How to connect a socket to a lamp

In order to connect an outlet to a lamp or vice versa, you do not need to have any knowledge. However, it is very important to follow safety precautions and certain rules for working with electricity. You have to connect an outlet to a lamp for various reasons; someone wants to make an extension cord so as not to drag a carrier around the room, while others have other goals in order to connect the outlet to the lamp with their own hands.

Be that as it may, before connecting the outlet to the lamp, you should make sure that the device is completely disconnected from electricity. Moreover, the lamp should be turned off not with a button or something else, but completely. If this is not possible, then before connecting the socket to the lamp, turn off the power to the house or apartment using the machines on the electric meter.

Advantages and disadvantages

Advantages of this cartridge:

- ease of disassembly and assembly

- time-tested reliability

- contact pads are fixed with screws

Firstly, if necessary (burnout, melting), they can be replaced. Or simply tighten it when the contacts loosen and the connection heats up.

By the way, these screws need to be tightened initially, even before directly connecting the wires. This will extend the life of the socket and light bulb significantly.

In 90% of cases, the light bulb stops shining because the central contact heats up and its plate-shaped area begins to bend, gradually moving away from the lamp base.

Flaws:

- inconvenient connection to screw terminals

To ensure good contact, you will have to unscrew them entirely from their seat.

Moreover, if you have a non-Wera screwdriver with a bunch of additional “chips,” then this screw often falls out and rolls into the most inappropriate places.

Although experienced electricians do without completely unscrewing the screws and bending the neat rings on the copper conductors. The entire connection is made much easier.

The veins are stripped a little more than usual (2-3 centimeters), and the screws are only loosened. Next, place the vein under the washer with the screw and make a turn strictly in the direction of tightening the thread.

This is necessary so that when tightening the screw, the ring does not unbend, but rather tightens even better.

After this, bite off all the excess protruding behind the bolt with side cutters. You should end up with some kind of half ring.

All that remains is to squeeze it with platypuses to a full ring.

It is not yet possible to tighten such a connection. It should “play” in its seat.

Take the second wire and do the same procedure with it. Only then can the screws be tightened as far as possible. As a result of such a connection, there is no need to unscrew anything, make some rings in advance, guessing the diameter of the bolts.

All this is adjusted directly on the cartridge itself. Saving time and labor costs is obvious.

The only disadvantage of this method is that the wire consumption will be a couple of centimeters more than usual.

Connecting wires - phase and zero

The cable is connected in the following sequence.

First of all, before starting work, you need to find out which of the wires in the cable is a phase. This is the main point responsible for the safety of all further assembly.

This is done using an ordinary indicator screwdriver.

The phase in the cartridge should arrive only at the lower central part of the base, and nowhere else.

The connection contact is shown in the photo below.

Why is this so important? The point is that you should never have a live threaded part in a chuck. Not many people know, but when a light switch (one-key, two-key) is turned off, only one of the conductors is broken.

The second one continues to go directly to the cartridge. Now imagine that an electrician accidentally mixed up a phase with a zero and sent a neutral wire through the switch.

As a result, at one fine moment, the light bulb in the chandelier may not just burn out, but burst, destroying the glass bulb.

You will turn off the light to replace it, and with such a replacement, you will have to come into contact with the base anyway.

And if a phase comes to it, and not zero, then you are guaranteed to come under voltage.

There are generally lamps entirely with metal socket housings. If you mix up the connection of the wires here, and in an emergency, the entire lamp will be energized.

You can also often observe a situation where, when you wrap a light bulb in a socket, for some reason it does not light up. The reason here lies in the bending of the central contact. It just doesn't reach the base patch.

To correct this defect, it is enough to bend it back. Many people do this with non-insulated screwdrivers or a knife.

As a result of careless actions, you will definitely touch the side contacts, and they will be energized.

As a result, you are guaranteed an electric shock. In this case, experienced electricians advise not to use screwdrivers or foreign tools at all, but to use the cartridge itself.

