It is difficult for a novice moonshiner to immediately decide to buy a good moonshine still, but learning the basics of distilling requires something.

We will tell you how to make a moonshine still from a saucepan with a minimum of parts.

Even if you don’t have a large saucepan and you have to buy one, a distiller will cost you 5–10 times less.

Required parts

To create a simple distiller you will need:

- a saucepan with a volume of 7 to 40 liters, always with a lid;

- a stainless steel or copper tube 2 meters long - for the coil;

Peculiarities . A copper tube can be used from an old broken refrigerator. A copper coil will ensure the release of a delicious, aromatic distillate, especially when using grain or fruit mash.

- a piece of plumbing pipe with a diameter of about 45 mm for the refrigerator and two plugs for it;

- thermometer. This is not a necessary thing, but very important for a moonshiner. It is the thermometer that allows you to qualitatively divide the distillate into fractions and take for consumption only the highest quality moonshine, which contains a minimum of harmful additives.

- fittings, couplings, fum tape, epoxy glue;

- materials for fastening the cover. They are selected based on the specific situation. This could be a pair of anchors and a piece of aluminum profile (if the lid is flat and you can remove the nozzle from it), small clamps or strong clothespins, a specially cut holder (if the handles of the pan rise above the lid), etc.

Reference . The most harmful substances are contained in the distillate, which drips very first, at a temperature of 60 to 75 ° C.

It contains poisonous methyl alcohol, acetaldehyde, ethers and acetone. This liquid is called heads and is poured out mercilessly. There is no drinking alcohol in it at all, since ethyl alcohol begins to evaporate at 76°C.

And at temperatures above 85°C, “tails” rich in fusel oils begin to appear. They are collected separately and used during the next distillation. Added to the mash, they will increase the yield of high-quality strong moonshine.

RESULTS

RESEARCH, RESEARCH ´Ð¸Ð¼ ÑÑÑÐ±ÐºÑ Ð¸Ð· ÑÑÑопаÑника и зап¿Ð °Ð¸Ð²Ð°ÐµÐ¼ Ñоединение.

Â

UR ROOM. ROOM ROOM »

RESULTS RESULTS. RESPONSIBILITY RESULTS.

Making a refrigerator

1. Making a coil. We take a prepared stainless steel or copper tube and any round oblong blank of such a cross-section that the resulting coil fits freely into the plumbing pipe, leaving a 0.5 - 1 cm gap on both sides.

We plug the tube on one side using an accessible method (we clamp it with pliers, put a plug) and fill it tightly with sand. We put the same plug on the other end. We wind the spiral, leaving a gap of up to 0.5 cm between the turns.

On both sides, the coil should have a straight part of 3-4 cm for connecting tubes (supplying alcohol vapor and discharging the finished distillate). After making the plug, remove it, pour out the sand, and rinse it under running water.

Peculiarities. It is strictly forbidden to wind a tube that is empty inside - it will either flatten or crack.

2. Assemble the cooler. Let's consider the option of using a plumbing pipe, as one of the simplest:

Important. Before the coil is ready, you should not cut the PVC pipe, since it is very easy to guess the length.

- We determine the length so that the coil fits inside, and the straight parts protrude a couple of centimeters outside. Cut off the pipe.

- Now you need to cut off the threaded part from the two fittings (for water inlet and outlet) to get a flat bottom.

- Holding the fitting with pliers, heat its bottom over a fire and apply it to the plumbing pipe in the places where they will be attached, slightly melting the landing spots.

- We clean, degrease these parts of the pipe with acetone and glue the fittings with epoxy glue.

- After complete hardening, we drill the pipe directly through the fitting. We clean the back side.

- Having tried on the coil, we make two holes in the plugs (choose durable ones!) exactly along the cross-section of the tube.

- We stretch the tubes into the holes, glue the plugs to the pipe with epoxy, and carefully treat the exit points of the coil tubes with it.

The refrigerator is ready. First, make sure it is tight and you can test it on water - rinse it and get distilled water.

