145

no comments yet

0

Author:

Rasskazov Pavel.

Reading time: 5 minutes

Having been involved in poultry farming for several years now, I have heard a lot about feed steamers. The grain mixture or mixed feed is processed there with superheated steam. At first I considered it pampering - until one day, due to an outbreak of some kind of intestinal disease, I almost lost my entire livestock. Since then I have acquired such a device - and I don’t regret it.

So that the piglet eats with appetite

Every pig owner wants their animal to eat with appetite and be happy with its weight gain.

How to achieve this? You will have to work hard to create an appetizing menu for the pig, and not be content with just scraps from the home table and chopped root vegetables. The investment of time and effort, believe me, will pay off handsomely. So, here are ways to make your pig's food more palatable. Roasting grain is a simple and affordable method that can be used on a peasant farmstead or on any small farm. When toasted, the grain is disinfected, the starch partially breaks down into more digestible monosaccharides, the grain becomes sweeter and is better eaten by animals.

How to roast grain? The grain, moistened to the swelling stage, is poured onto metal baking sheets, sheets or ditches and fried for 10-12 minutes at a temperature of 100-180°C, stirring continuously. The finished grain turns brown. It is fed to suckling piglets from 3-7 days of life until weaning.

To increase the digestibility and taste of cereal grains, malting can be used. This process does not require special machines and equipment. All you need is a suitable container and a warm room (18-20°C). In containers, vats, barrels, bathtubs, tightly packed boxes, pour crushed grain in a layer of no more than 40-50 cm and fill with hot water (90 ° C) in a ratio of 1.5-2 parts of water to one part of grain, mix thoroughly, close tightly cover and insulate. To speed up fermentation, it is advisable to add malt in an amount of 1-2% of the feed mass. The food, soaked and mixed with water and malt, is kept in an insulated container for 3-4 hours at a temperature of 50-55°C. It’s easy to make malt in your own backyard. To do this, barley is moistened, scattered on trays or in boxes in a layer of up to 10 cm and kept for 2-3 days at a temperature of 20-25°C. After sprouting, it is dried, ground and used as malt. Malted feed is fed primarily to suckling piglets, weanlings and suckling sows in the amount of 10-20% of the total weight of grain given.

Concentrates are given to pigs in a moist form mixed with roughage and succulent feed. It is advisable to feed part of the concentrates (one third by weight) in yeast form. So, if the daily diet of concentrates contains 1.5-2 kg, then 0.3-0.6 kg of feed in yeast form can be given from them. Oats and barley yeast best. For these purposes, baker's, brewer's, alcohol, feed, hydrolysis and other yeasts are used. They contain almost all essential amino acids, many vitamins (B1, D, E, etc.), enzymes, hormones, trace elements and other substances that accelerate the growth of animals. Yeasting of feed can be done using straight and starter methods. With the straight method, the dough (sourdough) is first prepared.

Pour 4-5 liters of warm water into a container and, stirring thoroughly, dilute 50-100 g of baker's yeast in it. Then add 2 kg of concentrated feed and mix the mash. Preparation of the dough lasts for 6 hours. Add 15 liters of warm water (40-45°C) and 8 kg of feed to the finished dough. The mass is stirred every hour. The duration of feed yeasting is 3 hours. Mineral supplements can be given either in a mixture with the main feed or in pure form from separate troughs, but they must first be well ground. It is effective to feed pigs a mineral mixture consisting of bone meal (40%), chalk (30%) and table salt (3%). The following amounts of this mixture are fed per head per day in winter in winter: 70 and 100 g, respectively, for pregnant and suckling sows; suckling and weanling piglets (respectively) 25 and 40 g; fattening pig - up to 60 g.

And further. A pregnant sow should not be given more than 500-600 g of rye flour per day, as a large amount causes constipation. A pregnant or lactating queen should not be fed stillage (it sours quickly and can cause digestive upset), as well as malt sprouts obtained by preparing malt from sprouted grains (they quickly deteriorate), and starch pulp.

Poisoning of pigs can occur when feeding poorly fermented feed, spoiled milk, dairy products, meat and fish, rotten vegetables, etc. There are cases of poisoning in pigs when feeding boiled beets. During slow cooling (5-12 hours), nitrates are formed in the beets. To prevent poisoning, when cooking beet mass, it is necessary to quickly bring it to a boil, boil well and cool in a cool room. Raw beets are also well digestible by animals. Sprouted potato sprouts contain a lot of poison. The sprouts should be broken off from sprouted tubers, the potatoes should be steamed and given to pigs in small quantities. It is forbidden to give animals water left after boiling potatoes, as it contains many harmful substances.

Read other articles on this topic here.

Ovens for feed preparation and steaming

The preparation of feed for feeding animals for personal use consists of operations related to their heat treatment. It is irrational to use kitchen hearths or heating and cooking stoves for these purposes, since this is associated with significant excess fuel consumption and the duration of the feed preparation process. Feed boilers and boilers, which are placed in the courtyard outbuildings of the estate, should be considered rational devices. In such equipment, you can prepare a daily ration in one fire and maintain its temperature over a significant period of time. At the same time, the cooking and heating time of feed is reduced, and fuel is saved.

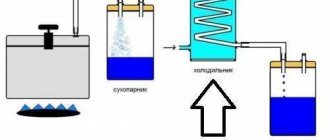

The furnace for preparing feed (Fig. 132) is a water heating device that is common in individual construction. Similar equipment is used to boil water in field camps. The firebox 2 is located directly under the boiler 7. The combustion products pass through the firebox, located at the rear of the firebox, and enter the annular channel 6, covering the outer surface of the boiler 7. Next, the flue gases are directed through the chimney 8 into the pipe, and then into the atmosphere.

