“He has golden hands” - this is what they say about craftsmen who are able to assemble a miracle of modern technology from scrap materials. Despite the abundance of inexpensive ready-made equipment in stores, self-taught craftsmen successfully design and create household appliances, units for the garden plot and very effective devices for the workshop.

It turns out that you can also assemble a vacuum cleaner with your own hands. The main thing is to understand the design, find the necessary parts and allocate some free time. We offer three interesting models for independent experiments.

Making a cyclone using plastic buckets

When assembling a cyclone filter from a bucket, 2 plastic paint containers with a volume of 10 liters are used as a base.

Material with tool

In addition to two containers, you will need: a plumbing pipe and an outlet with a diameter of 32 mm, an air filter for a car, plywood, iron roofing sheet, fasteners, corrugated tube, glue, silicone sealant. Tools required: knife, felt-tip pen, jigsaw, screwdriver, compass, hacksaw, awl, glue gun.

Assembly

The assembly process has the following order.

- Remove the lids from the buckets and cut one of the containers in half.

- Make a narrow box out of plywood and place a plumbing pipe inside so that it holds very tightly. Fill the empty space between the walls and the pipe with silicone sealant.

- Step back 7-10 cm from the edge of the bucket and use cardboard and a sheet of paper to make a template that exactly follows the bend of the side surface of the container.

- Place the template against the box and mark the bend.

- Using a jigsaw, cut the structure along the line along with the tube.

- Place the box against the wall of the container and use a felt-tip pen to mark the hole for the pipe from the inside (you need to make sure that the pipe is at an angle inside). Cut a hole and install the pipe.

- Place the box with the pipe against the cutout, use an awl to pierce holes in the container around the perimeter of the plywood, screw in the screws and secure the structure to the bucket. Fill the joints of the container and box with sealant.

- Step back 70 mm from the bottom of the bucket, measure the diameter of the circle, transfer the dimensions to the roofing iron and cut out the circle, and then cut it in half from the middle and spread the edges at an angle of 300°. The resulting shaped insert should be placed sideways in the container. It is designed to create a vortex flow of sawdust, tiny dust and shavings, as well as to transfer debris to a collection container (half of the second bucket).

- Cut off the bottom of the bucket with the tube and insert it into the storage tank.

- Cut a hole with a diameter of 32 mm in the lid of the bucket, into which insert a pipe 30 cm long, leaving a 7 cm long piece outside. The pipe must be glued and the cracks sealed with sealant.

- Attach a corrugated tube with a nozzle for removing debris to the side tube.

- Attach the vacuum cleaner hose to the section of pipe coming out of the cover. Place a universal car filter on the tube from the inside of the cap.

- Measure the diameter of the filter from the outside, cut out a tin plug of the appropriate size with three tongues. Fix three tin strips with bent upper ends onto them with rivets or screws.

- Attach the bent ends of the strips to the lid from the inside. Install the plug into the filter hole from below and seal it. That's it - the cyclone filter is assembled.

https://youtube.com/watch?v=nOO_PKw3pEs

Features of work

When the cyclone filter assembled in this way becomes clogged, it is pulled out of the garbage receptacle and thoroughly cleaned. It is recommended to service the car filter as often as possible, otherwise it will become completely clogged and cleaning efficiency will decrease.

Hose design features

Most corrugated hoses for cleaning equipment are a tube made of elastic material (polypropylene).

The tube is usually no more than 1.5 meters long. Thanks to the corrugated surface, the accessory has the ability to stretch within small limits.

Classic design of the working hose of the vacuum cleaner. Two movable pipes are connected to each other by a corrugated elastic tube. This design makes it easy to manipulate the accessory when cleaning.

One end of the flexible conduit ends in a short piece of rigid plastic tubing. This part is a connection link with the extension rod or directly with the working nozzle of the vacuum cleaner.

The opposite end of the hose is equipped with a short locking pipe, through which a locking connection is formed with the vacuum cleaner module. This lock pipe is actually also a continuation of the corrugated tube.