We recommend reading: Important rules for washing and cleaning a moonshine still

Owners' opinion

Opinions of users of home hot smoked smokehouses differ. Some advise purchasing the unit in a store, since it is distinguished by its functionality. Others argue that if you have the skills to work with a welding machine, such an installation can be done no worse than in a shop. The main thing is to correctly determine the shape, size and strictly follow the assembly technology. In this case, a good result is guaranteed. A home smokehouse with a stainless steel water seal is a functional and easy-to-use device. With its help, you can prepare delicious delicacies with your own hands in a short time. This will require a minimum of skills and costs. With the help of a smoking unit assembled at home, the dishes are no less tasty than store-bought ones.

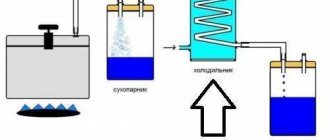

Sukhoparnik

This detail, although not mandatory, improves the quality of the distillate significantly , since the lion's part of the fusel remains inside the container, which serves as a steam chamber. The design is very simple: a glass jar with a screw cap, in which two holes are made and fittings are installed - for the supply of vapor from the distillation cube and the outlet - to the refrigerator.

On the way through the jar, the vapors cool and lose fusel oils, which remain at the bottom of the container without getting into the final product. The steamer is installed on silicone hoses between the distillation cube and the refrigerator.

More on the topic: What is a steamer needed for and how is it used?

History of distillation

The history of distillation began so long ago that there is no exact data about it. The right to pioneer such an amazing process is shared by several countries.

The beginning was made when people paid attention to the processes occurring in nature, or rather, the water cycle

The first mentions of alcohol came from Antiquity. People appreciated the taste of the juice of fermented berries and fruits. However, the process happened quite naturally. The first mention of a device that resembled a modern device came from Egypt. The diagrams were drawn on the walls of the temple of Memphis and later noticed by Zosimus. At one time it was believed that the history of distillation began in China, but there is no direct evidence for this.

Alembic

It is the pan that will serve as the distillation cube. The most suitable materials are stainless steel or enameled steel . Aluminum is not the best solution due to the ability of the metal to enter into chemical reactions with mash, forming compounds harmful to health that will be added to moonshine.

You don’t have to “spoil” the pan itself, but only remake the lid, so that in the future it can be used for its intended purpose.

But sometimes it makes more sense to connect the steam pipe to the side in the upper quarter of the pan. Here it’s the moonshiner’s choice. Let's consider the sequence of actions.

Regardless of whether the tube for removing alcohol vapor is in the wall of the pan or in the lid, you need a hole for it. Here are some options:

- There are homemade devices where a ready-made hole in the lid (usually glass) is used for the steam line, to which a handle is screwed. In its place they put a fitting on which a silicone tube is placed leading to the refrigerator. There is no need for a distiller - just put the handle in place. Glass lids almost always have an additional hole for steam to escape. There are two options - either seal it (for example, with epoxy glue), or expand it a little, equip it with a capsule and put a thermometer;

- drill a separate hole in the lid and also install a fitting;

- a hole is made in the wall of the pan, retreating 3 - 4 cm from the top, and a connecting fitting is installed.

Attention . It is extremely important to seal all connections so that alcohol vapor enters only into the tube provided for it, and does not break through the cracks. Not only does this result in a loss of the final product, but it also poses a risk of fire.

We recommend reading: What causes moonshine stills to explode and how to avoid it?

The cheapest do-it-yourself distiller (from Georgiy Kavkaz)

The cheapest equipment can be made from materials you already have on hand. Pressure cooker is good. Stainless steel beer keg - great!

If you don’t plunge into the wilds, then it’s much easier to still pay 3 thousand rubles for a coil with a ready-made steamer and a refrigerator. This will save you a lot of effort, time and material. If you are not looking for simple ways, then a Caucasian-style moonshine , which was presented in his video by moonshiner Georgy Kavkaz .

Georgy is working his magic on the future device.

The idea is that you just need a still, along with some pipes, adapters and fittings. The manufacturing process looks like this:

- We take a polypropylene pipe 1 meter long and 25 mm in diameter. We cut two tees into it with fittings for water.

- We insert a copper tube 1.5 meters long and 14 mm in diameter into the polypropylene.

- We pour sealant along the edges of the PVC pipe so that the space inside it is airtight. Cold water will move along the contour of the polypropylene and cool the moonshine vapor in the copper pipe.

- We connect the copper steam line to the distillation cube through a 12 mm nipple cut into the lid.

