The most powerful bow as a hand weapon (excluding crossbow) is considered to be a compound bow. It is a very powerful throwing weapon with pleasant ergonomics (or even design). The projectile exit speed is about 90-100 m/sec. The design is initially capable of confusing due to the presence of a large number of elements of very different shapes. An arrow is usually used as a projectile - long, with feathers and a feathery tail.

Compound bow.

What is a compound bow

The essence of the design is the presence of a pair or several pairs of asymmetrical blocks with eccentric axes. This device works as follows:

- The tension of the bowstring bends the shoulders, which are tightened by cables.

- The cables go through blocks that wind them, twisting and moving around their axis.

- The tension of the bowstring and the shape of the blocks create potential energy, which, when the bowstring is released (when the fingers unclench and nothing holds the bowstring), turns into kinetic energy.

- In this case, the extremely sharp, impulsive movement of the bowstring gives movement to the arrow, which leaves the bow guides with high acceleration and rushes in a certain direction.

The high pulling force of the bowstring, which seems directly proportional to the tension force, is created largely thanks to the blocks: contrary to the first impression, the archer's muscular force expenditure becomes lower, and the bow's tension becomes greater.

Compound bow. The most interesting thing is the distribution of the appearance of energy over time. Maximum kinetics is imparted to the arrow not at the very beginning, when the shoulders begin to work, but at the end, when the blocks are activated, which rotate the shoulders with acceleration. This adds acceleration to the arrow.

The downside to the operation of the blocks is that when collecting the cables and tightening the bowstring, a certain moment of their peculiar bending occurs: the block is rotated, after which the reverse opening requires a little effort.

This leads to the fact that holding a compound bow in a tensioned state is much less energy intensive than for other designs. As a result, aiming and waiting are performed for an increased amount of time.

These and some other features of the compound bow make it an almost ideal weapon for a hunter or fisherman.

The evolution of the bow to a block design brought its production into the enterprise: while a conventional bow was made by hand, with the development of technology and increasing demands, such a design became quite complex. However, it is possible to create a compound bow on your own, even at home.

Varieties

Among all the popular models of bows for hunting, the following classification can be distinguished. Each option is more complex in design than the previous one:

- The traditional bow for hunting seems to have come to us from our ancestors - similar weapons were used in the old days. It is made only based on the dimensions of the hunter - height and arm span. The design is simple, so you can easily make a homemade bow for hunting; you only need one piece of wood to make it. They are not very powerful, although they are quite large, so they are unlikely to be suitable for a modern hunting enthusiast.

- The composite model is made on a wooden (modern bows are made from composite) base, which is supplemented with internal linings and tendons. The main element requires careful preparation, however, the finished products are much closer in shape to sports models than simple ones.

- A compound bow is a powerful hunting weapon that has sufficient ergonomics and a high arrow launch speed (90 m/s or more). Their production has moved to factories, since the design of the blocks is difficult for manual assembly, and it is unlikely that you will come across a good homemade compound bow. For the most part, these models are sporting, but such weapons are best suited for hunting purposes.

Tools and materials

Compound onions are made in a number of ways and in various designs:

- from lumber and round wheels;

- from plastic pipes (PVC or other elastic polymer) or skis;

- from metal springs or simply metal plates with high shock absorption.

It is possible to create a design yourself. People have long tried different methods in large numbers.

For example, a tolerable onion at home is made from the following materials:

- lumber bars without visible defects, dimensions – 50x4x2 cm, 2 units;

- bars measuring 17x4x2 cm, 2 units. (cuts are made in each for springs);

- bars with a length of 45 cm, 2 units;

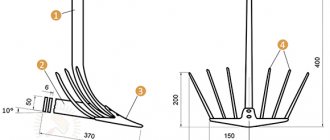

- springs – 2 units; Necessary parts for collecting onions.

- metal wheels, 2 pcs. (symmetrical ones are also allowed - the size is suitable for a car window lift);

- steel furniture corner, 8 units;

- steel door hinges (suitable for furniture), 2 units;

- corners with a width of up to 4 cm, 2 units;

- studs with a length of up to 5 cm (under the axes of the blocks), 2 units;

- U-shaped fasteners (for fastening blocks), 4 units;

- self-tapping screws for wood, up to 35 units. regular and up to 5 units. longer;

- synthetic rope or bowstring cable - depending on the size of the assembled structure.