Traditional break points for vacuum cleaner hoses are the area where the corrugated hose meets the process end. Cracks or tears form due to increased load on this area during the cleaning process

The practice of using vacuum cleaners notes that it is along the junction lines of the elastic corrugation with the end rigid elements that most often a rupture occurs, and a breakage of the hose is considered one of the most common breakdowns of a vacuum cleaner.

Meanwhile, the formation of even a small rupture in the hose leads to a significant loss of efficiency of harvesting equipment.

Do-it-yourself construction vacuum cleaner for cement dust – Metalworker’s Handbook

07.03.2018

3253

Repair and construction sites are characterized by accumulations of dirt and dust. Therefore, for high-quality cleaning of floors and walls, it is better to use professional models.

When it is not possible to buy a construction option, we try to get it at home from improvised materials and an old unnecessary vacuum cleaner.

A homemade construction unit will help cope with the following contaminants: wood and metal shavings, debris from repairs and dust.

DIY construction vacuum cleaner: from a household vacuum cleaner or from improvised means

During construction and repair work, a large amount of waste is generated associated with the processing of certain materials.

Construction waste combines both small dust particles and large fragments, so an attempt to use a regular household vacuum cleaner, at best, ends in rapid clogging of the internal filters, and in the worst case, failure of the device itself.

For those who are professionally involved in repairs, the only correct way out of the situation is to purchase a high-quality industrial vacuum cleaner designed for cleaning construction waste.

If the repair is local in nature, the costs of such expensive equipment for rare use are unjustified.

In this case, you can upgrade your household vacuum cleaner or make it yourself, which is what will be discussed in this article.

How to make a construction vacuum cleaner

It’s quite possible to make a homemade construction vacuum cleaner yourself.

To make a device that captures fine construction dust with the ability to clean the air, you can use an old household vacuum cleaner as a base.

To collect large fragments of construction waste or cement dust, you can assemble a structure by making it from available materials.

From a household vacuum cleaner

To upgrade the version of a vacuum cleaner from a regular one to a construction one with a water filter, you need to take the old model of the device. In addition, you will need:

- plastic bottle 5–6 liters;

- old aluminum pan;

- a small piece of corrugated tube;

- metal plate with a pipe;

- tools: soldering iron, construction knife, screwdriver.

The first step is to replace the internal filters. Instead of thick paper materials, you need to install foam rubber sections cut to size at the input of the device.

The filtration system at the outlet of the device will be replaced. The standard filter must be removed. In its place, a metal plate is attached with self-tapping screws, cut to the size of the seat, with a welded nozzle for the hose and a through hole at the place of its attachment.

A plastic bottle is supposed to be used as a reservoir for the water filter. To add strength to the structure, it is necessary to select a solid container, which will also be fixed to the vacuum cleaner body from the back using self-tapping screws.

The bottle should fit tightly inside this container. For these purposes, you can use an old aluminum pan of suitable diameter.

Also, a handle with two holes is attached to one side of the metal utensil, and the third is drilled into its body at the bottom.

Causes of defects

Cracks, tears, and punctures on the body of the vacuum cleaner hose can appear for various reasons. However, the main reason, of course, should be considered improper handling of this part.

What user actions lead to the appearance of defects on the body of the corrugated tube?

Take a closer look:

- Towing a vacuum cleaner from place to place via a hose.

- The tube is bent at unacceptable angles during the cleaning process.

- Inaccurate use when cleaning objects with sharp edges.

- Storage not according to instructions.

The natural cause of the formation of defects should also be considered the expiration of the product’s service life, wear, and poor quality of the material.

Often, violation of operating rules by owners of harvesting equipment leads to the appearance of defects on the body of the corrugated hose. When working with a vacuum cleaner, it is not recommended to use physical force directly on the hose

Towing a vacuum cleaner from place to place by pulling the device by the working hose is a fairly common practice.

At the same time, many owners of vacuum cleaners perform such “tricks” completely unaware of the impending consequences. Meanwhile, the instructions for any vacuum cleaner clearly state that you cannot do this!

