For good care of your garden, hedges and gardens, a hedge trimmer is one of the most necessary tools.

A high-quality hedge trimmer is not cheap, so those who know how to make various equipment with their own hands often try to make such a tool themselves.

The necessary components are usually right at hand of the owner of any garage. If not, then purchasing them at the nearest hardware store is not difficult.

Next we will tell you:

- what types of homemade hedge trimmers you can make with your own hands;

- which cutting tool is best suited for a grinder (angle grinder, angle grinder) or chainsaw and how to make it work;

- what tools and materials are required to make a hedge trimmer cutting tool.

Survival ideas: what you can do with your own hands from an ordinary chainsaw

This tool is convenient because it does not depend on the current source. You can work with it away from home. If you suddenly need a pump, a generator, a snow clearing device or an ice ax - a chainsaw will become the heart of any homemade machine. This way you will not only save money, but also get truly powerful and reliable equipment. Based on a 4-8 liter gasoline engine. With. you can build a home sawmill, a snowmobile sled, a generator for lighting, and even a cultivator. Let's look at the most popular homemade chainsaws and their manufacturing technologies.

Do-it-yourself ice drill from a chainsaw: diagram and practice

They say that you can’t pull a fish out of a pond without effort, but in winter I would like to limit this effort to twitching the jig. An avid fisherman is never limited to one hole.

Three, five, or even more holes are a guarantee of success

But if the ice is 0.5 m thick, you will spend most of your time drilling, losing strength and mood. An ice drill will help you cope with this task quickly and effortlessly. Let’s see how much such a gadget costs: from 8,000 rubles. Why buy it if you have a chainsaw ? To make an ice drill, you will need an old electric drill - we will use it to make a drive. How to make an ice screw from a chainsaw with your own hands:

ImageDescription of work

| An electric drill will require a working gearbox. |

| You need to make such a tool from a part of an armature from a drill, a bushing and a 27 head. It will directly transmit rotation to the drill. |

| One more element needs to be made with your own hands from a piece of metal and a pipe. This is a gearbox mount. |

| The mounting structure is fixed to the saw using two bolts. |

| This is what a gearbox with a bushing mounted on a saw looks like. |

| A drill is inserted into the sleeve. In the future, a drill tube is placed on it and secured with a bolt. |

Important tip! The key to successful operation and safety of the tool is the presence of a guide for the movement of the drill. Many people neglect this part of the design, and as a result, the drill breaks within the first minutes of use.

How a homemade design will work is shown in

DIY chainsaw generator

Among the tools for survival in any conditions, the generator is far from the last place. What to do if the electricity suddenly goes out at your dacha, and not only will you be left without light, but the heating will stop working without a pump. To protect yourself, it is better to prepare the simplest generator from a chainsaw in advance.

All you need is an old car generator, a chainsaw and a bicycle chain with sprockets

Use a bicycle gear to transmit torque. In this case, the saw should operate at minimum speed.

“Friendship” and homemade products from this chainsaw with your own hands

“Friendship” is the ancestor of the “Ural”, and it has become a popular basis for homemade products for the same reason. “Druzhba” has a powerful 3-liter two-stroke engine. With. The device even has a chain brake.

This model has very comfortable handles, and the body is made of high-quality metal.

“Ural” and “Druzhba” are distinguished by increased strength and endurance, like most engineering solutions from the times of the USSR. In addition, they are fueled with low-octane gasoline, and this is a significant saving. The only disadvantage of this technique is the weight.

READ How to Remove a Sprocket From a Husqvarna 136 Chainsaw

Chainsaw : which brand to choose. It is difficult to imagine life on a summer cottage without working with wood. An important tool for this is a chainsaw . So which model is right for you according to your goals and budget?

Another option for “high-altitude” pruning

A chain saw is used for this. This tool leaves an even cut and does not cause much damage to the tree. However, it is not suitable for working with high-lying branches - the saw should be upgraded. For this:

- take a strong rope 10 to 12 m long;

- cut into two identical parts;

- a load is attached to the end of the first segment and thrown over a high branch;

- the other end is connected to the edge of the tool;

- then a second rope is taken and tied to the remaining end of the chain saw.

By pulling the string from side to side you can cut the branch. This can be done alone, but it is more convenient to work with an assistant.