To process materials and install elements you will need the following tools:

- wood hacksaw or jigsaw;

- a hacksaw for metal (will replace the first one if it is missing);

- screwdriver for hardware;

- file and sandpaper.

Hunting pneumatic arrow throwers

Of course, gunsmiths could not ignore the pneumatic principle.

A few years ago, a slight stir was caused by information about the appearance on the market (albeit foreign) of a certain superweapon - Airrow Stealth Model 8S1P (pictured)

Either a CO2 cylinder or compressed air was used as an energy source. This example, costing under $2,000, sent a 16-inch 2512 boom (Easton XX75) at speeds of up to 600 ft/sec, or more than 180 m/sec. Such indicators are unattainable even for modern compound crossbows; 410 fps is still a kind of “ceiling” for production models.

One point was not at all clear - what to do with the plumage? For devices operating over short distances, it is not necessary, and under water it completely interferes. But for the stated speeds of Airrow Stealth, the distances must be hundreds of meters. It was suggested that some cunning modifications of arrows were used here, which, like cruise missiles, opened the tail after leaving the barrel. As it turned out, the trunk was precisely the solution - it was no coincidence that manufacturers asked such sums for their products, since the design turned out to be very complex.

In fact, in this case, a standard crossbow arrow acted as an over-caliber projectile and, with the “heel” removed, turning into an ordinary aluminum tube, it was simply put on a thin inner barrel. Well, the thick outer one served as a kind of figured guide, inside which the feathers of the stabilizers and the blades of hunting broadheads slid without being damaged.

By and large, the “Airrow Stealth” cannot be called a crossbow either. Yes, the technical solutions used in it are very ingenious, but still the device itself is nothing more than an air gun (gas-cylinder or pre-pumped), on the basis of which it was created. The manufacturing company, in fact, specializes in the production of air rifles. They are mainly known among hunters, since the range of models covers all major calibers - from the classic .177 for airguns to the mighty 38.

The same can be said about the new product on the market - the Pioneer Airbow arrow thrower from the famous manufacturer of air rifles and pistols, also produced under the Benjamin brand.

This is a very real hunting machine, delivering a solid 450 fps, or almost 140 m/s, with a hunting arrow weighing 375 grains. These indicators are quite enough for this:

Of course it's impressive. And yet the deadly “Pioneer”, like the previous model, is also not a crossbow. This is, in fact, the same air rifle with PCP pre-pumping (see “Air rifles for hunting”), which served as the basis for our hero. Here it is, my dear, “Crosman Benjamin Bulldog .357 Realtree-Xtra”:

Moreover, the domestic armory (formerly Luftmaster), known for its Lesnik PCP rifles and the ultra-compact Anchutka, a new product on the market, began accepting orders for the Kashchei pneumatic arrow gun .

It is based on the same technical solutions as the Pioneer, only the price is completely different for obvious reasons. By the way, “Kashchey”, in order not to conflict with weapons legislation, is certified as a “device for installation, rescue and reconnaissance work in hard-to-reach places.” Well, that's not a bad idea. I know the developer a little, I saw test shootings - it’s impressive.

Current insert. The first shootings of the “Kashchey” with a chronograph showed the following results: with a heavy hunting 640-grain arrow, the speed was 78 m/s, i.e. “muzzle energy” is about 126 joules. With a 350 grain arrow, standard for many throwing weapon manufacturers, speed indicators will increase to approximately 105 meters per second.

By the way, since August 2016, even ordinary serial PCP rifles can also be used to throw heavy hunting crossbow bolts (see “Air Arrows”).

Pictured is the " Seneca Recluse 500cc Ultimate Hunters Combo ".

Update January 2022

Mountain Air arrow launcher: our next response to the overseas Pioneer

Colleagues warned me about the imminent start of production of the device presented below in advance - almost two months ago, at the beginning of December 2022. Well, the long-awaited new product has arrived on the arms market!