Bending of the pipeline at an unacceptable angle can occur when the owner of a vacuum cleaner, in the heat of cleaning, seeks to reach areas that are theoretically inaccessible due to the operational and technical parameters of the cleaning equipment.

This bending of the corrugated sleeve contributes to the rapid appearance of a crack or rupture. Therefore, manipulations with the hose during vacuuming should avoid bending the corrugation at steep angles

Several times such attempts can end quite successfully. However, the strength of the material with respect to unacceptable loads is not unlimited. Therefore, at the most inopportune moment, the pipeline will simply burst in the place where there was an unacceptable bend.

Cleaning work can be carried out under different conditions. For example, when cleaning furniture whose frame has metal parts with sharp edges. If the hose is handled carelessly under such conditions, there are all the prerequisites for cuts to appear on the body of the corrugation.

Finally, the rules for storing cleaning equipment, specifically described in the vacuum cleaner instructions, also cannot be violated, since violation here is one of the reasons for the malfunction of the vacuum cleaner hose.

The storage conditions of household cleaning equipment accessories directly affect the quality of the material from which the same working hose is made. Therefore, violations of storage rules contribute to the appearance of defects

Thus, storing the device together with accessories, or separately accessories, at a temperature below the recommended one leads to a decrease in the strength of the corrugated tube material.

Sudden temperature changes, loaded conditions, and unacceptable bends are also critical for the hose material.

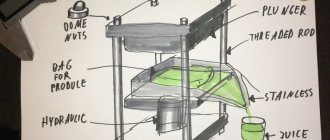

Key components of the construction vacuum cleaner (SP) design

It is difficult to imagine the design of an industrial vacuum cleaner without a vortex compartment, the structure of which is presented below.

Before starting independent work on the manufacture of a construction vacuum cleaner, it is necessary to analyze the design specifics of this equipment.

Industrial joint ventures are characterized by solid power and impressive weight. The use of equipment with such characteristics can significantly increase the period of uninterrupted operation. However, the more powerful the electric drive power in such a device, the more serious its mass. This factor determines the creation of industrial modifications on platforms with small wheels. This measure makes it easier to move and use the unit.

The waste collection department must be made of the highest strength material.

The best option is rust-resistant steel (stainless steel). Its surface is additionally coated with an antibacterial agent.

The design must include a filter component. You also need to equip the equipment with a device that automatically notifies you when the container is filled with garbage.

In order for the device to work for a long time and without interruptions, it must have a special cooling technology. It will prevent overheating during operation.

There are usually two additional components: a mechanism for reducing the noise level from a working device and backup garbage tanks.

How not to burn a household vacuum cleaner

Most modern models have a built-in safety valve. It shows when the filters are already clogged and at this moment additional air flow opens.

True, this is already considered an emergency situation. Your task is not to wait for the valve to operate, but to use a slightly different trick.

Some devices have a draft regulator directly on the handle in the form of a hole that opens or closes. It should just be opened slightly for any type of work.

If you do not have such a factory regulator, you can drill a small additional hole with a diameter of 12 mm in the bucket lid itself.

Well, and most importantly, do not forget that any household vacuum cleaner, no matter how you modernize it, has a certain period of continuous operation. Be sure to record the start time and do not work longer than the prescribed period.

That is, just take breaks. At least to shake the homemade filter. And it just shakes itself along with the bucket.

When the dust container is significantly full, open the lid of the bucket and lightly pull the tube out from the guides at the bottom of the bag.

It will open and the debris and dust can be removed. After that, put the entire structure back together and continue working.

Normal operation of the bag is enough for about three full fillings. After this, cement dust in the fabric itself begins to greatly inhibit the air flow.

You will have to either replace the filter with a new one, or not just shake it, but thoroughly clean it of all fine debris and continue working as if nothing had happened.

Which is better to buy a garden vacuum cleaner for collecting leaves and debris in 2022

Finding yourself in a store or in the vastness of online resource catalogs, your eyes literally run wild. The number of available offers in various price segments is growing year after year, and the design and capabilities of devices are improving. However, the risk of purchasing a low-quality device is also increased.

