Alambiki Samodel.ru, Pivovarnya.ru, Alambis

Portuguese devices called alambics are considered elite equipment.

which is entirely made of copper. Most often they are given as souvenirs (with a cube volume of 5 liters), but there are also much more serious things for 20, 30, 60 and even 100 liters of mash. Approximate prices from the official website Samodel.ru for Alambiki Lux-plus:

Classic alambic.

- For 5 liters - 17 thousand rubles.

- For 10 liters - 24 thousand rubles.

- For 20 liters - 30 thousand rubles.

- For 30 liters - 38 thousand rubles.

- For 60 liters - 88.5 thousand rubles.

- For 100 liters - 140 thousand rubles.

As you can see, the cost of these devices is noticeably higher than classic stainless steel distillers, so not everyone can afford such luxury.

You can read about the difference between copper and stainless steel here -.

If you have little idea what an alambik is, you can watch the video on the Bondarnaya Lavka Youtube channel. The author spoke in detail about the design of this device and its differences from the classics.

Useful tips

Many moonshiners do not undertake to convert a flask or keg into a still and prefer to buy a still. And there are reasons for this, because mistakes cannot be made. If you still have a goal to make a homemade device, then it is recommended to follow these useful tips:

- It is not recommended to take a large can if you want to experiment with the flavors of the mash.

- The rubber lining is most often found on cans. It needs to be replaced with silicone to ensure greater tightness. Also, the can may have a damaged lining.

- It’s worth buying a milk can if you have the opportunity to build in a heating element yourself or heat the moonshine still with gas.

- To put on the silicone hose, you need to soak it in hot water.

- To distinguish PVC from silicone, the hose must be set on fire. Silicone does not produce a pungent odor or smoke.

- Instead of sand, you can add soda to the coil.

- The best option for a coil for a moonshine still, made with your own hands from a milk can and keg, is made of copper.

- If the device is built with a heating element, then you need to clean the mash well to avoid particles sticking to it. This will also make the moonshine cleaner.

- The keg needs to be cleaned well so that the moonshine does not have a beer aroma.

- A tubular electric heater, which is designed to operate in water, cannot be used in devices without liquid.

- For 10 liters of mash you need 1 kW of heating element power; this rule applies to the use of both cans and beer kegs.

The best solution for a home distillation still is a milk can or beer keg. Each container has its own advantages and disadvantages. The choice must be made based on your own capabilities and preferences. The can has more fans. But, no matter what the moonshiner uses, during assembly you must follow all the instructions, then there will be no complaints during the work.

Making a distiller with your own hands

In order for the drink to be tasty, it is necessary to use water that is well purified from impurities and microelements. An ordinary water filter will not cope with this task, so you can use a homemade distiller. The quality of water purification of such a device is in no way inferior to the characteristics of the liquid obtained as a result of purification with an industrial distiller.

To make a device at home, you will need a brass or copper tube for cooling steam, a sealed metal container for boiling water, a container for collecting purified liquid, silicone or rubber hoses, wire, clamps and pliers.

A tube is inserted into a hermetically sealed container with water through the hole made, through which the vapor will pass and cool. Next, this outlet tube is inserted into a container to collect purified water.

Alembic

Experienced home brewing professionals often choose a container in favor of a distillation cube. This container is very convenient and can be bought in specialized stores. Such cubes are made of copper, aluminum and other high-quality metals. They differ in the volume of liquid placed and the diameter of the inserted tube. On the market you can find containers from 12 to 51 liters. The price of such products varies depending on the material, manufacturer, volume and ease of use. A small stainless steel distillation cube can be purchased for an average of 3,000 rubles.

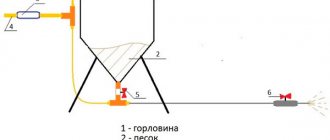

Sukhoparnik

A steam steamer (reflux condenser) is a device that separates steam from water droplets and scale particles. It allows you to make moonshine taste better, separate it from fusel oils that inevitably get into it during cooking, and prevents mash from getting into the finished moonshine if it splashes out of the tank. The steamer reduces the production time of the drink. It is a hermetically sealed vessel placed inside the moonshine still between the coil and the distillation tank. The reflux condenser is connected to the last special tubes through which the steam moves outward. First, the mixture of all vapors is condensed in it, and then the ethyl alcohol re-boils due to the continuous supply of heat. Most fusel oils are retained in the steam tank.

If the moonshine still does not include a reflux condenser, to obtain a good quality drink you will need to distill the resulting product again.

Fridge

In moonshine brewing, a refrigerator is used to condense alcohol-containing vapor. This element is required for the process of producing an alcoholic drink. It is best to connect the refrigerator to a water supply so that cooling occurs most intensively. This option is not acceptable for everyone; there are others: immersing the refrigerator in a container of water or ice; cooling due to ambient temperature. To connect the cooler, you need hoses, a tripod for mounting and a faucet attachment. It is advisable to make the connection in a vertical position or at a slight angle.

