Do-it-yourself crane beam for a garage-workshop

When we repair a car or assemble a vehicle with our own hands, it is often difficult to do without such a device as an engine lift.

A factory-made beam crane has significantly high prices, but at the same time, with its dimensions, you will be forced to look for space in the garage. However, there is a more profitable solution - creating a homemade beam crane with a collapsible structure. Its production requires significantly less money than when purchasing an industrial model of the lift. We offer a version of a homemade crane beam, which was built by one of the folk craftsmen.

List of materials required for the construction of the lift:

• racks – made of square pipe 100x100x2350 mm – 2 pcs.; • cross rod – made of seamless pipe, cross-section 100 mm, length 4150 mm; • rod supports – made of pipe, cross-section 110 mm, length 1200 mm, sawn into two parts. • base and bevels - from a corner 100x100 mm. • the supports are fixed to the rods using M 16 bolts.

The principle of operation of pulley hoists

The only simpler device for moving heavy objects is a metal scrap. The main element is a wheel with a chamfer in the middle of the outer surface, the axis of which is fixed to the ceiling beam. You can throw a hoist over it, and the lift with a gear ratio of 1 to 1 is ready. To increase the leverage, let's pass the hoist through another loose wheel, the axis of which is connected to the load, and fix the hoist at the top of the structure.

The gear ratio will become equal to 2. Now we will attach another wheel to the ceiling, and pass the end of the hoist through it, securing it to the axis of the lower wheel. The gear ratio will become equal to 3. And so on, by adding one wheel at a time and changing the mounting location of the hoist, you can increase the gear ratio.

The location of the wheels relative to each other may be different.

The most compact designs are those with single-axle wheels. The design of such devices has two wheel holders. Having studied the drawings of the chain hoist, it will not be difficult to assemble it with your own hands. You will need two clips:

- traverse;

- carrying bracket;

- cheek for mounting parts;

- wheel (block);

- emphasis;

- bearing;

- sleeve;

- axis;

- axle holder;

- bearing oiler;

- hoist limiter;

- screw;

- bearing;

- cheek.

The end of the hoist is fixed to one of the clips.

Pulley hoists also have disadvantages. To increase the gear ratio by 1, you need to add one wheel each time, as a result the weight of the mechanism increases. In addition, bending the cable on each wheel requires force, reducing the efficiency of the device. You can reduce these losses by increasing the diameter of the wheels, but at the same time there will be an increase in the weight and dimensions of the pulley. Other types of lifts do not have these disadvantages.

Read also: How to test a high-capacity electrolytic capacitor

Step-by-step making of a crane beam with your own hands

The master took the rollers for the cable from the elevator door drive.

The author installed the structure on rollers that were previously on a warehouse cart. To manufacture the lifting mechanism, a manual worm-type winch was used; its maximum lifting capacity is 1000 kg. The master welded it onto one vertical post.

The design is easy to disassemble and does not require much space.

Required tools and materials

To assemble the structure yourself, you must first prepare a set of tools and materials. In particular, you will need:

- square pipes for racks;

- seamless pipe with a cross section of 100 mm for the cross rod;

- pipes with a cross section of 110 mm for rod supports;

- metal corners 100x100 mm;

- M16 fixing bolts;

- telpher;

- welding machine.

Xiaomi 24 in 1 screwdriver set

Xiaomi products have always been distinguished by functionality and excellent quality, and a set of precision screwdrivers from this company was no exception.

The set is made in the form of a box, which at first glance can be mistaken for a power bank; it houses a screwdriver and 24 bits of various configurations. In a screwdriver, the bits are located in a magnetic holder that holds them securely.

The bits are magnetic and can easily withstand a bolt or screw, which greatly simplifies and facilitates the speed of assembling and disassembling the equipment.

Everything is done at the highest level and looks simply gorgeous, with this set of concepts it is impossible to promote, for you it will simply cease to exist, a high-quality and very beautiful instrument.