- We turn on the water, heat the mash and get full-fledged moonshine from a Caucasian distiller.

The final price of the apparatus without a distillation cube: 1500 rubles . Polypropylene pipe 1 meter, copper pipe 1.5 meters, 2 fittings, 2 PVC tees, 1 nipple, silicone sealant.

If our instructions seemed too complicated to you, then I recommend that you watch a short video from Georgy Kavkaz . The guy talks to the point and without unnecessary fluff about the manufacture of this device and suggests all the dimensions.

Assembly

If everything is done correctly, there should be no problems. But the most important thing in ensuring tightness is to secure the lid. Here - who will come up with something:

- if the handles are welded in metal, located on the sides of the container and do not protrude upward, the lid of the pan can be firmly and securely fastened using anchors and a strong strip (aluminum profile, strip of thick metal, strong board, etc.) with corresponding holes on the sides. In this case, the anchors are hooked onto the handles of the pan and tightened with nuts until they are firmly connected. And the top of the pan with mash already poured in 3-4 layers is wrapped with fum tape, which will ensure tightness;

Advice. If you cannot remove the handle from the lid, you will have to make a cutout for it in the upper clamping profile you are using.

- The raised metal handles of the pan make it possible to firmly press the lid with any durable material by threading the clamp into the handles. Moreover, these can be two clamps on both sides, and the presence of a handle on the lid in this case is not a hindrance. Don't forget about fum tape;

- Often pans have plastic handles, so it is better not to use the option with anchors - the handles can break at the most inopportune moment. When seating the lid deeply, try to press it at least with clothespins (preferably with small clamps) and coat it with the usual dough together with the clamps. This ancient method of sealing a moonshine still works well today.

The creation of a moonshine still from a saucepan is not limited to the described methods. Many people add reinforcing and even distillation columns to the design, and come up with their own ways of attaching the handle.

How do you feel about making a moonshine still from a pot? Are you ready for such creativity? Tell us in the comments. Like and share the article with your friends.

Methods for heating a moonshine still

1. Open fire. In most cases, this means heating on a gas stove or burner, but there are also coal and firewood. The advantages of this method: simplicity, accessibility and often cost-effectiveness.

Flaws:

- high inertia - it will not be possible to quickly reduce or increase power, as a result, it is difficult to control the temperature in the cube; experience is required;

- it is very difficult to insulate the distillation cube to reduce heat loss in order to save money;

- installation of automation is practically useless;

- high fire hazard of open fire.

Distillation in the fresh air with wood.

What kind of device, what color of moonshine 2. Built-in electric heating elements. Devices (one or several at once) are mounted directly into the cube. Heating elements made of stainless steel or brass are suitable.

Advantages:

- quick temperature change (high controllability);

- possibility to install automation and insulate the cube.

Flaws:

- solid particles can burn to the working surface of the heating elements; careful filtration of the mash is required before distillation;

- Electric heating is often more expensive than gas heating;

- From time to time the heating elements burn out.

3. Induction cooker. It runs on electricity and can be stationary or portable (used more often in moonshine).

Advantages:

- low inertia – quick change of heating intensity;

- good temperature control - induction cookers are equipped with automation, no need to install separate units;

- in comparison with heating elements, the entire surface of the bottom of the cube is evenly heated; burning of the mash occurs in rare cases.

Flaws:

- the cost of an induction cooker is quite high;

- You can only use distillation cubes made from materials containing a magnet (stainless steel, cast iron), while aluminum and copper containers without magnetic inserts welded to the bottom are not suitable for heating.

Only stainless steel and cast iron cubes can be heated on an induction hob

4. Heating using steam (steam generator). First, the water is brought to a boil and served directly into the container or onto the outer walls. The system allows you to control (automate) the entire process and eliminate the risk of burning, therefore it is suitable for distilling thick mash. But due to the complexity of implementing the design and the need to purchase (manufacture) special equipment (steam generator), it will not be considered further here.

We recommend reading

- When to cover grapes for the winter and how to do it correctly

- Vodka at home

- Labels for bottles of moonshine: templates for labeling...

- Bourbon: what is this drink and what is the secret of its popularity

- Growing grapes from cuttings

- Purifying moonshine with milk at home: it’s worth...