Do-it-yourself lawn mower - manufacturing methods, assembly

Most homeowners strive to buy a branded lawn mower. However, the high prices for some models make the equipment inaccessible to many people. In this case, you should not be upset, but try to assemble the lawn mower with your own hands, using parts from a chainsaw, grinder or an old washing machine.

Which engine is suitable for production?

The mower can be assembled using any engine. Most often, homemade products are equipped with gasoline and electric motors. Much less often - with batteries previously removed from old VAZ, GAZ or Moskvich cars.

When choosing an engine, it is important to consider several important criteria:

Homemade pole saw from a Husqvarna 142 saw and pipes

- power - it is best to equip a homemade mower with a gasoline or electric motor with a power of 2-4 liters. With. Engines with higher power are suitable for lawn mowers designed for tall grass and uneven areas;

- type of cooling - this factor plays a role in the case when a gasoline internal combustion engine will be used to assemble a homemade product. It is best to choose a motor with forced air cooling - its design is simpler than in liquid-cooled power units. In addition, air-cooled internal combustion engines do not require special maintenance. All you need is to promptly clean and periodically change the air filter;

- anti-vibration system - its presence only affects the comfort when using garden equipment. As for efficiency, homemade lawn mowers, both with and without an anti-vibration system, cope equally well with mowing vegetation.

Among the additional functions in the motor design, it is necessary to highlight the soft start system. It reduces the engine rotation speed when it is turned on, preserving the integrity and extending the service life of its main parts.

Safety precautions

A lawn mower is a dangerous device, and a homemade one is especially dangerous. For safety reasons, mowing should be carried out in compliance with the following rules:

- Closed shoes are worn, long trousers are worn.

- The eyes are protected with glasses.

- It is necessary to ensure that children and animals are at a safe distance from the machine when mowing. It is 30 m (with a knife it can throw out a stone or branch).

- Work is carried out only in sufficient lighting.

- The electric lawn mower should not be used on a wet lawn.

- Do not leave the device without turning it off.

- Maintenance, cleaning and repairs are carried out only with the engine switched off.

- Lawn mowing on uneven terrain is carried out not up and down the slope, but across it.

Move the lawn mower on hard surfaces only with the engine turned off.

How to make a lawn mower from an electric drill?

The transformation process involves only two steps:

- a shaft with a knife mounted on it is mounted in the chuck;

- A tin protective casing is attached to the body using a clamp.

This type of lawn mower is inconvenient to operate, so it should be considered only as a temporary option.

Chainsaw Crafts Friday! — Community “It’s interesting to know...” on DRIVE2

The chainsaw is very popular among home craftsmen because it is a universal drive for original homemade designs.

- Light weight and solid power combined with compact dimensions allow this “lumberjack’s dream” to be combined with an ice auger and a bicycle, a sawmill and a winch.

- Anyone who can confidently work with a welding machine, an angle grinder, and, if necessary, can even use a lathe, can make interesting homemade products from a chainsaw with their own hands.

- In this case, knowledge of the basics of design and drawing will be very useful, since the accuracy of all dimensions and quality of assembly are the main conditions for the normal functioning of a unit driven by a chainsaw.

- Without going into technical details, we will consider the most interesting designs using it.

- Options for homemade chainsaws

The first thing that comes to mind when you think about what can be done with a chainsaw is its use as a sawmill. Many developers had to split logs onto beams with this tool.

Holding the saw suspended in your hands, it is very difficult to control the accuracy of the entire length of the cut. Therefore, with a log length of three or four meters, it moves far away from the intended mowing line. This problem can be solved quite simply. To do this, the chainsaw is rigidly fixed to a frame, which moves along a guide profile.

In this case, the log lies motionless and is neatly sawn along its entire length without wobbling or oblique seams. If you equip such a mobile carriage with four lifting screws, you can accurately set the thickness of the sawn timber.

A sawmill using a chainsaw will also work on boards without problems, only in this case there will be too much waste, since its cutting chain is several times thicker than the saw of a band sawmill.

- Snowmobile

- A lightweight homemade snowmobile made from a chainsaw is more complex in design than a sawmill, since here you need to move the gas and clutch to the steering wheel, and also take care of the shock-absorbing suspension of the supporting frame.

In addition, you need to develop it yourself or use ready-made drawings of the caterpillar and correctly transfer torque of sufficient power to it from the motor. Since the chainsaw does not have its own transmission, the clutch on such a snowmobile is fitted with a centrifugal clutch with a serpentine belt and chain.

