When building a house and landscaping a site, it is often necessary to make round holes in the ground. They are needed when constructing a fence - for installing poles, when building gazebos, installing arches and other light utility structures. The same holes, but with a larger diameter and depth, are required when constructing a pile foundation. These holes are made with a motorized or hand drill. There are plenty of them in stores, but many people prefer homemade ones: they are often more productive and reliable than factory-made products. In addition, you can make a drill with your own hands of any design, and there are many of them.

Modifications

Before making your own, you need to consider various models of hand-held eartheners. Taking a suitable design as a basis, one should determine its characteristics: productivity, cutting force, ability to work with hard soil. Perhaps for individual use you will have to make a combined device that combines successful solutions from several models.

Basic diagrams of auger tools

The basis of the earth rotor is the screw part - the auger. It is made welded from thin-walled steel disks. The latter are cut from the center to the outer diameter and bent. As a rule, from 1 to 4 rings are taken to make a screw. The volume of soil that can be extracted in one pass depends on their quantity. However, with a larger number of rings, the drill is more difficult to rotate and remove from the ground. The soil is cut by the auger itself or additional blades. In the first case, the working edge quickly dulls on plant roots or stones. And the blades are made of durable steel and do not require periodic sharpening.

Aftercare

Extension sections designed for deep drilling are assembled before work and disassembled immediately after completion. It is advisable to regularly lubricate all bolted and coupling connections of the drill and additional sections - oil or grease will not allow them to “stick” to each other. If the drill penetrates the ground tightly, then its blades and cutting edges are cleared of adhering clay and wound roots, which significantly impede the advancement of the tool during drilling.

Making a handheld excavation auger for personal use is not difficult. You just need to be able to use welding, a drill and other everyday construction tools of many summer residents, as well as understand a little of the drawings.

Materials and tools required for making a drill

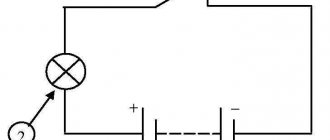

Manual drilling diagram.

Before you start working directly, you should stock up on all the necessary materials and tools. The master will need:

- a piece of gas pipe (for making a vertical stand);

- a fragment of high-strength sheet steel (for the production of propeller blades);

- a piece of smooth reinforcement (metal rod) with a diameter of 16-20 mm (for making a handle);

- welding machine;

- welding clamp;

- lathe;

- emery wheel;

- electric drill;

- set of metal drills;

- angle grinder (grinder) with a metal disc;

- gas key;

- assembly vice.

Welding and finishing

The general sequence of actions for making a welded drill can be as follows:

- mark pipes and steel sheets according to the drawing (using a construction marker);

- cut them according to these marks using a grinder;

- make marks at the joints of the handle, axle and blades (the axle pipe of the future drill should fit into the newly cut blades without noticeable effort);

- Using a welding machine, weld these parts in the required sequence, observing the drawing proportions and dimensions.

The final processing of a homemade drill is as follows:

- Sand the drill - remove any burrs, straighten the welds (if any irregularities remain). The tool, when put in order, is easy to use, does not hurt your hands and does not cling to work clothes.

- Place pieces of hose onto the handle (if the drill is manual). The ends of the horizontal crossbar (gate) must fit into the hose with force.

- Sharpen the cutting edges. This will allow you to drill the soil more efficiently.

- Paint the instrument after production.

Any paint dries in a maximum of two days. The product is ready for use.

Step-by-step production of a drill

Draw a circle on a metal sheet, marking the center. This will be the blade. Next, this circle needs to be cut out using a grinder, and then a cut line must be drawn that runs along the diameter line. Then we draw a cutting line, which should correspond to the circumference of the collar. The resulting disk must be divided into two parts and holes for the knobs must be cut.

At the end of the pipe, which will act as a wrench, we use a grinder to cut four longitudinal lines, 3-4 cm in length. After this, you need to form a tip from them using a hammer, while you need to collect the cuts at the very center of the pipe. The resulting tip must be processed by welding and ensure that the knob does not become clogged with soil during operation.

The next step is to connect the knob to the disk by welding. This is done at a distance of 5 cm between them and at an angle to the plane of rotation of 20 degrees.

Next, we proceed to the extension pipe, which should be equipped with a handle. This part must be welded in the letter “T” and be sure to weld the amplifiers to it in the form of a “kerchief”. The workpiece is threaded through the driver, and a hole is made through them so that the parts can be fastened with a pin. Several such holes need to be made in order to be able to adjust the length of the product.

The work ends with sharpening the blades. The edge of the cutter must be processed in such a way that when rotating, the tip of the blade is directed downward.

Protective covering

To avoid rust on the parts of a homemade pole drill, you need to thoroughly clean them with sandpaper and treat them with a primer and phosphating solution. After this treatment, the finished product can be painted.

When using the device, you need to disassemble it after each use and clean all connections from dust and dirt, and also coat them with a special lubricant that repels water. You should not miss this moment, since proper care of the tool will be a good prevention of bolt jamming and will allow it to work smoothly for a very long time.

Drilling a well using an ice auger

There is a drilling method that will require minimal financial investment. This is manual drilling of wells using an ice drill. The tool is used as a drill, and homemade rods are used to build it up.

The knife of the ice ax will serve as an auger, and steel pipes with a diameter of up to 25 mm can be used as extension rods. To make the process go faster, reinforced cutters are welded to the winding edges of the improvised auger

Among other things, the work will require casing pipes to form the wellbore, a shovel and a device for removing cuttings from the site.

Drilling with an auger made from an ice drill includes the following operations:

- Preparation. We dig a guide hole: a hole two bayonets deep.

- We lower the drill into the resulting recess and begin to screw it into the ground, using the rule for tightening the screws. It should be remembered that after every three or four revolutions the tool is removed to the surface and cleaned.

- After the first meter has been penetrated in depth, we begin to form the trunk. To do this, a casing pipe is lowered into the well; its diameter should be slightly larger than the diameter of the drill. It is best to choose lightweight plastic parts equipped with threads for connection.