You can buy a refrigerator in a store or use a homemade device. There are three types of commercial cooling element depending on the material: plastic, glass and metal. Glass refrigerators have proven to be the best. In turn, they are divided into direct and reverse. And straight lines have another classification - ball, coil and straight. The most powerful is the coil refrigerator, which will provide the necessary operating parameters even under cooling conditions through the environment.

Coil

A coil is a tube wound on a cylindrical surface (plastic or metal pipe, rolling pin) in the form of a spiral. The material for the coil must be safe for humans, not react chemically with alcohol, have good thermal conductivity and sufficient flexibility.

Stainless steel, copper and brass have these qualities. The longer the coil, the better its cooling properties, but the distillation speed will be lower. Before curling the tube, it is necessary to give it the greatest strength to prevent creasing. For these purposes, you can fill it with gravel or water and then freeze it. The ends of the tube must be soldered. When winding the tube, you need to ensure a distance between the turns of approximately 1 cm. After receiving the finished form, you need to remove the contents from the tube and rinse well. The finished coil is lowered into a reservoir with coolant, the volume of which should be 5–6 times larger than the coil itself.

Second step

Very often, beginners wonder how to seal the lid of a flask for a moonshine still? This aspect is very important, since alcohol vapors will escape from a poorly sealed can, which will negatively affect the volume of finished products. You can seal the structure after the holes for the hose and temperature sensor are ready. Special rubber layers are provided for food tanks. When converting such a container into a moonshine still, home craftsmen remove this gum and wrap it with FUM tape. Afterwards the product is placed in a container with water and boiled. Afterwards the layer is installed back. At the connection points of the hoses and thermometer, it is more advisable to use silicone gaskets, which are tightened with nuts. Experts recommend excluding rubber, as it will begin to melt under the influence of high temperatures, and the alcohol will have a specific aroma. In the absence of silicone, it is best to coat problem areas with dough. If it accidentally gets into the drink, then the distiller does not have to worry about its quality.

Selection of containers

The main and most important part of the moonshine still is the tank. It is also used for distilling and boiling mash. The best material for this container will be a copper cube for distilling liquid, which will serve you faithfully for many years. The properties of copper are ideal for the process of moonshine brewing. Containers made of stainless steel are also good for use as a cube and have a long service life. Enameled containers will last no more than five years, even if you protect them from chips. An aluminum can reacts strongly to the components of the mash and oxidizes over time, which spoils the taste of the finished product.

4) Installation of instrumentation and automation

Autoclave instrumentation and automation: pump valve, thermometer, pressure gauge, safety valve with a ring for forced pressure release.

To pump up back pressure at the beginning and end of autoclaving using a pump, a valve must be installed. Here we use a wheel extension from a Gazelle, which is attracted by the cut off upper part of a conventional tubeless valve. You can also take a long brass valve from any load wheel and cut an M8 thread on it to secure it with nuts to the body of the autoclave.

The thermometer, since the operating temperature range of the autoclave is 0 - 120 degrees, is used with a scale of up to 160 degrees.

The pressure gauge, since the operating pressure range is 0 - 3.5 bar, is used with a scale of up to 6 bar.

To release air from the autoclave when the pressure is exceeded, a safety valve is needed. The valve is used from the pneumatic brake system of a ZIL-130 car (the driver’s name for the valve, sorry, “fart” - that’s what you should ask in the store) with minor modifications: - replacing the rod spring with a weaker one, since the valve is designed for pressures in the region of 10 bar, and we need to limit it to somewhere around 4 bars. – flatten the tip of the movable valve stem, drill a hole in it for a ring, by which you can manually pull the stem and forcefully release the pressure from the autoclave.

– grind the valve ball more tightly, because in a car it is not required to have a perfect fit, but here it is necessary for the valve to be securely locked at low pressures.

Grinding in the valve ball: by gently squeezing the ball against the fitting in a vice, it is necessary to achieve the appearance of a mirror strip at the contact point.

Ready autoclave

Sheath for cleaver

The kit is assembled. Leather 3.4-3.6. Plant oak Fiebing's paint. Screw rivets 10mm. Threads 1.0

For the judgment of the respected community.

How to make a simple distiller from a saucepan?

To assemble the device you will need a minimum of parts, which will allow you to start manufacturing:

- Pan, volume can be from 7 to 40 liters. A lid is required.

- For the coil you will need a stainless steel or copper tube. Length – 2 m.

- Plumbing pipe with a diameter of 45 mm.

- A thermometer to make it easier to separate harmful fractions.

- Fitting, coupling, fum tape, epoxy glue.

- Parts for attaching the lid. They are chosen according to their capabilities, based on the situation.

Assembling the device begins with the refrigerator. First, make the coil itself. A copper or stainless steel pipe is prepared. You need to find a round blank in advance, which will then allow the coil to fit into the plumbing pipe. There should be up to 1 centimeter of gap left on both sides. The tube is closed on one side, and sand is poured on the other. The second side is also closed. Next, make a spiral; the distance between its branches should be no more than half a centimeter. There is no need to curl the entire length of the pipe. Leave about 4 centimeters on both sides so that you can connect the tubes later. Next, the sand is removed and the pipe is cleaned. Filling the pipe is necessary so that it does not lose its shape during bending.