Unscrew the cylindrical threaded body and insert its side edge between the two contact pads.

Next, grab the central patch with the edge and bend it towards the top. In this case, you will not create any short circuits, and you yourself will not come under voltage.

And it doesn’t matter whether this cartridge is on the wall or on the ceiling. Everything is done in the same way in both cases.

Therefore, remember - the neutral conductor should always come only to the threaded part of the base.

Purpose of the cartridge

The electrical network in a home or workplace consists of wires and electrical appliances, as well as various electromechanical products. Such devices include an electric cartridge. It connects a lighting device (LED, fluorescent or any other light bulb) with a cable and fixes it in a ceiling, wall or table lamp.

The sockets are used for all types of lamps. It is important that the light bulb has the same base as the electric socket. Otherwise, it will not be possible to connect it. Such devices are made from different materials - thermoplastic, ceramics, metal, heat-resistant polymers.

Installation of an apartment or house electrical network

To figure out whether it is possible to wire an outlet from the switch, you need to have a good understanding of the structure of the home electrical network. Understanding its structure determines the possibilities for making modifications.

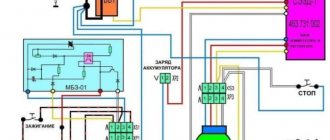

Main diagram of the apartment electrical network

The path of apartment wiring begins with the input panel, which is powered by a cable coming from the external house electrical network. The panel device is located in the entrance of the house or at the entrance door of the apartment. Inside there is a circuit breaker, which receives power from the cable. In Soviet-built houses in which the electrical network has not been updated for a long time, switches perform the functions of an automatic device. Cables from the panel switch are directed to the electric meter and then to each of the machines serving the group. The groups do not communicate with each other, and their number is determined by how many loads there are in the apartment. They can be distinguished according to criteria such as ease of placement or type of load used. A strict rule is to separate appliances located in living quarters and those located in the kitchen and bathroom into different group connections. From each of the machines, the cables are pulled into distribution boxes (one or more), to which apartment light switches and sockets are connected. This design optimizes maintenance of the electrical network and masks utility networks.

Connecting switches and sockets

To understand how to properly connect an outlet to a switch or to a network, you need to remember the instructions from the Electrical Installation Rules. They establish that the process of connecting an outlet to the electrical network requires three cables with different functions. To simplify the visual determination of the functions of the wires, they should differ from each other in the color of the insulating material (in practice, electricians sometimes ignore this rule).

When connecting the socket, use the following cables:

- Phase, the function of which is to power the serviced outlet, carrying electric current to it. This is the only wire whose insulation color is not regulated by the rules: the main thing is that it differs from the colors of the other two cables.

- Neutral wire with a blue or light blue sheath. Like the phase, it is connected to the power contacts of the socket in the distribution box.

- Grounding, whose role is to protect residents from electric shock when touching the body of an electrical appliance, as well as to prevent short circuit situations. Its insulating material is yellow or green. The wiring is connected to special socket contacts designated for grounding.

It is practiced to combine sockets with each other with a parallel connection to the network or serial. In the first option, each of the combined elements remains independent.

In the case of connecting a switch, only two cables are required, and both of them are phase. One is placed at the input of the connected device and connected to the group line phase. The other is led from the light switch output to the junction box and connected to the phase of the lighting device. The neutral wire of the latter must be brought out into the box, bypassing the switch, to the power cable.

Disassembling the lamp socket

In order to accurately separate the equipment into its component parts, it is necessary, firstly, to unscrew the upper fragment of the device so that its ceramic base is visible, which, in turn, is connected to the contacts. Then this part must be taken out and disconnected from all elements adjacent to it. It is very important to understand how the light bulb socket interacts directly with the wire. Connecting equipment to a stationary switch must be accompanied by connecting the phase cable to the central contact. After this, it is important to make sure that the resulting system works reliably. To do this, you need to apply a light source with a base to understand that the contact obtained as a result of assembly is bent to a distance of at least 2 mm. The assembly of the entire element is completed by screwing the housing into a cylinder.