Carrying out calculations

To ensure that the design matches the size of the room and functions in the required work space, it is important to carry out calculations before performing installation work. You can prepare a drawing indicating the dimensions of all components yourself or use a special calculator. The standard parameters in the calculations are the following:

- height no more than 2.5 m for repairing passenger cars and carrying out work that requires lifting and moving heavy objects;

- the load capacity depends on the type of hoist used and, as a rule, is 800-1000 kg;

- construction width - from 4 m;

- rack dimensions - 120 cm.

If there is a need to work with larger equipment, the lifting mechanism can be additionally equipped with vertical A-shaped racks. Also, if desired, it is possible to make the structure easily disassembled, which is important in conditions of limited space or in case of rare need to lift loads.

Technical description

A lifting hoist, also called a hoist, can be manual or electrically driven for automated use. According to technical characteristics, the equipment is a mechanism for lifting and moving various loads, including car parts.

The mobile trolley can be placed in any room, regardless of the available space and ceiling height. Depending on the type of design, the load capacity can reach 10 tons. A standard hoist is capable of lifting loads to a height of up to 12 m . The structure consists of the following elements:

- chain hoist, consisting of several blocks connected to each other;

- cylindrical coaxial gearbox;

- disc braking system;

- output shaft;

- hanger with hook.

Assembling a crane beam for a garage

When assembling a load-lifting garage crane with your own hands, you must sequentially perform a series of actions according to the instructions. By adhering to the installation rules, you will be able to make a structure that will serve you well for many years. The key steps in assembling homemade equipment are preparing the frame and securing the crane beam for lifting, holding and moving loads.

How to make the base frame of a crane lifting mechanism

The main load falls on the equipment racks, so to securely fix the structure it is necessary to build a strong frame . The construction of an element involves the following actions:

- Legs for the faucet are made from metal corners using a welding machine and welded at an angle of 45 degrees on each side of a pipe with a diameter of 110 mm. Metal triangles are welded to the posts to create spacers.

- To ensure the movement of the structure to the horizontal base, rollers are welded on both sides of the racks. It is important to use casters designed for metal containers as they can support a lot of weight.

- A pipe is placed on top of the structure along which the lifting mechanism moves. The length of the pipe depends on the size of the garage and your own design requirements.

- The roller for moving the cable is fixed to an I-beam, which is pre-welded in the center of the pipe.

- For additional stability of the frame, a pipe with a square cross-section is welded to the beam. It is placed on top of the beam so that there is a 20 cm protrusion on each side.

- The cross pipe is inserted into a pipe with a square cross-section and through openings are made for the clamps on both sides. Mounting bolts are inserted into the holes and tightened.

Installation of lifting mechanism

The main element of the crane is the lifting mechanism, which can be manual or automatic. The tefler consists of a cable and a winch installed on the side of the rack. The cable moves due to the rotation of the rollers. Additional fixation of the elements is not required; it is enough to secure the lift to the rack.

A self-made crane can be equipped with lifting equipment that is used in elevators. Such mechanisms are highly reliable and able to withstand massive objects.

To simplify repair work, it is possible to connect an electric drive to the lifting element. To automate the design, a motor with a power of 300-500 W is suitable. The electric drive is mounted to the base of the crane beam.

The design, equipped with an electric drive, is widely used in large-scale garage repairs and car disassembly for spare parts when a complex of work is required. According to the principle of operation, manual and automated cranes do not have significant differences.

Where is it used?

The lifting device is used to move loads of various sizes and weights. These can be household appliances, metal structures and car parts. In production facilities, equipment is used to lift loads and place them on top shelves.

There are several types of design that differ in installation method, design features, control option and other technical characteristics. When choosing the appropriate equipment option for a garage, it is necessary to take into account the individual needs and parameters of the room.

Manually driven

Hand hoists are used to lift objects to low heights. The lifting capacity of manually operated equipment varies from 1 to 8 tons. The traction force on the lifting mechanism is 30-65 kgf, which provides a speed of 0.3 to 0.1 m/min. The weight of the structure depends on the material and additional components and ranges from 50 to 400 kg.

Gear manual

Chain hoists with a gear mechanism are used to perform installation work within a garage or in open space. The equipment is controlled at the load securing point. Gear models are equipped with a hanging hook and are easy to install and operate. The design features of gear hoists allow them to be used as independent equipment or as a lifting element for cranes.

