This winter, the battery suddenly began to fail me; at the most inopportune moment, it self-discharged almost to zero for reasons unknown to me, which made it impossible to start the engine at the most inopportune moment. No short circuits were found in the banks, and after recharging the battery worked normally. The only drawback of this battery resuscitation was that the recovery time was too long. I used a very cheap wall charger that took at least 12 hours to fully charge the battery. For this reason, it was decided to make a powerful power supply from a welding inverter, with which it would be possible to quickly charge a car battery with minimal time. The Resanta SAI 140 apparatus was used as a basis.

Source dvoroz.ru

general information

Many welding inverters, whether domestic or professional, can be equipped with a built-in start-up charging function. A typical example of such a device is Caliber SVIZ 200AP.

This and similar devices are considered start-charging devices, since you can connect any battery to it and charge and/or start it. An inverter with a starting-charging function is a welding machine, a starting device for a car, and a battery charger in one housing. Comfortable? Still would!

Using such a device, you can start a car engine in cold weather, recharge a car battery and other types of batteries. In any difficult situation, you can solve many everyday problems with your own hands.

Therefore, we answer the most popular question: “Is it possible to charge a battery with an inverter welding machine?” Answer: yes! But only if the device is equipped with this function.

Introductory information

In theory, everything seems much simpler. But in application, certain conditions must be met. The current in the electrical network must remain uninterrupted and not fall below 180 Volts.

Or your welding unit must cope with low voltage work. Such equipment is not cheap.

It is not even discussed that you must have access to electricity. But some country houses and dachas, garages located far from the urban area are not connected to electricity.

What to do in this case. Our opinion comes down to buying a fuel generator for welding. But not everyone wants to spend extra money, especially if you rarely use welding.

The correct option under such circumstances is to use a 12-volt car battery. Some specialists manage to connect the battery to a welding inverter.

Even to carry out non-long-term welding. In our review we will write whether it is possible to carry out welding tasks using a 12 Volt battery. Is it really necessary to take such risks?

Peculiarities

Charging any battery with an inverter welding machine requires compliance with certain rules and knowledge of the features. We will list the main nuances that you should pay attention to.

First, about the batteries themselves, in particular car batteries, since they are most often charged using such inverters. During operation, the battery loses its properties, as a result, the capacitive characteristics decrease. And if you add subzero temperatures to this, the battery will “sit down” at a catastrophic rate. Because of this, you simply will not be able to start your car normally. What are the ways to solve this problem? The battery can be connected to the battery of another car or started “from a pusher”.

But these methods are ineffective and often do not work when “revitalizing” a modern foreign car. In such situations, an inverter with a built-in charger start-up function comes to the rescue. Of course, you can buy a separate unit designed exclusively for charging. But the inverter is more functional in everyday life. They can both recharge the battery and perform welding.

Application

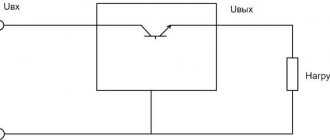

Please note that for these purposes you need to use only a special welding inverter with a start-charging function. An ordinary inverter machine is not suitable for these purposes. It is simply not designed for this. A device with a start-charging function is capable of reducing the output voltage to the required 12 or 24 Volt battery. But a regular inverter will simply output 50 Volts and your battery will burn out.

A welding inverter with a charging function must be switched to this mode before carrying out work. By default, it does not perform the charging function. Set the voltage you need (12 or 24 Volts, depending on the battery). Also setting Amps. We recommend using a ratio of 1 to 20 relative to the power of the battery itself. So, when setting 3 Amps, you can charge a battery with a capacity of 60 Amps.

The battery needs to be charged for no more than an hour, ideally no more than 40 minutes. This is usually more than enough to start any internal combustion engine. But if you need to fully charge the battery from scratch, then charge for 2.5-3 hours, while reducing the current. If your battery is 60 Amp, then set no more than 1.5-2 Amp on the device.

Safety precautions

In appearance, batteries do not pose any danger, since all their “internals” are enclosed in a durable casing. But this does not mean that you need to neglect safety precautions when using car batteries. Moreover, when connected to an inverter.

If you need to remove the battery, move it, or perform any other actions, use special gloves. Ideally, you also need to choose the right clothes, but you are unlikely to think about this while sitting in the garage. Therefore, at least have thick gloves with you. If you get electrolyte on your skin, wash it off immediately with the solution. The solution can be made from soda or ammonia with water.

