Fans of making homemade alcoholic beverages eventually come to the need to improve quality. The best solution is to obtain pure alcohol and dilute it according to the required recipe.

A rectification column will help you obtain pure alcohol. More recently, information about home rectification was inaccessible; today a large number of specialized forums and blogs cover in detail the process of home rectification and the construction of corresponding equipment.

The essence of the rectification process

Rectification is the process of purifying alcohol from light ethereal and heavy fusel components, ridding the product of glucose, sugars and acids. The rectification process allows you to obtain pure ethyl alcohol up to 96°.

The resulting raw materials are used for technical and medical purposes, as well as for the preparation of high-quality alcohol.

Reference. In order to make a device with your own hands without errors, you need to understand the physics and chemistry of rectification processes.

Raw alcohol or mash is heated in a cube. The vapor rises along the drawer, the heaviest parts condense at the bottom of the packing and flow into the cube. Easier vapors rise above the packing, condense and flow into the cube. A new portion of vapor rises, heats the already flowing phlegm, light fractions evaporate from it - the fundamental principle of heat and mass transfer comes into force.

The lightest particles reach the Dimroth refrigerator, where they cool and drain. When the vapors in the distillation column are “lined up” on floors in accordance with density, alcohol selection begins at the top of the column. Beginner rectifiers make a mistake precisely at this stage - either they allow “choke” - excessive reflux, or they take away a lot of product, then the “storey” suffers and the resulting alcohol will contain impurities.

Making a distillation column at home is quite difficult. Serious manufacturers calculate and test their products in detail and include detailed instructions. The DIYer has a choice:

- Repeat the idea of popular manufacturers, copy an existing device. If necessary, changes and modifications can be made to the tested diagrams.

- Design your own scheme, different from others.

Differences between a mash column and a conventional moonshine still with a steamer (distiller)

Oddly enough, the mash column looks more like a distiller rather than a distillation column. They are very similar in the following ways:

Classic distiller with steamer.

- The resulting moonshine is aromatic. In a mash column, the purification of alcohol vapors is not so strong as to eliminate all taste and smell. The output is a distillate of very high strength or under-rectified.

- The degree of purification is usually about the same. Due to the complexity of setup, moonshiners usually do not use all the capabilities of this equipment. The slightest movement and haste can lead to the fact that the product can become saturated with harmful fractions in a second. This is especially noticeable when a 90-degree product is diluted with clean 40-degree water. The smell of fusel is revealed in all its glory. By following the rules of distillation, the quality can be significantly improved.

Let's now look at the differences that are found in these devices. They are quite significant, so they must be taken into account when choosing equipment for work:

The presence of a reflux condenser is considered the main difference.

- Different appearance. The distiller usually consists of a steamer and a refrigerator connected to each other by steam pipes. A mash column is a structure made of a pipe, a reflux condenser and a refrigerator.

- Different strengths of moonshine. The distiller can produce up to 65 degrees during the second distillation, but usually people start to give up their tails and end up with something around 55 degrees. The column will make you up to 90% alcohol without any problems.

- Different distillation technologies. Due to the presence of a reflux condenser, the entire process is aimed at the most accurate selection of the head fractions from the main product. The quality of the resulting alcohol will depend on how well the moonshiner succeeds.

- Different price. The mash column is obviously more expensive, as it requires more material and serious work by craftsmen.

- Difficulty of care. Conventional moonshine stills are quite difficult to clean properly. There will always be some foreign odor in the steam pipes, which can only be removed by very intensive or special cleaning. The column usually has clamp connections, so cleaning does not take much time and effort.

What does a distillation column consist of, and its drawing?

A home craftsman can make a drawer distillation column. It forgives many mistakes, and the result will be guaranteed.

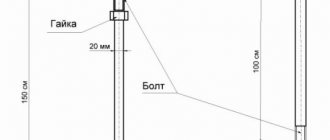

Distillation column drawing

Alembic

This is a container where heaters are built in and mash or raw alcohol evaporates.

