Today, a loom in the house is exotic. And some 70-80 years ago every village housewife had one. In many ways, this is a plus, because it means that the modern standard of living allows everyone to purchase ready-made clothes and fabrics, rather than waste time and effort on making them. However, modern women (and men) are increasingly interested in this forgotten craft, recreating ancient village weaving looms. Let's find out a little more about the features of these devices, as well as how you can make them yourself at home.

Weaving machine and its structure

This device was invented before our era. Over the past millennia, its design has been improved. However, some elements remained unchanged.

The basis for fabric production on any loom is vertical threads. They are called the main ones. The very process of creating a canvas is the interweaving of horizontal (weft) threads between the base ones. To do this, manual looms use a shuttle (a rectangular, flat spool with pointed edges). Its shape allows it to easily slide among the warp and pull through the weft threads.

Another important part of any loom is the reed. This is the name given to the frequent comb used to compact the fabric after each shuttle run. Without such “combing”, the finished fabric will be loose and uneven. In most household and industrial weaving looms, a special bar with teeth is used instead of a reed.

The last integral element of each such device is the frame that controls the base threads. Their function is to take turns raising either the even or odd ones. Thus, a more reliable and varied weave of the fabric is achieved.

Types of machines

These devices are classified according to different indicators.

- By design they distinguish between flat and round looms. The latter is used to produce only a special type of fabric.

- Based on the width of the fabric produced, narrow (up to 1 m) and wide (over 1 m) machines are distinguished.

- Based on the type of weaving of threads, weaving devices are distinguished that produce simple fabrics (eccentric), with a small pattern (carriage) and large-patterned fabrics (jacquard) for the production of the most complex patterns.

- Regarding the principle of operation, there are: manual, semi-mechanical, mechanical and fully automatic machines.

Particularly worth highlighting are the so-called frame looms. Usually they are completely devoid of any mechanisms; they have to be woven by hand.

Short story

Judging by ancient Egyptian images, already in those days humanity invented some kind of handloom. Most peoples had a similar design. This is evidenced by the drawings and archaeological finds that have reached us.

As a rule, they were woven from threads of plant (linen, silk, hemp, cotton) and animal origin (wool yarn). Naturally, such fabrics were not very strong and durable. To provide clothes for the family, they had to weave every year. In this regard, almost every peasant family had a home loom.

Although weaving was practiced in every family, there were craftsmen who specialized in the production of special fabrics or carpets (tapestry). For many centuries this profession was very profitable and prestigious.

Everything changed with the advent of the mechanical loom. Now it was possible to produce large quantities of fabric with minimal time and labor. Gradually they began to equip factories that produced cheaper fabric than weavers. Soon the latter were forced out of the market. By the beginning of the 20th century, the weaving profession was losing its former prestige. Now they were engaged in the production of homemade linen only for their own needs.

As a rule, machines inherited from grandmothers were used for this. Or we had to make them ourselves.

Information on how to make a loom was taken in those days from two sources. It was either a manual by I. Levinsky, published back in 1911. The book was called “Improved Handloom”. It contained fairly clear illustrations, with the help of which it was not difficult to assemble the necessary equipment.

The second reference book was V. Dobrovolsky’s manual “How to build a loom and weave simple fabrics,” published in 1924.

Both publications can still be found in libraries today.

By the beginning of the 80s, the standard of living of the peasantry began to rise. This allowed many of them to give up weaving, buying ready-made fabrics in stores. Now the looms were gathering dust again in closets and attics. Only fans of this craft have preserved them. It is noteworthy that today most of them are well over 70 years old.

Since the 2000s (when store shelves were filled with various factory-made textiles), interest in making linen by hand has increased again.

History of the Slavic woven carpet

Among the Slavs, the creation of floor carpets, paths, and bedspreads is one of the “grassroots” techniques. At first, this craft was practiced only for the needs of ordinary people. These things did not require a serious level of skill, as required by weaving lace and weaving thin fabrics. And the tools used to create them were the simplest.

- In most cases, they wove ordinary paths from unnecessary fabric items that had served their purpose. Strong, dense threads were used as the base, but the transverse ones were strips of fabric. Homespun paths were popular in our country in the nineteenth century.

- Sometimes they took flax waste and straw to create rugs. Such things were usually laid out at the very entrance to the huts. To create both, in most cases an old loom made of wood was used.

- The workflow is quite easy. Transverse threads are pulled between the stretched threads of the base using the interlacing method. From time to time they will need to be compacted with some reeds, which are similar to combs. They used them to assemble transverse rows into a large canvas.

Factory machines

If you are wondering how to make a DIY loom, then you are one of those who want to create their own textile products from scratch. To do this, it is not necessary to make the machine yourself. You can buy it.

Read also: Soldering iron for SMD LEDs

There are hundreds of varieties of factory-made looms on sale. Domestic or European manufacturers provide a guarantee for their products, so you can buy machines without fear that they will not be able to work.

Judging by the reviews, among Russian manufacturers the best are looms and Pelsi. The latter specializes in the manufacture of wooden toys.

As for manufacturers from other countries, their products are many times more expensive.

How to make the simplest machine from thick cardboard

The process of creating fabric itself is not very complicated. If you plan to weave small items like belts, bracelets or napkins, you can make a very simple handloom.