✅ Prepare food using a feed steamer

Preparing feed for chickens using a feed steamer looks like this:

- First I prepare the grain mixture. To do this, I feed the required amount of grain into a regular household grinder (they are sold in every poultry store and are cheap): barley, corn, wheat, sunflower... The exact amount of ingredients and their ratio depends on what age and what breed you need feed. I will not describe the composition of the grain mixture in detail - I have already mentioned this: for example, here. The main thing here is to lightly spray the mixture with water to reduce the dust fraction.

- After the raw material is ground, it must be mixed thoroughly. With every piece of equipment I've ever used, the grain is stacked in layers when grinding. You can, of course, make a receiving hopper with blades and driven by an electric motor, like a concrete mixer - but I can’t even get my hands around it, and I don’t see much point. I prefer to use an electric drill with an attachment in the form of a construction mixer: a couple of minutes of work - and everything is homogeneous. Before I bought it, I simply took an aluminum plate and used it to mix everything inside the bunker barrel.

- I load the ground grain mixture into the steamer container and lightly moisten it. This is necessary: otherwise the grain may even become slightly charred - especially if you use heating elements connected directly to the container for heating, like some of my friends.

- I turn on the heat.

- The grain mixture is heated to 105-120 °C using a series of steam bursts. The lid of the steamer, of course, must be closed at this time; you can only open the valves to relieve pressure - so that it all doesn’t explode right in our hands.

- It lasts at this temperature... I’ll be honest here: I don’t know how long to keep it. Some people heat it up for 3-4 hours, I don’t keep it in my steamer for more than 40-50 minutes - I’m running out of water in my boiler.

- The lid opens, the grain mixture cools and dries (in a natural way: while it cools, excess moisture comes out of it with steam).

That's it, this is where the procedure ends. The raw materials are ready. You can cool, scatter into sterile containers and use when needed.

Fermentation. How to make a delicacy for chickens from ordinary grassRead

Limestone grit is a replacement for chalk in the mineral feeding of poultryRead more

Mixed feed and feed for chickens: should you give preference to a particular feedWatch

A few points to pay attention to:

- Mixing blades. At first, I simply used a closed container for the grain mixture, into which a ring connected by hydraulic hoses to the boiler-steam generator and eight pipes to it were inserted, releasing superheated steam deep into the grain mixture. It was burning - just go. Then I bought a used concrete mixer on the market, cleaned it, remade it a little - and now I also mix the grain mixture during steam processing. You can do without this - but then you need to keep an eye on the temperature, pressure and processing time: chickens don’t peck at coals.

- We load premixes only after steam treatment. Never before! Vitamins disintegrate completely at 100-120 °C.

- I sometimes add mineral additives (the same shell) before steaming , and sometimes later - but then I additionally heat them separately, on a baking sheet in the oven or even on a sheet of iron over a fire (I sometimes prepare egg shells this way). Calcium isn’t going anywhere, but it’s dangerous to give it in its raw form.

Pine needles for chickens are the best cure for any disease. How to prepare and giveRead

How to make grass meal for feeding birds with your own hands. My home methodRead more

Mixers for chickens. Three recipes that I use to feed birds in winterWatch

Digester boilers are classified according to their “useful” characteristics, for example:

1. Boiler volume. Boilers with a volume of 60 liters, 100 and 160 liters are common. 2. Specification. Some boilers are only suitable for boiling food, while others can also be used for stewing. 3. Method of heating the contents. There are direct and indirect heating methods. Modern boilers, for the most part, use the so-called “steam-water jacket”

to heat the contents. That is, they use indirect heating. 4. The presence or absence of additional cooking tools. For example, the KPEM-60-OM boiler, whose volume is 60 liters, has a built-in mixer. This expands the initial capabilities and allows you to simply mix the contents of the boiler or whip it. 5. Boiler design type. Monolithic or tiltable construction. The convenience of removing prepared food depends on this. 6. Type of fuel. Solid fuel, electric, steam, gas.

The operating principle of the vast majority of existing digester boilers is to heat their contents with a mixture of steam and water from the “jacket”, which, in turn, is formed during the operation of the boiler’s heating elements. As a result, boilers are made with double walls that separate the directly “useful” part of the boiler, which is filled with contents, from the rest of the part, in which the steam-water mixture is heated. Thus, the mixture located between the dividing walls acts as a heat transmitter from the heating elements to the food compartment. It should be noted that precisely thanks to this design, there is no possibility of burning of products prepared inside the digester boilers.

Some boilers have the ability to adjust the power and temperature of heating food. An example is the Apach APKE-77 700 series boiler, which has a four-position power level switch. The ability to change the heating temperature of food makes it possible to cook different foods in different ways. For example, by setting the temperature to +80°C, you can cook vegetables in such a way that they do not lose their beneficial properties during the cooking process. By setting the heating temperature to +100°C or higher, you can speed up the food processing process.

The classification has already described a feature of some boilers in the form of additional built-in cooking tools. Returning to the KPEM-60-OM boiler, which, in addition to the built-in mixer, is structurally equipped with a tipping mechanism, we can separately note the advantages of it and similar boilers, for example, in cooking salads or purees. You can cook two hundred kilograms of mashed potatoes in such a cauldron in just 40 minutes. And mixing the same amount of salad takes only 5 minutes.

Digester kettles are an excellent modern way of cooking food, aimed at producing large volumes. All that is needed to operate the digester is electricity (or other fuel, depending on the boiler itself) and a connection to a source of cold and hot water. By supplying the boiler with the resources necessary for its operation, you can cook fairly large volumes of food for a long time, while keeping energy costs to a minimum. At the same time, the most economical, in terms of energy consumption, are electric digesters.

In the Restaurant Service online store you can select and buy food boilers with delivery to any region of Russia and Kazakhstan.

Source