Capacity Specifications:

- Strength. The weight of the distillation pipe will rest on the lid, so the cube must be rigid.

- Chemical neutrality to alcohol. The ideal material is food grade chromium-nickel steel (stainless steel).

- Convenience. The container needs to be lifted, moved, and stillage drained from it (distillation). The volume of the container is calculated depending on the required performance of the device and the power of the heaters.

- Insulation. Heat loss should be minimal. therefore, both the walls and the bottom should be “packed” in insulation without cold bridges.

Drawer drawer for moonshine still

The drawer is a pipe that is installed on a cube. In fact, this is the main frame of the distillation column. There is a plate-shaped drawer, but it is rarely used at home.

Characteristics:

- Strength. The wall thickness of the drawer is usually taken from 1 to 1.5 mm. This creates sufficient strength with low weight.

- Chemical neutrality.

- Insulation. In order to arrange pairs of different factions “by floor” in a column, the drawer must be well insulated. A sleeve made of foamed polypropylene or polystyrene foam trays used in plumbing are ideal.

- Collapsible. For ease of cleaning and storage, the drawer can be made collapsible - from 30-40 cm elbows. This will allow you to adjust the height of the device, which affects the speed and quality of the product.

- Availability of viewing glass areas.

- Diameter. If it is a thin tube (up to 2 inches), no packing is needed - all processes take place on the walls. Such a column is called a film column. Diameters higher require the use of a nozzle - a sealing packing to increase the heat and mass transfer area.

Instead of an afterword

The alcohol obtained through rectification is much higher quality than the distillate from a classic moonshine still.

But along with the positive aspects, there are also disadvantages : the requirements for equipment are much higher, and its production is more expensive; in addition, operation also requires high skill.

Therefore, it is not so easy to clearly determine which is better, a good moonshine still or a distillation column, but, of course, there is an intermediate solution - a mash column. It produces a distillate, but not a rectified product, of very high quality, and it is easier to use, it’s all a matter of priorities.

Design selection

The size and design of the device depends on a number of factors:

- Required performance. with higher productivity, the padded drawer will be higher and wider - the pair passes more. The cooler and extraction unit must also provide sufficient efficiency. The minimum length of the drawer is 1.5 meters, it is better to make it collapsible from three bends - 1 meter, 0.2 meters, 0.5 meters. this will allow the device to be used for both distillation and rectification.

- Possible sizes. Often home distillation columns are limited in size due to ceiling height. Shifting the dimrot refrigerator in the upper part of the apparatus, or placing it perpendicular to the drawer (Thor's hammer) will help save space.

- Access to metalworking technologies. A stainless steel device will last a long time and will not oxidize alcohol, but to connect the parts you will need argon welding or stainless steel electrodes. Cooking stainless steel is difficult. If possible, you can use laboratory heat-resistant glass, but it is too fragile. An excellent option for the DIYer is copper. It is easily soldered with a gas torch; there are a large number of them on sale.

- Volume of refilled raw materials. The larger the cube used, the higher the productivity should be. Evaporation of alcohol occurs at 75 - 80 ° C; lowering the temperature will reduce the speed of the process.

- Budget. With a minimum budget, you should consider a simple but effective design with mechanical adjustments. If the budget is not tight, the device is supplemented with precision needle taps, additional components and automatic control.

How to achieve better results?

When operating a distillation column, certain measures must be observed to ensure normal operation and obtain a high-quality final product.

Particular attention should be paid to activities in the following areas.

Elimination of “flooding” of the installation

This “disease” is associated with the slowing down and stopping of the flow of reflux, which leads to its accumulation in the cylinder and blocking the steam flow. As a result of “flooding”, the pressure inside the column increases, causing loud gurgling and noise.