To do this you need a sheet of thick cardboard. If you don’t have it on hand, you can use juice or milk packaging material.

To begin with, take an even rectangle. Next, equal distances are measured along the edges and tiny rectangles are cut out at the top and bottom. All.

Now the warp threads (vertical) are pulled through these holes and secured. An ordinary gypsy needle will act as a shuttle. Using it to stretch horizontal threads between the main threads, you will gradually be able to weave a small piece of fabric.

Of course, on such a primitive machine it will only be possible to weave coarse fabric. However, most craftswomen who began their creative journey with such a device advise in their reviews not to neglect this machine. It will be an excellent budget start that will help you get your bearings and understand the process a little. In addition, once you start working on it, you will be able to decide for yourself whether this trade is interesting to you.

PVC pipe loom

Make a simple loom from PVC pipe. This tutorial shows you how to make a simple loom using affordable PVC material!

I wanted to build a loom because I've been seeing a lot of really cute weaving projects on home design blogs lately and always thought, "I could do that!"

Inventors shop at a budget Chinese online store.

Happy reading, I'm sure you can make your own machine too!

Step 1: Tools and Materials

Here are all the tools and materials I'm using in this build. I really like using PVC because they look a bit like giant structured Tinker toys.

Step 2: Marking where the pegs will go

DIY electronics at a Chinese store. I put masking tape on the PVC pipe and then used measuring tape and a permanent pen to mark 1/2" distances, starting and stopping 1" from each end so the joint could still slide down to the pipe Later.

Drawing a straight line on a cylindrical surface is a pain, so... tape to the rescue! I've learned from previous PVC trades that the easiest way to make markings along a curved pipe surface is best with a guide attached to the surface, rather than holding a wavy tape measure in place

I used a tool to make small dents in the PVC along each of my 1/2″ marks.

These small indentations will act as guides for the screws to go into the soft PVC plastic. The magic about using self-tapping screws is that you don't have to pre-drill.

Step 4: Align the Pegs

The pegs/screws protruded from the pipe at different heights and I wanted to make sure that none of them were at risk of being pulled out, nor were they so strong that they couldn't fit into the twine behind the screw head.

I got down to eye level with pegs and quickly completed this task with a hand screwdriver, but if your hand isn't tired from holding the drill, you can use this tool as well.

Step 5: Completing the Assembly

I posted a parts diagram on the materials step more closely, but the loom actually came together within seconds of setting the pegs.

The knee joints go along the bottom of the square, and the 3-way joints go along the top of the square, and the pegs lie across the loom.

Once the square is assembled, the 6-inch piece fits into the back of the 3-way joints and connects to the 45-degree joints and the remaining posts and end caps.

Step 6: Making Adjustments

I used a hammer drill to make sure the connections were REALLY secure. Along both rows of pegs, I hammered to align the pegs a little more so the string wouldn't slide behind them, and oriented the top row pegs toward the ceiling.

Step 7: Start stringing the twine

I started the tension by creating a slipknot in the string and tightened it to the peg, which was 12 pegs from the edge.

I used synthetic thread for my warp, which in hindsight was a mistake, I should have used some natural, more forgiving fiber - cotton twine is probably ideal.

Step 8: Install the Twine

Make sure your warp is not too tight. I learned this the hard way. The first time I positioned the pegs facing me, the pipe slipped out of the seams when I installed the base. The second time I rebuilt the loom so that the pegs were pointing towards the ceiling, and when I dropped the base it seemed to flex less and more rigidly.

Step 9: Create the Shuttle

Shuttles are things that carry yarn through the warp. They are usually narrow, flat, long spools of yarn that can be easily inserted and pulled between the fibers. It's much easier to put thread between the fibers than a whole spool of yarn, I made it from cardboard in 2 seconds.

Step 10: Start weaving!

I'm just starting out so I didn't try any fancy stitches or patterns, I just went back and forth slowly adding layer after layer. Getting the tension right was a little tricky, but easier once I started.

Step 11: Continue

Okay, I didn't realize weaving was such a timely skill! Although it was very meditative, this part took approximately 4-5 dedicated evenings to complete.

Each time I started or ended with different strands, I simply used one knot to attach it to the warp strand.

Step 12: Removing the Piece from the Loom

Removing the piece from the loom was very easy, all I did was rotate the top PVC pipe so the peg heads were facing the table top and the loops slid off the loom.

Step 13: Tie the Edges

I know some people like to add stripes or pom-poms to their woven pieces, but for my first attempt I just went with the easiest tying method - regular knots.

I took two warp strands at the same time and wrapped it around my finger to create a tight knot.

Step 14: Gluing the Loose Thread

I had a couple of loose ends that had come loose that I wanted to hide in a piece from the tails that were left hanging off the edges. Using a yarn needle, I wove them into a couple of columns, then glued the tails together.

I used Fabri-Tac because I knew it had a short open time and a very fast drying time, although I think it takes 24 hours to cure completely.

Once the tails were completely dry to the touch, I trimmed them closer to the piece.

Step 15: Training

I mentioned this above, but if I didn't pull the base as tight, the piece would end up bending a little in the middle due to the sides getting tighter as I went up the loom.