Lever

The manually operated lever hoist is equipped with a hanging hook and can be secured to support beams or wire rope. The manual operating principle ensures independence from the presence of electricity. The design provides a locking mechanism for fixing objects in a suspended state.

Worm

Worm hoists, by analogy with other varieties, are used to lift and lower loads. When equipped with additional elements, worm hoists can move objects along an I-section monorail track. You can hang a stationary hoist on a hook manually or make a complete version connected to a mobile trolley.

How to make a frame for the base of a crane lifting mechanism

In order to make a frame for a small beam crane in a standard garage with your own hands, you will need the following materials:

- I-beam (4 - 4.5 meters) - the required footage depends on the height of the garage;

- pipe (diameter 10-12 cm), length 2.4 meters - 2 pieces;

- one square pipe (10x10 cm);

- corners (10x10);

- manual hoist and hoist;

- bolts (M16) with nuts.

If you plan to build a mobile crane beam, then you need four more rollers and a hoist.

The procedure for making a crane frame with your own hands:

- We weld the legs of the crane - you need to weld the corners on both sides to the I-beam pipe;

- The location of the corner is at an angle of 45 degrees. The result is a kind of stiffening ribs that will firmly fix the stand, which bears the bulk of the weight of the load carried by the crane;

- We weld two triangles and spacers on each crane post.

- if the crane is a mobile beam, then on both sides from the bottom, on each stand, a roller must be welded horizontally - ordinary rollers for metal containers will do, furniture rollers will not withstand the weight;

- At the top, we fix a pipe as a crossbar along which the lifting mechanism will move;

- We weld an I-beam in the center of the pipe to secure the roller along which the steel cable of the crane’s lifting mechanism will move.

- We weld a piece of square pipe on top of the I-beam (to give rigidity to the frame) - 40 cm. The pipe should protrude on both sides by at least 20 cm. It turns out that the side post is located in the middle of the crossbar stiffening pipe;

- We insert the transverse pipe of the frame crossbar into the square pipe;

- We drill through holes for fastening bolts on both sides of the square holder and in the crossbar pipe itself - we need rigid, reliable fixation on both sides of the vertical post.

Worm worm hoists - a compact strongman

In addition to these main types of manual hoists, there are also others. Lately, worm gear hoists are often used. To operate, they are hung stationary or a mobile “cat” is used. This is convenient for moving loads horizontally; such hoists can move along I-beams. There are a lot of models of this type of device. They are used for lifting or holding loads in a raised position; they are also suitable for moving. Everything happens along a special suspended track made of I-beam profile.

Their advantage is that work can be performed in small spaces, and the distance between beams and loads can be insignificant. Such hoists can also be used for work outdoors.

They have some features, for example, a rotating casing (and the design can rotate all 360 degrees) allows you to control work from anywhere, that is, you can raise and lower the load in any position. This creates additional safety; during operation, the operator can be located on the side of the hoists and also from the load itself. This type of hoist is also distinguished by its reliability, wear resistance and low-heating brake. All this makes them quiet and comfortable. And thanks to the low building height, you can work with this equipment in confined spaces in vertical positions.

Installation of lifting mechanism - manual or automatic

To mechanically lift loads onto the frame, you need to install a manual hoist - a worm winch and a cable. How to attach the hoist to the frame:

- on the side of the rack we install a manual worm winch (load capacity 800 kg, no less);

- The steel cable moves along rollers.

This mechanism makes it easy to lift the engine or car by the hood on one side.

You can use the lifting mechanism and rollers from the elevator door as a drive. The rollers there are reliable and durable.

An electric lift drive can also be installed on the manufactured base. A 300 - 500 W motor will be quite enough for simple repair work in the garage.

Such cranes are often used for the repair and reconstruction of old wooden houses. The construction of a log house will go faster if the logs are laid using a mobile homemade crane. In this case, the width of the frame is the length of the logs.

You can also make a simpler lift for the engine, on one support, watch the video.