The phenomenon can be provoked by the following reasons:

- Exceeding the permissible speed of steam flow, which can be caused by excessive heating of the liquid in the cube;

- Excessive filling of the cube with raw materials or blockages in the lower zone of the pipe;

- The pressure at the bottom of the column is too low, which is typical for high mountain conditions;

- An increase in voltage in the supply network, which causes an unplanned increase in the power of the heating element;

- Violations in design or technology.

Installing automatic control and regulation of the process helps to avoid this unpleasant phenomenon.

Particular attention is paid to heating the raw materials and filling the cube

Timely removal of the finished product and settling heavy fractions

In the first case, the technique is simple - at the initial stage (until temperature and pressure stabilize), only a quarter of the highly volatile vapors condenses with the final product and is removed outside, and then its maximum volume is removed.

The appearance of sediment from heavy fractions is more difficult to detect. You have to focus on the smell and color of the liquid at the very bottom of the column.

Correct preparation of the installation for start-up

Before starting rectification, it is necessary to check the condition of the apparatus, first of all, the tightness of the column. To check, the outlet of the finished product is shut off and cold water is pumped in.

Only after making sure that the installation is tight can you start pouring raw materials and heating the cube.

You should not expect miracles from a household machine and should not replace a moonshine still. The minimum strength of the initial liquid must be at least 30%, otherwise the output will not be a product that is close in strength to pure alcohol.

When making an installation with your own hands, you must not allow loss of thermal energy through the column body

It is especially important to protect the lower part, i.e. zone up to the first reflux condenser

It is recommended to use as thermal insulation:

- Styrofoam,

- penoizol,

- modern foil insulation.

Distillation columns allow you to deeply purify liquids or separate the light fraction. In industrial settings, they find application in many industries, incl. With their help, oil refining is ensured and high-quality alcohol is produced.

At home, such installations are suitable for producing very strong, high-quality alcoholic drinks from moonshine. When used correctly, they are completely safe and effective.

Optimal calculations

The column calculation begins with determining the following parameters:

- Possible height. Practice shows that for a home device the optimal height is 1.5 - 2 meters. If a gas stove is used as a heater, the height of the drawer will be 1.2 - 1.5 meters. The diameter depends on the height, the average ratio is 1/50. For example, a drawer of 1.5 meters should be no more than 32 mm. (rounded up to standard pipes).

- Power of the heating element or heater. A 1.5 meter drawer will have a capacity of approximately 300 ml/hour, which corresponds to 300 watts of heating element power. The heater power must be sufficient to heat the mash volume to 70 °C within 1 hour, and also be able to be optimally regulated.

- Volume of a cube. This is an insulated container with a convenient size and transportable. To save room height, the diameter and height should be approximately the same. The amount of heated vapor depends on the volume of the cube. Beer kegs of 25, 30, 50 liters are convenient for home use. It is better not to use aluminum cans or tanks - aluminum quickly corrodes.

- Coolers power. The cooler must fully cope with the condensation of vapors with minimal water flow. There is no exact formula for calculating the power of a cooler; the number of turns and length are selected experimentally. For our design, 30 centimeters of a tightly wound spiral from a 6 mm tube is sufficient. It is better to make a refrigerator with a power reserve and regulate the flow rate of cold water.

Advantages and disadvantages of distillation systems

Pros of distillation:

- with repeated purification and distillation, the quality complies with GOST standards for the tolerance of impurities;

- the taste of moonshine has shades of the raw materials from which the product is made;

- the devices are cheaper;

- high speed of forcing.

Minuses:

It is impossible to obtain pure and at the same time strong alcohol - chemical dehydration will be required.

Pros of rectification:

- with column distillation, especially multi-level distillation, a very pure product is obtained, unattainable for moonshine distillate;

- You can immediately produce high-strength alcohol.

Minuses:

- the process takes longer;

- high costs for water and heating;

- the device is not cheap;

- understanding the process is quite difficult.

