A dacha is not only a place for growing plants, but is also a symbol of summer relaxation and prosperity. The dacha is considered an example of a cozy atmosphere. Textiles play a big role in creating a beautiful environment. Curtains for a country house are available in a variety of styles, materials and colors.

Light window curtains

Do-it-yourself carpentry workshop: expectations and reality

Why make a carpentry shop at all? I don't have a definite answer. If you just want to make something with your hands from wood, then there are workshops where you can come, pay money to rent machines and a workplace, and do everything there. It is not necessary to have your own premises and your own equipment. If you want to engage in woodworking as a business, then the competition here is high, and it’s difficult to find your niche. So I'll start by explaining my own motives.

It all started in 2015, when I realized that my old shed at the dacha would soon fall apart and I needed to build a new one. I calculated the required area, amount of materials, estimated costs and construction time. I poured the foundation, bought wood the next year and started building with a friend. Initially, I did not intend to make a workshop. I was just building a new shed to replace the old one to store tools and equipment.

Naturally, everything went wrong during the construction process. A friend said: “We have such cool six-meter beams, why are we going to cut them?” And he suggested building a two-story barn. If you've ever built a frame structure, you can see that we've made a ton of mistakes. Now I am gradually strengthening and remodeling the barn. The next catch was the desire to make a basement: “We haven’t sewed it up yet, let’s dig it up and pour concrete?” In general, I spent a total of two calendar years on the basement. Because of it, I could not cover the floor on the first floor, although I already had a sheathed, fully finished barn. Only there was a floor on the second floor, and a pit on the first floor. It got flooded a couple of times, overall it was a lot of fun. So my advice is: don't make basements if you don't need them. There are now two boxes of apples in my basement; I don’t actually use it.

We wanted to make furniture, and this became the first obstacle that was not obvious to me. Woodworking is a rather difficult task. Here you need a lot of specific knowledge, which, on a whim, can take a very long time to acquire. Therefore, I advise you to read specialized literature or study somewhere. And then I didn’t understand this at all: “I have a machine, I have some money, I’ll buy other machines and do everything.” Naturally, it didn't work out that way.

I began to figure out what manipulations with wood I needed to do and what I needed to buy for this.

Sawing

First of all, the workpieces need to be trimmed

- make even cuts

perpendicular

to the workpiece. It doesn’t matter what kind of furniture you make, stools or cabinet sets. It is important to be able to cut accurately, ideally also at certain angles.

If you are a serious enthusiast, you can do this manually using a miter box. But still, a miter saw is a must-have in a carpentry workshop. It will be difficult without her.

It is desirable that the saw has a broach, that is, it allows cutting fairly wide workpieces. The tool is good and not particularly expensive. The main thing, as with any other tool, is that there are no backlashes and you can set the angles you need.

The tree also needs to be dissolved or trimmed

, that is, sawing

along

. To do this, you need a circular saw, preferably installed in a cutting table. You can also unravel using a manual circular saw with a parallel stop or along a guide rail, but it is much more convenient and productive to do this on a table.

With planing

For wood, the situation is more complicated, because it is not easy to plan a wide enough workpiece with a hand plane. To do this, you need to develop skill for a long time, remove wood in different directions, taking into account the location of the fibers, constantly monitoring the uniformity of removal across the entire width and length of the workpiece. Simplify your life - but do not improve the quality of processing! - can be done using jointing and thicknessing machines.

Important: a thickness planer does not replace a jointer, but complements it!

The jointer allows you to first obtain

one flat plane

of the workpiece, and the thicknesser,

based on this plane,

levels the opposite side. For beginners, this combination of two machines makes it easy to obtain even workpieces of relatively large length and width, uniform in thickness. This is very important when making furniture. But buying two machines is very expensive and often redundant for an amateur. Therefore, there are a lot of tutorials on the Internet on how to make a surface planer or jointer from an ordinary hand plane and two blocks.

Threads

Just like fabric, threads provide enormous scope for the use of imagination and the embodiment of the flight of creative thought.

A charming topiary will be a great gift for a woman. To make it, you only need to take a balloon, thread, glue, a cocktail stick, and a pot for home flowers. All this can easily be found in every home. But the admiration of the recipient of the unusual plant will know no bounds.

