniture stapler;

- set of self-tapping screws;

- seat upholstery material;

- PVA glue for working with wood;

- sandpaper with different grain sizes;

- hand saw or jigsaw;

- plane;

- screwdriver and electric drill;

- safety glasses and work gloves.

Hand wooden plane

Be sure to prepare paint and varnish materials and decorative finishing products. It is also necessary to purchase various stencils, rollers and brushes for painting the finished product. Once everything you need is at hand, you can get to work.

Traditional simple stools

Timeless classics live not only in the facades of buildings. Time-tested solutions are also preserved in the designs of stools. Adding smooth lines to their appearance eliminates boring angularity.

In the photo below we see the classic version. Thanks to the rounded drawers and legs, it looks quite decent. The milled grooves on the legs also improve its appearance.

Simplicity has its own charm. Designers successfully play with this quality, creating deliberately rough, brutal products. Artificially aging furniture is not an easy task. The author had to work a lot on the product, the photo of which we see below.

The category of classic “stool design” includes designs with drawers under the seat. To do this, use wide side frames and hinged lids.

Children's stool puzzle

A great way to decorate a child's room is to make small stools in the shape of a puzzle. If you make several of these products at once, they can eventually be combined into one large bench. Below are step-by-step instructions for this process.

Step 1. Prepare supplies to create a stool. We need boards for making the top part and beams for the legs.

Consumables

Step 2: Place one board on the table and draw large puzzles on its surface. A simple pencil is used for this purpose.

Puzzles are drawn with a pencil

Step 3. Place the marked board on the second one and, aligning them, screw them together with self-tapping screws. To create children's stools, it is not necessary to use wood - plywood can also work.

The boards are leveled

Step 4. Screw the screws so that they do not stick out from above. This will make it easier to carry out further work.

The boards are twisted with self-tapping screws

Step 5 . Cut the material into several pieces - this will make it easier to cut out the puzzles. You can cut with a regular saw, but with a jigsaw all the work can be done in a few minutes.

Wood cutting

Step 6. Carefully trim away any unwanted parts of the wood, following the marks made in pencil.

Excess parts are cut off

Step 7. Sand the cut areas to make the surface smoother.

Sanding parts

Step 8 . Sand the cut out puzzles with sandpaper. This is necessary to eliminate all irregularities and chips. Upon completion of work, carefully inspect the product. Repeat the procedure if necessary.

Processing puzzles with sandpaper

Step 9 . Drill holes for the legs. They must be the same so that the finished chair stands level. Therefore, if you twisted two boards together, now you need to unscrew the top part of the chair and make a through hole in it.

Holes for legs are drilled

Step 10 . Connect the top and bottom parts of the future structure again. Use old screws for this.

Connection of upper and lower parts

Step 11 . Make marks on the blanks for the stool legs. It is advisable to make the stools low, so a leg length of 30 cm will be sufficient.

Future legs are marked

Step 12 . Using a jigsaw, carefully cut off the legs and sand the cut areas.

Legs are cut off

Step 13 . Make the first two crossbars, securing them with wood glue.

The crossbars are attached with wood glue

Step 14 . Mark, drill holes and glue the ledgers in the next two crossbars. All the steps performed are similar, so you just need to follow the workflow shown in the photo.

Trying on crossbars

A hole is drilled in the leg

Step 15 . Once the legs are ready, glue them to the base and press down with something heavy for a while. Good wood glue needs 3-5 minutes to completely harden.

The product must be pressed with something heavy

Step 16 . Using the same technology, make several stools at once, and then check them for evenness. If necessary, use a sander or plane. Try to connect all the puzzles together, thereby getting one bench.

Sanding finished stools

Step 17: Paint the stools. Since they are for children, it is advisable to paint them in different colors. Moreover, it is not necessary to paint the legs - just coat them with varnish.

Painting stools

Step 18 . Wait a little while for the paint to dry. Now the puzzle stools are ready. You can enjoy the result of the work done.

Ready-made puzzle stools

5 stools that turn into a bench

Another photo of the products

Manufacturing options

There are two ways to make a chair or stool from a solid log without using any fastening elements:

- By firing method;

- Cutting out the product with a chainsaw.

Both manufacturing options require subsequent grinding and finishing work.

Firing method

Using this method, you can easily make a stool from a log, or a piece of furniture such as a bar stool. To create a product, you need to take a hewn log of suitable height and diameter and make two cross-shaped cuts in it, perpendicular to each other. It is most convenient to work with a chainsaw. The depth of the cut depends on how tall the legs should be.

The log is placed in an open area and a little flammable liquid is poured into the center of the cuts. This could be machine oil or fire starter fluid. After this, the center of the log at the cuts is set on fire. The combustion is controlled by turning the log with the required side to the wind or by placing small twigs inside the log.

Using this method, it takes about 8 hours to make a stool.

Chainsaw

Using a chainsaw, you can cut not only a stool or bar stool from a solid log, but also a product with a backrest. In this case, the design can have both standard and unusual shapes. The final result depends on the desires and imagination of the author, as well as the geometry of the lumber.

A chair made from a log using a chainsaw

The work consists of gradually cutting out individual elements from a solid mass. In this case, either a chopped log or a log with bark can be used.

Stylish wooden stool

After practicing with simple types of stools, you can try yourself in making more complex designs. These include a “slat” stool, detailed manufacturing instructions for which are given below.

Step 1 . Make a sketch of all parts of the future structure on a piece of whatman paper. There are only two such details.

Sketch of future details

Step 2 . Using a utility knife or regular scissors, carefully cut out the drawn parts.