Varieties of hoist designs

There are several types of design that differ in installation method, design features, control option and other technical characteristics. When choosing the appropriate equipment option for a garage, it is necessary to take into account the individual needs and parameters of the room.

Manually driven

Hand hoists are used to lift objects to low heights. The lifting capacity of manually operated equipment varies from 1 to 8 tons. The traction force on the lifting mechanism is 30-65 kgf, which provides a speed of 0.3 to 0.1 m/min. The weight of the structure depends on the material and additional components and ranges from 50 to 400 kg.

Gear manual

Chain hoists with a gear mechanism are used to perform installation work within a garage or in open space. The equipment is controlled at the load securing point. Gear models are equipped with a hanging hook and are easy to install and operate. The design features of gear hoists allow them to be used as independent equipment or as a lifting element for cranes.

Lever

The manually operated lever hoist is equipped with a hanging hook and can be secured to support beams or wire rope. The manual operating principle ensures independence from the presence of electricity. The design provides a locking mechanism for fixing objects in a suspended state.

Worm

Worm hoists, by analogy with other varieties, are used to lift and lower loads. When equipped with additional elements, worm hoists can move objects along an I-section monorail track. You can hang a stationary hoist on a hook manually or make a complete version connected to a mobile trolley.

Tools and materials

The crane beam consists of a guide, a lifting mechanism and end beams. This is a convenient design that can be used not only indoors, but also outdoors. Before you start making it, you need to make calculations and prepare a drawing.

Tools and materials you will need:

- for support rods - several pipes 11 cm in diameter;

- for a cross rod (solid) - a pipe 10 cm in diameter;

- hoist and manual hoist;

- for the rack - a pipe (with a square cross-section) 10x10 cm;

- under the base and for bevels - metal corners 10x10 cm;

- M16 fixing bolts;

- welding machine.

Mobile crane racks

Instead of ceiling trusses, special overpasses can be installed for suspended modifications. Such structures are more often used in open areas. Mobile crane racks are made of metal structures and mounted on the concrete surface of the working site.

The columns are interconnected and do not require attachment to fixed structures or walls. The size of the overpass is calculated depending on the technical specifications and the required load capacity. The mobile structure consists of:

- several types of beams, among them - load-bearing, span I-beams and others;

- running carriage;

- lifting telpher;

- remote control.

Calculation

The calculations for the 250 cm high crane beam were made for working with passenger cars. The crane is capable of lifting elements weighing up to 800 kg. The width of the structure is 415 cm, and the size of the racks is 120 cm. For larger equipment, the lifting mechanism is equipped with vertical A-shaped racks. To securely fasten the bar to the supports, scarves are used.

Assembly instructions

It will take 2 days to assemble a simple or movable structure. The process of making a crane beam with your own hands:

- The main load that the crane will move falls on the stand. To securely fix the structure, you need to make a frame. To do this, legs for the tap are welded from metal corners. The corners are welded to the pipe at an angle of 45° on both sides of the pipe.

- To make spacers, 2 triangles are welded to each rack.

- For a mobile structure you will need rollers. They are welded to a horizontal base, positioned on both sides of each rack. To prevent the rollers from breaking and to withstand the weight, use products that are designed for metal containers. Furniture cannot be used.

- A pipe is installed at the top of the structure. It is designed to move the lifting mechanism.

- The roller for moving the cable is mounted on an I-beam. The I-beam is pre-welded at the central point of the pipe.

- To give the frame additional stability, a pipe with a square cross-section is welded to the beam element. It is placed on top of the beam so that it protrudes forward by 20 cm on both sides.

- The transverse pipe is inserted into a pipe with a square cross-section and through holes for fastenings are drilled on both sides. Bolts are used as fasteners. The homemade frame for a U-shaped crane is ready. The pipe in the form of a crossbar is securely fixed in the upper part of the product, and the entire structure is stably placed on spacers (legs).

- Mechanical lifting is designed to lift parts. It can be manual or automatic. A manual hoist consists of a winch and a cable. The worm winch is mounted on the side of the rack. The movement of the steel cable occurs through rollers.

- The structure can be equipped with a lifting mechanism, which is used in elevators. This mechanism has strong rollers.