How to connect a cable with three wires

Many people have a question: where to connect the ground wire if you have 3 wires in the cable? After all, there are no more free connectors on the contact insert.

This third wire must be connected to the body of the lamp itself. Usually on a chandelier or sconce, there is always a factory place where the “ground” should be connected.

Therefore, the third wire does not go directly into the cartridge itself. When stripping a cable, always make this yellow-green conductor longer, at least twice as long.

Although it should be noted that some types of ceramic bases have similar connectors.

1 of 2

They are a metal plate placed in the center of the product. If space allows, you can make a connection on it.

Marking

In accordance with GOST, products with Edison threads are divided into three main types - E14, E27 and E40. The former are called “minions” and are used in microwave ovens and freezers, the latter in lamps, and the latter in organizing street lighting. The principle of operation is the same everywhere, and the differences are related to the design and dimensions.

There are markings on the cartridge body. When decoding, you can find out the characteristics of the product. E14 is installed in devices with a current consumption of no more than 2 A and a power of up to 440 W, E27 - up to 4 A (880 W), E40 - up to 16 A (3500 W). Each model is designed for 250 V AC.

Connecting old-style carbolite

Let's start with carbolite ones. This cartridge is collapsible and consists of three parts:

- cylindrical body with thread

- bottom

- ceramic insert with contacts

Most often in our apartments we use cartridges marked:

- E27

- E14

The value in numbers indicates the diameter of the lamp base in millimeters that is suitable for this socket.

The letter “E” indicates that it belongs to the screw series with Edison threads.

There are also pin type, G series and some others presented below.

Such products are designed for a current of no more than 4A. That is, in a 220V network you can connect a load of up to 900W to them.

Mounting methods

In most cases, the socket is connected to the lighting fixture through the bottom. There is a hole in the bottom for entering an electrical cable. The E27 series is available with M16, M10 or M13 threads, and the E14 - M10.

For current-carrying wires

Direct connection of the cartridge to the wires is unacceptable! First you need to ensure reliable fastening of the product in the lighting fixture (lamp or chandelier), for which a plastic sleeve with a hole in the center necessary for the cable is installed on the bottom. A plastic screw is mounted to the sleeve for further fixation.

Connect the socket, clamp the wires with a plastic screw. The sleeve is intended for mounting decorative parts, and the screw ensures reliable fixation of the lampshade and the device suspension.

On the phone

The socket is attached using a metal tube, which allows you to hang heavy lampshades from the ceiling. The tube is equipped with additional nuts, with the help of which the fittings for the chandelier, including caps, are installed. The entire load falls on the metal tube, and the wires needed to connect the power are pulled directly through it.

Cartridges with threads on the outer surface of the body can be decorated with lampshade rings and other decorative elements.

Bushing

Tubular bushings are used for fastening sockets in table lamps and wall sconces. Products are made from sheet materials. It is enough to make a hole through which the cartridge should be attached using a sleeve.

Due to the heating of the light bulb, plastic bushings can become deformed, causing the socket to begin to wobble. Replace plastic with metal.

The mounting thread varies, as there is no specific standard for E27 socket sockets. To replace a plastic bushing with a metal one, use resistors. Before breaking, disassemble and compare the threads so as not to ruin the product in vain.

With screwless terminals

The body and bottom of the cartridge, using screwless clamp contacts, are connected to each other using two latches. The bottom of the product is screwed to the threaded tube, after which the electrical wires are inserted. The body is made in the shape of a cylinder and is attached to the bottom.

Elements are subject to repair and maintenance. Use a screwdriver and move the latches to the sides so as not to damage the cable when dismantling the product.

Varieties according to installation method.

In fact, installation method is how exactly the product is attached to the lamp in a lamp or other electrical equipment. If a few years ago there was no alternative to a threaded connection, now pin-type cartridges are used. The latter involve fastening using pins located on the base.