After handling, remove gloves and wash your hands thoroughly with soap. Don't eat near the battery, don't smoke, and generally take this seriously. Need a break? Leave the batteries in a separate room and leave yourself.

If your batteries are dirty, they need to be cleaned. This can be done using the same solution of ammonia with water. Use a clean, dry cloth. If you removed the batteries from the car, then clean the holes in the plugs so that there are no blockages. Otherwise, there may be excess gas pressure.

And in general, remember that batteries can be a potential source of danger to your life and health. Better protect your skin from acids and electrolytes, protect your eyes and mucous membranes. Do not perform any manipulations with batteries while intoxicated. Keep a small fire extinguisher nearby just in case. After all, not only the battery, but also the inverter itself can become a source of danger.

These rules are simple and obvious, but in the process of work, most masters forget about them. And then they regret it. Be smart and prevent a lot of problems by practicing safety precautions.

How to make a starting charger for a car with your own hands? Reasonable savings

How to make a starting charger for a car with your own hands

It will be useful for all drivers to know, since it does not contain scarce parts. It is quite easy to assemble it yourself if you have the necessary parts and experience in repairing electronic equipment. Such a device is also useful because, in addition to helping to start the engine, it can be used to recharge a dead battery.

What is the difference between a charger and a jump starter?

Today, several types of such devices are produced, among them the following products can be distinguished:

- Devices for battery charging only;

- Engine starting devices;

- Combined products for charging and starting the engine.

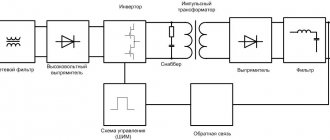

Let's take a quick look at their design features. Products of the first type can be transformer or pulse. Charging is possible with constant or pulsed currents. Launch-only devices have large overall dimensions and weight.

For the most part, they are made on the basis of welding machines, by isolating an additional output that provides 15-16 volts. And finally, combined devices that can recharge the battery and, if necessary, start the engine.

How to choose a circuit for such a device?

To assemble such a device, you need to have at least a little experience in handling measuring instruments and a soldering iron. Be able to understand radio circuits and setup of radio-electronic products. If all this is available, you can begin to select a circuit diagram and complete the necessary radio components. There are few of them and they do not belong to the category of scarce ones.

If such work is being done for the first time, you should choose a not very complex circuit for the starting charger, and in the future, as you gain experience, you can move on to the manufacture of more complex and reliable devices. You can choose a suitable scheme on the Internet, as well as in many printed publications. You just need to take into account the fact that the starter consumes a current of approximately 200 Amps, so if the device has an ammeter, it is necessary to ensure that it is turned off when trying to start the engine.

Features of its manufacture

Before starting work, you need to prepare tools and components. You may need the following components:

- An electric soldering iron with a power of approximately 100 watts;

- Soldering acid and solder;

- PCB plate for mounting the device;

- Transformer with a power of 1500 Watt;

- Cooling fan, suitable for computer;

- Powerful diodes with current from 100 Amperes;

- Electric drill and set of drills;

- Wire for connecting to a 220 Volt network;

- Cable for connecting to the battery, its cross-section must be at least 10 mm2;

- Cable products for windings;

- Clamps for this cable, preferably quick-release;

- A set of bolts and nuts for fastening mounted parts.

“Russian welding”: how to properly connect batteries for welding work in the field

– Do you have spare parts for UAZ? - Yes, what do you need? – Electrodes, wire and electrical tape... (bearded joke)

Repairing a car using welding in the field - a curiosity or a life saver?