To increase traction, a “traction” gear is placed on the caterpillar drive shaft, the diameter of which is larger than the size of the chainsaw drive sprocket.

There are usually no problems with the steering mechanism, since it is taken from a regular bicycle or scooter and modified so that the central axis moves the rods that turn the skis. The snowmobile engine power must be at least 5 horsepower, so it is better to use a Ural chainsaw for this purpose.

The winter line of homemade vehicles will be complemented by snowmobiles made from a chainsaw, which are structurally simpler than a snowmobile. The driving force is provided by a large diameter screw, which directly rotates the gasoline engine.

A significant limitation for the cross-country ability of such a machine is the low power of the chainsaw. Therefore, you can only move on them on a flat surface of compacted snow, ice of a frozen lake or river. To travel across the fields you will need an engine with a capacity of at least 12 horsepower.

Those home inventors who would like to make a backpack-type helicopter from a chainsaw should know the same thing. Such a machine will require not one, but at least two engines operating in a coordinated mode.

This vehicle is most often made for the sake of principle rather than practical use. The main driving force of its creator is the desire to test his strength as a mechanic and prove to others the original use of this cutting tool.

The basis for the design is usually my grandfather’s old chainsaw and an equally ancient bicycle, with which you can carry out any experiments on converting the frame for mounting the drive.

Power is transmitted here through a gear pair using a bicycle chain, and the start of such a homemade product is reminiscent of preparing for cutting firewood.

Less common are more advanced models, the basis for which is a mountain bike equipped with reliable brakes and shock absorbers. This chainsaw moped is equipped with a gearbox with a gear ratio of 18:1 and a CVT transmission, which allows you to comfortably move on it at the speed of a regular bicycle.

READ Anchor For Circular Saw Interskol Video

This option for using a chainsaw is quite simple, since the task here is to transfer torque from the saw motor to the propeller. A homemade outboard motor does not need to install a transmission. For it you will need to make a reliable adapter on a lathe from the saw drive gear to the propeller shaft. The propeller can be used from a standard outboard motor.

The photo shows an option in which there is a gearbox in front of the propeller that changes the angle of rotation of the shaft by 90 degrees. In simpler models, they do without it by mounting the engine on the boat so that the shaft is immersed in the water at a slight angle.

It is difficult to make a full-fledged walk-behind tractor from a chainsaw due to lack of power and traction. But many home craftsmen were able to build a lightweight motorized cultivator based on it.

The design of such a machine is very simple: the motor rotates a pair of gears and transmits increased traction force to one drive wheel.

The chainsaw motor is no different from rotating the cutting chain or the auger mechanism of a snow blower. Here everything depends only on the design abilities of the creator and his ingenuity.

Using a STIHL chainsaw with a power of about 3 kW, you can easily build a good device for clearing an area of loose snow. To simplify the design, some craftsmen refuse to install wheels and use conventional sled runners.

The most important part, which determines how well a homemade snow blower will do its job, is the auger assembly. It is driven by a gear pair and a chain. The blades are made of thick cord rubber, and the intake device is made of galvanized steel sheet.

Frame design You can fit a plastic sewer pipe under the snow thrower by attaching it to the intake body.

The most daring inventors have long been eyeing the possibility of using a chainsaw as an engine for an aircraft. However, this instrument is not strong enough to master airspace. Therefore, no one has yet succeeded in making a backpack helicopter out of one chainsaw.

Calculations have shown that this requires at least four chainsaws (total power from 20 hp) of a forced design, which would allow them to increase speed several times and work in a coordinated mode.

- Motor drill

- This device is useful not only when building a fence or foundation from screw piles, but also during winter fishing, when you have to drill dozens of holes in thick ice.

Since the ice auger operates at low speeds, to adapt the chainsaw motor, it is connected to the auger through a reduction worm gear.

- Winch

- A motor winch is a very useful device, because with its help you can not only easily pull out a stuck car, but also lift a heavy load to a height, pull a boat onto land or move a cut tree.

The power of such a homemade product depends on the power of the chainsaw used, and its pulling force can reach 1500 kg. Such a winch must be equipped with a sling belt, hooks and anchors for attachment to the ground, tree trunk or car.

The camping power station is assembled on the basis of Ural or Druzhba chainsaws. It consists of a frame, an engine with a gear reducer, a control panel, a generator and connecting electrical cables.