Next, the coolant is collected. To do this, take a plumbing pipe; this is a more affordable choice. The length must be determined so that it matches the coil, it must fit. And a few more centimeters need to be left on top of this. You need to put fittings on the ends of the tube, but the pipe is cut off from them, leaving only a smooth surface. It is easier to put the fittings on by heating them over a fire. They are fixed with epoxy glue.

When the glue has hardened well, the pipe is drilled in the place where the fitting is located. Holes are made in both plugs. The tubes are pulled into them, then the plugs are glued with epoxy resin.

A steamer is not a necessary part of a home moonshine still. But its benefits are difficult to overestimate. It cleanses the distillate from harmful impurities and fusel. It's very easy to make. Take a jar with a lid. The lid should have two holes for tubes that supply and remove steam. In the container, the vapors are cooled and purified. The place of the steamer is between the distillation cube and the refrigerator.

Completion of work

At this stage, the craftsman needs to connect the hose from the tank to the cooling device. It can be made from a plastic water pipe, both ends of which must be plugged with two plugs.

This should give you two lids. Make two holes in each using a soldering iron or drill. One large one is for the pipe coming from the flask, the second - half an inch - for the fitting. Installation is carried out using special couplings. Cold water will flow into the device through a small hole. Next, the caps are screwed tightly onto the pipe and carefully sealed. Due to the fact that during the distillation process strong pressure is generated inside the refrigerator, the plugs, as some artisans claim, can fly off. To prevent this, experts advise fastening them with plastic clamps. Before attaching the second cover, a small hole is drilled in the side of the refrigerator for a bolt. It is clamped with nuts

It is important that there is a silicone gasket on the inside, the purpose of which is to prevent cold water from leaking from the refrigerator. A hook can be mounted on the outside of the bolt, through which the entire structure will be attached

At the outlet, a thick tube from the common line is connected to a silicone hose. A distillate will come out of it.

How to make a parrot for a moonshine still?

The design is simple, not to say primitive; no “engineering thought” or precise calculations are needed here. Therefore, feel free to start making it and get a wonderful parrot for your home distillation needs for pennies.

Made from corrugated stainless steel

The simplest design is made from half a meter of stainless steel corrugated pipe. To make a parrot, you just need to bend the tube. To drain the moonshine and insert the thermometer, cut one part of the tube halfway and bend it so that the liquid can drain.

This structure must be secured. As an option - in a piece of board, in which a groove has been selected in the middle for a bent tube. You can also take any unnecessary container from a tin can and fill it with diluted plaster. “Down” the structure evenly in it and wait a little while for the plaster to set. The parrot with the stand is ready.

The big disadvantage of this design is the use of non-food grade stainless steel. Because of this, the finished moonshine may have an unpleasant aftertaste due to compounds that are clearly not healthy.

From two syringes from the pharmacy

Large disposable syringes are needed - preferably 5 ml, but 2 are possible. Depending on the planned height of the parrot - 2 or 3. You will also need:

- IV tube;

- glue gun;

- lighter or mini-burner;

- gypsum;

- screw cap from a glass jar or small tin can.

Having collected the necessary parts, start creating the device:

- Remove the plungers from the syringes.

- Place a piece of IV tube 10-12 centimeters long on the ends where the needles are inserted.

- Cut the tip off the needle cap to make a tube.

- In the upper part (where the piston is inserted) of one of the syringes, make a hole for the resulting tube.

- Insert the tube and melt the connection with a lighter (burner) and additionally treat it with a glue gun so that it does not leak.

- Glue the solid syringe above the one with the inserted tube.

- Cut off the rubber bands from the pistons and glue them into the syringe above. These are the legs.

- Place the legs in plaster and let them harden.

Place the alcohol meter in the lower syringe, and place the upper one against the tube through which the distillate flows. As the lower syringe fills, the alcohol meter will float, indicating the strength, and the moonshine will flow through the spout into a substitute container.

From copper tube

For “advanced” distillers – jacks of all trades – the best solution is a copper parrot that is safe in terms of product purity and reliable in operation.

You will need:

- copper tube with a diameter of 25 mm and a height of 22-25 cm;

- the same tube, but with a diameter of about 10 mm (on the spout of the receiving tube) up to half a meter long;

- copper adapter from 25 to 35 (for intake funnel);

- plug for the main tube;

- drill;

- soldering iron

The design of such a parrot can be seen from the picture.

When selecting heads, it is not only unnecessary, but a hindrance, since the heads are mixed with the body and the whole selection becomes meaningless. Many harmful components of distillation will get into the main part.

Look at what ready-made offers are on the market:

It is quite possible that to begin with you will make a parrot according to the simplest scheme. But for venerable distillers, a copper design will be the best. Be creative, distill moonshine correctly and consume it in moderation.