Threaded connection - a classic scheme with screwing in a light bulb. The phase is transferred from it to the light bulb when the latter is completely twisted and contact of the base sleeve with the contacts of the socket is ensured.

There is a third option - combined devices with a GU10 base, used in modern chandeliers. First, the light bulb is inserted into the socket, then screwed into the lock until it stops. Elements with a rotary-threaded connection are characterized by a complex design, but are irreplaceable where lighting devices are subject to periodic/continuous mechanical stress, including vibration.

Device

The design features of the cartridges depend on the series. Type E devices are most often used. Therefore, the structure of cartridges can be considered using their example:

- The outer body with a sleeve on which there is a thread.

- Donyshko.

- The insert on which the contacts are placed.

Thanks to two brass plates on the insert and threaded mounting strips, electric current is supplied to the detachable lamp connector.

In the image above you can see how the plates are in contact with the base part.

To avoid electric shock, connect the phase conductor to the central contact of the base.

G-type sockets function in the same way, but their structure is simpler than that of the E-series devices. In addition, the pin devices transmit current to the detachable bulb holder in a slightly different way.

Varieties according to the type of base.

The choice of base depends on the light bulbs used:

- For almost all housekeepers, fluorescent and conventional lamps, type E27 with a traditional threaded connection is used. The socket is suitable for household LED appliances and a range of halogen lamps.

- Small light bulbs can be used with E14 type sockets (minions). The number in the marking indicates the diameter - in this case 14 mm.

- G-chucks are products that use pin fastening. Suitable for housekeepers and halogen lamps with the same design.

How to connect a light bulb socket

Connecting a lighting socket to the electrical wiring of a house is carried out using one of two methods - detachable or permanent. In the first case (the method is called “screw”) fastening is carried out using a threaded screw or a special terminal.

Permanent fastening is associated with homemade soldering or press-fitting at the product manufacturer. The last procedure is relevant for elements of the G4-G10 series. Two insulated cables are pre-lead from them, the length of which does not exceed 100 mm. The elements are attached to the electrical wiring using a terminal block.

Ordinary electric

First you need to understand the assembly procedure of a conventional electric cartridge. A ceramic liner is made, onto which a brass plate is pressed, used as the main contact. On the other side of the liner there is a steel plate; a screw is screwed to it, ensuring reliable fastening of the plate to the liner. The same screw also performs another function - current flows through it to the main contact.

When tightening the screw, use a lot of force, which is due to its participation in the transmission of electric current from the cable to the light bulb. The same sequence of actions is used to attach the second brass plate, after which the main contact is bent so that it is level with the side ones.

Next, form rings on the conductors, thread them through the bottom and secure them to the steel plates. If the cartridge is used in an electrical circuit with a stationary switch, the wire transmitting the phase should be connected to the central contact. To check the reliability of contact, you need to install the light bulb in the base and make sure that when it rests on the side contacts, the main one bends by at least 2 mm. In case of less deflection, the main contact bends upward.

A cylindrical body is attached to this structure, then the cartridge can be used. Select light bulbs by matching the markings on both products.

Cartridge with terminals

When connecting electrical wiring to modern sockets, screw clamps on terminal blocks are used. The approach significantly speeds up the process of connecting and installing an electrical device.

The body is made of plastic, monolithic. Using a special rivet, the wires that supply the base are attached to the body.

Note! The main disadvantage of a product with terminals is the impossibility of repair, so if it fails, you need to completely replace the cartridge with a new one. Among the standard sizes, the most popular are the E14 and E27 model series, which are also used in conventional electrical products.

Screwless electric

The most modern design involves the presence of special holes on the cartridge body - usually four (grouped in pairs). Wires are pulled through the holes, fixed with brass contacts using a spring mechanism. Pairwise connection of contacts simplifies the parallel connection of light bulbs in chandeliers or lamps. Electric current is supplied to the first cartridge, and subsequent ones are connected to it using jumpers.

Important! In this way, you can connect many housekeepers that consume a minimum of electricity.