Do-it-yourself pole saw from #HandmadeHit!!!#SteelBeetle burns

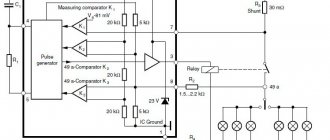

1 – chainsaw 2 – gearbox 3 – cord drive belt 4 – tension bar 5 – generator; 6 – control panel; 7 – clamps; 8 – supporting frame; 9 – saw tooth stop; 10 – nut for fastening the frame to the gearbox; 11 – drive pulley

A good owner will not throw anything away in vain, especially if we are talking about high-quality metal. If you understand the nuances of heat treatment of metal, you can make a solid forged knife from a chain that has served its purpose.

This thing looks no worse than the creations of Arab blacksmiths who forged swords from the legendary damask steel.

- Serious competitors of chainsaws in the wild are Beavers, which, in addition to self-sharpening teeth, have other advantages)

- Happy Friday everyone!

- Source

Snowmobile

Work begins with the snowmobile frames and track block, which are made in the form of 2 welded spars. In the middle parts, 50x36 corners are used; metal plates of 2 mm thickness are installed in the front and back. The latter have the edges bent by 90°, which adds rigidity to the parts.

A hole is made in the front plate for the shaft that drives the caterpillar, in the rear plate - for its second axis, which is a tension one. Near the latter, on both sides of the frame, tensioning devices for the caterpillar and chain drive are mounted.

5 brackets with open grooves are welded to the side members from below. They contain the axles of the track rollers supporting the track. The last 18, 3-4 pieces each. on each axle - front and rear at the edges, middle ones - in a checkerboard pattern. The axles are secured in the grooves using nuts and locknuts.

The rollers come from a unit that is used for sorting potatoes, the axles come from a potato digger. The axles are released, machined, and an M10 thread is cut. Between the rollers, to fix the position, duralumin tubes of the appropriate diameter are placed.

3 racks are welded onto each spar using 30x30 angles. They are connected at the top with the same crossbars:

- a steel sheet 2 mm thick is welded to the front and middle on the right side, on which a gearbox with an intermediate chain drive shaft is mounted;

- Between the other pair there is a box with a lid that serves as a seat.

A transverse beam is welded to the front ends of the side members - the crossbeam of the front axle. At its ends there are bushings for the steering skis, in the middle there is a stand that forms the engine subframe. All parts are made from water pipe with an outer diameter of 32 mm.

The caterpillar for the motorized dog is from Buran. It is shortened by 50 cm and stitched. Drive and tension gears are made like “Buranovsky” ones from strong plastic 1.5 cm thick.

For the caterpillar drive shaft, a pipe with an outer size of 28 mm is used. On the edges:

- The flanges are welded to which the gears are attached through the holes.

- Pin tips are pressed into the shaft holes, the diameter of which is previously ground to fit bearings 80204. One of the tips is made longer and a driven sprocket is placed on it, through which the shaft is driven into rotation. It is secured with an M14 nut, under which the end of the axle is machined and a thread is cut.

Similar to the drive shaft, but with 2 identical tips, a tension shaft is made.

The chainsaw engine is mounted through its frame on a motor subframe - a rack located on the cross beam. The gas tank is located on top. The gearbox is rotated 180° and secured to the site. A speed reducer is also installed on it - an intermediate shaft. Sprockets with a number of teeth of 38 and 10 are attached to it. Chains for transmitting rotation are taken from the Voskhod, Minsk motorcycle.

The steering includes:

- support-steering skis on which levers are installed;

- the bipod of the steering shaft, to which the ski levers are connected by rigid rods;

- motorcycle 2-lever steering wheel with a gas control lever near the right handle.

The walls and bottom of the box are covered with 4-layer plywood or boards. Its lid serves as a seat: for its manufacture, 6-layer plywood is taken, covered with a layer of foam rubber and leatherette.

https://youtube.com/watch?v=KxtDdf-N3pY

How to make a winch and sawmill from a chainsaw with your own hands

Homemade products from the Urals often help in construction. So, when constructing buildings from solid wood, it is necessary to dismantle the logs into beams. The sawmill from the Ural chainsaw makes it possible to perform this action as quickly and accurately as possible, while maintaining the accuracy of the cut. The main advantage is that there is no need to perform any complex alterations. The device simply needs to be securely fastened in a homemade frame, which can be made of metal corners or profile pipes. The log for processing is then placed on prepared guides.