- Connecting an electric lift drive will make repair work easier. An engine with a power of 300 to 500 W is suitable for installation. It is mounted on the base of the structure.

How does a manually driven hoist work?

A hoist is a suspended lifting device. It can be manual or electric; the second option is, of course, more common. A hoist, in general, is a special mechanism for lifting or lowering various loads, as well as for moving them. The lifting capacity can be up to 10 tons, and objects can be lifted to a height of up to 12 m - you must admit, not bad for a manually driven mechanism.

Based on these indicators, this device can be used to move various heavy goods, these can be household appliances - gas stoves or refrigerators, freezers or washing machines, and the like. Trade workers often use them to put goods on shelves. You cannot do without manual hoists during construction or repair work, where you often have to lift building materials or tools .

An ordinary manual chain hoist has the following main elements: a chain hoist, consisting of movable and fixed blocks connected to each other; two-stage cylindrical coaxial gearbox, which has a manual mechanical drive; output shaft; specialized disc brake; additional load braking system; block pendant with hook. The operating principle is based on traction and load chain systems that have round links. The main types of manual hoists: gear and lever.

How to make a crane beam in the garage with your own hands

In order to make a garage lift with your own hands, you will need:

- For racks - pipe with a cross-section of 100x100, length 2350 mm - 2 pcs.

- For the cross rod - a round pipe with a diameter of 100 mm and a length of 4150 mm.

- For supports – round pipe with a diameter of 110 mm and a length of 600 mm – 2 pcs.

- For bases and diagonal supports - corner 100x100 mm.

- M 16 bolts for attaching supports to rods.

- Wheels (for example, from a warehouse cart) – 4 pcs.

- Manual winch with a lifting capacity of up to 1 ton.

- Cable and rollers (for example, from an elevator door drive).

Dimensions are approximate and subject to adjustment to suit the size of your garage.

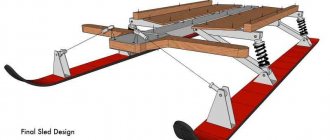

Crane beam device

The mechanism is a U-shaped structure (bridge) with a lifting mechanism. In large auto repair shops, both parts may be movable. The bridge moves on rails, the lift moves on a span beam. In garages, to save space, rails are not laid, and the bridge is equipped with wheels.

The crane beam device consists of supports, a span beam and a lifting mechanism. The supports are welded from metal pipes and channel bars. A manual or, less commonly, electric winch is used as a lifting mechanism.

Girder cranes are of the "floor operated" type, as opposed to those that are handled from a cab. To make the mechanic's work easier, the garage crane can be equipped with an electric winch . This will increase manufacturing and maintenance costs, but if it is necessary to frequently dismantle engines and other heavy units, it will pay for itself. In rural areas where there are power outages, insufficient power or voltage surges, you should give preference to a manual winch. Especially if we are talking about a personal garage and not a private workshop.

What devices are there for lifting loads to heights?

Register or login:. Steel rope or chain has much greater rigidity. Since bending such a cable when running against a block requires additional force, it must also be taken into account.

The force of the approaching and escaping cable arises as a result of the interaction and friction of the rope threads. As you know, efficiency is the efficiency factor, that is, how effective the work performed was. It is calculated as the ratio of work completed and work expended. In the case of a pulley block, the formula is applied:

The lifting mechanism consists of several blocks. The total efficiency of a pulley block is not equal to the arithmetic sum of all individual components.

For the calculation, a much more complex formula is used, or more precisely, a system of equations, where all forces are expressed through the value of the primary S0 and the efficiency of the mechanism:. Since the efficiency value is always less than 1, with each new block and equation in the system, the value of Sn will rapidly decrease.

In construction, during installation work, it is not always possible to fit a crane. Then the question arises of how to lift the load with a rope.

Hello dear homemade people. Do you really need a crane? So let's do it. Small-sized, with a boom that rotates and lifts, with a carrying capacity of two bags of cement, or 30 pieces of brick, or 3 large buckets of concrete. I made one for myself, and now I can’t imagine how my wife and I could have built a two-story cottage with an area of 2 m2 if this crane had not existed.