Another note about skew: I used synthetic thread because that's what I had, but in retrospect I wish I had used heavy cotton thread instead, it would have provided more and maybe solved some of my stupid skewing issues. by tension.

All the pictures of actual weaving that I include in this tutorial are basically me playing, "drawing" and learning the nuances of a home loom. Thanks, I hope this inspires you to try making a loom!

Source

Frame type machines

If you've mastered the cardboard jig and are ready for more, it's worth taking up making a frame loom.

It's easy to do. A rectangle or square of the size you need is knocked out of wooden planks. Next, nails are driven evenly into it from above and below. They will serve as fasteners for threads.

Before starting work, a base is stretched between the upper and lower rows of nails. Next, weft threads are passed between these threads.

If the frame is very large, it is worth making a small shuttle for it from a piece of the remaining plank. To do this, you need to sand it well, give it a thin streamlined shape and make grooves along the edges so that it is convenient to wind the thread onto it.

If the frame size is modest, you can use a large gypsy needle.

Please note that for this type of hand loom a reed is already required to ensure that the fabric is dense. This comb can be made from the same wooden plank by cutting holes in it corresponding to the location of the threads on the nails.

If you plan to sew clothes from woven fabric, you can make frames in the shape of patterns for future parts. This way, you won’t have to waste extra material when cutting, which you spent so much effort creating.

Weaving loom for rugs

In addition to clothes, bed linen and towels, our grandmothers wove carpets and bedspreads on their looms. To create such products, the same classical devices were used. However, they are quite bulky. In addition, it takes a lot of time and effort just to thread the machine to start working on carpets.

Therefore, a simpler weaving device, the frame type, is very popular.

As a rule, rugs that are well known to all of us are created on such a machine from scraps of old clothes. You can also use special thick woolen threads.

How to make such a loom with your own hands? Quite simple. It is an improved version of the classic frame. However, it will be larger and longer. As fasteners for the base threads, you will have to use large nails or screws with thick legs and wide heads.

Pay attention to the special detail. You need to place 4 metal loops along the four edges of the machine. They are needed to fix 2 rods. When working on a rug, they will need to be inserted into its edges so that the width of the finished product is uniform.

DIY machine for weaving rugs

A loom is a piece of equipment that makes it possible to handcraft beautiful and unique things. These can be rugs, special runners, tapestries, as well as bedspreads for furniture, scarves, bags, and even fabric for coats. It is quite possible to create a weaving loom on your own.

History of the Slavic woven carpet

Among the Slavs, the creation of floor carpets, paths, and bedspreads is one of the “grassroots” techniques. At first, this craft was practiced only for the needs of ordinary people. These things did not require a serious level of skill, as required by weaving lace and weaving thin fabrics. And the tools used to create them were the simplest.

- In most cases, they wove ordinary paths from unnecessary fabric items that had served their purpose. Strong, dense threads were used as the base, but the transverse ones were strips of fabric. Homespun paths were popular in our country in the nineteenth century.

- Sometimes they took flax waste and straw to create rugs. Such things were usually laid out at the very entrance to the huts. To create both, in most cases an old loom made of wood was used.

- The workflow is quite easy. Transverse threads are pulled between the stretched threads of the base using the interlacing method. From time to time they will need to be compacted with some reeds, which are similar to combs. They used them to assemble transverse rows into a large canvas.

Rectangular

The easiest way is to create a frame on which you can quickly make a small-format tapestry. In fact, this is an ordinary weaving loom, where all the work is done by the master himself. You can call the frame a hoop , which is easy for the master to work with, since this tool can be carried and installed anywhere.

- It is enough just to lay out 2 slats parallel to each other, onto which you need to hammer nails. The warp threads are pulled over them. Weft - transverse threads - are pulled with your own hands using a shuttle.

- You can use simple, standard weaving. Then the canvas will turn out to be one color. To do this, we drag the shuttle first under the even threads of the base, then under the odd threads. By changing the color of the weft, you can make cross stripes on things. To create an ornament, you will need more complex weaving. Then the shuttle is passed under the base threads, no longer in a checkerboard arrangement, but depending on what pattern you decide to use.

- If you place a printed image under the stretched threads of the base and use several different colors, you can easily make a real picture. These products are called tapestries and require patience, time, and skills from the craftsman.

Round

Hoops for creating products do not always have to be rectangular. To make round carpets you will also need a frame of a suitable shape.

If you take a hoop and pull the base threads so that they intersect in the central zone, you can easily achieve this. In this case, weaving starts from the middle , and the rows will be arranged in a circle, “snail-like”. It is very easy to assemble such a loom yourself. You can even use a special hoop. The shuttle remains the same design.

Stationary

When creating huge canvases, working on a frame is very difficult. And it’s completely impossible to make long special paths. There is no way to work here without a stationary machine.

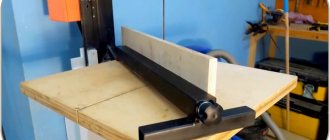

The drawing gives a simple diagram showing how to make a loom. It provides a horizontal frame onto which the base threads are pulled, and a vertical frame responsible for creating clearance for the passage of the shuttle with the weft thread and the shuttle. All elements are made of wood. Metal fasteners, nails, and rubber gaskets are also .

