The quality and decent appearance of any interior largely depend on correctly selected furniture. In addition to cabinets, sideboards, coffee tables, shelves and chests of drawers, the style of the room is determined by upholstered furniture, the quality of its finishing and covering material. In classic interiors, designers prefer to use quilted carriage screed, which came into fashion when equipping living spaces several centuries ago. However, factory-made such products are too expensive, and not every average person can afford them. In this regard, many home craftsmen purchase fabrics or leather and do the work of making and installing a carriage coupler with their own hands.

Carriage screed on the wall

What is a carriage tie?

Carriage screed is a special type of finishing of upholstered furniture in a classic style, the technology of which originated more than 300 years ago in Europe. Throughout the history of its use, right up to the present day, this type of interior design has been associated with vintage luxury and wealth. The technology got its name because initially the seats of carriages for aristocrats were upholstered in this way, after which the fashion for this type of finishing moved to the interiors of rich houses.

Carriage screed on furniture

Today, the carriage screed has lost mass popularity, but, at the same time, is in active demand among adherents of the classical style of decorating apartments, offices and private residential buildings. Over the course of a long time, the carriage screed, which also has a second name - “capitone”, has changed significantly, and designers offer many options for quilted covering for upholstered furniture, walls, decorative panels, high headboards and other interior items.

Carriage tie at the head of the bed

Advantages of carriage screed

The type of room decoration under consideration, combined with a classic interior, has many advantages over other techniques aimed at expressing the similar style of the room:

- Increased comfort during use - soft quilted upholstery in combination with high-quality leather, corduroy, velvet or thick fabric ensures comfortable seating for residents.

Leather product

- The surface is always in a taut state; new folds do not form on it during prolonged use. Sofas, panels and other interior elements are easy to clean wet or dry.

Material stretching

- When properly selected high-quality material, “capiton” has an increased service life. Thanks to the tension of the tie, jamming and friction of surface elements among themselves is eliminated, which guarantees their long-term safety, even during intensive use.

High-quality velvet screed

- Threads, buttons, braid and other finishing elements securely fix the material, giving it increased strength.

Buttons for the product

- When physical wear and tear is reached, when the coating needs to be replaced or restored, it is easily replaced with a new one, without the need to purchase filler or a new piece of furniture.

Capitone repair

- One of the main advantages of this technology is the possibility of widespread use on any type of surface. Experienced designers suggest using carriage screed not only on furniture and headboards, but also on parts of wall structures, columns, on vertical or horizontal panels and on many other interior details.

Carriage screed in the interior

- The carriage screed is one of the main elements of expressiveness of several eras in many countries. Vintage interiors, the English style of the 19th century, and even the Empire style of the first half of the 20th century are perfectly combined with the “Capitone” surface finishing technique. This style is the best way to add luxury and respectability to a room.

English style finishing

Empire style finishing

- If the carriage screed is installed on the wall, a porous filler made of natural or synthetic materials greatly increases the level of sound and heat insulation. It is advisable to use this decorative element when decorating the inner surface of walls bordering street space, as well as adjacent rooms belonging to other residents.

Filler

- When installing carriage screed on walls or ceilings, unlike classic painting, plastering or wallpapering, this type of finishing does not require leveling the supporting or enclosing structure. The soft elastic material levels out all unevenness, and on the finished surface of the fabric or leather, defects are completely masked.

Elastic surface

- This type of finishing device allows you to absorb sounds, which is especially important for large rooms with sparsely arranged furniture - in the absence of echo, comfort during its operation increases.

Soundproof barrier

- This type of finishing is a classic of the genre that will always remain relevant and will not go out of fashion. Adherents of the vintage style don’t have to worry about the fact that the decoration will have to be changed in a few years, as the interior design style of an apartment, office or private residential building is hopelessly outdated.

Carriage screed in a modern interior in a modern interior

Considering the degree of tension of the canvas, when installing a carriage screed, you should choose only high-quality material of increased strength. Thin fabrics or cheap leatherette can easily tear in the first months after the start of use.

Base repair and filler replacement

If the furniture needs repair, then before restoring the screed and upholstery is the most appropriate moment for this.

The top layer of foam rubber is removed immediately, the inner layer with perforations is assessed for drying and maintaining its shape. If replacement is necessary, you must first measure the hole diameters, pitch and row distances, and transfer them to the drawing. You need to cut holes in the foam rubber according to the markings made with a marker; do this with a conveniently sharpened tin can. Perforated foam rubber is laid in 2-4 layers of 12 mm each, with one solid layer of the same thickness placed below and above. It is recommended to fasten the layers of padding with glue, which is applied by spray or brush.