And here a simple chain hoist finds its application. To make it and fully operate, you need to make calculations, drawings, and choose the right rope and blocks. Before you start building a chain hoist with your own hands, you need to carefully study the drawings and choose a suitable scheme for yourself.

You should rely on how it will be more convenient for you to place the structure, what blocks and cable are available. It happens that the lifting capacity of the pulley blocks is not enough, and there is no time or opportunity to build a complex multiple lifting mechanism.

Then double chain hoists are used, which are a combination of two single ones. This device can also lift the load so that it moves strictly vertically, without distortions. The most important role in building a chain hoist with your own hands is played by the rope

It is important that it does not stretch. Such ropes are called static

Stretching and deformation of a flexible connection causes serious losses in work efficiency.

For a homemade mechanism, a synthetic cable is suitable; the thickness depends on the weight of the load. The material and quality of the blocks are indicators that will provide homemade lifting devices with the calculated load capacity. Depending on the bearings that are installed in the block, its efficiency changes and this is already taken into account in the calculations. But how can you lift a load to a height with your own hands and not drop it? To protect the load from possible reverse movement, you can install a special locking block that allows the rope to move only in one direction - the desired direction.

When the rope and blocks are ready, the diagram has been selected, and the calculations have been made, you can begin assembly.

For a simple double pulley you will need:. The homemade lifting mechanism is ready to use and will provide double the strength benefits. Now, to raise the load to a height, just pull the end of the rope.

Do-it-yourself winch from the starter

By bending around both rollers, the rope will lift the load without much effort. If you attach an electric winch to the homemade mechanism that you build according to these instructions, you will get a real do-it-yourself crane.

Now you don’t have to strain at all to lift the load; the winch will do everything for you. Even a manual winch will make lifting the load more comfortable - you don’t need to rub your hands on the rope and worry about the rope slipping out of your hands.

In any case, turning the winch handle is much easier. In principle, even outside a construction site, the ability to build a basic pulley system for a winch in field conditions with a minimum of tools and materials is a very useful skill. It will be especially appreciated by motorists who are lucky enough to get their car stuck somewhere in an impassable place. A hastily made pulley will significantly increase the performance of the winch.

Recommendations for making the device

Above we looked at what a beam crane consists of: supports, a span beam and a hoist. Manufacturing takes place in several stages:

- Weld the vertical supports in the shape of an inverted T with two diagonal supports.

- Weld the span pipe to form a U-shaped structure.

- Install the wheels.

- Weld a winch to one of the side supports.

- Install the lifting mechanism: fix the rollers, stretch the cable and hang the hook.

Ready-made drawings can be found online, but it’s easier to make it yourself by adjusting the product to the size of the garage.

If for some reason this type of lift is not suitable, you can make a goose garage crane with your own hands - it will take even less time. The gooseneck crane has an L-shape, where the vertical stand is equipped with a jack rather than a winch. It is rolled under the car from the front and the engine is lifted by pumping a hydraulic jack. The boom moves upward and lifts the load.

Another interesting solution that will help save space is a suspended crane beam. Unlike the supporting structure described above, the span beam is attached to the ceiling by means of a rail (I-beam). This option requires sufficient ceiling height and strength of the building.

All devices must be tested with a load 20% greater than the maximum intended load.

Lever hoist – advantageous physics of load capacity

This type of hoist is necessary for working with small loads, the weight of which is no more than 5 tons, and it can be raised to a height equal to the height of a person. It all depends on the design solution. Raising, lowering and moving is carried out using a lever built into the body. The hoist is controlled by an operator located near the device. Such models are good for tensioning cables and lifting loads. Since they are not suitable for a large volume of work, utility services find use for them.

They are necessary when you need to tension cables or install pipes at the bottom of trenches, as well as for installing hatches. With their help, foresters pull out stumps, and industrialists place heavy equipment in workshops. Often their purpose is to lift a load in order to work with it, which is how a jack works. This can be various repair work, for example, in car repair shops. To make working with lever hoists easier, they are additionally equipped with special trolleys.