A laser target designator is a good thing that allows you to clearly identify the target. A bright red (less often purple or green) dot is clearly visible even in poor lighting. Pneumatic weapons equipped with a laser target shoot more accurately and accurately.

However, this device, even the simplest plastic one, costs more than 1000 rubles. It doesn’t matter - the craftsmen have figured out how to save many times over by making their own laser device to mark the target. Next we will tell you how to do this yourself.

What do we need

Let's stock up on the necessary materials - it will be easy to get them, since they are sold at every step. This:

- Laser pointer - regular or in the form of a keychain. It’s just better to take not a Chinese one in a fragile plastic case, but a domestic one - they are more reliable, and they have better lasers.

- Batteries – “tablets” (you can take those that are in the pointer) or two mini-AAA type fingers.

- A thin wire (preferably silicone acoustic or in a fluoroplastic sheath) - a little more than a meter.

- A piece of sheet metal or aluminum for clamps, bolts and nuts.

- Drill, soldering iron, pliers, tape, file.

Device power supply

We will need a minimum of 3.7 V. Old batteries from mobile phones and AA batteries can provide this. You just need to connect them in parallel with each other. To check the operation of a device or a stationary laser pointer, a stabilized power supply is suitable.

At this stage, you can already test the operation of the device. Point it at the wall, floor and turn on the power. You should see a tuft of bright reddish color. In the dark it looks like a powerful infrared flashlight.

You see that the glow is far from laser: the beam is too wide; he just begs to be focused. This is what we will do next.

Disassembling a laser pointer

Disassembled laser pointer and battery

Important: Where the case is described below, a method is proposed that involves leaving the laser pointer intact (called “Option 2”). If you like it more, you can skip this section. Otherwise we do this:

- We unscrew the back part, take the pliers and gently pull, pulling the laser head out. However, you can do it simpler: take a hacksaw and carefully cut the pointer lengthwise.

- As a result, we get a board with an LED, which is located in a metal (brass or silumin) case. On the board we have a power button, which will still be useful, a resistor, and also a spring that closes the negative contact.

- The board needs to be cut to the maximum length (to the resistor), and the button must be desoldered.

Setup and calibration

After assembling the homemade device, you need to configure the laser level yourself.

It is necessary to check it - calibrate it for measurement accuracy. To perform the test, you will need an additional bubble level. Calibration is carried out as follows:

- The device is placed in the center of the room and marks are made on opposite walls at the point of intersection of the planes.

- The level is moved to one of the walls at a distance of approximately half a meter, another mark is made above or below the first one.

- The device is turned to the opposite wall and a mark is placed.

- The distance between the marks on both walls is measured and the error is calculated.

For example, the difference between the marks on the first wall is 4 mm, and on the second - 3 mm. The resulting error is 1 mm. If it is larger, then the device requires adjustment.

The measuring device, assembled independently, can be placed on a tripod or adjustable pedestal, which will give the product convenience and functionality

To perform vertical calibration, mark two points in the vertical plane and check the marks against the bubble level.

If no deviations are noticed, then the plane builder is ready for use. If there is a discrepancy in the readings, the homemade laser device is adjusted by changing the location of the platform or articulated fork.

Making a power supply

This process depends on what kind of weapon is supposed to be equipped with a laser target - with a shotgun it is easier than with a pistol. Therefore, first we will select the location for installing the power supply.

“Tablets” take up less space, they can simply be secured with tape, not forgetting to make the correct electrical connection and soldering the wires: “plus” and “minus”. For fingers and mini-fingers, you can adapt some kind of housing (for example, a pencil case for brushes, cutting it off). The arrangement of metal contacts is similar to that found on any remote control.

What is a holographic sight, its operating principle can be seen in the video at this link. Aiming mark and design features of the sight.

Working on the body

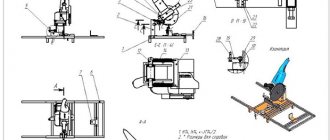

Target designator ready for installation on a weapon

Option 1. We need to cut the pointer body by attaching a shortened module to it. We remember that we will also have a backdrop and a laser head. Now we connect it all together: the laser head, a cut piece of the body and its back part (in which we first drill a hole for the wire).

The “minus” wire will go to the resistor, and the “plus” wire will go to the head of the laser module. We put the button that we desoldered from the board on the handle - this will be most convenient. To do this, drill a suitable hole.

Option 2. A very ingenious method in which you do not need to disassemble the pointer. We take an empty twelve-gram CO2 canister, cut off the neck from it, and make a hole in the back that is slightly larger than our pointer. From the cut edge of the can we make two more perpendicular holes with M4 threads for the adjusting screws.

The switch will be a bolt screwed into another threaded hole (it is made where the pointer button is located). We screwed the bolt in and turned on the device, unscrewed it a little and turned it off.

Then we wrap the back of our pointer with electrical tape or tape, ensuring that it fits snugly into the body of the can. In the front part, we will place a piece of porous rubber between the body wall and the pointer (thanks to this, the screwed-in bolts will move the beam horizontally and vertically).