Making a moonshine still from a beer keg

What modification is needed?

Kegs are used to store beer; the manufacturer is concerned about the safety of the material. In addition, the containers are designed for high pressure inside. These are some of the advantages. However, rework is still needed. What does it consist of:

- Installing a thermometer in a keg or other container is important for any moonshiner. The device helps to accurately determine the temperature and separate fractions during distillation. They use bimetallic, electronic, digital. But a glass thermometer is not suitable, as it is quite fragile.

- The coil is a part of the distiller that cannot be replaced by anything. The copper tube is located inside the refrigerator and turns the vapor into a liquid.

- In any case, you will also have to make a flow-through or non-flow-through refrigerator. Each type has its own advantages, but it is still recommended to ensure a flow of water.

- The heating element is built into the distillation container if the container is large, or simply for convenience. Its high price is fully justified by the large number of advantages.

- A steamer or bubbler is not a mandatory part, but cleaning cannot be avoided in any case. Therefore, it is better to install a device to automate this process.

Installation

Installation of all parts of the moonshine still occurs in the same way as with a distillation cube from a can. There are no special features. At the same time, a steamer and a refrigerator with a coil are connected. A thermometer and heating element need to be built in. It is recommended to start with the heater as it will take longer.

heating element

To install a heating element, it will take time and preparation. Usually the heater is sold complete with parts (nuts, washers), but if they are not there, you will have to work hard. It is worth making sure that there is enough power to heat the existing volume of the keg.

To attach the heater, you need to make holes. There should be two of them, of the appropriate volume. It is advisable to do this closer to the bottom, about 5 cm from it. There is another option for ensuring tightness: wrap plumbing tape around the thread

It is very important that no lye remains. Before connecting the heater, the connections are insulated.

Thermometer

Installing a thermometer usually takes even less time. Specialized stores sell devices that are designed to be built into a distillation cube. Such a thermometer must have a capsule and a fitting for attaching to moonshine stills, including those made from beer kegs, made by yourself. The fastening should be at the top of the pipe. Fum tape is most suitable for sealing.

Aluminum

Last ed. 15 Oct. 07, 12:09 from Andrey

Not advisable. It is better to store it in glass containers that meet GOST standards for use in the alcoholic beverage industry.

You can find out more about the use of cookware made of aluminum and other materials here:

IT IS FORBIDDEN.

You can’t put alkali in

the mash

!

Or you need to titrate

, and this is a gimmick!

The reaction of the mash should be neutral

! It’s easier with chalk; it can (and should) be put in excess (small). The advantage is that calcium salts are part of the fusel.

And if you make an alkaline reaction of the mash, it’s even worse than an acidic one - hello protein hydrolysis.

When aluminum is dissolved in an alkaline medium, hydrogen is released, which produces explosive mixtures with air in a wide range of concentrations. Your cube might explode. And according to safety precautions, it is PROHIBITED to work with hydrogen in enclosed spaces!

I did the primary distillation in an aluminum milk can on a gas stove. I didn’t notice any scale on the can. You may be right about heating elements, but scale is very easily removed with a weak acid (acetic, citric), to which aluminum is quite resistant. And then, hydrocarbonates are highly soluble in water. Simple carbonates are poorly soluble, so there won’t be a lot of calcium in the solution! Now, if only the installation was flow-through. then yeah. And there will definitely be enough shadows for one distillation - they won’t burn, and after distillation, rinse the shadows with table vinegar and they will be as good as new!

Last ed. 17 Sep. 08, 02:07 from Kotische

Any column has a finite separation capacity! The less crap at the entrance, the more efficiently the column works. I also believe that it is better to fight acidity not at the mash stage, but in moonshine. And as for efficiency, Kotische, it depends on what is considered efficiency. According to the classics, efficiency is a reduction in the content of impurities. If the impurity at the input was 0.5%, and became 0.05%, then the purification efficiency is 95%. But if at the input the same impurity will be one hundred billionth, the column will not notice it, and the efficiency will be completely zero.

On the other hand, my column easily separates alcohol from the impurity - water - when its concentration is 97%, and alcohol - 3%. So, I think a slight decrease in the acid content at the rectification input will have little effect on the quality of the output product. Since my cube is made of stainless steel, without a shadow of a doubt I treat the moonshine with NaOH before rectification. This is not possible with an aluminum cube.

3) Re-equipment of the lid clamp

Remove the standard aluminum clamp with a latch. We roll the round lid of the flask and tap it around the perimeter so that the rubber gasket from under it is not squeezed out by high pressure. We make a hexagonal or round pressure plate from a fairly strong metal with six holes Ф10 mm with a diameter of 24 cm. (The circle is divided into six parts by laying out a radius of 12 cm on it).

We make hooks from loop screws, cutting off the excess so that they fit freely on the handles of the flask.