- When the drilling tool begins to descend into the face to its full height, we attach an extension rod to it. This can be done in two ways: screw the part if there is a thread, or add it using a steel pin-rod if there is none.

- During the work, we continue to form the casing string. As soon as about 10-15 cm of pipe remains on the surface, we attach the next one to it. The connection must be strong. This is usually done by threading or soldering.

- We periodically check the verticality of the trunk. If the drill begins to hit the walls of the casing, we level the structure using wooden wedges. They get stuck between the soil and the casing.

- After water appeared in the well and the decision was made to stop work, we install a filter and carefully fill the gap between the soil and the casing with gravel.

The casing can be installed after completion of drilling work. In this case, plastic pipes are inserted into the well and connected in series after the previous part is lowered down. This is not the most rational way, since you will have to clean the face of sludge again.

Plastic pipes are very light, quite durable and inexpensive, so they are most often chosen for constructing a well casing

Experience shows that drilling a well with your own hands is quite possible, although quite labor-intensive. You should take the matter seriously: choose the right drilling method, select the necessary materials, study the instructions and then get to work. The result of your efforts will be clean water from your own well on the site.

Auger drill

Due to the large number of turns, an auger auger creates significant resistance, that is, it is much more difficult to work with it than with a garden auger. But augers are used mainly in the presence of a mechanized drive - when making a drill for deep wells - for water, for installing underground probes for a heat pump, etc.

This is what an auger drill looks like

To make a homemade auger drill, you will need several metal disks. The number of disks is equal to the number of turns. The disks are cut identically, a hole is cut in them in the center for the rod, as well as an identical sector - so that they can be welded.

A sector is marked in the rings and cut out

The discs are welded on one side, then, slightly stretching the resulting accordion, the seam is welded on the other side. Rings are welded on the outer disks. The welded discs are placed on the rod, the lower edge is welded.

It turns out to be such a big spring

Next you will need a winch. The blank for the auger is secured, the winch hook clings to the ring and is stretched to the required length, after which the auger is boiled.

Almost done

Final assembly

Before drilling wells, a deep drill is assembled gradually, plunging deeper into the underlying layers of soil. Before further drilling, the master will check whether the next section is securely fastened: if it is accidentally unscrewed, it will be extremely difficult to get it (and other sections, including the drilling section) without special tools from an already drilled shaft

Disassembling the drill is carried out in the reverse order, being careful not to drop the undisassembled part to the bottom of the channel

Each of the extension sections (pipes) is welded to its coupling on one of the sides of the latter: this will facilitate and simplify assembly and reduce the likelihood of unscrewing during deep drilling. Before the first use, the drill is ground: the resulting irregularities, for example, after welding, are removed in order to reduce injuries.

How to make a cable impact drill

The mechanism of the impact drill is quite simple in design. To manufacture and assemble it, you will need the following material resources and equipment: a thick-walled pipe of the required dimensions, angles, sheet steel, a tape measure, an angle grinder, a welding machine and a manual or automatic winch. To make and assemble an impact drill, you should perform some steps in the following sequence:

- A tripod is assembled with a height of no lower than 2 meters.

- The top of the tripod is equipped with a special unit that allows you to install a manual or automatic winch.

- A percussion instrument is being made.

To do this, you need a pipe with an outer diameter that matches the diameter of the future well. A piece of thick sheet steel is welded onto one end. Then a hole is made in it in order to fix the cable. And at the impact end of the pipe, sharpening is made around the entire circumference. To ensure the strength of these elements, they need to be hardened. The instrument should also be equipped with additional weights.

The basis for placing the working tool is being prepared. A shallow hole is cut in the ground. The wireline drill is then mounted on a tripod and positioned so that it can be completely immersed in the prepared area under its own weight.

The procedure for carrying out drilling work

Following the sequence of work ensures excellent results:

- Assemble the hand drill according to the instructions. Equip the main element with a handle (the initial stage of drilling takes place without the use of an extension rod).

- Remove the surface layer of soil 10-15 cm.

- Place the TISE foundation drill on the formed platform.

- Start rotating clockwise, avoiding significant force - a hand drill goes deep quite easily. Avoid side loads to avoid deformation of the rod.

- After filling, remove and completely empty the storage tank from the soil. Remove any large stones by hand, after loosening the soil. Chop large plant roots and trim with pruning shears.

- Compensate for the lack of depth with an extension rod. Repeat the procedure until the required depth is achieved.

- Start widening the bottom of the pile hole. Set the required position of the folding paddle. Use a special cord that lifts the device upward. Downward movement occurs under the influence of its own weight. Lowering causes cutting of the soil filling the soil receptacle. Repeat the operation many times.

Which drill is better?

Drills for drilling wells come in two types: spiral (disc, auger) and spoon. Each type has its own advantages and disadvantages and is used for a specific type of soil.

Spiral drill - advantages and disadvantages

The versatility of the spiral type allows it to be used not only for constructing wells, but also for other gardening and construction work.

Advantages:

- Wide range of applications. Used in the construction of fences, pile foundations, planting, etc.

- Fast and easy penetration into the ground.

- At shallow depths, soil is automatically removed from the well using a drill auger.

- Easy to make with your own hands.

Flaws:

- To excavate the soil, it is necessary to disassemble the boom.

- Not suitable for loose and rocky materials.

- Small passage depth.

- You have to frequently clear away the worked-out soil.

Spoon drill – is it worth choosing?

The advantages of a spoon drill over other types of hand drills justify its use.

- Used for loose soils.

- Soil excavation is carried out by the lower and side edges of the drill.

- The width of the passage is greater than the diameter of the drill, which makes it easier to remove it from the well.

- You can rotate the drill not only manually, but also with a drill or hammer drill.

- The simplest design and manufacturing method.

Expert advice

- To make drilling a well easier with hand tools, you can use a bailer. It makes it easier to lift the soil to the surface, since the rock is collected in a special container.