How to attach a ready-made laser target to a weapon

The easiest way to do this is with clamps made of tin or aluminum with a thickness of 0.8-1 mm. You will also need two bolts and nuts for them. To make it neat, we grind off the caps of the bolts. We will fuse the nuts into plastic blanks - this will help to quickly adjust the laser pointer.

There are also options for finding a mate for a weaver or picatinny rail, but they are more labor-intensive. For example, you can take a cable channel strip for a red dot sight. But it still needs to be attached to the laser center itself - accordingly, tinkering with the body. And then it makes sense to make it rectangular.

Homemade products from a washing machine engine:

1. How to connect a motor from an old washing machine through a capacitor or without it 2. Homemade emery from a washing machine engine 3. Homemade generator from a washing machine engine 4. Connecting and adjusting the speed of a commutator motor from an automatic washing machine 5. Potter's wheel from a washing machine machines 6. Lathe from an automatic washing machine 7. Wood splitter with an engine from a washing machine 8. Homemade concrete mixer

Laser "target designator" for a shotgun

The idea to build this thing came while hunting, when I was trying to explain to my partner where a wounded animal lay:

— The third bunch of wormwood to the right of the bush... You see.

To which I received an answer with a phrase from an anecdote:

- Don't be smart - point your finger!

I made the first version in the evening. It looks like it took me longer to describe it than to do it. All this was done precisely as a “pointer”, but upon first testing it in the field, it turned out that it could well work as a laser sight for a shotgun (but not for a bird). The spot is quite noticeable at shotgun range (of course not in sunny weather) and reduces the time required for aiming. Remaking a laser pointer.

I bought a Chinese laser pointer in a store, the axis of the beam and the geometric axis of the body more or less coincided. I removed the cap covering the battery compartment. No batteries needed yet either. Fixed the switch in the on position. To do this, insert a piece of thin rubber into the hole for the button in the case so that the button is pressed and the rubber does not protrude from the case.

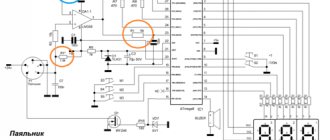

Rice. 1. Layout diagram of the switch in the additional part of the housing.

The next step is to install the latching switch. I pulled out all the internals from the second laser pointer (fortunately, they cost pennies) - you only need the aluminum body. A “slider” microswitch was built into the housing (see Fig. 1). One of its contacts was connected to the body. I cut a hole for the button. The excess part of the body was cut off.

As it turned out in practice, such a switch is not very convenient to use. It is difficult to feel it blindly with gloves. Something like a toggle switch is better, which is what I used in the second option.

For the coupling connecting the two parts of the case (main and additional, with the switch), I used the battery compartment cap. I drilled a through hole with a diameter of 3.5-4 mm in the cap along the axis and secured an M3 screw with a nut through dielectric centering washers (see Fig. 1). There should be no electrical contact between the screw and the cap. We connect the screw to the free contact of the switch. An additional housing was fixed on the side of the cap that does not have a thread. In this case, you need to make sure that there is good electrical contact. In the factory design, the cap rests on the “plus” of the battery and ensures its contact with the body. We don't need this. It is necessary to file the central contact so that it protrudes 1-2 mm from the bushing. The bushing flange protruding beyond the body dimensions was removed with a file.

We insert the batteries, connect both parts of the body and check the operation of the converted pointer. "Target designator" housing.

Features of laser hair removal of the face, legs, abdomen, bikini area and other parts of the body

The vegetation on the body is heterogeneous; in some areas the hair follicle lies deep, in others it is not. There is also a dependence on the stage of hair growth: early or mature. These reasons have a great influence on how laser hair removal proceeds in the deep bikini area or the area above the upper lip.

Deeper hair follicles lie in the following areas:

- armpit area;

- breast;

- back;

- hands;

- thighs and legs;

- bikini area

In these areas, the follicle can lie at a depth of 4 mm, which means that a device operating on long waves is needed here.

It is also known that when treating the bikini area and armpits, the patient will experience more pain than during the procedure on the legs, for example.

This is already due to the fact that in the armpit and bikini area the skin is much thinner, and therefore more sensitive, than on the back or legs. Important

! The face and bikini area are the areas most affected by hormones. This means that any hormonal surge in the body can lead to hair growth after the procedure.

The procedure is simpler and easier for the cosmetologist and the patient in areas with a shallow follicle, such as the forehead, chin, area above the upper lip and cheeks. These areas take less time and are less susceptible to irritation and discomfort during the procedure.

In addition, this procedure can be performed with almost any type of laser. How to do laser hair removal on more delicate areas, for example, in the deep bikini area - most often with a diode laser

. Cosmetologists recommend it because of the provided cooling system, which partially relieves discomfort.

Clients of cosmetology clinics are not only women; many men experience discomfort and embarrassment due to the abundant hair on their back and abdomen. Patients who have resorted to laser hair removal describe the procedure as a panacea.