The upper hoop of the flask, made of a cast alloy similar to silumin, contains two handles and supports for the clamping mechanism. The 4 exit points of the flask handles, as well as the two points of the clamping mechanism, form a regular hexagon. We insert a bolt into one support and sharpen the other a little so that the hook screw fits freely into the hook. As a result, the pressure plate with freely hung hook screws and wing nuts should fit freely onto the flask.

Pressure cover with six screws and wing nuts

Waxing.

I melt the beeswax in a water bath. As soon as the wax melts, I apply it to the flask with a brush. I pour the melted wax inside the flask and shake it for about 20-30 seconds, and pour out the excess. For waxing items that will come into contact with food or water, only beeswax can be used. Do not use paraffin under any circumstances! Beeswax is a natural product and is safe for your health, but paraffin is made from petroleum - this is extremely dangerous! Paraffin can be used if you are making re-enactment flasks that no one will drink from.

Moonshine technology

Now I will quickly tell you the entire sequence of the process, and then we will talk in more detail about each stage. So, how is moonshine prepared?

- First, prepare a special solution consisting of water and sugar. Sugar can be used either in its pure form, or any sugar-containing raw materials (berries, fruits, etc.) can be used. This solution is called wort.

- The wort is then processed into mash using yeast. During fermentation, yeast eats sugar and produces ethyl alcohol and carbon dioxide (there are other fermentation products, but not about that now).

- The mash already contains alcohol, but the percentage of it there is very low. Typically 8-12%. To extract alcohol from the mash, it is distilled using a moonshine still. The distillation process is also called distillation.

There is nothing complicated in this process. The whole point is that the mash is heated to a boil, and the steam that evaporates is cooled to a liquid state and poured into a separate container. This condensed liquid is our moonshine.

- Then comes the purification of the moonshine. During the fermentation process, in addition to ethyl alcohol, yeast by-products are also formed. It is necessary to get rid of these impurities, because... they are harmful to health. Some even very much so. And these impurities greatly spoil the taste of the drink. We will talk about types and methods of cleaning in the section below.

- The final and completely optional step is flavoring and tinting the moonshine. Moonshine is infused with various herbs and spices, which give it a rich color and smell.

I have listed the main stages of making moonshine. Nothing complicated, right? Now let's look at each point in more detail.

But before that, I want to note that all the stages mentioned are equally important. If the technology is not followed or low-quality raw materials are used, the output can result in a foul-smelling and even hazardous liquid.

Is it possible to use aluminum cookware - truth and myths, benefits and harms

So, first, let’s find out what materials aluminum cookware is made from. In food production, pure aluminum and some alloys of this metal are used to make such utensils. They change the physical properties of aluminum, affect heat resistance, as well as its ductility.

As a rule, ready-made aluminum sheets are used in production. These sheets are then stamped into kitchen utensils. Basically, the process uses the method of minting or forging

Of course, not many people, when buying such dishes, pay special attention to the issue of manufacturing. However, it should be noted that forged cookware has greater strength and thermal conductivity

Those utensils that are made only from aluminum, without adding additional substances, are very popular

However, it is comparatively more expensive

Those utensils that are made only from aluminum, without adding additional substances, are extremely popular. However, it costs comparatively more.

Myths associated with the use of aluminum cookware:

The use of aluminum cookware can cause a variety of diseases. This myth is considered the most common and unconfirmed. Be that as it may, there are no studies that address this topic. In addition, it is impossible to know exactly the possible number of aluminum particles that penetrate the human body. At the same time, thanks to numerous examinations, it became known that aluminum enters the human body in 2 ways: thanks to the products that we are used to using for heartburn, and thanks to antiperspirant deodorants, which contain aluminum hydroxychloride. Many people use these cosmetics every day. They don't even think about what consequences this may have. The effect of this substance on the skin has been officially studied and is therefore considered negative. Therefore, it is wrong to say that aluminum cookware is the cause of a particular disease. Because our ancestors cooked in these dishes and were completely healthy. Aluminum cookware is short-lived. Those kitchen utensils that are made of thin metal can, of course, become deformed - this is the basis for this conclusion. To prevent the dishes from becoming deformed, it is necessary to purchase one that has thick walls. It costs much more, has thick walls, but weighs more. Plus, on the outside there is most often a ground wheel

It is very important to choose high-quality kitchen utensils and properly care for them, then they can last for many years

Aluminum cookware

Now let's list the positive and negative aspects of aluminum cookware. Positive:

- Small price. This also applies to products that are coated with Teflon, stone, and ceramics. Due to the presence of an aluminum base, the cookware is slightly more expensive than similar analogues.

- Increased thermal conductivity. Cookware made of aluminum tends to heat up quickly and also cool down quickly. This makes it possible to save your time, which will be spent on preparing food. As a rule, such containers are used to heat porridge, milk, and boil eggs.

- Aluminum cookware does not rust. And all because it has a thin oxide film that appears on the surface of pots, plates, spoons... This film is very durable, therefore, the food does not come into contact with the metal itself.