This special do-it-yourself loom helps create fabric by eliminating the need for the craftsman to pick out the warp threads with his own hands while pulling the cross threads through the weaving process.

Weaving technology

What is the operation of the machine? The fact is that the even warp threads are passed into the holes of the vertical frame. First, by moving your foot, this part goes down . As a result, a gap is created between the warp threads, into which the shuttle is passed.

- A new row is made by moving the frame up. At the end, the even threads rise, again creating a gap. The weft thread passes through, and a “basket”, checkerboard weave is formed on the material.

- The manufacturer compacts the rows with reeds, knocking them into the product. Many machines have power tools to perform this action, which makes the job very easy.

- It is important to take into account the need to regulate the tension of the warp threads. For this purpose, screws are used, which the manufacturer has the ability to unscrew or tighten as he chooses.

- It is also necessary to take into account the distance between the threads of the base. The ability to adjust it also expands the functionality of the tool.

- Creating a loom that has mechanized weft insertion makes the work even easier and helps to improve the quality of things.

Round machine for rugs

Many people like round floor mats rather than rectangular ones. To weave them, you need to use a round loom.

You can make it, for example, from an ordinary plastic hoop. Just make sure that it is not curved, as this will affect the quality of the finished product.

First, the edges are marked around the entire circle. Next, you can drill holes at the marks or drive in nails. Some people simply tie the threads to the rim itself. However, with this technique, the finished rug will not be of very high quality, since poorly secured threads can sag or move out.

If you were not lazy and made normal fasteners for the base, you can start working. To do this, the main threads are pulled radially. The machine begins to resemble a bicycle wheel. Now you can start weaving the rug from the very middle.

As a rule, this machine is operated by hand. Reviews advise using a miniature shuttle or a large needle only when making very thin fabric.

Read also: What is poured into a hydraulic car jack

Interesting weaving with children

Getting into weaving is actually very interesting. Although at first glance it may seem that this is a very tedious task. Not at all.

We decided to try making looms for ourselves and the children out of cardboard and try this out together. 5 girls aged 5 to 7 years old wanted to do this kind of weaving with pleasure.

We weren't sure that the little ones would succeed, but we decided to just try.

It turned out that they like it this way! By the way, the end result was some cool crafts, and it was impossible to distinguish the children’s ones from the ones we made. We liked the girls' results even more, as they were larger and brighter. And believe me, children enjoy the weaving process.

What you will need for weaving and the “loom”:

- a piece of cardboard about 12x20 cm and two cardboard strips for the top and bottom parts

- scissors or utility knife

- yarn (any colors, bright colors are best for children)

- plastic needles (to make it safe for children)

- scotch

- pompoms (optional)

- branches

Making the machine:

1. Mark with a ruler the places on the top and bottom of the cardboard where you will make cuts (threads will be inserted there later).

2. Use scissors or a utility knife to cut the marked areas.

3. Now stick the prepared strips on the top and bottom of the cardboard (as in the photo).

4. Now insert a thread into each of the slits, securing each one at the top and bottom of the cardboard. Do not pull too hard to avoid damaging the yarn. Secure at the back with tape.

- The machine is ready!

- Let's start weaving:

1. Cut the thread approximately 2 meters in length. We thread it into a plastic needle. We tie a tight knot at the end of the thread.

2. We begin to zigzag stitch the first row.

3. You need to start the next row with a thread that you did not pick up with a needle in the first row, so that the stitches are staggered. Keep an eye on this so that everything works out for the children.

If something is not straight, you can gently correct it with your fingers. But just be careful not to stretch everything. We would like to warn you right away that you are unlikely to get it perfect the first time, but don’t despair!

4. After one thread runs out, take a thread of a different color. This way the result will be more interesting.

You can use many colors in one craft. Secure the end of each thread that hangs in a knot, and simply cut off the excess.

We remove the product from the “machine”:

1. Using careful movements, peel off the tape that secured the warp threads. Very carefully remove the yarn from the “loom”.

2. Now take the threads that are left hanging on each side and tie them together.

You can figure out how to tidy up the back of the product yourself. It's simple. Can be glued with special textile glue. Or you can glue it with adhesive tape (as in the photo below).

OK it's all over Now! In principle, the product is ready. But to make it even more interesting, you can decorate it with pom-poms or beads.

We used ordinary sticks that we found in the forest. We put our craft on them (using an extra thread and a plastic needle) and then started decorating. We attached the pompoms to the back, securing them with the same adhesive tape. But you can fantasize and come up with your own design.

The final touch was to attach the thread on which our craft will hang. Well, it's quite simple - tie another thread to the stick itself.

Of course, there are many activities for children. But weaving will become something new and unusual for your child. This is also useful because you will also be weaving with your baby. Good luck!

Source: https://ihappymama.ru/interesnoe-tkachestvo-s-detmi/

How to make a machine from plywood or wood

If you have enough space to accommodate a full-fledged weaving device, it is worth trying to make a more professional model. Most often they are made from plywood or wood.

There are many ways to make such a device with your own hands.