The result remains for many years, the procedure is almost painless and takes little time. One procedure on the back takes up to one and a half hours, on the stomach – up to forty minutes. For women who have the same problems, the procedure time for the abdominal area is 20 minutes, about 30 minutes for the sacrum and décolleté area.

What is the problem?

It’s no secret that the most modest tactical flashlight, mounted on a Weaver rail, like a laser laser, costs at least two to three thousand of original wooden ones, and devices of advanced models are even more expensive. The Weaver bar itself, attached to the barrel, is another one and a half to two thousand. However, in my experience, neither laser lasers nor TFs are widely used in hardball.

However, situations happen when you need to break into a darkened room, basement, etc., where there is nothing to do without a flashlight, besides, tripping over something in the dark is not good for your health and a weapon, for example Drozd, can be damaged, and it’s easier to shoot at the enemy. In addition, such flashlights have three modes - bright, dim and flashing (strobe). When such a strobe is pointed at an enemy in the dark, he becomes somewhat disorientated, which can be used to advantage. And the laser target, for example, can be used to simulate cover, so as not to waste bullets, for zeroing sights, for target designation, and directly for aiming a weapon at a target at medium distances. In addition, these canopies add ambiance to the weapon. But buying expensive devices for the sake of it personally was a bummer for me. Moreover, this idea came to my mind long before hardball - they were shooting rats in the basement. Opponents of such a body kit loudly shout about the unmasking qualities of both the laser target and the TF. So we need to use it wisely, then we will get more positive qualities.

Skin care after hair removal

No matter how carefully laser hair removal is done, some kind of inflammation on the skin still remains. On skin that is less irritable and tender, there may be only slight redness during the day. On irritated skin, inflammation may linger. In order not to aggravate the consequences, cosmetologists recommend applying sprays, ointments or cream. There are special anti-inflammatory and regenerating drugs.

After the procedure you should not do the following:

- visit a sauna or steam bath;

- wet the treated area;

- use cosmetics on the treated area, except for medicinal ones (listed above);

- sunbathe and be exposed to UV rays without protective equipment.

Let's start making a tactical flashlight

In general, to do or not to do is up to the fighter. So what's the point? Piss in the toilet, and here's what you need.

To produce a tactical flashlight we will need:

- A whale light with or without an adjustable point width, but definitely not a lamp, not a diode, but a semiconductor one (if you’re in a tank, instead of a light bulb, there’s a small square that burns very brightly and also uses batteries much more economically). For some models, the beam hits 150 - 200 meters (200 - 800 rubles);

- Epoxy plasticine cold welding (70 - 150 rubles).

- Well, for final fixation you will need two clamps or a screw if we are attaching it to the body.

First of all, we zero the sight, unless it is zeroed, of course. After this, we make a pad out of plasticine and place it in the place where the flashlight comes into contact with the weapon. We stick a flashlight on this pad and constantly, until the plasticine hardens, keep the flashlight point on the crosshair of the sight, this is the most crucial moment, if you miss it, you will have to do it again. In my opinion, the optimal distance to the wall where we combine the flashlight point and the crosshair of the sight is 7-10 meters. When the plasticine has completely hardened (for different brands the time ranges from 5 to 20 minutes), we check it again and preferably leave it overnight so that the lantern does not touch anything. Clamps are needed because the plasticine will come off over time; in this design it has the role of a position stabilizer. By the way, in the morning you can tear it off yourself and use a file (how can you do without a file in Russia) to cut off all the excess, after which we attach the structure to the weapon and use a regular marker of the appropriate color to even out the color.

Ready tactical flashlight

Safety precautions

The device we end up with is not a harmless toy! Before you make a laser, take care of your safety: getting the beam into your eyes is harmful to the retina, especially if the invention is powerful. Therefore, we advise you to carry out all work in special safety glasses, which will save your eyesight if something goes wrong and you accidentally direct the laser beam into your own or a friend’s eyes.

When using the laser in the future, remember these simple safety precautions:

- Do not point the laser beam at flammable or explosive objects.

- Do not shine into reflective surfaces (glass, mirrors).

- Even a laser beam fired from a distance of up to 100 m poses a danger to the retina of humans and animals.

What about the laser center?

The situation with LCC is similar. We choose any laser keychain, pointer or some other crap with a laser (thanks to the whales, the choice is huge). Of course, it will be better if it is in a metal case, but a plastic one will last a long time. Then everything is the same as with the lantern. The difference is that there is no need for rigid fastening such as clamps or screws. The keychain has a negligible weight and is small in size, so it holds up well. Well, if you fix it at all. By the way, these key fobs are of two types, where you need to hold the button so that the laser shines and where you press the button - it lights up, press it - it goes out. I prefer the first option, the batteries last longer. The second option is no, no, but you’ll forget to turn it off.

Question of price?

In total, we’ll match the grandma. A tactical flashlight will cost 300-350 rubles, a laser target designator is even cheaper than 150-200 rubles. Now try to equip a weapon with factory gadgets for that kind of money!?

In principle, it is also possible to install these body kits on pistols, but here a problem immediately arises with the holster.

Well, in short, what I wanted to write. Go for it. I'll be happy to see the comments.