The habit of drivers of past generations to carry half a trunk of tools and half a trunk of spare parts, fortunately, is a thing of the past. A modern car with good and timely preventive maintenance, even if it is at a very advanced age, rarely presents fatal surprises, after which further movement can only be continued on a “tie” or on a tow truck. However, there is and remains a class of car enthusiasts who still vitally need to have a lot of spare parts and a solid arsenal of tools, which includes, at a minimum, a drill and an angle grinder. We are talking about owners of honest full-size frame SUVs who practice tough rally raids and serious travel to places where you can call for help only with the help of a satellite phone... To lands where, according to the text of a popular jeep sticker, “even wolves are afraid of shit” , 80th and 100th “Cruisers”, riveted “Defs”, old “Patrols” are taken, but, let’s be honest, you can find Ulyanovsk SUVs there much more often. And since the quality of parts for UAZs still leaves much to be desired, every true UAZ driver knows very well that he has to rely only on himself - on his level 80 field repair skill and a stock of hardware and tools that a car shop would envy! You will still laugh (s), but welding occupies a very honorable place in the mobile arsenal of an advanced jeeper, and sometimes it is the only lifeline that allows you to get out of the taiga or even continue the route! A broken kingpin in the steering knuckle, a burst clamp on the outboard cardan bearing, a cracked panhard rod - it is completely unrealistic to carry every conceivable spare part with you (although I would like to!), and often it is possible to restore the car's mobility in extreme conditions with the help of welding. Today, a wide range of mobile cordless tools are available for sale (and are becoming cheaper - systematically, although not as quickly as we would like), which until recently were firmly connected to a 220-volt power outlet. However, powering a welding machine in the field from a car’s electrical system is still extremely difficult, if not almost impossible. Yes, mobile welding machines powered by built-in lithium batteries have already appeared on the market, but the cost of under a hundred thousand rubles clearly does not contribute to their prevalence among people in the foreseeable future... And through a 12/220 volt converter, even the lowest-power 220-volt inverter welder with an electrode - a “kopeck piece” will require an exorbitant load on the battery and generator from the car’s electrical system - more than 200 amperes... And this is for a burning arc, without taking into account the jump during ignition... We recently talked about a unique Soviet gadget - a car welding machine, but this is rather an interesting technical a curiosity, and not a serious device, especially since such devices have not been produced at the factory since the 90s. However, welding is simply vital for a jeep driver - what can you do? Everything is very simple: the solution to the problem was found by our grandfathers and is successfully used to this day. We are talking about welding using car batteries! A 12-volt car battery is a source of a fair amount of electricity with a high output current - exactly what you need for welding. To operate a two-millimeter electrode, two batteries connected in series are sufficient, and for a three-ruble electrode, three batteries are optimal. Even a single jeeper often has two batteries - a starter and one that powers the winch, but if you need to weld massive parts and require heating with a thicker electrode, the third battery is borrowed from colleagues in off-road competitions or fishing/hunting.

How does it work?

Technically, the motorist's field welding machine is extremely simple, although it has some features. All welding actually fits in your pocket: these are one or two jumpers connecting two or three batteries in series into a “garland”, and a pair of working cables - with a holder for the electrode and with a “crocodile” for ground. Well, of course, you also need a mask - a simple compact shield or at least just black glass. In extreme conditions, you can do without a comfortable, but large and fragile chameleon-type helmet...

There is only one nuance in the manufacture of such a design: all connections to batteries (with wires with a cross-section of at least 25 square millimeters) must be made exclusively using factory-made terminals! Even the cheapest, rootless Chinese ones, at a hundred rubles a pair. The contact must be very tight, and any “winding” to the lead tips of the battery quickly causes severe local overheating and melting of the battery terminals.

The most common questions about mobile welding

Those who hear about mobile-vehicle welding using starter batteries for the first time have many questions. The most common ones sound something like this: – Is it possible to cook with one battery?

– No, 12 volts is not enough for stable arc ignition.

There should be a minimum of two batteries (24 volts), ideally three (36 volts). The Jeeper formula that has developed over the years is as follows: “two batteries are cooked with a 2 mm electrode, three – 3 mm.” – Is it difficult to cook with such a “welding machine”?

- Very easy.

An ideal direct current and its sufficient magnitude make it easy to ignite, maintain an arc and lay a more or less high-quality seam for anyone who has minimal electric welding skills. – How long can you cook continuously on one battery charge?

– It is generally accepted that without the risk of subsequently not starting the engine, you can “burn” a dozen electrodes during such welding.

Well, sometimes a dozen and a half. As a rule, in field conditions there are no breakdowns for which there are not enough electrodes to weld. Well, if you still didn’t keep track, and after welding the battery does not start the engine, then this is unlikely to become a problem - the rare “jeeper” today does not have a backup emergency booster with a lithium battery. – Are such tricks harmful to batteries?

– Yes and no... The welding current itself does not exceed the current that the starter takes from the battery during everyday engine starts.