I think “ Mountain Air ” (pictured) could become a bestseller not only here - at the very least, but 450 fps with a 450-grain bolt. The same famous “Benjamin Pioneer Airbow” produces seemingly the same 450 fps, but with an arrow weighing only 375 grains. And at the same time it costs from 999 dollars, and not with us, unfortunately. Yes, with a set of arrows, but this is not ice - the bolts are original, “pioneer :)), ordinary crossbow bolts will not fit...

It is clear that it is difficult for any manufacturer to compete with the global Crosman Corp (now Velocity Outdoor, see “Where Crosman pneumatics are made”). But - honestly! — I would like to wish our colleagues success, including commercial success. Moreover, they have another premiere on the way - a “universal soldier” :)) with interchangeable barrels, capable of acting both as a arrow thrower and a classic PCP rifle.

PS So, according to strictly confidential information that has just arrived, “Mountain Air” has just replaced the hero of Russian folk tales “Kashchei”.

Update, October 2022.

The Newest "Pneumatic Crossbows" of 2022

Comrades, progress cannot be stopped - this year several more samples of arrow throwers from mass producers of pneumatics entered the arms market.

These are two models from the German “Umarex” (pictured “ Umarex AirSaber”

)…

...and the super-powerful Hatsan Harpoon (photo below). Read more about them in the article “ New models of air guns. Part 2 ".

So, such devices, or more precisely, most of them, cannot be called crossbows in the true sense of the word, at least on formal grounds. However, these devices, mainly based on pre-pumped air rifles (PCP), have become increasingly popular in recent years, especially in the hunting field.

It would seem that it makes no difference what and how the projectile is pushed, the main thing is that it should be an arrow. But, following this logic, the APS (Automatic Underwater Special) can be classified as crossbows.

Something is clearly wrong here...

Selection of components for onion harvesting

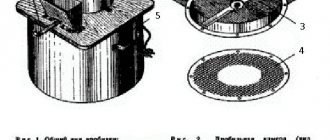

Components of a compound bow.

For the manufacture of a bow as a structure subject to repeated bending and high stress, it is important to select the highest quality materials.

Regardless of the type of material (wood, metal, fiberglass or ordinary plastic), no defects are allowed: curvatures, pores, cracks, foreign inclusions and knots can lead to breakage of the bow at the most important moment.

The bow itself is not as important as damage to the face and organs of vision, which are constantly near the weapon when using it.

Excessive humidity and mold are also unfavorable.

Making the handle

Preparation for onions.

Creating the handle requires care - the remaining parts will be mounted on it.

- Short ones are attached to the longest bar using furniture corners.

- After installation, the longest self-tapping screws are screwed in for reinforcement.

- The assembly is sanded with emery, during which the original shape and roundings are given.

- At this stage or earlier, planing with a knife is performed to obtain the required shape.

Material to create

Among wood species, yew is optimal - flexible and durable. Also suitable:

- willow;

- ash;

- juniper;

- cedar.

When harvesting with your own hands, cutting is carried out in cold weather. The bark is removed only after drying. It is recommended to use a variety of impregnations and protective compounds.

Gluing the handle

The most effective is a solid piece. If there is a need to increase its size or obtain significant arrow reach power, there is a way to create a multi-layer handle.

- Blanks made of plywood, boards or composite material are coated with glue (special high-strength - for composites or helicopter type) and wrapped in gauze.

- Fiberglass is much more reliable, but at home there are enough materials at hand.

- The blanks are laid out on top of each other and covered with glue.

- The resulting sandwich is assembled to the required thickness.

- At this stage, bending is performed - it will be difficult to bend the dried structure.

When forming, self-tapping screws are useful - but in small quantities and with a symmetrical installation.

Hole for fastening

Holes and grooves are made in the arms (short bars) for installing wheels.

- Pins with wheels are threaded into the holes.

- The studs are covered with angles or U-shaped brackets and attached to the handle with short self-tapping screws.

How to make and stretch a bowstring

In addition to synthetic rope, which has a limited service life due to abrasion, other materials are used:

- nylon thread (is wear-resistant, but the thickness leaves much to be desired);

- fishing line (designed for high dynamic loads);

- cord made of lavsan, polypropylene and other polymers;

- slings from climbers' equipment (Kevlar fiber created for extreme conditions).

Natural fiber works best.