- If a hand drill cannot be lifted to the surface, you can build a lever on a raised platform from barrels or logs. Thus, the drilling process will not only be facilitated, but also accelerated, because the volume of soil lifted up can be increased.

- To reduce the labor intensity of work and speed up the drilling process, special devices can be used to twist the drill.

- Homemade drills can be useful to you after the construction of the well. For example, you can use them to dig a foundation for fence posts, make pile foundations, and plant plants.

How to make an auger drill

You can make your own spiral drill of 2 types for rotary drilling of wells: with a spiral cutting element, with a hemispherical disk knife. For work you will need:

- A metal rod or strong pipe is the base, a hollow pipe of larger diameter is for the container on the rod of the spoon.

- Couplings for connecting rods, metal handle - a piece of reinforcement, rod, up to 40 - 50 cm long.

- Metal sheet if a spiral knife is planned.

- Steel discs with teeth from an electric saw.

Metal circles of different diameters are suitable for forming a cutting surface

Spiral simple and two-stage drill: drawings

How to make a classic drill with a spiral band knife for a sand well? It is difficult to make such a tool with your own hands without special machines for working with metal. The difficulty lies in the preliminary hardening and bending of the metal strip. It is necessary to select steel with a thickness of 1.5 - 2 mm. Next, the hot strip is bent on a machine, giving the strip a spiral shape.

A spiral drill with a long cutting band cannot be made without equipment

Only after this is the tape welded to the base. During the connection, symmetry is monitored: the turns must be positioned strictly parallel to each other and at a certain angle to the horizontal line. The edge of the tape is sharpened and the surface is painted.

Drawing of a simple drill with two knives at an angle

Starting from the simplest design, you can improve the tool and make a drill that is suitable for drilling shallow wells of different diameters.

For production, take 3 disks of the same thickness with different diameters. Each is cut into 2 halves, one edge (bottom) is sharpened. Holes are drilled in all parts to connect the petals.

Drill parts

A circle of smaller diameter is welded to the base so that the edges of the two halves form an angle of 30 degrees. Larger diameter knives are attached to the upper one using nuts and bolts.

Ready-to-assemble drill with replaceable blade sets

The rod is formed with thread cutting or a coupling with finished thread is welded to the upper edge: in this case, there is no need to install protection against unwinding during operation.

Bringing the rotary drill into working condition

It is not enough to learn how to make a drill for a well yourself. It is necessary that the finished drill can be used to perform the work. To do this, it is necessary to equip it with a handle or handle, as well as a detachable drill pipe.

Making a comfortable handle

The handle is an important structural element. It is necessary so that the drill can be rotated comfortably. The design of the handle is also not as simple as it seems.

It can be envisaged that it will be operated by one person, but sometimes more people may be involved in drilling operations. The complexity of the process depends on the quality of the soil and the depth of the future well.

Before you make the handle of your drill, you need to decide whether you will rotate it yourself or invite someone to help you

The handle is made of rolled metal, which has a decent margin of safety. After all, this part of the drill needs to withstand significant loads without springing or damping the applied forces. Welding is used to connect the handle and the upper edge of the split pipe.

Construction of a detachable drill pipe

The drill is a multifunctional tool. With its help, you can not only build a well, but also, for example, dig a pole. If you use it for gardening, you can do without a drill pipe. A one and a half meter base will be enough to dig shallow holes.

But we need a drill in order to drill a deep enough well with it. What to do in this case? There is no point in leaving the barbell in one section and simply lengthening it.

The length of the rod and the ability of the metal to resist torsional forces are inversely proportional. It will be impossible to work with a long single-section rod.

The drill is a multifunctional product that will not gather dust without work when the well is already ready. With its help you can make the life of a gardener much easier.

There is only one way out: you need to make a drill pipe that will consist of detachable sections. The length of one section, a detachable rod, should be 1 meter or a little more. There are so many such sections that need to be built in order to eventually reach the planned well depth.

You may also find useful information about choosing a pipe for a well, set out in our article: Which pipes are best for a well: types, which one to choose and why.

The length of the string of rods attached to the drill will be increased gradually as the drill moves deeper.

There are several options for connecting rods into a long drill rod, these are:

- Threaded coupling . To create such a connection, a thread is cut inside each section that will correspond to the dimensions of the connecting element. The threaded coupling is made to the required length. All we have to do is exclude the possibility of spontaneous unscrewing of the connection. For these purposes, a cotter pin clamp is used. This method is simple and reliable.

- Nut and bolt. They are welded to rods made of small diameter pipes. This is a fairly simple, but not reliable option. You will have to weld on a thin-walled pipe, on which such a connection is unlikely to be strong. In addition, in order to fix such a threaded connection of the rods, additional efforts will have to be made.

- Welded couplings. Cut from a pipe whose diameter is larger than that of the rod. Then tightly weld the coupling to the pipe at one end of the section. Insert the next section freely into the same coupling on the other side. Now you need to secure the sections so that they do not rotate. To do this, you can insert a bolt across the pipe and secure it with a nut on the other side.

To make a drill for a deep well with your own hands, several rods are connected. Moreover, it is better if their connection is extremely simple. After all, during the drilling process, the tool will rise to the surface so that it is freed from the ground.

Each rise of the drill is accompanied by its division into its component parts, and each subsequent descent is accompanied by new assembly and extension.

Gas pipes with an internal Ø 33 mm can serve as drill rods for digging shallow excavations (up to 25 m) (the use of Ø 42 and 48 mm is acceptable). The length of the pipes of individual rod links is 1-3 m. Before purchasing pipes for rods, they should be carefully inspected. Material with poorly welded seams is not suitable for drilling

In addition to the drill itself, other tools are used to create a well manually, which are worth mentioning in this article.

For example, if the well is already ready, but pulling the tool to the surface of the earth is not so easy, you can use a lifting mechanism that works on the principle of a lever.

When choosing a method for connecting a detachable drill pipe, you need to remember that during operation the pipe will have to be repeatedly disassembled and reassembled

When the drilling procedure is delayed, and the drillers themselves lose strength, they would be greatly helped by devices that help turn the drill inside the well and screw it in as it deepens.