The most harmful moment is before the arc ignites, close to a short circuit. But in reality it is extremely short-lived, especially since we are saved from pure “KeZe” by some resistance in the welding wires and the crocodile contact. To put it simply, the rare use of batteries for welding in extreme conditions will not significantly and noticeably harm them. – How to regulate the current when welding with batteries?

– In the simplest version, which is most often used, no way. Some advanced users use “resistances” made of thick steel wire spirals connected in series with the electrode, simply thrown to the ground, or some powerful resistors from electric trains. But for occasional use, you can do without adjustment.

How to weld using a battery

It should be within 200 - 280 mA. If necessary, it is adjusted by selecting turns. The transformer should be run for a while to check how hot it is. If heating does not occur, wind the secondary winding. Before this, the core is also carefully insulated.

For the secondary winding, you need a wire with a cross-section of 10 mm2, the number of turns is from approximately 15 to 20, it is selected experimentally so that the output voltage is approximately 16 Volts. Power diodes must be installed on radiators to cool them. All parts are mounted on a PCB plate. A fan for cooling, as well as measuring instruments, are installed in the finished case.

We tried to answer your question about how to make a starting charger for a car with your own hands. The simplest circuit of such a device is considered, however, when using it, certain rules must be followed so as not to prematurely damage the battery or radio-electronic products installed in the car.

Welding with battery electrodes

I have heard about welding from car batteries for a long time, and there are also videos on YouTube confirming this. And in principle, I had no doubt about this because the characteristics of the batteries allow this to be done. Firstly, there is a large current, up to 600A from a 55Ah battery, and with a battery of larger capacity there is an even greater maximum current, so even a large excess of current is obtained rather than a lack of it. But in general, a year ago I needed to weld a motorcycle frame and a side trailer for it, but there was nowhere to connect a welding inverter at the dacha.

At my dacha I have my own electricity, a small solar power plant is installed, and there is a 12-220 volt converter installed there with a maximum power of only 1 kW, and naturally it will not handle welding. But at that time I had four batteries in my power station, two of 65Ah each, and two more of 90Ah each, so I decided to see for myself that it was possible to cook from a battery. In general, I brought two batteries to the welding site and connected the battery in series at 24 volts. The electrodes were 2.5 mm in diameter.

Let me say that I managed to brew it, and quite well.

, but most likely there was not enough voltage because

the arc ignited very poorly

and good penetration was not achieved, since the arc barely burned and often simply went out. But what surprised me was that if the electrode gets stuck, it heats up to red in a second and melts. I haven’t observed this with conventional welding, but here you have to be more careful, the electrodes burn out in one fell swoop when they stick.

Just recently, at the beginning of February (2016), I needed welding again, but I already had three 90Ah batteries. I was making a frame for a wind generator. With three batteries connected in series

The welding turned out to be excellent and with a lot of current.

Is it possible to cook using a car battery?

Is it possible to carry out welding work using a 12 Volt battery? All owners of remote country houses and garages where there is no electricity are thinking about this. The mains current simply may not be enough to operate the inverter equipment.

This point is the subject of controversy. Of course, you can take the battery from your car, charge the welder, then return it to its place.

But additional questions arise. How good and strong the weld will be. Will the weld burn out? Will the battery itself deteriorate?

Based on our own experience, we declare that it is possible to cook using a 12-volt car battery. We will not say that machine batteries are suitable for powering a welding unit.

But they will be good additional insurance for these purposes. Car batteries have a large power reserve. Theoretically, they can charge a low-power welding inverter.

How to make a welding machine from a car battery

I started welding with 2 mm electrodes, and at first I even burned a few holes in the metal because the current was too high. Then I welded with 2.5 mm electrodes, but the current was still too high and I had to cook very carefully so as not to burn through the thin 3 mm metal. I even cut such metal freely with electrodes. Then I didn’t have any other electrodes, but I think 4 mm electrodes would have gone freely under such a current. Overall it cooks great

except that the current is too high, which there is nothing to limit. But you get used to it, and it’s quite normal to brew something even serious.

But it’s better not to deeply discharge the batteries, otherwise they will deteriorate quickly, but the high current will do them no good. I will say that from three 90Ah batteries you can easily burn 15-20 electrodes each and the batteries do not discharge much, and such a number of electrodes is already decent.

Below are some photos of batteries and welding

This is what the batteries themselves look like when they are connected in series; my welding wires are 35 kW.