To reduce the likelihood of such a development of events, we suggest paying attention to several interesting models selected by the editors of Tehno.guru especially for our readers

Among the electric garden vacuum cleaners for cleaning leaves (corded and battery-powered):

| Model | Construction type | Operating modes | Average price (as of April 2022), rub. | Appearance | Tehno.guru editorial rating, point |

| Garden vacuum cleaner-leafer Stanley STPT600 | Manual | Blowing/suction | 3 500 | 8,8/10 | |

| Portable unit - Ryobi RBV3000CSV leaf blower | Backpack | Blowing | 9 490 | 9,4/10 | |

| Vacuum cleaner-blower KRÜGER VBK-3000 | Manual | Blow/suction + mulching | 5 100 | 9,5/10 | |

| Leaf vacuum cleaner with shredder Bosch ALS 25 | Manual | Blowing/suction + grinding | 6 000 | 9,7/10 |

Among the electric models, we can especially note the vacuum cleaner-blower KRÜGER VBK-3000 (Germany) 3000 W.

The device is as comfortable as possible to use – it comes with a shoulder strap, which redistributes the load from the hands and allows you to work with the blower for a long time. The Kruger garden vacuum cleaner has a mulching function. The device operates in two modes – blowing and suction. The spacious 45 liter grass catcher holds a large amount of waste. The operator will not have to constantly be distracted by cleaning the bag - simply replace it with another grass catcher, additionally supplied with the device.

Gasoline garden tools for collecting leaves and debris include:

Read also: The largest pear varieties

| Model | Construction type | Operating modes | Average price (as of April 2022), rub. | Appearance | Tehno.guru editorial rating, point |

| Vacuum cleaner for cottage and garden Champion GBV326S | Manual | Blowing/suction + grinding | 7 600 | 9,1/10 | |

| Garden blower Ryobi RBL26BP | Backpack | Blowing | 9 700 | 9,3/10 | |

| Professional grade equipment Cub Cadet CSV 050 | Wheeled | Suction + grinding | 56 800 | 9,8/10 |

Reviews about the Champion GBV326S model:

More details on Otzovik: https://otzovik.com/review_6182637.html

How to adapt the device for machines and tools

To be able to draw in waste when using manual and stationary tools, you will need a system of adapters. Typically, a vacuum cleaner hose ends in a curved tube, the diameter of which is comparable to the fittings for dust bags of power tools. As a last resort, you can seal the joint with several layers of double-sided mirror tape wrapped in vinyl tape to eliminate stickiness.

With stationary equipment everything is more complicated. Dust extraction systems have very different configurations, especially for homemade machines, so we can only give a few useful recommendations:

- If the machine's dust extractor is designed for a 110 mm or larger hose, use plumbing adapters with a 50 mm diameter to connect the corrugated hose of the vacuum cleaner.

- To connect homemade machines to a dust catcher, it is convenient to use press fittings for 50 mm HDPE pipes.

- When designing the dust collector housing and outlet, take advantage of the convection flow created by the tool's moving parts for greater efficiency. For example: the pipe for removing sawdust from a circular saw should be directed tangentially to the saw blade.

- Sometimes it is necessary to provide dust suction from different sides of the workpiece, for example, for a band saw or router. Use 50 mm sewer tees and corrugated drain hoses.

Advice from professionals

To assemble an industrial vacuum cleaner yourself, experts advise using a motor whose speed exceeds 6 thousand. To do this, you can remove the motor from an old household vacuum cleaner, washing machine, or refrigerator compressor. The engine of a kitchen dishwasher is rarely used: such units cannot withstand heavy loads and quickly burn out.

A metal or plastic bucket is used as a body. You will need to make a hole in the bottom of the tank to allow air intake. The container is required for garbage collection. The following tanks can be used for this:

- ordinary;

- container with water;

- cyclone compartment.