The products are characterized by simple and quick connection - strip the end of the wire and insert it into the correct hole on the socket body with a clamp fastening.

Many chandeliers and lighting fixtures use thin stranded wires. It is unrealistic to ensure their reliable fastening in the body of a screwless cartridge. Choose chandeliers with serviced wire ends or solder an alloy onto the multi-core cable yourself so that the wire becomes single-core. Tinned ends are easier to insert into the contact of a screwless product.

If you don't know how to use a soldering iron, there is another way. Before inserting the stripped end of the cable into the hole, place a metal rod there that is larger in diameter than the wire itself. A nail and a screwdriver will do. Pull back the spring contact and insert the stranded wire into the hole without any problems. Remove the nail (rod) so that the contact clamps the wire strands. The same method is used for dismantling. Pull the cable lightly to check the connection is secure.

Preparatory work

Before proceeding directly to the connection process, you should complete a number of preparatory work and decide on the location of the future switch. Preparatory work includes work related to the selection of the wire, the switch itself and the circuit that it will power.

Wire selection

Before connecting a switch from an outlet, we should correctly select the wire with which the connection will be made. After all, choosing the right wire will significantly reduce the likelihood of a fire or other breakdowns.

- To select a wire, we need to know the rated power of the electrical appliances being switched, from which it is then not difficult to derive the rated current. This is done according to the formula, where I is the rated current, P is the rated power, and U is the rated voltage, which for a single-phase network is 220V.

- Having calculated the rated current, we can use table 1.3.4 PUE for copper conductors or table. 1.3.5 for aluminum wires, to select their nominal cross-section (see Calculating the wire cross-section by power).

Note! In most cases, when you connect a switch from an outlet, it switches one or two light bulbs. Because of this, the rated current is small and according to the table. 1.3.4 and 1.3.5, you can use a small cross-section wire. But according to the table. 7.1.1 PUE, the cross-section of this wire in any case cannot be less than 1 mm 2 for copper wire or 2.5 mm 2 for aluminum.

- Another aspect to consider when choosing a wire is the way it is laid. Indeed, if it is laid indoors in an open way on insulators, according to Table 2.1.1 of the Electrical Installation Regulations, its minimum cross-section should be 1.5 and 4 mm 2, respectively, for copper and aluminum wire.

- If the wire will be used for external laying in an open manner on rollers or insulators, then its cross-section in general should be no less than 2.5 and 4 mm 2, respectively, for copper and aluminum wire.

Switch selection

Before you power the switch from the outlet, it is important to choose the right switch itself. This aspect is often neglected, which is why switches often fail. This aspect is especially important if the switch will switch large loads.

- First of all, we select the switch according to the rated current. When choosing a wire, we have already calculated the rated current of our network, therefore, using the same numbers, we select the rated current of the switch. Currently there are 6, 10 and 16A models on the market. More powerful switches can be found, but they are rare.

- The next important selection factor is the method of mounting the switch. For hidden wiring, a recessed version of the switch is used, and for open wiring, respectively, with an outer box. Here the choice depends entirely on the method of laying your electrical wiring. The only exceptions are bathrooms and showers, in which paragraph 12.22 of VSN 59 - 88 recommends using only hidden wiring. But given that it is prohibited to place switches in these rooms, the method of installing the switch can be any at your discretion.

- Our instructions also advise taking into account the installation location of the switch. For outdoor installation, switches with IP no lower than 44 should be used. Of course, it is better to use switches with a higher degree of dust and moisture protection, but the price of such models increases in proportion to the level of protection.

Errors during installation and operation

At the end, we will briefly summarize and make a selection of common mistakes that you should avoid when connecting and servicing a light bulb socket.

1Connecting the phase conductor to the threaded part of the base.

How it all ends was described in detail above.

2Do not forget to tighten the screws that secure the contact plates to the ceramic liner at the very beginning.

You can solder all the wires super securely, but if these screws are loose, then heating of the connection is still inevitable.