- How to clarify wine: the most popular and effective methods

- Cranberry in alcohol: homemade tinctures and liqueurs with…

- Moonshine from rice: how to make homemade distillate using…

Simple beef stew recipe

The process of preparing such stew is quite simple and even a novice housewife can do it. You can preserve deli meats only with the addition of spices or using vegetables in the recipe, for example, onions, carrots, bell peppers.

Components:

- Beef – 2 kg.

- Meat broth – 1 l.

- Spices, salt - to taste.

The preparation of the dish is as follows:

- Simmer the whole pulp in a saucepan with added water until half cooked.

- Transfer the ingredient to a baking sheet lined with foil and place in the oven. Cook the meat for 60 minutes until golden brown.

- Cut the beef into pieces and place in clean jars. Pour the boiled broth over the slices. Add spices to the container to taste.

- Transfer the jars to a wide saucepan, pour water into the container up to the shoulders of the jars. Sterilize the workpieces in a water bath, covering them with lids, for 1 hour 45 minutes. Seal the jars, cool upside down under a blanket and store in a cool place.

Preparations for the winter

Step-by-step technology for the second distillation

Dilute the raw alcohol to a strength of 15–20%

After the first distillation of the mash, you get raw alcohol. Usually, at this stage, harmful fractions are not separated, but distilled at maximum power, so that the yeast cooks less and a minimum amount of harmful substances is released.

Before the second distillation, you need to dilute the raw alcohol to 15-20% strength. This can be done in the following ways:

- Use the moonshiner's calculator. It will be necessary to measure the strength of the product before diluting, then substitute all the values and add the required volume of water. This is the most accurate and correct approach to the matter.

- "Approximately". Since precision accuracy does not matter, you can simply estimate the required volume of water and pour it into the cube. A slight variation in strength is quite acceptable.

Why are we doing this? After dilution, the connection between moonshine and fusel oils weakens (an unpleasant odor appears), so it is easier for us to separate harmful fractions. From a security point of view, this is also correct.

What water is best to use? Clean and drinkable. Possibly from the tap.

A moonshine still with a steamer significantly reduces the content of harmful substances in moonshine.

Cleaning moonshine before the second distillation

This step is optional, since good distillation cleans the product of fusel quite well. But there will definitely not be any unnecessary cleaning.

There are many approaches, and they all have a right to exist. We will recommend the easiest and fastest cleaning method using activated carbon.

- Pour the diluted raw alcohol into one container.

- Add activated carbon to it at the rate of 1 tablespoon per 1 liter of moonshine (can be used in tablets or BAU and KAU from the store).

- We insist from 10 hours to 10 days (optional).

- We make a dense filter from gauze or cotton pads, and then filter the liquid.

The resulting smell becomes more pleasant and the taste softer. I do not practice this myself, since I consider it inappropriate to waste my time on such operations.

Consistency of professional carbon for cleaning (BAU).

We separate harmful fractions during the second distillation

After you have poured the diluted raw alcohol into the distillation cube, you can proceed directly to distillation.

- Turn on the stove at full power.

- When the temperature reaches 60 degrees the refrigerator should already be working.

- At 78 degrees the first drops of moonshine will appear. It is necessary to reduce the power to a speed of 1-2 drops per second and remove the heads. Aim for 50 ml of heads for every 1 kg of sugar in the mash. This liquid should not be drunk.

- After selecting the heads, change the receiving container and begin collecting the body.

- Selection must be stopped at the moment when the strength in the stream drops to 40%. The thermometer will read approximately 95–96 degrees.

- Everything else can be collected as tailings and distilled next time.

A thermometer is not necessary, but it simplifies the whole process quite well.

Therefore, purchase equipment with it or embed it into the design of the device yourself.

Don't be greedy and take away all the harmful fractions of your product.

We dilute the product to the classic strength of 40%

We take any moonshine calculator, substitute the values and dilute the product to 40% strength. If you prefer stronger drinks, then use your own technology, although they usually focus on the number 40.

Wait at least a day until the moonshine is completely mixed and its taste stabilizes. Many people note that after a few days the liquid becomes more pleasant and easier to drink. This really makes sense, but not many people have the patience for such things. But in vain!