The remaining balls of yarn will be used to make pompoms. From fluffy lumps you can later make:

- decorations for keychains, handbags, clothes;

- hair accessory;

- soft toys for children;

- unusual rug;

- photo frame.

If you want to try yourself in the “real” business, you can knit a soft scarf or warm socks. Both do not require much skill or talent.

In the future, the set can be supplemented with mittens and slippers.

Turning

The three operations described - trimming, jointing and thicknessing - will allow you to make only some very simple products. In a good way, you still need to master turning, that is, turning workpieces that are figures of rotation. For example, round legs for a stool or table, vases, bowls, or some other products. And in this case, you can’t do without a lathe. Of course, you can turn to the experience of generations and make an adapter from shit and sticks, with the help of which you can turn cylindrical blanks on a circular saw, but this is a dead-end path.

If you want to make something more complex than a cylinder, you will have to buy a lathe. Fortunately, this is one of the simplest machines; it consists of a cast iron frame, a motor, a collet and a stop for a chisel (rest). You can find many interesting models on the secondary market, and there are also quite a few new modern models.

In order for you to get high-quality furniture, if you want to make it for yourself or sell it, you will have to equip the workshop with many other equipment.

The nuances of creating garden crafts

If you decide to decorate your yard yourself, then don’t rush. First, you need to carefully study the photos of garden crafts that are available on the Internet and the descriptions for them.

If you want to build something new, that’s only a plus. The main thing to remember is that the design of the landscape should be in harmony with the future decor.

For an original and thoughtful landscaping of the territory, it is necessary to adhere to the following sequence of steps:

- Exploring possible design solutions for garden crafts.

- Drawing up a plan for their location on the land adjacent to the house.

- Assessing your own capabilities. Making adjustments to the diagram.

It is logical to arrange garden crafts from scrap materials in accordance with their purpose:

- for figurines of snails, waterfowl, and amphibians, the best place is the shore of an artificial reservoir;

- songbirds, owls, birds of prey, squirrels are appropriate in trees;

- The hedgehog can be placed under a bush.

In addition, the dimensions of landscape decorations must correspond to the size of the territory.

Drying

The wood needs to be dried

, and dry

according to a certain method

. Wood is usually sold at “natural moisture content,” meaning it contains about 25–40% moisture. If you make something from such wood, then as it dries the product will warp and crack. Regardless of how many layers of varnish you apply to it. Generally speaking, wood is a living material and is subject to seasonal changes in air humidity, which is why its linear dimensions fluctuate throughout the year: in length (along the fibers) the fluctuations are extremely insignificant, and in width a piece of wood can swell and shrink by tens of millimeters, depending on the overall size of the product.

Therefore, the main rule is that the wood must first be dried to 8 - 12% humidity, only after which it can be used.

How to dry wood in an apartment? Carefully fold the boards as far away from the radiators as possible, arrange the layers with bars of the same width and press something on top. It is advisable to coat the ends with paint, since this is where moisture evaporates most intensively and cracks may appear along the boards. It’s great if you can buy chamber-dried wood that has already been dried; this will help you avoid numerous defects if you start drying it yourself.

Bend

Probably almost all of you have seen such beautiful tables and chairs with bent legs. It looks very impressive. If such legs are cut and sawed out, they will turn out to be much less durable, because the longitudinal integrity of the fibers will be damaged. It is best to achieve this shape by bending the wood. To prevent workpieces from breaking, you must first increase their ductility. In production, chemical plasticization of wood is used, and amateurs usually have only one method available: first moisten the wood and then heat it, after which they can gradually bend the workpiece.

rooms for the night on the Kuzminki metro

Tree of joy for beads

Convenient because you can see everything at once. The more decorations, the larger the tree needs to be “grown”. The wider the base should be.