Scheme for making a sawmill from a chainsaw with your own hands

You don’t have to create drawings for a sawmill using a chainsaw with your own hands, because a large number of ideas are available on the Internet that are suitable even for a person without experience.

The safety of using the structure is ensured by the fact that you do not need to move the log yourself. For this purpose, a carriage with a saw is used, which, depending on the thickness of the log, is fixed at the required height. Once switched on, the frame moves precisely and the cut remains neat and even. You can use the device not only for solid timber, but also for sawing boards for the purpose of harvesting firewood.

A homemade winch will also be a good helper during construction, because with its help you can easily lift loads to a height and move a cut tree. In addition, using a winch, you can pull out a stuck car or pull a boat out of the water onto the shore. The operating efficiency will depend on the gear ratio; in some models the figure can reach 1.5 tons.

A chainsaw sawmill will allow you to easily and quickly turn logs into timber

To make the device convenient to use, you will need to make a durable frame using welding. The motor, gearbox and drum with braking system should be firmly secured to the frame. To fix the frame on the body, holes and lugs should be provided through which the device can be installed on any surface.

We care for the lopper and work with it correctly

The operation of such a power tool is quite simple. You need to connect it to the mains or charge the battery if you have a cordless lopper, and, having fixed it in the desired position, simply press the corresponding button. But in order for the tool to serve you for as long as possible, you should familiarize yourself with some features of caring for it. In addition, many gardeners will probably be interested in learning how to use high-altitude devices.

First, before starting work, check whether the tool is working properly. Secondly, do not forget about safety precautions. Wear special clothing with long sleeves, preferring pants rather than short shorts. It is also advisable to work in closed shoes, this way you will avoid unwanted injuries. To protect your eyesight, wear safety glasses.

you can What to make from a chainsaw

All homemade products can be divided into 2 groups:

- the most simple grinder (devices, ice drill, pump, winch, walk-behind tractor, boat motor, bicycle, moped);

- more complex objects and mechanisms (sawmill, snow blower, snowmobile, snowmobile, helicopter, power plant, solid forged knife).

To manufacture all of the above devices, you can use various brands of chainsaws. When choosing them, you should take into account the necessary power for normal operation. alterations of everything for the manufacture of various devices use the following brands of chainsaws: Druzhba, Ural, STIHL.

What kind of homemade products can be made from the Druzhba chainsaw and other devices?

Even without the use of additional parts, the chainsaw is capable of performing a wide range of tasks. If you purchase additional attachments for the classic design, you will be able to expand the possibilities of using the device on the farm and get the following devices:

You can purchase special attachments for a chainsaw or make the necessary tool using it.

- snow blower;

- brush cutter;

- pump for pumping water;

- petrol cutter;

- decanter.

Some craftsmen, armed with basic knowledge of mechanics, create additional accessories for chainsaws with their own hands, which can significantly expand the scope of use of the tool. To remake it, you need to understand the operating principle of a universal motor drive, which is easy to use for the manufacture of other devices. Thus, taking a motor from a chainsaw, you can create the following devices:

- ice drill or drill hole;

- boat engine;

- a car or bicycle with a motor;

- lawnmower;

- generator.

The reason for the popularity of homemade chainsaws “Druzhba-4”, “STIHL” or “Ural” is a large number of advantages:

- powerful engine;

- light weight and compact dimensions;

- Possibility of use in extreme conditions.

As a rule, homemade products are made from Ural, Druzhba, and STIHL chainsaws.

Types of lumber

In order to effectively use a carriage, you need to know the techniques for making a particular type of lumber. The following varieties exist:

- carriage (double-edged beam). This is a log with a slab removed from both sides. As a result, two parallel platforms appear on opposite sides;

- timber This is a thick beam of rectangular cross-section, obtained from a carriage after cutting off the sides;

- board. A flat plank obtained by longitudinally sawing a log. Its thickness reaches 100 mm; material above this thickness is considered timber (or carriage). There are unedged and edged boards, obtained from logs or timber, respectively.

Basic accessories for chainsaws that have gained popularity

If you purchase special attachments for the tool, it will be extremely easy to install them; you won’t need to modify anything or disassemble the tool body. All ready-made accessories are designed specifically for installation on a chainsaw. Another important advantage of purchasing a chainsaw is its autonomy. This is explained by the fact that all electrical devices require a 220 V outlet. Using a chainsaw, you will be able to use homemade products in the field, be it a drill, an ice drill or a wood cutter.