- A string selected according to its length is placed into the grooves of the arms and wheels, and the ends are secured.

- The arms are screwed to the middle of the handle.

- Corners are mounted to them, and springs are placed on them.

- Changing the degree of initial tension of the bowstring is performed mechanically - by angular movement of the shoulders relative to the handle.

Making a bowstring with your own hands.

What do you need for arrows?

A stand is required for the arrow - it will save the bowstring itself and your fingers. A piece of sheet metal or hard plastic is suitable.

Arrows for a bow.

How to make a bow with your own hands - designs, sizes and detailed description of how to make a weapon

Surely many would like to have a bow and arrows made with their own hands. In this article we will tell you how to make this dream come true.

Preparation of material

The arch will be made with your own hands from acacia (can also be ash or elm) with a trunk diameter of about 15 cm and a length of at least 1 meter.

It would be nice if the barrel was a little thicker. This will make it easier to “find” the shoulders of the arch in the body. The trunk should be fairly straight, not twisted, without knots or branches.

This "trunk" can also be a large branch. If someone has access to a two-meter log that meets the above conditions, they might be tempted by a bow made from a single piece of wood. Then he will skip the gluing step.

What other wood is used

For production you can take ash, rowan, willow, juniper, oak, birch. It is recommended to cut the branch in winter after frost. Before making a bow and arrow, it is necessary to determine the opening of the future shooter's hand.

Cutting a branch takes longer than cooking the onion: the broth can be up to 30 cm. A branch 3-4 cm thick should be flat, without knots. Wood plays an important role in how to make a bow and arrow with your own hands.

Barrel processing

So where to start making onions with your own hands? With barrel processing. Below are instructions.

The trunk should be cut with an ax so that it has straight cut ends, which should be painted with rubber paint. This will allow you to monitor the wood as it dries and possibly prevent cracks from occurring.

The trunk is then cut in half. If there is a knot, the cutting line should intersect it. This requires 2 wedges and a hammer. The ax can be used as a wedge, but understand that the ax can be broken. A wedge is inserted into the thicker end of the barrel.

When the wood breaks, a second wedge is inserted into the crack to free the first. These steps are repeated until two strips of wood are obtained.

Note. If the trunk breaks asymmetrically, it should never be “straightened.” It is possible that one of the parts will no longer be useful for anything and will have to get rid of it.

The bark is removed with a sharp ax (or other tool, such as a plane). After this, the tree is placed in a dry and cool place.

The main idea behind these steps is to dry the wood slowly and evenly. In the notes of the old masters it was written that the target humidity should be 10%. If you have nothing to measure, you will have to trust your instincts.

The above mentioned events can also be separated from each other by a break of several days. There's no rush here. Drying should last at least 2 months.

After about 5 weeks, you can gradually move on to the next stage. The wood is still too wet, but removing any unnecessary excess will speed up the drying process a little.

If during this time the pieces of wood begin to become covered with white mold, they should be placed higher in a drier place so that they do not collect moisture from the soil. If cracks appear during drying, the wood should be moved to a cooler place. The reason for these shortcomings is the lack of bark on the trunk.

Next, the most beautiful piece of wood is selected. Now you can get started; When making a compound bow with your own hands, the steps may vary.

"Finding" the arc

The base surface is the part of the tree without bark. This surface is processed to a minimum.

Another thing to pay attention to is the rotation of the barrel. A twisted barrel is not suitable for bows. You can try to make corrections, but the chances of success are low.

After determining the position of the bow arms, a dividing line is drawn between them. The shoulders need to be separated so that they can be connected again, but in a slightly different way. The trunk is cut with a saw.

An ax or plane removes fragments that are definitely not useful. Leave to dry further. You can’t be too zealous here, as a very thin block will warp when drying.

You need to leave a little more material at the ends, which will serve as a connecting piece. If you plan to make carved griffins, this must also be taken into account when planing, leaving an appropriate allowance.

It should be understood that this piece of wood once lived its own life. And now it needs to be revived, but in the form of an arch. All steps need to be done slowly and carefully to make a bow with your own hands.

Shoulder gluing

A wedge-shaped notch is drawn on one of the shoulders (exactly on his back). The diagram can be found on the Internet. The cut should be 10-15 cm long. The marked fragment is cut out.