There should be two rollers at the very beginning and at the end. Threads are wound onto one, and finished fabric onto the other. The ideal option is to make them with bolts or handles with the possibility of fixation.

If your machine does not have a separator that facilitates the slipping of the shuttle, you should first attach not 1, but 2 rollers. One will place the even warp threads, and the other will place the odd warp threads.

The last required detail is the reed. It can be made from 2 wooden planks with nails often driven between them.

When threading the machine, the threads will need to be passed between these teeth.

If all this is done correctly, you can get to work.

Machine tools from other scrap materials

In addition to wood and plywood, weaving jigs of the above type can also be made from other materials. For example, from plastic pipes. When making miniature models, ordinary combs or cards are used. A photo of such a machine is presented above.

Also, when making miniature models, ordinary combs or cards are used. And the machine itself can be built from a cardboard box.

If you want to show your creativity even in the way of creating your own loom, go for it! You will succeed.

Nowadays you can buy almost all home craft products in stores. But sometimes you don’t have the money to buy it or you want to make something yourself. Recently, the variety of interiors has simply gone off scale. Designers often use antique items to create a unique and unique atmosphere in the home.

Many people cannot afford to hire a designer and purchase unusual decorative elements, so you can make such items yourself. For example, woven carpets will add color to the interior. And if they are made on their own, they will delight you every day. Moreover, with them your home will become cozy and warm. In addition to carpets, you can make napkins or lampshades. All these items are made using a loom.

All these things were made using a handloom. The first looms were large wooden structures. There were weaving looms in almost every house. And they were taught to use them from childhood. The skills of patterned weaving were passed down to the younger generation. Ancient looms were mostly shuttleless.

If you are interested in an activity such as weaving, then you can make a loom with your own hands at home. The loom is widely used in the modern world. The shuttleless table loom is also designated as STB. It is used in the processing of various fabrics to obtain finished products.

How to weave a masterpiece “on your knees”: unusual looms

Do you love to weave, and suddenly find yourself far from your favorite machine?

You can’t decide to buy a rather large and expensive machine?

Do you love learning new techniques but aren't sure you need a loom?

Maybe you like to do everything yourself, even if it’s easier to buy?

You don't know what else to do with your child?

Do you admire the ability to make anything out of anything?

Then this creative collection is for you!

The loom is simple, like everything ingenious. Here is the appearance and detailed drawing:

Does it look very archaic? Try to look at it through the eyes of a modern person! For example, like this:

You can make a fashionable modern frame from plastic pipes:

Here are more compact desktop machines for those who are not yet ready for big feats:

When you don’t have the strength to weave as much as you want, you can greatly simplify the design:

And if you are ready to start with something very small, then you can use ideas for bead weaving, because on all these “looms” you can also weave with threads:

I would also like to say something about weaving on cardboard. It is usually woven by stretching threads onto a rectangular piece of cardboard with slots.

But once you turn on your imagination, you begin to understand that the possibilities of the cardboard “machine” are almost limitless:

More creative ideas:

Or even like this (cheap, cheerful and develops fine motor skills for the child):

After practicing fine motor skills, you can move on to more serious physical activity:

Well, if you really don’t have anything at hand, then attach one end of the base to your belt, and the other to your own legs - a very ancient and respected method, by the way.

Do you think it’s impossible to do anything meaningful with things like this?

Yes, don't expect your first works to look like this:

But, with a little experience, you can do simple and stylish things:

Working principle of table loom

The design of the weaving machine involves laying threads using a special threader. The amount of yarn that enters the installation can reach 2-4 kg. Thus, you can work on the STB loom for a long time without stopping.

This installation is a combination of shafts. This is a roller-beam for winding thread on it and a roller for the finished fabric. The threads are made through holes - healds. The healds are connected to each other by a braid that is thrown over the heald rollers at the top and bottom. There are also two rollers, which are necessary when exiting the main part and the finished product, respectively.

The type of mechanism on the devices represents the formation of a pharynx. There are 3 types of mechanism:

- cam type;

- carriage;

- jacquard.

If simple patterns are intended to be produced, then the cam type is used. The cams also make it easy to move from pattern to pattern. The jacquard mechanism provides wide installation possibilities.

Depending on the filling width, the machines are divided into wide (from 25 m) and narrow (22 m). If there is a multi-color weft addition, it becomes possible to introduce threads of different textures and densities.

Main stages of work:

- Yawning.

- The process of inserting the weft into the shed.

- Surf the duck to the edge of the product.

- The mechanism of movement of the product.

- The process of lowering the web from the warp shaft.

Weaving loom - how to choose the right one and make it yourself, features of use

We wear clothes and use other textile products, but sometimes we don’t think about the process of creating them. They are made from materials for the production of which a weaving machine is used. This device has been used for several thousand years and has its own history and characteristics.

What is a loom?

It represents the equipment needed in the textile industry.

A weaving loom is a device on which fabrics of different textures and compositions are produced - cotton, wool, silk, linen and other fabrics.

These can be woven, smooth, pile materials used for the manufacture of clothing, household textiles, carpets and other products. Another name for such a device is krosna.

How does a loom work?

The principle of its operation is simple. Whether a home loom or an industrial one is used, the algorithm for its operation is as follows:

- Threads are threaded through the eyes of the healds.