3Connecting multi-core wires without soldering or tinning. 4Connecting phase and zero to two adjacent contacts of the keyless chuck and creating a short circuit.

5 Squeeze-adjust the central plate in the carbolite cartridge when bending it, using a non-insulated tool.

Connecting a stranded wire

If you have multi-core wires, then there is no way to do this without first forming a ring and soldering it. Otherwise, 100% reliability and durability cannot be achieved from such a connection. The contact will simply be crushed by the screw head.

In this case, the veins are first divided in half and twisted.

After which a free ring is formed around the bolt.

It then needs to be soldered and then connected.

The extra tails after the ring are bitten off.

Before all these procedures, do not forget to first place the “butt” from the cartridge on the cable itself.

Otherwise, you won’t be able to assemble it after this and will have to twist the cartridge a second time.

The second disadvantage of carbolite products is connection time.

The entire process of disassembling and reassembling, unscrewing and tightening screws, takes from 5 to 10 minutes. Therefore, the procedure for “loading” a carbolite cartridge cannot be called quick.

How to replace a cartridge in a chandelier

After you are convinced of the presence of a malfunction, we proceed to active actions. To replace a part, you should study its design. The most common modifications of the cartridge:

- Domestic designs - base, carbolite E-27. The body consists of carbolite, dismountable, internal elements are porcelain. The cartridges are practical to use. In this case, the damaged individual unit is replaced.

- Chinese ceramic modifications, base E-27. Solid. Attached to the surface with several screws. The contacts are connected with rivets. If any component fails, the cartridge must be completely replaced.

- Domestic ceramic modifications, E-27. The collapsible porcelain case consists of two halves. The cartridges are street (with small lugs for fastening), end-mounted and suspended. Replacing/disassembling the product does not require any special skills.

- Plastic cartridges with end mounting type, E-14 base. The individual halves are secured with plastic latches. The power wires are secured with screw or spring clamps. For such products, the plastic thread running in a small depression has virtually no contact with the base. The aluminum base and brass plate oxidize, the space between them increases and contact disappears. Therefore, it is advisable to install a new cartridge.

Replacing the cartridge in lamps and chandeliers is not difficult. The most important thing is to show patience and attention, since almost all the parts are small.

The main reasons for replacing the cartridge.

It is necessary to replace the socket in a chandelier not only due to manufacturing defects, but also due to design features. If the lamp is closed, the temperature inside the bulb increases greatly. Sometimes this leads to melted wiring.

In old sockets, contact with the lamp deteriorates over time. This can cause frequent breakdowns of the latter. After incandescent lamps burn out, sometimes fumes form on the terminals, which leads to poor contact. Simple cleaning rarely brings positive results, so the holders are replaced.

Another reason for replacement is the desire of people to switch to energy-efficient LED lamps. Since they are produced with a smaller base, there is a need to change the seat in the lamp. All holders have an identical design. They differ only in the diameter of the thread.

How to connect a socket to an electrical socket

Sometimes there is a need to install an outlet, but the nearest distribution box is far away. I encountered such a case when I was renovating my bathroom. It was necessary to install an additional lamp near the mirror and provide the ability to connect electrical appliances, such as an electric razor.

A wall lamp – a ball – was already installed in the bathroom. I connected two more wires in parallel to the contacts in the electric socket and connected a socket to them in parallel. True, when the light in the bathroom is turned off, the outlet is also de-energized, but there is a positive side to this. In case of water leakage from the upper floor, there will be no short circuit even if water gets into the socket.

The socket in the bathroom or shower room should be installed as far as possible from the bath or shower to prevent splashing water. I installed a standard outlet and it has lasted over 17 years without any problems. Although it is better to install a sealed one, designed for rooms with high humidity.

Once again I had to connect to the electrical socket in the toilet room when installing an automatic light sensor and retrofitting the toilet with a bidet function.

In ancient times, when electricity bills were based on the number of light bulbs and sockets in an apartment, a device popularly known as the “rogue” was widely used.