If something went wrong, it needs to be fixed. The second lever is sharpened for a cut wedge. First with an ax or saw, then with a wooden file. It is important to adjust both shoulders so that (when viewed from behind) they form a straight line.

You can help yourself by drawing an axis of symmetry on them. Then three nails are driven superficially along these axes: one near the future connection and two on the griffins.

If all three “coincide” with each other, the arc is straight. Epoxy resins are best suited for gluing. After joining, everything is twisted using carpenter's clamps or rope or twine.

The seam reaches maximum strength in a week, but the arch can be worked on in two days. After gluing, it is recommended to check whether the arms are offset relative to the axis. The previous model is used for correction.

Excess wood outside the lines drawn on the template is removed. A second model is drawn showing the thickness of the shoulders. If your shoulders are bent, this line is best drawn with a ruler. After submitting the application, the premium is removed. Traditionally, you can use a plane, saw or axe.

In this form, the arch should resemble a rectangular strip. The surface of the convex was rounded with a file so that the cross section was shaped like the letter “D”.

Slowly but surely the process of creating a combat bow with your own hands is progressing.

Arc formation

To form it, you will need a beam of approximately 10x10x100 cm; a homemade crossbow and a future arch are made from this beam. To do this, “thresholds” are made on the bar, cutting them every 5 cm along the entire length. They must be deep enough to hold the rope.

Instead of thresholds, you can nail short nails that will perform the same function. The end on which the bow hilt rests is inserted into the saddle so that the bow is firmly attached to it. In one set, the string is made approximately 10 cm longer than the bow.

The “crossbow” is attached by pulling the bowstring onto the griffin, and the bow handle rests on the crossbar saddle. Gradually he moves on to the next “thresholds”, looking around the back of the arch. If you bend more, it means it is weaker. Then the next file is archived.

The shoulders should bend evenly along the entire length, except for the handle. Otherwise, the hardest parts of the shoulder are sawed off. Throughout the process, it is necessary to maintain the arch and not stretch it to its maximum length before it is formed. Of course, only the convexity, that is, the inner part of the shoulder, is processed.

Very often it turns out that the formed arc is too difficult for the archer's skills. To reduce the pulling force, it is necessary to trim both arms evenly from the middle side and reshape the bow. Then measure the voltage again. And so on until the end.

At the end of the work, the file is replaced with increasingly fine-grained sandpaper. The operating time will, however, increase, but the effect will exceed expectations.

This phase is perhaps the most tiring of all, and at the same time the most difficult, because without “getting used to” bending the bow, it can break.

Bowstring

An ideal bowstring should be thin, strong and not stretchable. The thinner the string, the better the bow's performance. However, it must withstand arc voltage of more than 7 times. The best material in terms of availability, price and parameters is the so-called dratva linen.

Practice shows that a drape folded 8 times can withstand a load of up to 25 kg. You can reduce the number of fibers to obtain better parameters, but this increases the risk of string breakage and, as a result, bow breakage.

You should remember about strengthening fragments that work with an arrow (sleeve) and griffins (rings). In these places the bowstring most often breaks. The bowstring has one or two rings.

In the case of two rings, it must correspond to a certain arc length. Once he has it, the archer ties the free end to the crossbar, drawing the bow. Thus, he has the ability to adjust the degree of deflection of the bow.

Here the terminology is noteworthy: the archer draws the bow, threading the string, and draws it back, preparing to fire.

There are many ways to weave fibers. Examples can be found on the Internet.

Service

Do-it-yourself wooden arches are very sensitive to moisture and must be protected from moisture. Otherwise, it may become permanently deformed. In turn, it should not be overdried (for example, over a chimney), otherwise it will dry out and may crack.

Modern wood paints effectively prevent the exchange of moisture with the environment and are recommended for people who have limited choice of storage space. However, experienced experts say that the onion must “breathe”.

To make this possible and at the same time protect it, the raw wood is regularly rubbed with warm linseed oil. However, this is a dirty job that needs to be repeated periodically.

What other options

An intermediate solution when caring for onions at home can be painting the onions with linseed oil. The aroma is not very pleasant, but it is excellent as an impregnation. However, after 24 hours the smell disappears.