- When the first frame is raised, the even threads are raised, and the odd ones are at the bottom.

- Between their rows a shuttle is thrown, in which there is a bobbin with a transverse thread (weft). It unwinds and then lies between the threads of a woven base consisting of longitudinal threads.

- After moving the shuttle, the first raised bar returns to its place.

- When a transverse thread is woven into a warp consisting of longitudinal threads, it is tightly fixed to the latter by means of a metal comb. This is how a loom equipped with a reed works.

- The next step is to raise the second heddle to move the odd threads over the even ones. The transverse fibers are laid on the longitudinal ones by throwing the shuttle in the opposite direction.

- Odd warp threads are covered by even ones due to the fact that the heald is lowered.

- The fiber is nailed with a metal comb.

Loom - history

People learned to weave mats from reeds and tree branches, after which they mastered a similar technique using fibers. Important points in the history of the development of the device:

- The first loom was a vertical one, and it was invented in 1550 BC. e. It was a primitive device on which longitudinal threads hung on one side and transverse threads on the other. Weaving took a lot of time and effort.

- In 1733, John Kane, an English clothier, invented a mechanical shuttle. The weaving machine was equipped with it for throwing threads. Thanks to this invention, labor and time costs for the production of canvases were reduced, and it became possible to produce them in large quantities.

- In 1785, Edmund Cartwright patented a foot-operated machine tool. The device was refined by other inventors and was improved by the 30s of the 19th century.

- In 1879, Werner von Siemens created an electrical device.

- In 1896, the automatic loom was introduced. Modern devices are descendants of this device.

Types of looms

There are several classifications of the device. In accordance with the principle of operation of the mechanism, it is divided into the following types:

- handloom;

- mechanical;

- semi-mechanical;

- automated.

Depending on the method of laying the thread, the device can be:

- pneumatic;

- hydraulic;

- foil

Air loom

This type of device is used for the production of materials from yarn and chemical complex fibers.

A modern pneumatic weaving loom has the following feature - the transverse thread is pulled into the shed using the pressure force of compressed air, which is supplied through pipelines from the compressor.

This type of device is used for the production of simple weave fabrics with a surface density of maximum 200 g/sq.m.

Hydraulic loom

This type of device is used for the manufacture of synthetic materials that are not wetted by water. This weaving machine has a design that involves drawing the thread through a drip jet of water. The latter is ejected from the nozzle under pressure. The speed of laying the transverse thread on such a device can reach 35 m/sec.

Rapier loom

This type of device is used for the production of both synthetic and natural fabrics. With its help, technically filtered and mixed gray fabrics are produced.

You can use a rapier loom for rugs and other items with a rough texture.

On this device, the transverse thread is pulled into the shed by means of grippers that are fixed at the ends of rapiers (flexible metal strips) that perform reciprocating movements.

Self-production of the machine

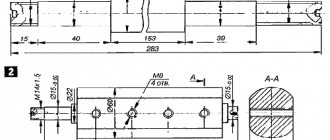

Many people are faced with the task of how to make a loom? Moreover, to spend less materials. So how to make a loom with your own hands? First of all, you need to adhere to the manufacturing scheme, which contains successive steps:

- A quadrangular frame is selected.

- Round openings are made in two slats.

- Slats with the smallest circumference are placed in the openings made at the ends of the bar and secured with wedge parts.

- There are grooves in the middle part of the side bar to accommodate the comb.

- The equipment has a solid bottom for stable standing.

- Nails are driven into the nearest round block at a distance of 5 mm to tighten the threads.

- At the rear of the installation, a rail is used to wind excess fabric.

The comb can be made from thick plywood. Its height reaches 15 cm. The length of the comb should be greater than the distance between the frames, which are located on the side. The number of nails driven in must be divided by two to obtain the number of teeth. Select the height of the teeth to be approximately 70-100 mm, and the width 5-7 mm. The interdental space is 5 mm.

Read also: How to solder headphones without a soldering iron

On the near shaft there are nails to which threads of equal length are tied. Then the threads are divided into even and odd. Behind the comb there is a moving shaft where the odd threads are attached. And the even threads are on the comb, namely, they are wrapped around the nails of the teeth. A homemade loom works according to the rule of winding the remaining amount of thread on a bar, and the base of the product is made.

Next comes the winding of the threads onto the wefts. The end of the thread is attached to the left side of the frame, which is located in front of the drive rack. When the bar is raised, the weft is pushed into the shed. Movement occurs from left to right. By alternating multi-colored threads, you can get designs on the product (checkered, striped).

Video: how to make a loom?

Do-it-yourself rug weaving machine

Nowadays you can buy almost all home craft products in stores.

But sometimes you don’t have the money to buy it or you want to make something yourself. Recently, the variety of interiors has simply gone off scale.

Designers often use antique items to create a unique and unique atmosphere in the home.

Many people cannot afford to hire a designer and purchase unusual decorative elements, so you can make such items yourself. For example, woven carpets will add color to the interior.

And if they are made on their own, they will delight you every day. Moreover, with them your home will become cozy and warm. In addition to carpets, you can make napkins or lampshades.

All these items are made using a loom.