It is imperative to evaluate how loose the plywood base of the screed has become. This is checked by the degree of compression of the sheet; bending of about 3-4 mm per meter is allowed. If chipboard was used as a base, it is advisable to reinforce it with an overlay sheet of 5 mm plywood 70-100 mm smaller in size. The holes for pulling threads through the shield are restored from the wrong side.

The load-bearing frame of the furniture has connection points; they all need to be checked for rigidity and further strengthened if necessary. In general, all connections are inspected, access to which is blocked by the casing. At the same time, the restoration of wooden parts and their varnishing are carried out.

Disadvantages of carriage screed

In addition to many advantages, professional designers and premises owners often note some disadvantages of carriage screed:

- A thick layer of lining material significantly reduces the internal volume of the room. Finishing like "capitonné" is appropriate in rooms with a large area and high ceilings.

Bulky furniture

- Carriage screed covering upholstered furniture or headboards visually enlarges the pieces of furniture. When it is used within standard apartments with small rooms, the comfort of the room is lost, due to the fact that the usable space of the room seems smaller than it actually is.

- If this type of finishing uses not leather or a high-quality polymer substitute with a glossy surface, but velvet fabric, then accidentally introduced oil, food waste or other contaminants leave a greasy mark on the surface, which is very difficult to remove.

Marks on the fabric surface

- If you choose cheap material, it is easily damaged by the paws of pets, or from rough mechanical impact when in contact with sharp objects.

Damage to the coating

- The complexity of finishing work and the increased price of high-quality materials compared to other types of design solutions for interior equipment.

The complexity of the screed device

All disadvantages are subjective and may not be taken into account. Properly selected colors, high-quality screeds combined with the overall style of a classic interior allow the owners to get an elegant interior and enjoy its use for many years.

Stages of finishing work

Each work process, including finishing, can be divided into steps that need to be followed sequentially.

Product drawing

A pattern for finishing a product is needed not only to create the correct pattern, but also to calculate the amount of fabric and fasteners needed.

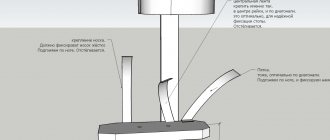

To correctly draw a drawing diagram, you must first draw the measured segment into squares, as indicated on the left in the figure.

Next, having found the middle of the square, the diamonds are marked. It’s good to make such a drawing on graph paper.

Markings on the fabric are made taking into account the overlap of the fabric to form a relief, so the squares should be larger than the pattern on the cardboard.

Fastening the pad

Foam rubber, as mentioned above, is attached to the base using special glue.

Next, using a pattern, transfer the markings of the prepared pattern. The cardboard drawing must be held well so that it does not accidentally move and disturb the geometry of the pattern. In large areas, it is recommended to call another person for help so that he can hold the pattern.

After the lining material has stuck well, holes are punched in it with a knife or a special nozzle.

In the same holes you need to make small holes in the wood through which the buttons will be sewn. Or, you can first make markings directly on the plywood, make holes, and then attach the packing.

Marking

Next, the pattern diagram and diamonds are transferred to the lining. To speed up the process, it is recommended to make one diamond out of cardboard and use it to transfer the markings.

After this, the fabric is marked on the wrong side, taking into account the overlaps. The rhombus increases in size by 4 cm. Marking can be done according to the same principle: first, points are transferred using a drawing, and then, using a layout, rhombuses are drawn.

The correctness of the markings and the geometric location of the stripes are checked.

After everything has been checked, it is necessary to make small punctures along all the fabric in the corners of the diamonds using a large needle or awl. This is necessary so that you can see where you need to attach the button.

Fabric fastening

Having placed the base in a position convenient for work, you can use several chairs and carefully lay the fabric on it.

Next, the threads for attaching the buttons are prepared. The same number of pieces of thread are cut as there are buttons prepared for fastening. The ends of the threads, so that they do not fray and the knot is more dense, are burned with a lighter or matches, and at the end a tight knot is tied, which should not slip into the prepared holes.

A thread is threaded through the holes made on top of the fabric so that one end remains on the fabric and the other is at the bottom, which will be attached to the plywood using a stapler. In the photo you can see how to do it correctly.

You should move one by one, row by row, consistently forming folds of fabric.

To form even folds, you can use a special stick.

It is recommended to start making a row of ties from the middle of the canvas, then there will be no distortions.

After all the folds are formed, the buttons are attached.

The finishing of the edges should also be taken very seriously, as they can ruin the entire picture. To do this, small cuts are made along the edges, the edges of which are folded to the wrong side and fixed to the plywood using a stapler.

The last stage is leveling and bending the corners. They should not contain many folds, and they should be even.