- Modern aluminum cookware has a protective coating. It extends the life of the cookware and also reduces the risk of aluminum particles penetrating into the food. Thanks to this move, the likelihood of changes in the taste of food and its aroma is reduced, which often happened earlier when oxidation processes started.

Negative:

- The increased thermal conductivity of aluminum is often the reason why food sticks to the surface. If you don't pay attention to every moment, you can simply spoil the food.

- Although cookware does not require extensive care, removing burnt-on food requires a lot of time. And the use of aggressive detergents spoils the surface or removes its protective film.

- Also, such dishes, as mentioned above, sometimes become deformed. Even if you handle it carefully, there is no guarantee that the original appearance of the dishes will not be damaged over time.

What to do with the products?

In fact, moonshine brewing in our country was initially seen as an opportunity to earn extra money against the backdrop of a general shortage of alcohol.

And today, many lovers of “hot drinks” prefer to buy a homemade product. For production, many additional elements are used that change the taste of the drink. Older men prefer the “natural” option. This allows professionals in this craft to quickly find a client base and recoup their efforts. However, the legislation imposes some restrictions. Obviously, the right to conduct business is enshrined in the Constitution, so it is extremely difficult to challenge it. However, you will have to follow established rules and procedures in order to receive income, and not problems with the law. For example, it is quite possible to produce alcohol for sale, but this is a business activity that, according to the law, must be licensed and be subject to a different taxation procedure. Accordingly, you will have to register as an individual entrepreneur, prepare all documents for government agencies and obtain the appropriate permission (by paying tax).

Firstly, alcohol is brewed in specially equipped premises and must eliminate risks to human life and health. Therefore, it will not be possible to do such procedures at home, and the room can only be used in one direction.

Secondly, there are requirements for equipment - technical standards have been established that the distillation apparatus must comply with. If the inspection authorities find a discrepancy, you can forget about the license until the deficiencies are corrected. Accordingly, a homemade device will not meet the established criteria.

Of course, most people interested in this issue will not deal with paperwork and obtain a license

We only draw attention to the fact that such a possibility exists, and administrative and criminal liability is provided for non-compliance with the law. Further actions are the decision of each person. Considering that sales to neighbors and acquaintances are not large supplies, supervisory authorities, in the absence of incidents, will not pay attention to your activities

Considering that sales to neighbors and acquaintances are not large supplies, supervisory authorities, in the absence of incidents, will not pay attention to your activities.

Cover of "Dog"

Good day. I’m not sure that the result is a dog of the Kani Corso breed, but it looks like a dog.

Thank you for your attention.

How to make a steamer?

The steamer is an indispensable element of every moonshine design. To make it you will need a glass jar. Its volume does not matter, the main condition is the presence of a tightly closing lid in which two holes must be made. The purpose of the first is to place a can pipe; in the second, a channel is installed that supplies liquid to the refrigerating chamber.

In order not to make mistakes in the calculations and make your own high-quality steamer, you need to take a pencil and draw on the lid the exact size and shape of the intended holes. It should not be forgotten that the slots must exactly match the dimensions of the pipes.

After this, you need to cut holes along the resulting contours, insert channels, and tighten the nuts. For more reliable fastening of the pipes, you can apply varnish or leftover dough to the joints.

The last stage of making a steamer is to close the can and ensure the tightness of the structure. Having completed these manipulations, you can connect the steamer to the refrigerator compartment

An important condition for a successful result is the correct position of the refrigerator. It is best if the camera is at an angle not exceeding 45 degrees

Advantages of milk cans

Milk flasks, even those that are many years old, have many advantages over other products suitable for a cube:

- This is an almost ready-made cube that requires minimal modifications. And even then, if you plan to heat it on a stove (gas or electric), only the lid will require changes; the can itself can not be touched at all;

- flasks are made of thick metal and have a large margin of safety;

- do not rust, durable;

- in the same vessel you can put mash;

- aluminum heats up quickly, transferring heat to the mash, thereby speeding up distillation;

- voluminous neck, which allows you to track and also easily wash the can.

The disadvantages include the presence of a special rim near the bottom of the can. It is difficult to heat such a flask on an electric stove, but for a gas stove, steam generator, heating element, this does not matter.

Methods for heating a moonshine still

1. Open fire. In most cases, this means heating on a gas stove or burner, but there are also coal and firewood. The advantages of this method: simplicity, accessibility and often cost-effectiveness.

Flaws:

- high inertia - it will not be possible to quickly reduce or increase power, as a result, it is difficult to control the temperature in the cube; experience is required;

- it is very difficult to insulate the distillation cube to reduce heat loss in order to save money;

- installation of automation is practically useless;

- high fire hazard of open fire.

Distillation in the fresh air with wood.

What kind of device, what color of moonshine 2. Built-in electric heating elements. Devices (one or several at once) are mounted directly into the cube. Heating elements made of stainless steel or brass are suitable.

Advantages:

- quick temperature change (high controllability);

- possibility to install automation and insulate the cube.