Previously, with the help of a device such as a loom, towels with patterns, tablecloths, rugs, sundresses and shirts embroidered in different colors appeared in homes. Not a single holiday would be complete without patterned towels. They also decorated people's huts.

All these things were made using a handloom. The first looms were large wooden structures.

There were weaving looms in almost every house. And they were taught to use them from childhood. The skills of patterned weaving were passed down to the younger generation.

Ancient looms were mostly shuttleless.

If you are interested in an activity such as weaving, then you can make a loom with your own hands at home.

The loom is widely used in the modern world. The shuttleless table loom is also designated as STB.

It is used in the processing of various fabrics to obtain finished products.

Working principle of table loom

The design of the weaving machine involves laying threads using a special threader.

The amount of yarn that enters the installation can reach 2-4 kg.

Thus, you can work on the STB loom for a long time without stopping.

This installation is a combination of shafts. This is a roller-beam for winding thread on it and a roller for the finished fabric. The threads are made through holes - healds.

The healds are connected to each other by a braid that is thrown over the heald rollers at the top and bottom.

There are also two rollers, which are necessary when exiting the main part and the finished product, respectively.

The type of mechanism on the devices represents the formation of a pharynx. There are 3 types of mechanism:

- cam type;

- carriage;

- jacquard.

If simple patterns are intended to be produced, then the cam type is used. The cams also make it easy to move from pattern to pattern. The jacquard mechanism provides wide installation possibilities.

Depending on the filling width, the machines are divided into wide (from 25 m) and narrow (22 m). If there is a multi-color weft addition, it becomes possible to introduce threads of different textures and densities.

Main stages of work:

- Yawning.

- The process of inserting the weft into the shed.

- Surf the duck to the edge of the product.

- The mechanism of movement of the product.

- The process of lowering the web from the warp shaft.

To facilitate the work, the textile machine has a drive and a device to start or stop the work. The device begins to work by supplying the drive to the main shaft, and then from it to other parts.

Many people are faced with the task of how to make a loom? Moreover, to spend less materials.

So how to make a loom with your own hands? First of all, you need to adhere to the manufacturing scheme, which contains successive steps:

- A quadrangular frame is selected.

- Round openings are made in two slats.

- Slats with the smallest circumference are placed in the openings made at the ends of the bar and secured with wedge parts.

- There are grooves in the middle part of the side bar to accommodate the comb.

- The equipment has a solid bottom for stable standing.

- Nails are driven into the nearest round block at a distance of 5 mm to tighten the threads.

- At the rear of the installation, a rail is used to wind excess fabric.

The comb can be made from thick plywood. Its height reaches 15 cm. The length of the comb should be greater than the distance between the frames, which are located on the side.

The number of nails driven in must be divided by two to obtain the number of teeth. Select the height of the teeth to be approximately 70-100 mm, and the width 5-7 mm.

The interdental space is 5 mm.

The comb is located in grooves on the side bars. The length of the comb is a distance less than the distance inside the installation.

A necessary part of a loom is the weft. The thread is wound on it. It is a movable element.

The weft can be made as a spool device or as a separate piece from plywood.

On the near shaft there are nails to which threads of equal length are tied. Then the threads are divided into even and odd. Behind the comb there is a moving shaft where the odd threads are attached.

And the even threads are on the comb, namely, they are wrapped around the nails of the teeth. A homemade loom works according to the rule of winding the remaining amount of thread on a bar, and the base of the product is made.

Next comes the winding of the threads onto the wefts. The end of the thread is attached to the left side of the frame, which is located in front of the drive rack.

When the bar is raised, the weft is pushed into the shed. Movement occurs from left to right.

By alternating multi-colored threads, you can get designs on the product (checkered, striped).

: how to make a loom?

Making a simple weaving device

You can also make a simple mini-device at home, which will serve as a play device for children, and also teach them how to weave.

A children's loom will be useful for teaching children the ancient art of weaving.

Using such a simple loom, you can make a compact rug that will be useful at home.

First, markings are made on the cardboard using a ruler. Even a child can participate in this process. Marking is carried out on opposite sides of the sheet in increments of 5-10 mm.

Small parallel lines are drawn along the marks. Next, cuts are made at the locations of these lines. At the end, we make the base using yarn.

Instead of yarn, you can use ribbon or ordinary thread.

The loom operates by threading threads into slits and then weaving. The yarn is made into a cut, and its end is located on the wrong side.

Threading the yarn should be done in the form of a snake. The end result is tying the resulting cutouts. On the other side, stripes of threads are also made. One side will be the front side and the other side will be the back side.

The front is a completed canvas.

You have to pull the threads smoothly so as not to bend the cardboard. You can use a larger needle for convenience.

The number of threads must correspond to the edge being an edge and the transition from row to another row to be made. You can move the threads close to each other using a fork.

So, such a loom for children will help you teach your child spinning skills without putting in a lot of effort.

Modern man, of course, is no longer interested in weaving, but we should not forget about our ancestors who used to work on these looms.

If you have a desire, then you can always make your own home machine and use it for any purpose.

Moreover, the size of the operating machine depends only on you.

You can tell children how the first looms were spun, and how a homemade device works. After all, getting into weaving is a very interesting activity.