Types of drills

A drill is a type of construction equipment whose function is to make a hole of the required size. It is used in various fields. For example, in the construction of bridges and fences, for gardening work (when planting trees and other vegetation).

They can be divided into:

- Hand drills. They are often used in everyday life by both beginners and advanced summer residents.

- Designs with automatic drive. Modernized hand drills. A motor is installed on them.

- Mounted. These are the same mechanized drills, only with the possibility of installation on special agricultural equipment (tractors, walk-behind tractors, etc.).

The first ones have the weakest design and purpose. They drill holes of small diameter and depth. Without the effort of the worker, such a tool is useless. But its advantage lies in its compactness, since it is small and light. It is quite convenient to transport it. With this tool you can easily make a hole for a fence or seedlings.

In this video we will look at how to make a hand drill:

It consists of a rod and a T-shaped handle on top of the structure. There is a metal tip at the bottom that performs the function of centering the tool. A little higher is the drilling mechanism itself, designed in a spiral shape. Often consists of 2-3 rows of metal round cutters. As an alternative, use a saw blade as the cutting part.

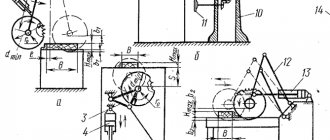

Power drills are made with a drive system. The design is more complex, but most summer residents can make such a manual drill for poles on their own. The drill also has a metal pipe with a handle, a tip and a cutting part. But an additional motor with a gearbox and drive part is installed. The auger (cutting) part moves due to rotational movements transmitted through gears from a gearbox with a motor.

This design is more powerful, but its strength depends directly on the performance and strength of the motor. The hole can be made deeper, up to 3 meters.

Mounted drills are designed to perform more complex work. The width and length of the holes are much larger. They are often used for the construction of bridges, train stations and other industrial purposes. With their help, you can make sheet piling fences for pits and trenches. Thanks to attachments, the cost of construction work is significantly reduced, as they have greater productivity and power.

https://youtube.com/watch?v=4j8lJtYjAVs

Alternative brace options

- For the purpose of planting vegetation, there is no point in making a complex structure, even the simplest garden drill. To do this, you can use a modernized shovel. It is necessary to prepare a high quality steel shovel and mark it for further modification.

- A 5-8 cm slot is made at the bottom and in the center of the shovel. Each edge is bent in the direction opposite to each other. The sides of the shovel also bend slightly, being a logical continuation of the lower blades.

- If the soil is soft, then a regular rotator will be ineffective. For this purpose, a mechanism with an extended cutting part is used. It resembles a kind of glass with longitudinal slots in which blades made of hardened steel are fixed.

Drill for making piles

The classic version of a drill for TISE is blades with a container for collecting soil. There is also a wider knife, which is necessary to create an expansion at the bottom of the pile. Using such a homemade drill for personal purposes is not very convenient, since the additional folding knife gets in the way.

In this regard, such structures are often made collapsible, where the folding knife can be dismantled. In general, it is recommended to use a regular garden drill to make a pile for personal purposes, and for expansion, make a separate knife with a container for collecting earth. The work is much easier in this case.

For this design, a scrap from a shovel is used as a knife, and a container for collecting soil can be made from a herring can. The knife is fixed on levers, and when lowered along the pile, it is in the uppermost position, as it is tensioned with a cable. When it reaches the bottom, the cable relaxes and the knife falls onto the walls of the pile, beginning to remove the soil and form an expansion of the desired size.

Alternatively, a dredger can also be made from an old propane tank. To reduce friction, the well is constantly doused with water. This tool can also be used on hard soils.

This is interesting: gas drills for earthworks.

Saw blade construction

Using an old saw blade to make a simple hand-held excavation auger is almost ideal. It is made of hardened steel, and it is strong, sharp and resilient. But it is impossible to bend hardened steel, since it can crack at the slightest deformation. In this case, the disk is cut in half and attached to the rod at the desired angle using welding or bolts.

If you use bolts for fastening, you must first weld the shelves for fastening the parts of the saw blade.

Such designs are characterized by high performance and durability. To make the drill even sharper, the edges (cut side) are also sharpened. The semicircular sides already have a good sharpening, which becomes sharper and more effective over time.

Hand drill design

A garden auger is a very useful device for any summer resident. It is very compact, convenient and easy to use. As a rule, it is made of solid metal. It effortlessly splits small stones and plant rhizomes into pieces.

With the help of such a device, you can easily dig a hole by rotating it around its axis like a corkscrew.

The main purpose of the drill is to dig holes for posts. Small wells are made by the cutting part of the device, which can be of various shapes:

- Two-blade;

- In the form of half-discs;

- Helical;

- Screw-shaped;

- Multi-tiered;

- Solid or removable.

There are models that start with small blades and gradually increase the top to larger sizes. A factory drill is not functional and effective in all situations, because the tool simply will not be able to penetrate the soil to the required depth, or its attachments will not be of the required diameter.

Although the cost of a factory-made pole drill is relatively affordable, it is quite possible to make a useful tool yourself, and at the same time it will meet all the necessary requirements. The technology for making a drill with your own hands is very simple, and its cost will be much cheaper than a factory one. You just need to decide on the parameters of the product.

Let's look at several different designs that are responsible for the efficiency and functionality of the drill:

Baking powder. This part consists of a pair of planes or a screw. The auger looks like a spiral, the knife is located on a rod. Soil receiver. This part collects soil, and it greatly facilitates the drilling of holes up to 35 cm in size. Forming plow. It is located in the lower zone

This design allows you to strengthen the columnar foundation, which is very important in the construction of massive structures. The auger is attached to the handle with a bolted connection. The length of the ready-to-use and fully assembled product is about a meter, which allows you to easily make holes up to 70 cm deep

If the hole needs to be deeper, then the structure can be expanded using a tube (500 mm). This element is a part with a nut and bolt, which are located at the ends of the pipes.