Experts advise making industrial vacuum cleaners with a cyclone chamber at home. If necessary, the device is equipped with a water tank. These industrial units are used for dust collection. To make a high-quality device, use a special corrugation or corrugation from an old vacuum cleaner. Otherwise, the tool will make a lot of noise during operation.

Since about 95% of dust gets into the homemade device, a powerful engine is used to assemble it. The higher this indicator is, the heavier the debris it will be able to absorb. An important point when making an industrial vacuum cleaner yourself is the degree of vacuum of the engine. This indicator should be as high as possible.

The volume of the internal container or tank should be medium. Large containers are impractical and ineffective. When making a tool yourself, it is impossible to take into account the degree of filtration of dust and dirt.

When purchasing a finished product, much attention is paid to the body of the unit. Experts recommend giving preference to construction vacuum cleaners with a metal body

In this case, special attention is paid to the attachments that come with the kit: the functionality of the industrial tool depends on their number.

During construction work, or during the processing of wooden products (this is not uncommon even in a modern apartment), a large amount of dust rises into the air. It settles on all horizontal surfaces; it is impossible to remove this debris with a broom and a wet cloth.

Applying a bandage

Such repairs are performed for punctures, ruptures, or cuts in the hose. A bicycle inner tube is used as a bandage, as it can stretch well.

Expert opinion

Alena Tsarevskaya

Subpage for an expert

If during repairs you take a chamber of smaller diameter than the hose and glue it, this will allow you to tighten the joint more tightly and firmly.

Repairs are carried out in the following order:

- Cut off the damaged area.

- Clean and degrease the cuts.

- Prepare a piece of bicycle tube 80-100 mm.

- Place this piece further than the damaged part.

- Apply glue to the ends of the cuts and the surface at the junction.

- Put the camera on, completely covering the joint.

The simplest model of a vacuum cleaner

For those who really don’t like to tinker with homemade products, we offer the simplest version of a vacuum cleaner. In general terms, the device consists of a plastic bottle. There is a hose on the neck to suck up debris. Inside the container, a motor with blades is attached to the bottom. A filter is installed between the fan and the inlet.

The materials you will need are a 1–1.5 liter PET bottle, a piece of corrugated hose, copper wire, a nylon stocking, batteries and stranded wire. The motor can be taken from a children's toy, but they are usually weak. In order for the vacuum cleaner to suck up debris well, it is better to remove the motor from a broken tape recorder or other electrical appliance.

The instructions for assembling the vacuum cleaner consist of the following steps:

Making a homemade product starts with the body. The bottle is taken from the Sprite drink. The choice is due to the irregular shape of the container, inside of which it is more convenient to place the parts. At the expansion site, the bottle is cut with a sharp knife. The top will form a lid.

The second part of the bottle narrows a little, and near the bottom it expands greatly. You need to randomly cut a narrow strip from the cut point. The narrowed part will easily fit inside the lid.

The housing is set aside and manufacturing of the fan begins. A durable and lightweight propeller can be made from a tin can for beer or drinks. Use scissors to cut off the bottom and top. The resulting cylinder is cut lengthwise, unbent and leveled to form a rectangular piece of tin.

A circle is drawn on the blank using a compass. The diameter of the propeller and the inside of the bottle near the bottom should almost coincide. Leave 2–3 mm for the gap so that the blades do not touch the walls.

A circle is cut out of tin using scissors. The blank is drawn with a pencil, dividing it into 8 identical triangles. Cuts are made along the lines, not reaching the center 10 mm.

The cut segments are bent at an angle. When rotating, the blades should draw in air, not push it out. In which direction to bend the petals depends on the direction of rotation of the motor shaft. Everything can be experienced experimentally. If the fan pushes air out, the petals can easily be bent in the opposite direction.

A hole is pierced in the center of the propeller with an awl. The impeller is placed on the motor shaft and secured with hot glue or a screw if there is a thread.

When the fan is running, air should come out from the bottom of the bottle. Holes are burned with a soldering iron, drilled or cut out with a knife.