The adapter cartridge that you see in the photo was screwed into the electric cartridge. On one side it has an external thread, like a light bulb, and on the other, an internal thread, like an ordinary socket. This crook had two brass tubes built into it, like a socket. The swindler allowed him to connect any electrical appliances to the chandelier. You can make such a crook yourself from an ordinary electric cartridge.

Connection from switch socket

You can solve this problem in two ways: by simultaneously connecting two devices to one wire, or by mounting a switch without manipulation in the junction box. Both options have advantages and limitations.

Connecting a switch from an outlet without a distribution box

This diagram assumes that there are no additional twists between the distribution panel, chandelier and switch. A wire is sent from the shield - two-wire if there is no grounding and three-wire if there is one. It must be led in one piece to the lighting fixture, and then divided so that the zero remains there, and the phase goes to the switch. The phase from the switch button is brought to the contact of the chandelier up the wall, and then along the ceiling.

If the chandelier has many light bulbs and there is an intention to connect it to a two-button switch, the panel wire is cut as described above, and a pair of wires from both buttons lead from the switch to the lamp. For this purpose, a cable with two cores is used. They are connected to the outgoing contacts of the switch (they will act as phases when the device is turned on) and the wire is directed upward to the chandelier. The wires are again separated by several centimeters and connected to the phase contacts of the chandelier.

This installation method has a number of advantages - it minimizes faults due to ease of implementation and the absence of connecting additional conductors, and is accessible even to an inexperienced technician. The disadvantage of this type of connection is that when cutting the cable, there is no insulating material on the disconnected cores. To avoid this, you can use single-core conductors with high-quality insulation. Then one independent cable from the panel bus is directed to the contact of the chandelier, another wire (phase) from the circuit breaker is led to the light control device, and from the latter a cable is laid to the chandelier (from one or two cores - according to the number of buttons).

Connecting a switch and socket from one wire

To install a box with one button, first connect the apartment panel to the distribution box using a double (with phase and neutral) wire. The lighting device is also connected to the distribution box with a two-core conductor. Then a trio of wires from the paired switch and socket are inserted into it, while a path must be laid from the phase clamp to the socket, and from the socket to the switch contact. The chandelier is connected with one cable to zero, the second - with an unoccupied switch terminal. If there is a grounding wire, it is connected in the junction box to the appropriate terminal.

Keyless chuck

Today, plastic quick-release chucks have also become widespread.

They work on the principle of the famous Wago clamps.

To disassemble such a cartridge, you need to carefully press the latches on both sides with a slotted screwdriver.

When you remove the cover, you will find that there are no screws inside at all where you could attach the wires. A person who is far from electrical installation work will not immediately understand such a design.

How to connect it? Everything is done very simply.

You need to strip the ends of the wires and push them into the small holes until they click. Moreover, most models have two pairs of contacts at once. And accordingly, not two, but four holes at once.

They are designed for convenient assembly of light bulbs into garlands. Insert the appropriate wire into one hole, and the one going to the next light bulb into the other.

Just don’t think about inserting phase and neutral into adjacent holes, otherwise you will create a short circuit!

Inside these contacts there are spring-loaded metal plates that provide the connection.

Here also do not forget about the correct connection of phase and zero.

The wires in such clamps are held quite securely, and even with a little force, they cannot be pulled out.

In order to still pull it out from there, you will have to turn the core in a circle while pulling.

Methods of fastening electric sockets in chandeliers and lamps

Most often you have to connect nodes that are located in lighting equipment. This imposes certain requirements depending on the mounting option and design of the lighting fixture. The most commonly used methods are:

- Fastening the socket in a lamp to a current-carrying wire is not allowed, since the load cannot be placed on this element. The exception is the use of cables with reinforced insulation designed for certain loads. But still, you shouldn’t hang massive chandeliers using this method. The light bulb socket is connected in the standard manner. The wire is pulled through a hole in the back and fixed in a stationary position with a special screw located on the side. It must be twisted so as to secure the wire, but not deform it.