Preparing for independent drilling

Before making a drill for drilling a well with your own hands, you should determine the following factors:

- Estimated depth of the water basin . If the water layer is located at a depth of no more than 10 m, the well can be awakened by any of the 4 methods above. For water intake with a surface electric pump, a small channel cross-section is sufficient, so it is more rational and simpler to use driving technology using a needle drill or screw penetration with a small diameter drill. If you plan to use a submersible pump in a column of standard casing pipes, a bailer or spoon-type structure is made. For drilling to great depths, as well as to shallow ones, there are no competitors to auger hydraulic drilling in terms of speed and efficiency; the use of the percussion-rope method with a bailer or a spoon drill is significantly inferior in time to auger drilling using water and may turn out to be economically unprofitable due to high physical stress and significant loss of time.

- Well diameter . For water intake from depths greater than 9 m from the surface level, you will need to use a submersible electric pump, which requires the use of a large diameter casing; in this case, drilling can be carried out using any of the above methods. An effective option for sinking clay structures is to use drilling in the casing, in which water is poured into it, and the soil in the form of liquid mud is extracted out with a bailer or spoon device.

Homemade spoon drills

Making a spiral screw drill

For auger drilling, drills equipped with a helical spiral are used. Such devices are driven into the ground not by blows, but by rotation around its axis. Making a homemade drill for a well with your own hands of a similar design is a little more difficult than a bailer bit. However, if desired, it is quite possible to create such a device.

The basis of the auger drill is a 32-50mm steel pipe. Sharpened knives cut from hard steel are welded to the lower end of the pipe. A piece of old spring is perfect for them. The length of the protruding parts of the knives should be equal to the diameter of the auger or slightly exceed it. With the help of knives, when the drill rotates, dense layers of soil are loosened, and then removed upward using turns of a spiral auger.

Screw

Making an auger is the most labor-intensive and complex process in making a do-it-yourself auger drill. Its petals are cut from a steel sheet 5-6mm thick. The first step is to mark the workpiece. Using a compass, draw a circle of the required size on the sheet. The diameter of this circle should be equal to the diameter of the well. Then we draw another smaller circle inside it: the diameter of the inner circle is equal to the diameter of the pipe taken as the basis of the drilling mechanism.

The next step is to cut out both circles using an autogen machine. The result should be a donut-shaped piece. We cut one edge of this “donut” and bend the edges of the cut at an angle of 25-40° relative to each other. This will be the first turn of the auger spiral of the drilling device.

We put the resulting workpiece on the base pipe and weld it. In the same way, we make another turn of the auger, put it on the pipe above the first turn, connecting them to each other. The number of turns depends on the height of the drilling device, and can range from 2 to a dozen or more.

The easiest way to deepen an auger drill is with human muscle power. To do this, levers from two pieces of pipe from half a meter to one and a half meters in length are attached to the top of the pipe with welded spiral petals. The greater the length and diameter of the drill, the longer the levers should be. They are secured by welding, bolts or keying.

Peculiarity

The peculiarity of auger drilling is the need to regularly lift the drill to remove loosened soil. With a large depth of the well and a significant mass of the drill, it can be difficult to perform such an operation by hand. To make the task easier, you will again need a frame with a lifting device - blocks and a collar. If possible, you can also use an electric winch for lifting.

Improved excavation drill

Take a square of sheet metal with dimensions 210x210 mm and a thickness of 3-4 mm, mark the center by drawing two diagonals, and using a caliper draw a circle of the desired diameter, then cut it out with a grinder. You will also need a three-quarter pipe and a bendix from the starter.

Using a special crown or on a lathe, drill a hole in the circle to match the diameter of the pipe. Weld a steel triangle to the bottom of the rod (you can use metal scraps left over from the square), and then insert a circle at a distance of 10 cm from its edge, securing it with electric welding. Make two cuts in the longitudinal section of the disk and bend them in different directions so that the bending angle is within 25–30°. Weld a bendix and a horizontal handle to the top of the pipe. The earth drill with your own hands is ready.

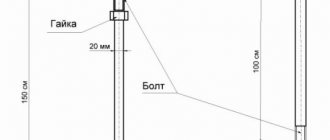

Drawings and dimensions

The product diagram is a template and allows you to visually estimate how the stages of the manufacturing process of the future tool are located. The dimensions of the garden auger can be as follows:

- handle (if the product is handmade) - crossbar 0.5 m long;

- rod – about 1 m (without additional sections);

- the diameter of the disk cut into pieces is 15-25 cm (reference point is ready-made saw blades for an angle grinder);

- tip length – up to 10 cm (peak or drill);

- the distance on the axis given for the installation of disks (taking into account the slope), after a peak or drill - up to 15 cm;

- The upward tilt angle of the knives is up to 30 degrees.

In an auger drill, the length of the “screw” (a monoblade with several turns) can reach up to half a meter. The tilt of the screw stroke can reach the same 30 degrees (at any point of the monoblade). The remaining parts of the auger drill are the same as those of a simple two-blade drill.

The dimensions of the drill for planting seedlings, such as tomatoes, generally coincide with the dimensions of the working part of an ordinary bayonet shovel. Its cutting edges are trimmed so that the bayonet of the shovel goes from round to straightened and pointed at an obtuse angle. The leaf fold is cut off from the opposite (upper) edge. A long (more than half a meter) concrete drill can be welded into the hole from which the handle is pulled out (under the universal hammer drill clamp). It is advisable to use a drill made from a shovel bayonet with a drive, since for manual drilling it requires more effort than the inclined screw of an auger or half-disc of a conventional garden drill.

A drill of any type can be equipped with additional sections. Each of them increases the depth of soil drilling by a meter. These extension sections are used when the owner decides to drill a well for water himself. One such section is used when the ground is soft. These can be posts for fences and other non-permanent structures, buried to 1.4 - 2 m.

Having decided what kind of hole drill you need, cut out a sketch for the blades from cardboard. It made cutting sheets easier and faster.