Flaws:

- solid particles can burn to the working surface of the heating elements; careful filtration of the mash is required before distillation;

- Electric heating is often more expensive than gas heating;

- From time to time the heating elements burn out.

3. Induction cooker. It runs on electricity and can be stationary or portable (used more often in moonshine).

Advantages:

- low inertia – quick change of heating intensity;

- good temperature control - induction cookers are equipped with automation, no need to install separate units;

- in comparison with heating elements, the entire surface of the bottom of the cube is evenly heated; burning of the mash occurs in rare cases.

Flaws:

- the cost of an induction cooker is quite high;

- You can only use distillation cubes made from materials containing a magnet (stainless steel, cast iron), while aluminum and copper containers without magnetic inserts welded to the bottom are not suitable for heating.

Only stainless steel and cast iron cubes can be heated on an induction hob

4. Heating using steam (steam generator). First, the water is brought to a boil and served directly into the container or onto the outer walls. The system allows you to control (automate) the entire process and eliminate the risk of burning, therefore it is suitable for distilling thick mash. But due to the complexity of implementing the design and the need to purchase (manufacture) special equipment (steam generator), it will not be considered further here.

How does the device work?

The operation of the device is based on the principle of squeezing and releasing the udder teat. This process occurs due to the negative pressure created in the glasses. It is maintained at 48 kPa, and the contraction frequency is regulated by a pulsator.

The device is connected to the mains and the switching mode is activated using the button. The manufacturer recommends letting the unit run idle for a few minutes. Then the milk hoses are clamped with special clamps. Now you need to open the valve on the manifold by pressing the button.

Next, aluminum cups are applied to the udder nipples one by one. Having securely fixed all the containers, remove the ring from the milk tube. Thanks to the operation of the vacuum pump, which is driven by the engine, negative pressure is created in the glasses. The milk begins to flow into the milk collector, connected by a tube to the glasses.

I did

I decided to find a little hobby for myself in the new year, and decided to make leather goods, because why not. Here are my first creations: 1.)

Beaver everyone. materials: crazy horse leather, edge treatment (chemicals) seta neutral

Which flask should you choose?

In Europe and China, stainless steel flasks are mainly used. Probably the main reason is that medical studies interpret the use of aluminum ambiguously. Allegedly, when interacting with an aggressive environment (which is mash), especially when heated, it oxidizes. This releases substances harmful to humans.

Even today we continue to produce aluminum flasks and pots.

However, for those who are worried about the material, there is an alternative - buy a stainless steel flask. They are produced in China and European countries and sold here.

Making a moonshine still from a 40-liter flask with your own hands is a creative activity.

Can selection

If you have an old Soviet can in stock, then the question of choosing a container is immediately resolved

But if you still plan to purchase a container, you should pay attention to the following important aspects:

- Material. Milking flasks made of aluminum and stainless steel are suitable for making moonshine.

- Capacity. A huge range of flasks is presented in different volumes, ranging from 10 to 100 liters. Usually moonshiners stop at 20-50 liters - the most optimal size for a still. When making moonshine in large quantities, there is no point in buying a small flask. But many experimenters prefer to have in stock a distillation cube from a small flask for testing.

- The neck should be as wide as possible. Often after distillation you have to scrape the burnt mash from the walls and bottom, and through a small neck it is almost impossible to do this.

- Tightness. If the can is supported, there is a possibility that the lid or rubber band may be deformed.

Having selected the required can, you should make a hole of the required diameter in the lid. First, you should purchase or build attachments yourself and orient the hole under it using a feather drill. Insert the fitting and tighten it with a nut from the inside, to make sure that the container is sealed, it is worth laying a silicone lining into the connection.

In the side of the vessel, slightly below the lid, you need to make a second hole for a special thermometer, secure the device again using a nut and a silicone lining. You can install a thermometer in the upper part of the can, but then the indicators will be less accurate.

Hoses

Connect the attached fitting to a special stainless steel gas hose and attach a steamer; you can make it yourself or purchase it in a store. Also attach a hose to the steamer and connect it to the refrigerator.

When choosing hoses you need to be guided by the power of the system itself

This will determine their length and diameter, which is important for maintaining pressure

Fridge

The device is used to condense steam. This is an essential element of a homemade moonshine still, thanks to which an alcoholic drink is obtained. There are 3 options for running the refrigerator:

- immersing the device in a container with cold water and ice;

- cooling due to ambient temperature;

- connection to the water supply.

The last option is not considered acceptable for everyone, so the first two methods are most often preferred.

There are several types of commercial refrigerators; the best ones are glass coils, which provide all the necessary processes even when cooling in ambient conditions. More details about this are written here.

It is recommended to connect a steamer or bubbler to the distillation unit, and it is best to use these two options together. The first device is responsible for rough cleaning, and the second one performs soft cleaning.