The back of the motor is placed in a plastic plug. The wires come out on the side. The motor is glued to the plug or screwed with bolts if the body has threaded holes.

Using a hot gun, a plastic cap with a motor is glued to the inside of the bottom of the bottle. The engine is located strictly in the center. They try to turn the fan so that the blades do not catch the walls of the bottle.

A filter is made to protect the motor from dust. A ring is bent from thick copper wire to the diameter of the bottle. A piece of nylon stocking is pulled over the frame.

The filter is inserted inside the bottle in front of the motor. The ring should fit tightly. On both sides of the filter, the wall of the container is pierced with pushpins. Stoppers will prevent the ring from moving. To prevent the buttons from falling out, wrap the area of the bottle with electrical tape or tape.

A suction hose is placed on the neck of the second part of the bottle. It can be made from a piece of plastic corrugation for laying electrical wiring. The connection between the hose and the neck is tightly wrapped with electrical tape. Working nozzles are made from any plastic tubes.

The two parts of the vacuum cleaner are done and just need to be connected. The wires from the electric motor are routed through the ventilation hole on the bottom. You can connect it to the power supply, but pulling the wires behind the vacuum cleaner is inconvenient. It is better to glue a plastic battery compartment to the outer part of the bottom. You can take the mobile vacuum cleaner with you on the road.

Preparatory actions

When you have stored all the materials to make a cyclone vacuum cleaner with your own hands, you can begin preparing the individual parts. First, in the upper part of the barrel, you need to cut an ellipsoidal hole for the inlet pipe, which will be attached to the wall of the barrel at a tangential angle, going inside by 10-15 cm. A hole of round diameter must be made in the lid of the barrel according to the size of the inlet coupling of the adapter from a sewer pipe 40X50 mm .

As an option, you can make a removable cyclone with your own hands with a home vacuum cleaner, if you use a piece of plastic pipe 40X100 mm, and insert the pipe into the lid, which will tightly close the larger diameter.

What is a cyclone for a vacuum cleaner

The dust collector or container for collecting dust and dirt is an important part of any vacuum cleaner. They come in several types: a fabric or paper bag (disposable or reusable), an aqua filter or a cyclone. The latter is most often installed in models intended for dry cleaning.

The cyclone filter for a vacuum cleaner is an air purifier. The system filters air using inertia or centrifugal force. Its operating principle is simple:

- Air is sucked in.

- A cyclone forms a spiral-shaped air vortex.

- Under the influence of centrifugal force, all dirt and debris are first pressed into the walls, and then settle as sediment on the filter. On average, a cyclone purifies the air by 97%.

Important! Such vacuum cleaners have more than one filter. First, the air flow passes through the primary cleaning (plastic mesh), after the cyclone - through the HEPA system (high-performance filter that traps the smallest dust particles and allergens). Due to their high efficiency, vacuum cleaners with a cyclone filter are used in various areas: at home, in construction, in refilling cartridges, in wood processing and paint shops, etc.

d. The cyclone is used wherever it is necessary to quickly and thoroughly remove fine dust and there is no possibility of frequently changing bags or water from the aquafilter

Due to their high efficiency, vacuum cleaners with a cyclone filter are used in various areas: at home, in construction, when refilling cartridges, in wood processing and paint shops, etc. The cyclone is used wherever it is necessary to quickly and thoroughly remove fine dust and there is no possibility of frequently changing bags or water from an aquafilter.

Why do you need a cyclone filter?

Construction, metal or wood dust appears to be completely harmless. But this is only at first glance. Working in a room where a lot of dust has accumulated can harm the respiratory system and cause serious illness. And the instruments will deteriorate from the endless stream of garbage. There may be several reasons:

- Dust gets into the tool and onto the lubricant inside it. As a result, it overheats and fails.

- If the device has moving parts, then dust may well hinder their operation and also lead to breakdowns in the future.

- Dust can clog special ventilation holes that are designed to cool the instrument. The result is overheating and breakdown again.

The cyclone filter will ensure the collection of any waste in production without harm to the vacuum cleaner.