Do-it-yourself loom: device, types

Today, a loom in the house is exotic. And some 70-80 years ago every village housewife had one.

In many ways, this is a plus, because it means that the modern standard of living allows everyone to purchase ready-made clothes and fabrics, rather than waste time and effort on making them.

However, modern women (and men) are increasingly interested in this forgotten craft, recreating ancient village weaving looms.

Let's find out a little more about the features of these devices, as well as how you can make them yourself at home.

Making a simple weaving device

You can also make a simple mini-device at home, which will serve as a play device for children, and also teach them how to weave. A children's loom will be useful for teaching children the ancient art of weaving. Using such a simple loom, you can make a compact rug that will be useful at home.

Moreover, this device does not require special devices. All you need is thick cardboard, scissors, a hook, a pencil, a fork and yarn. Instead of cardboard, you can use old plywood, chipboard or other rigid base.

The loom operates by threading threads into slits and then weaving. The yarn is made into a cut, and its end is located on the wrong side. Threading the yarn should be done in the form of a snake. The end result is tying the resulting cutouts. On the other side, stripes of threads are also made. One side will be the front side and the other side will be the back side. The front is a completed canvas.

You have to pull the threads smoothly so as not to bend the cardboard. You can use a larger needle for convenience. The number of threads must correspond to the edge being an edge and the transition from row to another row to be made. You can move the threads close to each other using a fork. So, such a loom for children will help you teach your child spinning skills without putting in a lot of effort.

You can tell children how the first looms were spun, and how a homemade device works. After all, getting into weaving is a very interesting activity.

It is difficult to find a needlewoman who would not like to try her hand at weaving at least once, but, alas, not everyone can afford to buy a weaving loom. There is an exit!

Making a machine at home seems to many to be too labor-intensive and time-consuming. We hasten to dispel your doubts and offer a simple and affordable way to make a loom with your own hands.

You will need:

- twine or cotton thread

- wooden picture frame without a backdrop (the width of the product will depend on its size)

- wooden slats (a long wooden dowel, which can be purchased at hardware stores, is best; its length should be no less than the width of the frame)

- scissors

Step 1

Woven fabric, as you know, consists of warp threads (running lengthwise) and weft threads (running across them). We will use twine as warp threads. Even if you use some other thread, the main thing to remember is that the warp thread should be strong, not too thick and not too thin.

Tie the end of the thread with a double knot to the lower left corner of the frame, then pass the ball through the frame, throw the thread over the top crossbar, and go down to the bottom.

Step 2

Your movements should resemble a figure eight: each time you go around the top or bottom crossbar, the ball should pass through the frame. Continue pulling the thread, making sure it is evenly and moderately tight, with no slack.

Step 3

The width of your final product depends on both the number of “loops” you create and the size of the frame. On average, you should make at least 10 and no more than 25 “loops”, the distance between them should be 1 cm. Keep in mind that the greater the distance between the threads, the easier it is to work, so it is better for beginners to start with a minimum number of “loops” and maximum distance between them.

When finished, secure the free end with a double knot.

Step 4

Look at your loom from the side - the threads should cross in the middle (if not, it means you didn't follow the figure eight when stretching).

Using a long wooden strip, we will divide the threads into two parts - insert it between the threads, exactly under the place where they cross, and then pull the strip to the top crossbar of the frame.

Weaving for children

Weaving: loom

What to weave on? Introducing a homemade loom. Its advantage is its simplicity, even primitiveness of manufacture and use.

To make the machine, take a piece of ordinary board (approximately the size of A 4), which must be sanded so that the child does not hurt his fingers. Self-tapping screws are screwed into the edges or you can use nails that need to be bent onto the outside of the block.

Self-tapping screws with wide heads so that the warp threads do not slip. We bend the nails for the same reason. Initially, cardboard was used as a machine tool. But its strength was not enough for our child. Therefore, the cardboard was replaced with a board, and quite thick (2 cm). Just hammer the nails in like that.

Weaving: materials

As strips for weaving, it is best to first use not threads, but knitted, well-stretchable fabrics. Take an old T-shirt or nightgown and cut it into ribbons (about 3-4 cm wide).

Next, we measure the strips along the length of the board (but with a margin at the edges), make a small cut with scissors and put the tape on the screw, pull it (the strips must be stretched) and on the other side we also make a cut and also put it on the screw/nail.

We do this with all the ribbons - this is the basis of the future rug or napkin.

Weaving process

Next we will need a large paper clip or pin (weft).

First you need to measure the strips according to the width of the machine (also with a margin), cut them and you can start weaving. We take a paper clip, string the edge of the tape onto it and begin to pass it through the stretched strips of our base. The strips passed through the base must be moved towards each other with a ruler.

The result of creative efforts

The result is this rug. The edges can be finished with ribbon, fringe, or simply stitched for strength.

And the last point is motivational. The craft must be used as a decoration, a gift, in a play activity, or simply in the household (a stand for a hot plate). The child must know that his work is meaningful. Weaving develops not only manual skills, but also remarkable talents such as hard work and patience. The site Non-standard Children wishes its readers such talents.

Source: https://mama-pomogi.ru/dosug/sdelaj-sam/tkachestvo-dlya-detej