Regardless of the chosen method, archery accessories must be protected from dust and moisture; Wipe them with a dry cloth from time to time.

Decoration

A bow must first shoot well and only then look good. Therefore, you should wait a little with decoration. It's better to shoot and test the bow first.

It is possible that after a while you will have to make small changes. Its handle and griffins can be shaped using a sharp knife and small files.

Alternatively, leather tape or linen cord can be wrapped around the handle to disguise the gluing area. One of the decoration ideas is to make an original inscription on the shoulders.

Good. The wooden arch with your own hands is ready!

Bow assembly

The process occurs without any particular difficulties. However, deviations may occur that can be easily eliminated:

- the selected material must be qualitatively homogeneous; if critical defects appear, the part must be mercilessly replaced;

- it is optimal to purchase blocks - for the first model, ordinary wheels are also suitable, but for high shot power you will need real products with eccentrics;

- To modernize and increase accuracy, a stabilizer and a rod are installed.

"Finding" the arc

The base surface is the part of the tree that has been cleared of bark. This surface is treated to a minimum.

Another thing to pay attention to is the twist of the barrel. A twisted barrel is not suitable for a bow. You can try to make corrections, but the chances of success are low.

Once it is determined where the bow's limbs will be located, a dividing line is drawn between them. The shoulders need to be separated in order to be reconnected later, but in a slightly different way. The trunk is divided using a saw.

An ax or plane is used to remove fragments that are definitely not useful. Leave for further drying. You can't be too zealous here, as the very thin strip will become deformed when drying.

Note!

- Do-it-yourself winch: classification, manufacturing materials, description of work stages + instructions for DIY construction

Do-it-yourself clamp - step-by-step production and description of options for using a clamp

DIY knife | A step-by-step description of how and from what materials to make a homemade knife

You need to leave a little more material at the ends, which will serve as a connecting element. If you plan to make carved griffins, then this must also be taken into account when planing, leaving an appropriate allowance.

It should be understood that this piece of wood once lived its own life. And now you need to make it come to life again, but in the form of a bow. All steps must be performed slowly and thoughtfully in order to be able to make a bow for shooting with your own hands.

Bow hunting

Due to its quality and properties, the bow is suitable for hunting birds and animals. But the following fact is of critical importance: the use of a bow (not just a compound bow, but such weapons in general) as a hunting tool is prohibited at the legislative level. It is not included in the lists of hunting weapons.

The use of a bow is allowed only for entertainment and sports purposes, subject to safety precautions.

- However, in fenced areas, training use for hunting purposes is allowed - with strict control of the actions by an experienced shooter and without the presence of unauthorized persons. The danger of a bow lies precisely in the fact that a mushroom picker or simply a lover of forest species is under the threat of a silent shot and the arrow itself.

- The bow is selected or made exclusively for yourself, otherwise posture and muscle function will be negatively affected.

- It is important to move slowly with a bow.

- If the arrow is inserted and the bowstring is pulled, it is never allowed to point the bow at a person.

- The shot (like releasing a bowstring) is done softly. To protect the hand and fingers, special gaiters are common - archer's gloves.

Hunting with a compound bow.

Quiver for arrows

As for the quiver, it is recommended to use durable, rigid material to make it. It is advisable to make a frame so that the arrows can be easily retrieved. The best option is a quiver with a semicircular bottom. He won't interfere. A round-bottomed quiver can roll around on your back, causing trouble. But it has a lot of capacity.

The frame can be made from branches, wire, the quiver can be sewn from felt fabric, and decorated with linen material. Or make it from leather, leatherette. A regular thick plait or braided rope will help position the arrows behind the shoulder. You can take them out at any time, point the bow at the target, and make a well-aimed shot.

Decoration

A bow must first shoot well, and only then look beautiful. Therefore, you should wait a little while decorating. It's better to shoot and test the bow first.

It may be necessary to make minor changes over time. Its handle and griffins can be shaped using a sharp knife and small files.

In addition, the handle can be wrapped with leather tape or linen cord to disguise the gluing area. One of the decoration ideas is to make an original inscription on the shoulders.

Great. A DIY wooden bow is ready!