You can weigh everything and decide which method to choose for yourself. But in any case, rectified alcohol is not 100% purified from harmful impurities, this is especially true for imperfect and homemade devices. But the distillate has quite acceptable characteristics, and if the distiller approaches the process responsibly and is savvy, his drinks will be much better than store-bought ones.

How to make plumbing fittings at home?

The steps are as follows:

- We purchase materials - 2 meters of 32 mm copper pipe; soldering tin; 15 cm of copper tube with a diameter of 8 mm, 2 meters of 6 mm tube; needle tap, plastic hose with a diameter of 8 mm. We purchase a ready-made nozzle or a substitute - ceramic gravel, metal sponge. The simplest connectors are clamps or brass threads.

- We make a king. We divide the pipe into sections of 1 meter, 0.3 meters, 0.5 meters. We solder a 10-centimeter piece to the lid of the cube, insert a mesh to hold the nozzle. At each joint we solder a clamp connection or plumbing thread made of copper or brass.

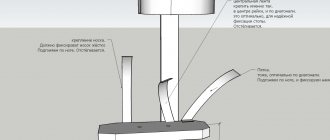

- We are assembling a selection unit based on Alex Bokakob. On a tube 0.3 meters long, closer to the bottom edge, we make two corner cuts at 30 - 40 degrees. We insert copper plates into the cuts, cut them and solder them. We drill a hole for the liquid sampling tube; the hole should be at the bottom of the “pocket” of the bottom plate. On the extraction tube we solder a thread for a needle valve, which will regulate the extraction. We insert a “forward flow” tube to the side and just above the extraction hole. It is needed to control the reflux ratio. The direct flow conducts reflux from the selection “pocket” below, and the reflux drips into the center of the nozzle. The middle part of the forward flow is made of a transparent plastic tube.

Functional purpose of a decorative column

Columns look good in an elegant interior. We will consider decorative structures, since creating columns from solid stone or concrete does not interest us (installing them in an apartment makes no sense). So why do you need plasterboard columns in an apartment?

- Decorative function is the first thing that comes to mind. It is clear that the design should be used in a spacious apartment, because in a small one-room apartment it will look stupid. However, this design gives the room sophistication and grandeur. If you also decorate it with marbled decorative plaster, the effect will be amazing. It is clear that in this case the entire apartment should be designed in a similar style.

- Concealment of utilities. In a toilet, a half-column can hide sewer pipes. The ventilation duct is well hidden in the kitchen. In some apartments there are layouts in which part of the kitchen is taken away by a garbage disposal pipe. Such horror must be hidden. Heating pipes and electrical wiring may also be hidden.

- In large rooms, the use of columns helps to visually enlarge the ceiling. This step is justified especially in cases where a multi-level ceiling was used.

- Sometimes plasterboard columns in an apartment are used to zone rooms. But this technique is only suitable for multi-room apartments and cottages, where the premises have a large area.

- Additional functionality. Sometimes niches or shelves are made in the columns for various things. This way the design becomes not only decorative, but also functional. The main thing is that this functionality does not come at the expense of decorativeness. This option is only suitable for rectangular columns.

Operating modes

The modes are as follows:

- Heating the mash to 72 -75 °C. The Dimroth cooler operates at minimum power.

- Warming up the column and building “floors” of reflux condensation. Throughout the entire column there is active bubbling and steam and mass exchange. It is important to prevent oversaturation of the column, otherwise there will be “choke” - phlegm will clog the entire diameter of the drawer. We select the power of the heaters so that the temperature near the sampling unit is 71 - 75 °C.

- Start of selection. When sampling by liquid, the slender pyramid in the drawer is inevitably disrupted, so the reflux ratio will need to be adjusted. The vapor density gradually decreases, and the intensity of selection also decreases. The first liquid selected—the “heads”—contains volatile ethereal components. The volume of the heads reaches 20% of the planned alcohol content.

- The main commercial alcohol is selected until the smell of fusel oils appears.