Preparing tools

Having decided on the materials, prepare a set of the following tools:

- welding machine (use an inverter rationally), electrodes and a protective helmet for the eyes of the master;

- grinder and cutting wheels for metal, protective casing (prevents metal shavings from flying towards the worker);

- a hand or electric drill with a set of metal drills (both high-speed steel and diamond are suitable);

- hammer, pliers and vice;

- sharpening machine (craftsmen purchase a round sharpening stone with a shank that is inserted into a hammer drill or drill);

- construction marker, tape measure, compass.

Before starting work, determine the characteristics of the hole drill. The following types are distinguished:

- Simple (dacha) - in it the cutting part includes two half-discs. They are installed symmetrically, tilted, on an axis opposite each other.

- Auger. A screw blade is twisted into several turns from a strip of steel. She is inseparable. It is extremely important to maintain a constant strip width, slope, bend curve along the entire length and the same distance between turns. One inaccuracy and the drilling equipment will become unstable, leading to slowdown and beating when drilling soil.

- A drill wedge is most often made from the working part of a shovel. The basic principle of its operation is not to screw the tool into the ground with subsequent destruction of the latter, but to wedge and immediately throw the cut soil out of the working area. The blades are positioned strictly vertically.

A simple means of small-scale mechanization for the garden

It is easiest to make such a tool yourself. Its design includes:

- cutting part made of steel sheet;

- drill tip;

- a rod made of round or square pipe;

- handle.

The cutting blades of the drill are made of two steel semicircles with a thickness of 4 mm and pointed edges. Their diameter is calculated according to the size of the required wells. In the center of the semicircles, a recess is cut out in the shape of the rod for a better fit. Blades are usually welded to a rod with a diameter of ¾ inch or 20×20 mm, but it is more convenient to make several replacement pairs and bolt them to the rod. To do this, you need to weld fastening shelves made of strong steel at the desired angle and make holes in them.

A 0.5 meter long handle is attached perpendicular to the rod, the length of which is made up of the depth of the hole and an additional 60 cm. A drilling tip is attached to the other side. It is needed for stability and initial loosening of the earth. If the garden auger turns out to be too long, you can make a collapsible, folding or telescopic rod.

Blade knives can be made from two round halves or from an open circle with offset edges. In any case, the edges of the blades should be separated by 30°. This is necessary for successful work on dense soils. Angles or stops made of thick steel will enhance performance.

Methods for connecting drill pipes

To drill long distances, the drill is extended under water using hollow steel pipes of standard diameters 21.3, 26.8 and 33.5 mm with a length of 1500 to 2000 mm, which are connected to each other in the following ways:

Threaded. In this technology, for connection, an external thread is used, which is cut at one pipe end, and an internal thread on transition couplings, which are short cylindrical sections with a diameter corresponding to the lower point of the pipe thread notch. Cutting is carried out manually with dies using die holders according to the old Soviet method or with modern, more convenient devices - cutters. After applying threads to the inner side of the transition couplings and the outer shell of the pipes at one end, a coupling is welded to their other edge, and extension is carried out by screwing subsequent pipes into the couplings of the previous ones.

Bolt and threaded coupling . With this method, a large diameter bolt is welded to one end of the pipe, and a long nut in the form of a coupling with an internal thread corresponding to the external thread of the bolt is welded to the other, and when connecting the pipe elements, they are screwed onto each other until they stop. The technology is reminiscent of joining factory-produced drill rods; factory connecting heads can be welded or screwed to threads instead of bolts and couplings.

Bolting and heads for drill rods

Pin . Joining pipes using a pin is the most optimal method, ensuring high speed of connection and disassembly of extension rods. To implement it, an internal coupling is welded to one side of each pipe, the next pipe is put on it and holes are drilled in them at some distance from the edge. Then a pin is inserted into the through channel of the two joined pipes, preventing them from being separated.

The disadvantage of pin fastening is the possibility of falling out of the holes; the easiest way to eliminate this disadvantage is to use a threaded bolt with a nut for fastening. True, this solution is ineffective for a quick connection; moreover, when used in the ground, the thread is constantly clogged with dirt, which significantly slows down the assembly and disassembly of the extension pipeline. It is more effective to use a pin with a lock, which is a rotating plate embedded in its end, similar to the design used for assembling scaffolding. But this system also has the disadvantage of using individual elements that can be lost; also, when the extension rod pipes rotate in hard soil, there is a high probability of deformation and damage to the weakened pin ends with limiting plates.

Pin designs

The best method for solving problems associated with the disadvantages of pin connections is to use a special design in which a U-shaped plate with an inserted pin is welded to the pipe opposite the through hole, and a restrictive pin is inserted into its body through a through radial channel. The limiter prevents the pin from being lost and falling out of the assembly, and is also an element with the help of which the pin is moved along the through hole, connecting and disconnecting the pipeline. Also, the outer U-shaped steel plate protects the pin and stop from damage when rotating in the ground.

If the above design seems too complicated to be manufactured at home, a good option is to purchase a factory-made pin for attaching soil drills, which is a bolt with smooth walls, in the head of which a hole is drilled and a rigid wire stop is inserted, which goes around the pipe and is put on on the other side to the end of a smooth-walled bolt.

Option for quickly connecting a borehole drill with pins

Using a hammer drill to make a drill

Homemade drills have some disadvantages, despite the fact that they are made according to their own drawings, taking into account their own height and type of soil. Among the main disadvantages, it should be noted that with the help of such devices it is possible to dig not very deep holes, and working with them on hard soils can be quite difficult. All this, as a rule, applies to manual devices.

If you connect the working part with a hammer drill, you will be able to increase labor productivity. Such a drill will be based on an earth auger, a hammer drill and an adapter. The latter can be replaced with a gearbox. An important factor is the number of revolutions of the hammer drill and power. The optimal value of the last parameter for a manual model is 2 kW.