Having studied all of the above, we can conclude that a carriage tie with your own hands is quite doable, the main thing is not to rush and do everything with the utmost care. The main rule to obtain a high-quality result is to correctly make the diagram and transfer it to the material and lining. And then, it’s a matter of technique and attentiveness. Using this technique you can transform a room and decorate any interior.

How to choose the right fabric for a carriage tie

The quality, as well as the service life of the carriage screed, largely depend on the characteristics and composition of the material from which it is made. When choosing fabric for covering, it is necessary to take into account the following features and requirements:

- Regardless of the composition, it should be taken into account that when manufacturing this category, the material is subject to strong tension, which is why it must have increased thickness, density and strength. Regular cotton fabric, or thin polyester or silk are not suitable for carriage ties.

Thick fabric for covering

Thick genuine leather for covering

- When choosing the density of the material, it is also necessary to pay attention to the elasticity of the fibers. The fabric is tensioned not only during installation - it remains in this state throughout its entire service life. Thus, fabrics that easily stretch when a load is applied will eventually become unusable, and the coating that has lost its shape will have to be changed.

Elastic fabric

- When making a carriage screed, many folds form on the surface of the material. In this regard, if there is a pattern on the surface of the material, upon completion of the work, most of its surface will be hidden in these folds. This means that with this type of finishing only plain material is used. At the same time, the use of a periodic meaningless ornament covering the entire surface of the material is allowed, since it will successfully merge with the folds after finishing.

- Considering that the cost of the work is quite high, the material must also be from a higher price category, and its quality must justify this price. As a rule, when constructing carriage screeds, dense, high-quality natural leather or multi-layer compounds with a velvet or smooth surface are used. Modern designers trying to create fashionable interiors often recommend using thick denim fabric. This significantly improves the quality of the coating, increases its durability during intensive use, and also adds originality to the bold design solution.

If you choose fabric or leather of poor quality, all expensive finishing may become unusable and must be replaced after 1 to 3 years of use. Purchasing an expensive coating followed by high-quality installation while following the technology will allow the surface to be used for decades without the need for repairs.

Auxiliary materials for constructing a carriage coupler

To make a panel from a carriage screed, or to decorate any interior detail using this technology, in addition to fabric or leather, you will need a number of auxiliary materials, since the coating is a whole complex structure:

- Base - a sheet of plywood, OSB, board panel and other elements of increased strength can be used as a supporting material. The thickness of the sheet for the base must be at least 5 - 8 mm, and the material must have increased strength against impact. Also, there are additional requirements for the flexibility of the material, which depend on the overall dimensions of the product.

- Fabric or leather for upholstery, the selection criteria for which are described in detail above. Also, it should be added that the material has many folds, which is why the construction of a wall or panel requires much more of it - 30% - 40% than the total area of the future product.

Leather range

Assortment of fabrics

- The carriage screed implies a soft volumetric surface, which is why elastic material of the internal padding must be laid between the base and the finishing coating. As such a composition, a well-compressible synthetic material that is not susceptible to settlement over time should be used. As a rule, foam rubber, which is sold in rolls, is suitable for such purposes. The perception of the volumetric structure will depend on the thickness of the packing material, and therefore the minimum value of this parameter should not exceed 50 – 70 mm.

Foam rubber for stuffing

- Finishing this type of surface always involves making deep stitches using special furniture nails with wide heads or buttons. You should purchase only metal products, as they will not crack or fly off during use.

Furniture nails with wide heads

- To stitch the fabric and attach buttons to it, high-strength thick nylon threads are required that can withstand a force of at least 15 - 20 kg.

High-strength nylon threads

- Dressing leather or fabric using carriage screed technology requires preliminary preparation of templates, which must be cut out of soft plastic or thick cardboard.

Cardboard templates

- The padding material must be securely fixed to the base before performing this type of screed. In this regard, a special adhesive composition that does not contain high concentrations of toxic substances will be required.

Furniture adhesive composition

Depending on the method of finishing the edge, you will also need to purchase additional tape, metal or plastic corners, a wooden baguette or other framing material that allows you to implement the design project.

Let's sum it up

It is quite possible to make a carriage tie without outside help - for this you will need to purchase materials and accessories, make a preliminary drawing of the project, and then place the marks correctly. Otherwise, it is recommended to follow the instructions and carefully re-read them several times to fully understand the operating principle. We also recommend watching the videos we offer so that your carriage screed turns out smooth and aesthetically pleasing the first time.

Source

Tools for installing a carriage coupler

Carriage screeding is considered a complex production process, which requires not only high-quality material or extensive experience of the craftsman, but also a set of special tools and other equipment:

- First of all, before cutting and starting work, it is necessary to take measurements. This procedure is carried out using plastic, wooden or metal rulers with a length of 1000 mm or more. Such measuring instruments are often used in many professional studios.