- If you want to extract everything possible from the raw material , we extract the “tails” - the last part of the alcohol-containing vapors. They contain a large amount of fusel oils; the tails are mixed into “heads” and used in further rectifications.

- Completion of rectification - turning off the heater, cooling the pipes.

The entire cycle, depending on the desired product quality, can last a relatively long time - from 8 hours to 2 days.

The average productivity of the column we assemble is 250-300 ml. 96° alcohol per hour.

Advantages and disadvantages of the device

Modern columns have individual advantages and disadvantages, but the main advantages are as follows:

- allow you to produce alcohol of high purity and strength at home;

- the resulting product does not require re-distillation, there is no unpleasant odor;

- they are equipped with all the necessary parts and can work independently, without the participation of a moonshine still;

- its use does not require special knowledge, you just need to make sure that the tubes do not become clogged during the cleaning process;

- help produce alcohol in industrial quantities, but this depends on the power of the product.

- quite a long process;

- output per hour is no more than one liter;

- finished devices have a very high cost.

Many lovers of homemade strong drink make home-made moonshine stills and skimp on cleaning, so the result is not quality, but a cloudy liquid with a tart, characteristic odor.

Is it necessary to design the equipment?

The process of calculating, assembling and testing homemade equipment brings great pleasure. The result after edits and improvements will be guaranteed. However, the first difficulties or failures can cool the ardor of beginning rectifiers.

The article contains only general recommendations for assembling the simplest device. There are a large number of technical solutions that increase the speed, autonomy and controllability of the rectification process, but they will significantly complicate the design.

As a result of independent design, even minor nuances influence the result - packing density, angle of inclination, diameter of Dimroth tubes... If you need a quick and guaranteed result, it is better to purchase a ready-made device from the manufacturer. When purchasing, it is important to know the device, productivity and purpose of the device, so as not to buy a fake or ineffective device.

Starter for chainsaw. Learning to do your own repairs

To quickly start any chainsaw, a starter is required. When the crankshaft of the tool is accelerated, the fuel-air mixture supplied to the engine is compressed and subsequently ignited. Therefore, the normal operation of a chainsaw starter determines the performance of the entire mechanism.

shurik-auto › Blog › Protection against theft. Knowledge base. Part 10 We close the “holes” in the defense on our own.

When protecting a car from theft, we almost always leave a huge hole in the protection. This is a service connector, an ECU unit and... a cigarette lighter.

1. Cigarette lighter

. It is in the cigarette lighter that the thief will insert power to the jammer, with which he will then leave!

It’s not difficult to make an additional hidden switch for the cigarette lighter on your own. Needs enough power. Too lazy to turn it off every time? Receive an additional “thank you” from the trick-or-treater.

2. ECU block

. It is usually installed under the dashboard on the engine shield or in the engine compartment. Controls engine operation. When installing an alarm system, installers install additional blocking relays on different electrical circuits. Also, the unit is locked until it receives a signal from the immobilizer unit. The usual method of theft is DO NOT SEARCH for installed locks, do not unlock the immobilizer - but BRING WITH YOU your obviously unlocked ECU unit. Remove the chip from the one installed in the car and insert it into your...

Also, they can simply steal the ECU unit. (for Mazda 6 - 20,000 rubles! new. For a box the size of 4 packs of cigarettes) The way to fight is to install an armor case. The case is screwed to the body with shear bolts. The block is attached inside together with the connector and closed with a lid. It is not possible to remove the connector.

3. OBD2 service connector

. It is through it that the thief can connect to the ECU and program the immobilizer chips or simply start the car.

You can do this. 1. Purchase two suitable male-female connectors. 2. unravel the wiring from the service connector, CUT off the connector with the required “tail”. 3. Solder the resulting ends in the machine to one chip. Secure it in the car. 4. Solder another chip, respectively, to the ends of the wires of the cut connector. 5. IMPORTANT. Naturally - do not confuse