A self-installed grinder attachment on a chainsaw allows you to use the equipment not only as a gas cutter, but also as an angle grinder. The nozzle is connected to the device via a special pin, and begins to rotate using a belt from a pulley attached to the drive sprocket shaft. Thus, the device is installed instead of the saw bar

It is important to choose the correct diameter of the nozzle circle; to do this, you must first study the instructions for the Druzhba chainsaw or other equipment used to make a useful device

The corroder is one of the most popular chainsaw attachments

Another common attachment among users is a corroder, used for cutting bark from trees. The attachment is also popular among woodworkers because it can be used to easily remove bark, knots and growths from untreated wood. Some people use a nozzle to create longitudinal or transverse grooves on the beam. There are mainly two types of coders:

- Drums. The main area of application is bark removal, the second name is decanter.

- Disk. Used to create various types of recesses.

There are several nozzles on sale that differ in grip width, most often 80 and 100 mm. If the knives become dull, there is the possibility of secondary sharpening. If the knives are completely out of order, it is better to purchase a new set from the manufacturer. The attachment itself is a cutter or drum mounted in a bearing assembly. Actuation is carried out by a belt drive, and the rotation speed is regulated by the force of pressing the accelerator handle. The diameter of the pulley also affects the speed: the larger it is, the higher the speed. Studs for installing the nozzle are included in the kit.

Cordless shears – compact lopper

Particular attention should be paid to cordless garden shears. Their main advantages include the price, since this tool costs half as much as the models described. The second plus is light weight. If the mass of previous copies was at least 3 kg, then these scissors weigh from 500 to 1000 g. Let's consider the most popular models.

BOSH garden shears of the ISIO series are equipped with a double type of knife, a lithium-ion battery of 1.3 and 1.5 Ah, for models of the 2nd and 3rd generation, respectively. All other parameters for these two models are the same. The blade width is 80 mm, the voltage is 3.6 V, and the operating time reaches 50 minutes. For an additional cost, you can also purchase an extension handle made specifically for this model.

Bosch cordless garden shears

Electric hedge trimmers of the ABC 10.8 Li series are more expensive. But the high cost is due to the configuration. These scissors are equipped with three high quality Swiss steel blades. In this case, one light press is enough to change the working tool. In this case, a 10.8 V lithium-ion battery is also installed. The duration of continuous operation can reach 100 minutes. Charging time is only 3 hours. The width of the knives is 100 mm, and the length is 120 mm and 200 mm. A comfortable handle, a soft pad, a special anti-lock system - all this will make the work as comfortable as possible, regardless of the thickness of the branches being cut. The cost of such a tool can reach $140, and it weighs almost a kilogram.

How to create a lawn mower using improvised materials

To quickly deal with tall grass or tidy up the lawn, a lawn mower must be among the owner’s tools. You can purchase an ordinary factory version of the equipment, which is convenient to use, but you should keep in mind that the price of the lawn mower will be significant. A homemade “Friendship” chainsaw made by yourself will cost one and a half times less than a factory device, and the power is quite enough for standard household use.

Regardless of the type of design chosen, the trimmer will consist of a drive, frame, control system and knives. For ease of operation, the device is additionally equipped with wheels, legs, handles and a protective casing in which the mowed grass is collected. The process of making a lawn mower begins with creating a frame of a convenient size, most often made of metal corners. The optimal size is 25x25 cm. In general, the progress of work on the manufacture of equipment looks like this:

- Using bolts, iron handles are attached to the finished frame, and wheels are mounted on the side parts.

- Having previously studied the characteristics of the Ural chainsaw or any other model, remove the handle and tire from the device.

- Using studs and nuts, the remaining part of the equipment is attached to the base. This must be done so that the gearbox shaft, rotated 90˚, looks down.

- At the next stage, you will need to lengthen the gas cable, and use two tubes to make a sliding shaft connected to the gearbox.

A lawn mower made from a chainsaw will cost much less than a store-bought one.

Elements from old baby strollers or wheelbarrows are used as wheels. If you use several pipes of different diameters for manufacturing, you will be able to make a device with a telescopic operating system that can change the length.

This is especially important if the device is often used by people of different sizes. Also, the creation of a telescopic shaft will help to regulate the height of the grass after the lawn mower passes

To ensure that the device lasts longer, does not fail after encountering hard stones, and effectively fights small bushes, it should be equipped with high-quality steel knives. For convenient use, it is recommended to additionally equip the mower with a grass catcher so that you do not have to collect the remains of the mown grass.