Use of all-metal construction

Installation using improvised means at home is quite difficult to do. For manufacturing it is necessary to prepare argon welding. In addition, you need to be able to work with it. But the design itself is quite simple and differs little from the factory-produced model.

You can make an all-metal distiller for moonshine with your own hands using the following components:

- The basis of the design is a container for mash. All other components will be attached to it. It must be made of all-metal stainless steel.

- Bubbler.

- Fridge. It should be pretty durable.

- Dephlegmator.

The reflux condenser should have a diameter of about 40-50 mm. It can be welded to the lid or screwed onto the fitting. The last option is more convenient to use. The column must be filled with balls of stainless steel wire mesh, glass and the like.

Preliminary preparation

1). Only drink moonshine when sober. Alcohol slows down the reaction. In the event of emergency situations, it is more difficult for a drunk person to quickly and adequately respond to a threat, and the feeling of fear is dulled. Often it is the neglect of this rule that leads to serious consequences.

2). The room should be spacious enough. Things, furniture, and household appliances should not block the exit from the premises and access to the turned on moonshine still. It is better to take everything unnecessary for moonshine (even small items) into another room. To avoid the accumulation of alcohol vapors, it is better to use household ventilation or organize ventilation through a window.

3). Install a fire extinguisher not far from the distillation (rectification) site. As a last resort, a bucket of water and felt (fire-fighting fiber) with an area of 3 square meters. meter, which can be used to cover the source of ignition to prevent oxygen from reaching the flame.

4). Change into closed clothing made from natural fabrics to protect your body from thermal burns. You can protect your hands with fabric gloves (they must be dry; wet ones will not protect you from high temperatures), and put rubber boots on your feet.

5). The house should have a first aid kit containing, in addition to the standard set, anti-burn medications, in order to provide first aid to the victim if necessary. The moonshiner must know how to use these products.

6). Provide quick access to emergency shutdown of the device (gas, water, electricity supply systems). In the event of an emergency, it should take a few seconds to shut down the systems.

7)

Visually check the condition of the equipment, paying special attention to the cooling system. It is advisable to equip the distillation cube with a blast valve and a thermometer

8). Protect the access of unauthorized persons to the room in which distillation (rectification) is carried out. Children and pets pose the greatest threat.

9). It is advisable not to heat the cube over an open fire (open fire is prohibited in rectification) so as not to burn the tubes and hoses. Electric stoves or induction analogues reduce the risk of fire. As a last resort, a gas stove with properly functioning burners will do, but not a fire.

Design and principles of operation

The design of the distillation cube is extremely simple - it is a cylindrical or rectangular container, equipped with the necessary pipes, and can have a removable top. Also, the structure of the unit can be supplemented by heating elements and a thermometer installed inside the container for more precise regulation of the moonshine distillation process. Homemade specimens can be made of aluminum, for example, when a food flask is used as a basis, from enameled steel, most often this is associated with the use of an ordinary saucepan or pressure cooker as a workpiece, or from stainless steel, if a keg is used as a basis.

A factory still is most often either copper, which is preferable for grain and fruit mashes, or again made of food-grade stainless steel.

The operating principle of the distillation cube is as simple as its structure. The mash inside the container boils and turns into steam. After this, the evaporated substances enter, depending on the structure of the moonshine still, either directly into the refrigerator, if this is the simplest design, or undergoing additional cleaning in a steam steamer and / or bubbler, if the design is simple, but with some additions, or through a reflux condenser or a rectification column, if the moonshine still is a serious installation for rectifying alcohol.

How to insulate?

Some craftsmen manage to insulate the distillation cube even with the help of an old cotton blanket or sweatshirt. But this is only permissible for cubes equipped with heating elements, and only in such a way that the surface of the “insulation” does not come into contact with the connection point of the heating element.

But today's building materials market offers us excellent heat-resistant foil insulation, moreover, at an affordable price. Why not take advantage of them. Visit any construction or plumbing store and choose for yourself a roll of insulation, covered on one side with a ball of foil.

Be sure to check that the base material is fire resistant (basalt or mineral wool, fiberglass meets this requirement). Your cube will not only be insulated, but will also look aesthetically pleasing.

Create reliable stills with your own hands to distill excellent moonshine that you won’t be ashamed of in front of your guests. Like if you liked the article. Don't forget to share it on social networks.