Depending on the number of revolutions, the drill can be connected to the hammer drill chuck through a gearbox. If the power is 2 kW, then a gearbox is not needed. If you want to make an earth drill from a hammer drill with your own hands, then you will need a tool that produces a working attachment speed of up to 300 per minute. This value may decrease. It depends on the properties of the soil on the site. To make a drill from a hammer drill, you need to prepare some materials and tools, among them the following should be highlighted:

- Angle grinder.

- Electric drill.

- Metal fittings.

- Cable.

- Sockets.

- Welding machine.

- Material for the cutting part.

If you are wondering how to make an earth drill with your own hands, then you need to pay special attention to the nozzle. To make it, you need to cut a piece 1 m long from a rod or tube using a grinder

Knives should be attached to the lower end. The base is cut off from the drill to install the attachment in the hammer drill chuck. The cut fragment must then be welded to the tube.

You can make an earth drill from a drill yourself using the same technology. If you do not use the base from an old power tool, you should cut out a seat for the chuck from a rod. An adapter can be inserted there. In addition to the manual model, you can make a stationary drilling rig. To ensure power supply, you should purchase or make an extension cord yourself.

Use of sheet steel

To make a drill with your own hands using sheet steel, just cut out a template from paper for the blades, and a metal circle along it. A hole is drilled in the center into which the rod is inserted. The two parts are fastened together by welding or bolts, depending on the chosen design.

- The diameter of the hole should be slightly larger than the diameter of the pipe. It can be either round or square, if profiled is used. A spiral can be made in two ways - cut a circle from the edge to the center and bend it in different directions (one up and the other down) or make a drill from two halves.

- In the latter case, the metal circle is cut in half after making a hole and then fastened to the rod according to the selected design model. In both the first and second options, it is necessary to bend the edges at an angle of 20-30 degrees. The smaller the angle, the easier the work process will be. But with a large inclination angle, the drilling process is much faster.

- On hard soils, the blades can become deformed under heavy load. Therefore, to strengthen the tool, supports made of thick steel are welded. The blades bend due to the fact that the steel is not hardened. It is difficult to find a sheet of hardened steel, but even if such material is available, it is unlikely to be able to bend it at the desired angle.

Drill for TISE piles

In the author's version, the TISE drill is a blade with an earth receiver and a folding wider blade, which forms an expansion at the bottom of the pile. But working with such a projectile is inconvenient - the folding knife gets in the way. Therefore, in some designs it is made removable, but in general, it is recommended to drill the holes themselves with an ordinary garden drill, and for expansion, make a separate folding knife with an earth receiver. This makes the work easier and faster.

Do-it-yourself drill for TISE piles - one of the options

A cut-off shovel serves as a knife, and the land receiver is made from a herring can. The knife is fixed movably; when lowered into the pit, it is pulled up by a nylon cable tied to the end. Having reached the bottom, the cable is weakened, the blade begins to trim the sides of the hole, forming the necessary expansion.

The photo below shows the second version of a homemade drill for TISE piles. The design is more complex, but also more effective. The plow blade is made from a piece of spring, sharpened and welded to a folding structure with bolted joints.

More complex design

The dredger is made from an old propane tank. The collection of soil occurs from below, which is why the receiver is made with a rounded bottom. It has two holes, their edges are sharpened.

Bottom view

This projectile works well even on dense clay. True, to reduce friction, the well must be constantly moistened with water.

Designs and Applications

There are three main designs of earth drills:

- Garden. Usually these are two semicircular blades welded at an angle to one another. A hand drill of this design is used to organize holes for planting plants, which is why it is called “garden”. But the same tool is used to make holes when installing posts for fences, gazebos and other light buildings. An example of a homemade earthen garden auger

- Auger drill. It differs in that it has a longer cutting part. It is used for the same purposes - to make holes for pillars. Due to its design - a longer cutting part - it needs to be removed less often, so drilling usually goes faster.

The auger drill is distinguished by spirally wound several turns of the spiral - Drill for TISE piles. This design is similar to a garden auger, but has an additional folding blade to form the expansion at the bottom of the pile characteristic of this type of foundation. Folding blade - features of the TISE pile drill

Garden earth drills that are easier to make. Depending on the type of soil on which drilling is carried out, their design is slightly modified. This is the beauty of homemade drills - they can be “sharpened” to specific conditions and it’s not just about the size - the blades can be made removable, bolted on, but also about the design features. Yes, ordinary drills in the store are inexpensive, but they are “universal”. They work well on “light” soils.” On loams, clays, marl, etc. they are ineffective.

Making a garden drill

A garden auger is the simplest but most effective design. It consists of:

This is a basic design, and there are many modifications to it. But let's first talk about what an earth drill can be made from.

Materials

As already mentioned, the rod is most often made from a round or square pipe. Diameter - from 3/4′ to 1.5′, profiled pipe can be taken from 20*20 mm to 35*35 mm.

Blade knives can be made from:

It is easier to make blades from a saw blade. In this case, the cutting edges are already ready. It will be possible to further sharpen the side edges to make the soil easier to cut.

The spear-drill is made from different materials - there are many different designs. They just make a sharpened rod. Then you need a piece of large diameter rod. The second option is to make something like a drill from the steel strip. And yet - a combination of these two.

Pike - one of the tip options

And finally - about the pen. It is more convenient if it is made of a round pipe. Its diameter can be selected according to the circumference of the palms. The main requirement is that you should be comfortable.

Knives and fastening method

First of all, you need to decide whether you are making a drill with your own hands with removable or stationary blades. If the blades are removable, weld shelves made of thick steel at one end of the rod. The shelves are made at an angle - so that the planes of the knives are separated at an angle of 25-30°.

After the shelves are welded, two or three holes are made in them for fasteners. Then the same holes will need to be made in the blades, and installed on bolts of substantial diameter.

One rod can have several sets of cutting blades - for holes of different diameters

You will have to cut holes in the center of the disks themselves so that they fit more tightly to the rod, but this operation is also required for the monolithic version - with welded blades.