These are actually 2 mm electrodes

Electrodes 2.5 mm

In this photo you can see the penetration from the back side, I didn’t specifically photograph the welding process itself, so I didn’t capture the welding quality specifically, but overall it cooks well.

And here is the result of the welding, the frame for the wind generator is welded.

If anyone is interested in the wind generator itself and welding, I wrote an article about making a wind generator and there is a video there where you can see what I did and how I welded it. That's all, if there is anything new I will write in the following articles.

E-VETEROK.RU wind and solar energy - 2013 Email: [email protected] Google+

Pure Sinus Perm:

Nice channel, just beautiful.

Pure Sinus Perm:

Well done, make more videos like this about three-phase power supply. Make a video about chickens and how many eggs they lay.

isak nyton:

Well, what did you film, you didn’t even show the trans

Anatoly Anatolyevich:

Well done

Own experience of cooking from a car battery

We will look at our own experience of using a car battery to power an inverter unit. You can test it yourself and duplicate our work to verify what you have received.

It should be noted that one regular car battery will not be enough. Know this is a fact. At first we wanted to power the inverter from one car battery.

Welding was carried out at low current, using electrical connections 2 mm thick. The arc hardly ignited. The seam went with considerable effort. Then they took out two car batteries and connected them one by one.

Types of memory

The most common types of batteries:

Most cars use WET batteries . These are lead-acid containers filled with liquid electrolyte. They require an aqueous solution of H2SO4 to function. The properties of the battery allow it to be used with any charger, regardless of its technical characteristics.

In AGM, GEL, sulfuric acid is used as an electrolyte in different states. These car batteries are more sensitive to changes in current levels and overcharging. To restore capacity, you will need to purchase specialized memory devices.

When choosing a charger, it is important to study the technical capabilities and battery parameters . One of the indicators you need to pay attention to is voltage. Passenger cars typically use batteries with a nominal voltage of 12 V. For trucks, the figure can reach 24 V.

Classification of memory

- Chargers. When charging the battery, do not turn on the engine.

- Launchers. Used to start engines up to 7 liters in volume. They are lightweight, can operate at low temperatures, and can be charged from a cigarette lighter.

Battery welding

Starting current indicator up to 600 A.

- Starting chargers. Combines the functions of the other two types. These are portable devices with a control panel and charge level regulator. They can gradually reduce the supplied current as capacity is restored; when the battery is fully charged, they can automatically turn off.

Battery chargers can be pulse and transformer . The first ones are small in size and consist of an inverter and a protective element that prevents short circuits. The latter are equipped with a voltage rectifier and transformer. This makes them more bulky. In terms of ease of use and technical parameters, pulse charging is better suited for modern cars of domestic and foreign production.

Characteristic

Main parameters of recharging equipment:

Rating of chargers 2018

- Caliber. A domestic enterprise that produces memory devices at an average price of 3–4 thousand rubles. The devices can charge batteries with a capacity of up to 100 A/h, rated up to 24 V. Models with increased current are suitable for restoring batteries with a capacity of up to 250 A/h.

- Bosch. The chargers are easy to use. The instructions for use indicate that the battery begins to charge after pressing just one button. All models are protected from dust and splashes. There is a function to save the specified settings and automatically turn off. The cost is more than 5-6 thousand rubles.

- Resanta. Latvian company. Automatic chargers are equipped with mini-batteries that start the engine even when not connected to the mains. The mobile model PU-2 additionally has a compressor, a USB input, and a flashlight.

- Orion. Devices from this manufacturer operate only in automatic mode and can smoothly reduce the current level at the end of the charging cycle. Voltage control prevents intense heating even during long-term operation and reduces the load on the battery.

- Cedar. Chargers from a domestic manufacturer are designed for 12-volt lead-acid batteries. Restoring capacity with a stabilized current supply, cyclic mode allows you to avoid short circuits and accidental polarity reversal. Even with a long-term connection, the device does not lead to overcharging or overheating. Price from 2 thousand rubles.

- Telwin. Italian manufacturer of car accessories. The most popular model is Nevatronic 12. It is suitable for all types of batteries with a nominal voltage of 12 V.

- Aiken. This brand produces many chargers suitable for cars, trucks, and motorcycles. The relatively low price (1-1.5 thousand) is explained by the fact that the devices function only when connected to the mains. Therefore, they cannot be used on the road.

A good charger may cost more than a new battery, but the cost is quickly recouped.