A steam steamer or reflux condenser is a special device that can separate steam from liquid compounds and solid scale particles. Thanks to this device, the taste of moonshine improves, the volume of fusel oils decreases, and accidental penetration of mash into the finished distillate is prevented. This is a hermetically sealed vessel where vapors are collected and compacted, and then the ethyl alcohol re-boils due to the continuous supply of heat.

There are two options for heating a multicomponent mixture in a flask, since smooth heating and careful temperature control are important in this matter:

- Installation of heating elements. The heating device features smooth temperature control, but there is no exact guarantee that the mash will not burn.

- Steam generator. The best solution, which is rarely used because it is quite expensive.

Alembic

So, the first element we will look at is the distillation cube. A distillation cube is a container in which the mash will boil during the distillation of moonshine. What can it be made from?

Most often in old, still Soviet devices, there is an aluminum cube. The distillation cube was made from a flask or can, in which milk was previously transported. It is not recommended to use such material for the manufacture of a moonshine still, because aluminum partially reacts with various acids and alcohol in the mash. In addition to the fact that unnecessary impurities appear in moonshine, with frequent use the aluminum still begins to leak after a short time and fails.

Enameled dishes. This material is neutral to acids and alcohol. If used carefully, without hitting or scratching, it can last quite a long time even with frequent use. However, it is quite difficult to seal a moonshine still from a pan well. Craftsmen have also learned to make cubes from a milking machine tank for cows, but this option is unlikely to suit a city dweller.

The most reliable option is food-grade stainless steel. Such a cube will serve for a long time; it does not come into contact with the mash, which eliminates additional harmful impurities in the finished product. However, cubes made from this material are quite expensive, and often ordinary galvanized steel is sold under the guise of stainless steel, and this is also not so durable.

You can also use a copper container as a cube, but as a rule, this is too expensive an option for a moonshine still.

The volume of the distillation cube must be selected according to the volumes in which you intend to produce moonshine. Ideal for household needs from 25 to 35 liters. It is important to follow one rule! Never fill the still completely, it should be filled to about 80%. This is done for safety reasons, so that when boiling, the pressure in the cube does not exceed the permissible value and the cube does not burst

When choosing a container for the distillation cube, pay attention to the width of the neck. It should be large enough to make it convenient to pour the mash and wash the cube after distillation. Don't forget about the size of the container as well.

The cube must be placed on the plate, be stable and not interfere with access to the entire apparatus

Don't forget about the size of the container either. The cube must be placed on the stove, be stable and not interfere with access to the entire apparatus.

You can make an electric moonshine still. For him, a distillation cube is made from a pressure cooker. It has a small volume, but it has its advantages - there is no need to use a stove, since it has its own heater, and it is initially sealed. You only need to make a hole in the lid for the steam outlet tube.

A milk can, preferably made of steel, is best. This is the simplest option. Just be sure to change the rubber gasket under the lid to silicone, because alcohol vapor absorbs harmful substances from rubber. This will certainly affect the quality, taste and smell of the finished product.

How to do it yourself: remove the rubber gasket, then apply silicone sealant to the edges of the lid and leave to dry. Repeat several times. Place cellophane on the neck of the can and close the lid. Keep it this way until completely dry. This will make an excellent silicone seal.

conclusions

Copper is, of course, an important component of distilling and it is unlikely that in the near future, despite its obvious shortcomings, large producers and home enthusiasts who are not indifferent to grain and fruit distillates will completely abandon it. However, you need to use it wisely:

It is advisable to use copper only in the steam zone of the moonshine still - the main refrigerator, where the condensation of alcohols occurs, it is better to tin or replace the copper elements with stainless steel. To minimize sulfur compounds (DMTS) and improve the organoleptics of the drink, it is most effective to use copper elements (copper helmet, drawer with copper nozzles, plate column with copper caps, etc.) in the steam zone during the first distillation of the mash

During the second distillation, it is most effective to use a copper still. Regular cleaning of the external and internal surfaces of copper products is the key to high-quality and tasty moonshine.

- It is advisable to use copper only in the steam zone of the moonshine still - the main refrigerator, where the condensation of alcohols occurs, it is better to tin or replace the copper elements with stainless steel.

- To minimize sulfur compounds (DMTS) and improve the organoleptics of the drink, it is most effective to use copper elements (copper helmet, drawer with copper nozzles, plate column with copper caps, etc.) in the steam zone during the first distillation of the mash. During the second distillation, it is most effective to use a copper still.

- Regular cleaning of the external and internal surfaces of copper products is the key to high-quality and tasty moonshine.

You can buy copper products for distillation in our online store “MirBir”. In the assortment you will find the best Portuguese copper alambics and components for them, modern Desstill distillers with a copper helmet and a stainless steel refrigerator, as well as Panchenkov (RPN) and Selivanenko nozzles, and much, much more. You can contact them for a consultation by calling their toll-free number or using the feedback form on the website.

Leather glasses case

Another handmade product made from genuine leather:

I bring to your attention a case for glasses, handmade from high-quality vegetable-tanned genuine leather, stitched with waxed thread, dyed and opened with a finishing (protecting the product from moisture).