Long ruler for textiles

- To accurately measure flexible material around a circle or any other curved surface, you will also need a flexible measuring tool made from fabric or polymer material.

Flexible measuring tool

- To mark the wrong side of the fabric before cutting or stitching, specialized fabric markers are used. These tools are clearly visible on any textile surface, but at the same time, when applied, the material does not get wet.

Textile markers

- To tighten and make holes, it is necessary to create a torque, which is achieved using a special device - a screwdriver.

Screwdriver

- To cut the product after applying a load, you need to purchase a bit with a built-in blade.

Cutter for screwdriver

- Punctures in fabric or leather are made using an awl.

Awl

- Bit attachment for a screwdriver or drill with a crown, for making round cuts in soft material.

Drill bit

- The cutting of the base in the form of plywood or chipboard sheet is carried out using a circular saw or an electric jigsaw with a replaceable cutting blade.

Hand circular saw

Jigsaw

- To secure fabric or leather to the base from the wrong side, after tensioning and stuffing, a furniture stapler with reinforced staples is used, which can easily pierce plywood.

Furniture stapler

Staples for furniture stapler

All tools used when making carriage screeds must be of high quality and in good working order, and the cutting edges must be well sharpened. Otherwise, good quality work will not be achieved.

How to prepare for the creative process?

Screeding a wooden floor with your own hands step by step

To make a carriage tie, you will need some materials. You will need to stock up on chipboard or plywood in the quantity required by the volume of work to be done.

In addition, you need to prepare pieces of fabric with unusual texture, a handful of buttons and buttons, as well as decorative fishing line.

Instead of the last thing, you can take lace or wire. Even in the process of making the carriage screed, you will need foam rubber and padding polyester (see photo).

Photo:

Upholstery material (fabric) should be purchased with a reserve, that is, so much that it is 50 cm larger in length and width.

Foam rubber, the thickness of which should be at least 5 cm, also needs to be purchased a little more than required.

The fact is that when making a carriage tie it will need to be bent, which may require about 10 cm of material.

The production of capitone is carried out using a number of tools and means. In this creative project you will definitely need glue.

It is advisable to buy a product that is intended specifically for working with furniture and glues foam rubber.

You can also use rubber glue made with the addition of rubber. It is prohibited to use nitro glue to create carriage screeds, as it can damage the material.

Photo:

Do-it-yourself carriage screeding is done without a drill equipped with a Zifenbor attachment, which allows you to make neat holes.

Of course, instead of this special tool, you can take a regular stationery knife, but it will cut curves in the substrate along the edges of the hole.

After preparing all the materials and tools, you can make a sketch on paper of the intended work, which will decorate the head of a sofa, bed or anything else.

At the planning stage of the carriage screed, it is important to determine its dimensions and configuration. Then you need to start making a template for capito

It is created from a cardboard sheet, which in size corresponds to the parameters of the finished product. They can be standard 10 cm in both length and width.

Photo:

To apply markings, you need to use a marker and a tape measure to make marks every 10 cm, and then draw lines horizontally and vertically.

Geometric shapes must have ideal proportions. If you decide to use a pattern with rhombuses, then first you need to mark the surface with squares, and then draw diagonals in them.

The points at which the lines intersect, as well as the vertices, must be marked with a felt-tip pen. Then they need to trace the resulting diamonds.

After this, holes must be made at the top points of the geometric shapes, which will become places for attaching buttons.

Briefly about the main thing

Carriage screed is a high-quality covering of walls, ceilings, furniture or headboards of beds. The screed is created by creating diamond-shaped folds on the material and fixing the figures with buttons to a rigid base made of plywood or chipboard. Before starting work, you need to choose a high-quality fabric that can withstand increased tensile forces both during installation and during operation. To carry out the work, you will also need a special tool and an extended working surface with the possibility of access for the master to the reverse side of the base. Work on the installation of a carriage screed is carried out in strict accordance with step-by-step instructions, and markings are carried out according to pre-prepared patterns.

Glue for fixing foam rubber on a plywood base.

- Holes in foam rubber and plywood, according to the drawn up diagram, can be drilled only after the glue has completely dried.

- To correctly apply markings to foam rubber, it is recommended to first apply it to cardboard of the same size as the panel to be covered.

- If fabric is chosen for covering the panel, it must be dense and of high quality. A thin version of the material will not be suitable for this purpose, since in the area of punctures and fastening nails, especially with inevitable tension, the fabric may “crawl”.

- You should not choose a material with a pattern for upholstery, since the finished panel or piece of furniture will look sloppy.