Drawn details cut out

Step 3 . Place the cut out templates on a large sheet of plywood and trace them. There should be a total of 11 thin parts, and 2 large structures.

Templates transferred to plywood

Step 4 . Carefully cut out the drawn parts using a jigsaw. To cut out the lower parts of the groove, it is recommended to use a regular jigsaw, as it is more convenient.

Next you need to cut out the parts

Step 5 . As a result, you should have the following elements. Once all the parts are cut out, you can proceed to the next steps.

Ready-made structural elements

Step 6 . Level the surface of the crossbars. To do this, they need to be folded together and secured with a clamp. File them first and then use sandpaper. The treated surface should be as flat and smooth as possible.

Fixed bars

Crossbars after processing

Step 7 . Start assembling the finished elements. To do this, use a small hammer and spacers. If necessary, treat the joints of wooden elements with wood glue. This will increase the strength of the structure.

Assembling the stool parts

Build process

If necessary, the joints can be treated with wood glue

Step 8 . Try to install each part on the same level as the others so that the structure looks even and of high quality. This is an important part of the work, so there is no need to rush when assembling wooden elements.

Parts should be installed at the same level

Step 9 . As a result, you should end up with a stool like this. Cover it with varnish, let it dry, and then use it for its intended purpose. This product will fit perfectly into any type of interior, so it can be placed in the living room, kitchen or country house.

Finished stylish wooden stool

Another photo of the result of the work

This stool will fit into any interior

Manufacturing technology

The manufacture of a chair or stool from wood is carried out in several successive stages:

- All necessary tools and consumables are prepared.

- According to the chosen scheme or planned project, the structure is manufactured.

- The finished product can be sanded and finished.

The fastest way to make a chair or stool is by using a chainsaw to cut the product from a solid piece of wood.

Tools and materials

To create a chair from a log, you may need the following tools and materials:

- Chainsaw;

- Ruler;

- Pencil;

- Mallet;

- Bit;

- Level;

- Grinder with an abrasive wheel or medium and fine-grained sandpaper;

- A log of suitable size;

- Stain or antiseptic;

- Varnish or furniture wax.

In the case where the product will be created from individual elements, you may also need screws or dowels, wood glue and a drill with cylindrical drills. And when using the firing method, a combustible mixture will be required.

Manufacturing

The principle of making a chair, chair or stool from logs or a solid log with your own hands depends on what final result is needed:

- Bar stool made of solid wood. It can be made by sawing with a chainsaw or firing. In both cases, for work you need a solid rounded or chopped log, the diameter of which is 30-40 cm. The height of the log is selected based on the size of the table. The optimal height is 70-80 cm. When manufactured by cutting, marks are made on the log 30 cm from the bottom and 10 cm from the top. These points will be the edges of the cut. Using a saw, a semicircular hole is cut out in the array. Its depth should be half the diameter of the log. Also, support for the feet in solid wood can be made by firing.

- Stool made from solid logs. For manufacturing, a log with a diameter of 35-40 cm is taken. The height of the array is 40 cm. When making a structure using the burning method, cuts are made in the necessary places and, wetted with fuel, they are set on fire. Also, a solid stool can be cut by making 3 equally spaced holes on both sides, 7 cm from the edge, no more than 2 cm deep. After this, diagonal holes, in the form of flower petals, are cut deep into the center. When all the points are connected by slits, the elements are disconnected. As a result, you can get two stools from one log.

- A chair with a back made of solid logs. For work, an array with a cross-sectional diameter of 40-50 cm is used. The height of the log can be different and depends on how high the back should be. It should be taken into account that the distance from the floor to the seat should be 40-45 cm. The optimal height of the log is 70-80 cm. During the work, only the seat with the back can be cut out. However, to create an original appearance, part of the support at the back of the chair can be sawn through. You can make any geometric cut, but its depth should not exceed 3/5 of the total diagonal of the log.

- The stool and chair can be assembled from separate logs of small diameter. To create such a structure, you will need 6 hewn or rounded logs 50 cm high and 4 logs about 35-40 cm long. The diameter of the logs can be 10-12 cm. To make the structure, 2 logs 50 cm high are laid parallel to each other and connected at a distance 5 cm from the top and 10-15 cm from the bottom with two 35 cm logs placed perpendicularly. The elements can be connected using dowels and wood glue, or long self-tapping screws. Another pair of legs is connected using the same principle. The reinforced legs are connected to each other by two logs 50 cm long. They must be placed at a distance of 10 cm from the top of the legs. A board measuring 50x37x2.5 cm can be attached to such a frame as a seat. Alternatively, the horizontal supports can be connected with slats made of small beams or logs, 3-4 cm in diameter. The step between such slats should not exceed 2 cm.

A chair with a back made of a solid log

When creating a chair, it is recommended to first clear the bark from the log. This can be done using a chainsaw, an ax or a mallet and chisel. It is permissible to leave the bark only if it does not have any damage.

Impregnation and polishing

The finished product must be sanded. This work can be done either using a grinding machine with an abrasive wheel of 140-200 microns, or with sandpaper. When using sandpaper, it is recommended to use medium to fine grit sheets. After thorough sanding, the surface of the chair should be smooth. In this case, the product may have irregularities if chopped logs were used for the work and they are provided for. However, there should not be any sharp elements on the surface.

After sanding, the product is impregnated with stain in several layers. You can use both colorless liquid and tinted solutions. However, if the created furniture will be used as garden furniture, it is better to use transparent impregnation. It will protect the wood from premature rotting and parasites.

If desired, the surface can be varnished or treated with furniture wax, additionally sanding the structure with soft leather.