Sheet steel

If you are going to make the blades from sheet steel, cut out a template from paper and use it to create a circle of steel. Drill a hole in the center - you will need to insert and weld a rod into it. Circle or square - depending on the chosen rod. The hole dimensions are slightly larger than the dimensions of the rod.

The edges should also be separated by 25-30 degrees. In this case, drilling efficiency will be maximum. If you work on dense soils (clay, loams with a predominance of clay), the blades may collapse under load. To avoid this, stops are added from a corner or a thick strip of steel.

The blades bend due to the fact that unhardened steel is used, but it is almost impossible to find it in the sheet, and even if it is possible, it is unlikely to be bent.

From a saw blade

If you have an old saw blade of a suitable diameter, you have found an almost ideal option. They use hardened steel, which is elastic and durable. But such a disk cannot be bent, so it is sawed in half and these halves are placed at the required angle.

This homemade drill for excavation works shows quite high productivity. Even used wheels have a well-ground edge. And to make drilling even easier, they also sharpen the drill on the sides with their own hands.

Modifications

In dense soils, it can be difficult to cut the soil with large blades. In this case, several blades of different sizes are welded onto the rod. From below, near the peak, the smallest ones are welded; above, retreating a few centimeters, the large ones are welded. There can be three such tiers, maximum four. The entire cutting part should not be more than 50 cm, otherwise it is physically very difficult to work.

If a drill is needed for shallow holes - for installing poles, etc., then this design is optimal - it is relatively light in weight and easy to work with. The working process is as follows: they lowered it into the hole, turned it several times, pulled it out, and poured out the soil stuck between the blades. But if you need to drill deep holes, you will suffer from carrying a small amount of soil from the depths. For such cases, a box for collecting soil is welded above the blades.

And all these are hand-made drills. All of them are highly efficient - it’s much easier to work than store-bought ones.

Details of the pit drill and features of its operation

Areas of application for garden augers:

- planting trees and shrubs;

- installing fence posts;

- installation of street lamps;

- arrangement of a drainage system;

- creating a well;

- drilling a water well;

- drilling holes for winter fishing.

Purpose – excavation of soil of the required diameter and depth by human physical efforts.

Productivity directly depends on:

- product design;

- what cutting element is used;

- diameter, depth of the hole in the ground.

It will take about 2-3 hours to make a hole up to 3 m deep with a diameter of 25-30 cm using a standard earth drill.

For deeper drilling, special equipment in the form of drilling rigs is used.

The manual design contains the following parts:

- Pen. It is customary to make it from steel. Has the same diameter as the shaft. For ease of drilling, they are welded perpendicular to the shaft (rod) in the shape of the letter T. Rubber pads are put on both handles so that there is no friction when moving, the hands do not slip and get less tired. The minimum length is 40 cm, the recommended length is from 50 to 60 cm.

- Rod or shaft. Material: round or square profile pipe. Diameter - from 0.5 to 1 inch. It is not worth making the bar thicker, as this will require a lot of effort. A handle is welded on one side of the rod, and a cutting part with a lance is welded on the other.

- Screw (cutting head). The key element of the earth drill. Responsible for loosening the soil and pushing it to the surface. Excess soil is removed when removing the tool from the well. The most popular option is the one with two steel semicircles sharpened at the edges. The diameter is selected according to the purpose. To improve the convenience of operation, the blades are made removable.

- Crowbar (spike). Made in the form of a large drill or blade. It is located at the bottom center of the product under the blades. Sets the direction of the shaft. In a strictly vertical position it enters the ground. Loosens the soil in the center, making it easier for the blades to work.

- Extension cords. These are additional nozzles or sections of the rod, with the help of which you can increase the drilling depth to 15 m. They are fixed with screw connections. Used when necessary.

For cutting elements, it is recommended to use steel as a material - this guarantees a long service life of the tool.

Do-it-yourself drill for wells

The drill for wells is made of metal. The drill itself is a structure made of a metal rod with a sharpened end. Knives are attached to the sides of the drill. For the knife cavities, you can use halves of a metal disk about 15 cm thick. Then the knives must be welded to the rod with an inclination of approximately 22 degrees. The halves of the disk are placed opposite each other. Between parallel knives the slope should be 44 degrees.

You can make a spoon drill for wells. It has the shape of a cylinder with a longitudinal cut on the side. The length of this drill is about 800 mm. This drill can be made from sheet steel, which must be rolled to the required size and fixed by welding.

To make it easier to overcome various layers of soil, the following drills are used:

- Spoon drills are used for sandy soil;

- the drill bit is used to loosen hard rocks;

- spiral auger (also called coil auger) is used for clay soils;

- The bailer makes it possible to lift the earth to the surface.

Necessary materials

The requirement for the wall thickness of iron pipes (3.5 mm) is explained by the strengthening of the product and the ability to work in hard soil. Discs for work can be removed from the circular saw or made independently. They will require metal sheets with a minimum thickness of 3 mm.

Tools that will be useful:

- Hammer and grinder

- Welding technology

- Locksmith kit

- Electric drill with metal drills

- Sharpening wheel for cutting elements.

If there is no tip with a drill, they are replaced with a drill with a tapered shank. The diameter must match the screw part. To avoid injury in home production, use soft bicycle handles.

Design features of the device

A hand-held post drill is designed to create holes in the ground at the level of the columnar foundation. That is why the design includes a significant cutting part, which differs in different types of devices. A very important nuance is that during the rotation process, soil masses must be excavated with further accumulation in the receiver.

The first stage is the correct selection of the unit design. There are some assembly features on which the further functionality of such a tool as a hand-held earth drill depends:

- Baking powder. It can resemble two inclined planes or be in the form of an auger - this is a spiral-shaped knife located in the bar area.

- Ground receiver. It is designed to collect soil and remove it after filling. Its presence is necessary if it is necessary to form holes whose depth exceeds 35 cm.

- Plow to form an expanded area at the bottom of the soil. This parameter will strengthen the future foundation. A plow is required when constructing large buildings with significant mass.

Before you make a drill for poles with your own hands, you must prepare drawings. They directly depend on what requirements are put forward for the design.