What to look for when buying an electric lopper?

When purchasing such a tool, special attention should be paid to the following characteristics. First, make sure the lopper can handle thick branches. Otherwise, you will only be able to work with young, immature trees and shrubs. Pruning more mature representatives of the flora with an insufficiently powerful unit will be impossible. For safety reasons, it is better to give preference to a device with a blade lock. This way you can protect yourself from injuries and unwanted wounds, because the sharp edges will always be closed. When purchasing an electric lopper, you should pay special attention to safety. It is important to have the “accidental start blocking” function. In addition, most models only work when the buttons located on the top and bottom handles are pressed simultaneously, that is, both hands will be involved.

Electric lopper for thick branches

Pay attention to the handles. If your garden has tall trees, then telescopic or boom units are suitable. With their help you can work even at a height of 5 meters.

Boom unit for tall trees

Homemade snow blower

A snow blower is a device that clears snow, which can be built on the basis of a chainsaw with a power of more than 3 kW. Many craftsmen do not use wheels, but install the simplest runners from a sled. A particularly important part in creating such a unit is the installation of a screw assembly, driven by a gear pair and chain. Rubber is used in the manufacture of blades, and steel is used in the construction of the intake device. A plastic sewer pipe attached to the intake can serve as a snow thrower.

Handmade chainsaw kart

A kart is a small car that does not have suspension and is capable of quickly reaching a decent speed. Such a car without a body consists of the following main components:

- Steering system.

- Brake system.

- Engine.

- Chassis.

Homemade karts often use a chainsaw engine. Before assembling the kart, the engine must be prepared (remove all unnecessary parts: tanks, chains, etc.). The teeth of the chainsaw sprocket are ground down, giving the sprocket the desired size. Next comes the installation of the engine mount.

Do-it-yourself go-karting from a chainsaw and other materials is relatively cheap and fun. Although the process of assembling the card is quite complicated and requires certain skills.

You can also build a buggy from a chainsaw.

A bike with a chainsaw motor

You can install a chainsaw engine on your bike. On such a bicycle moped you can accelerate to 50 km/h, and sometimes even higher. In order to design this transport, you need a chainsaw engine with a power of 1.5 - 2 hp. – this is enough to develop a speed of 30 – 40 km/h. It is clear that you need a container used as a gas pack; you cannot do without wires and a switch to connect the engine ignition, etc.

A bicycle made from a chainsaw consumes a minimal amount of fuel.

Various masters on the Internet tell in detail how to make a motor for a bicycle from a chainsaw.

Do-it-yourself sawmill from a chainsaw

For such a homemade sawmill, a metal frame is used, to which the saw is attached. Workpieces can be directed along a rail track. There are different variations of sawmills. To design a unit for longitudinal cutting, you need an adapter that is attached to the bar, and a guide that sets the direction of its movement. The guide is installed on a board that is attached directly to the log. Using this sawmill, logs can be divided into several parts (2 – 4).

Grafting pruner: features and purpose

The grafting pruner has become an innovation that allows you to obtain almost 100% results when carrying out vaccinations. The principle of operation of the device is as follows: using a precise blade on a pruning shear, a cut is made on the scion and rootstock. It is the ideal blade that makes it possible to guarantee a cut from which the two parts of the branch fit together. After using such a tool, the gardener only needs to secure the two parts in the chosen way. This device made it possible to radically change the views of gardeners on the grafting process; now it has become easy and elementary.

Today, manufacturers produce universal pruning shears with three types of attachments: V, U and omega, which allows you to perform various types of garden grafting. Now every gardener will be able to supply the attachment that is necessary for a specific tree and grafting method.

A special feature of the tool is its durability. As practice shows, one tool is enough for several thousand sections . Gardeners note that such a tool does not pose a danger to humans; its operating principle and design are thought out to the smallest detail.

Homemade winch

A homemade winch can use a gasoline saw motor, the power of which determines the traction force of the entire unit. In addition, the chainsaw winch is equipped with:

- tap block;

- hooks;

- belts;

- anchors.

Sources:

https://xnd1aspaq3c.xnp1ai/mebel/kustorez-iz-benzopily-svoimi-rukami.html https://armatool.ru/samodelki-iz-benzopily-svoimi-rukami-foto-i-video/ https://benzopilok .ru/samodelki/iz-benzopily.html