- Installing a socket connection in chandeliers with a supporting element in the form of a tube is much simpler. Here the load falls on the tubular element, inside of which the wire is pulled, which makes the design much neater. The cable is pulled out with a small margin and attached to the cartridge as usual. In the upper part it is connected to the power supply through a block; the connection point is covered by a decorative cap.

- Installing a light bulb socket using a bushing is used in both chandeliers and wall lamps, as well as table lamps. To do this, there is a threaded element in the upper part, which is inserted into the hole and secured on top with a nut of the appropriate size. It is best if the fastening is metal; plastic ones will become loose over time and cannot be repaired. Only complete replacement will help, since such parts are not sold separately.

- Mounting options with screwless clamps is even easier. This is a modern solution that has appeared recently and is increasingly found in chandeliers. In this case, you first need to screw the lower part of the element onto the thread through which the wire, usually a two-core wire, is passed. Then it is connected to the contacts and the upper part is carefully aligned with the latches and snaps into place until it stops. This system securely holds the element without additional fasteners.

This is what the screwless mounting of the lampshade looks like.

If you need to remove a screwless socket, you will need a thin flathead screwdriver. Use it to first remove one clamp, then the second, and then carefully remove the upper part from its seat.

The basic elements of any table lamp.

First, let's look at what elements the lamp includes.

- The support element (the “leg” of the lamp) provides support for the light source.

- Electromechanical elements - cartridge, wires and their fasteners.

- Lighting part – reflector, lampshade, light source.

The electrical part is usually hidden, so decoration issues do not apply to it. But the other two parts are quite amenable to flights of fancy and can be made from a variety of materials.

But electrical elements are key in terms of safety. Remember that working with electricity requires a certain set of knowledge (at least minimal) and experience. Otherwise, you should not experiment with devices that are hazardous to health.

Connecting the lamp

Diagram of a simple table lamp

So, the electrical circuit of the lamp is simple. To assemble it you will need: a cartridge, a cable, a plug and a switch. If you want a lamp with adjustable power, then a dimmer is included in the circuit.

The most common cartridge is threaded E27. It is simple, reliable, and easy to buy. "Minion" E14 is also a good option. The main thing is to connect the cartridge to the wire correctly . The phase wire must come to the central contact of the light bulb base. With such a connection, the likelihood of a person being exposed to current is minimal.

The phase wire comes to the central contact of the base, the zero is in contact with the screw thread. You can secure the wires in the socket with a soldering iron (non-separable method), screws, terminals or clamps.

Screw connection.

Terminal connection.

Connection with clamps.

The screws are tightened sufficiently to ensure a secure connection. In the event of a breakdown, such a cartridge can be disassembled and repaired. Terminals speed up and simplify the process. It is enough to insert the wire into the clamps with a little force: the internal springs will fix it and create reliable contact. The fastening of the wire in the socket must be reliable.

The wires for a homemade lamp must also be electrically safe. The simplest option is a round cable with a core cross-section of at least 0.35 m2 and double-layer insulation. (A good option is SHVVP 3×0.5, approximate price is 15 rubles per sq.m.). Places of connections, twists, and areas with the possibility of dampness are additionally wrapped with electrical tape. Mount the cable so that it is not strained in any position of the luminaire.

The Europlug is connected to the cable as follows:

Connecting the Euro plug

When connecting the switch , remember that the phase wire is broken.

Single-key switch connection diagram

Possible problems and errors

When installing a new cartridge, you can easily make a number of mistakes without practical experience. There is also a possibility of encountering problems that depend on third-party factors. Common errors and problems include the following:

- Attempting to repair a live lighting fixture. If the room is not de-energized first, there is a risk of injury.

- There are problems with the wiring. During operation, you may notice damage to the wiring and will need to be replaced. Without restoring the wiring, you may encounter more complex faults in the future.

- Incorrect connection of contacts. As a result of this error, the lighting device will not function correctly and may fail.