Prepare:

- wire (0.7 mm);

- paint+gilding;

- plaster + cup for it;

- PVA;

- white paper napkins;

- tape

Build a tree frame from double wire. “Break” each branch several times, then the number of places for things will increase. Wrap the result with tape. According to the instructions, dilute the plaster mixture and insert the frame into the center of the bowl. When the plaster dries, soak napkins in glue and cover the branches and trunk with pieces. Stop for a few hours until it dries. Then cover with paint, apply gold tone into the dents. Dry it. In addition to beads, the tree is suitable for storing earrings and bracelets. Take your treasures out of the box and hang them on branches in a convenient order.

Milling

A very useful and often necessary operation in woodworking. If we are talking about furniture, then at a minimum, you will have to mill the edges of the products, rounding them (I do not consider the option of manual processing with moldings). To do this, you will need a manual router, which would be nice to complement with a milling table with a more powerful machine installed in it. However, at first, one medium-power router is more than enough, if necessary, placing it on a table or using it manually.

Veneering

Previously, this term was used to describe the procedure of gluing carpentry products with plywood - thin sheets of wood of other, more valuable varieties. Nowadays we understand “plywood” as multi-layer laminated boards, and we call thin wood sheets “veneer”. Accordingly, instead of “veneering” today many people say “veneering”. Using veneer, you can give a beautiful, even sophisticated look to products made from “simple” types of wood that grow in our latitudes. For example, oak veneer can be used to cover birch furniture. By the way, today many examples of furniture, including “elite” foreign ones, are actually covered with veneer of more valuable species and are sold as made from solid wood, at much higher prices.

I don’t recommend that beginners start gluing veneer right away, since this is a non-trivial task that requires skill, patience, and in the case of large parts, also serious equipment in the form of powerful presses or vacuum bags for uniform gluing of veneer.

What to create site decor from

Having some skills in construction and having leftover building materials on hand, you can come up with a lot of decorative items to decorate your dacha or suburban area.

In fact, there are a lot of available materials from which you can create decorative elements; the main thing is to listen to your fantasies and boldly follow their realization. So, what can you put into action:

- Plastic and glass bottles

- Car tires

- Old, worn-out pots, barrels, buckets

- Wooden pallets

- Leftover building materials

- Pieces of furniture that have lost their appearance and functionality

- Broken flower pots and stuff.

Armed with the proposed ideas for creating decor, you can create truly unique compositions and items to decorate your site.

Gluing and protective and decorative coating

These are the main operations after the manufacture and assembly of the parts themselves. And for their implementation certain conditions are required. A barn is not a house; it is not heated. When I started carpentry, I realized that I couldn’t glue or paint it, because it was already winter outside and the workshop was too cold; I couldn’t even store materials at that temperature. At the same time, it is uncomfortable to work in a cold workshop.

This, of course, upset me very much, because insulating the barn would have been quite expensive. I recommend that you either immediately take care of insulation, or during the cold season, do gluing and painting in other warm rooms.

Suspended structures

Anything that can be hung on a hook, on a nail, on a loop, on a rail, on a crossbar, on a branch can be called a “hanging structure.” Old rubber boots nailed to the fence and serving as flower pots fit perfectly into this category.

This includes a “battery” of plastic bottles, up to half filled with soil, tied by the necks to a strong stick (pole, cornice, bracket), with slots for planting and watering and used for germinating seedlings. They can be painted, or they can be left in their original form - even so they look quite attractive.

A special place among crafts made from improvised materials is occupied by hanging flowerpots made from baskets, mayonnaise buckets decorated in various ways and figuratively carved car tires.

An interesting decorative solution could be a bicycle hanging on a fence, used as a shelf for flower pots. This composition exudes romance and mischief; it is easy to make and pleasing to the eye.

Connections

In carpentry, there are many types of joining parts to each other, differing in practicality, strength, aesthetics and durability. I will not talk in detail about all types; this is a topic for a whole book. Most often, parts are mechanically connected to each other using tongue-and-groove or dowel joints, which are coated with glue.

Everyone knows about purely mechanical connections: parts are attached to each other using screws, self-tapping screws, eccentric connections, and other metal devices.

Setting up a workshop

After spending a couple of years on a barn with an unnecessary basement, I arranged all the machines around the workshop and made a dust removal installation: I took a construction vacuum cleaner and installed a cyclone filter on a two-hundred-liter metal barrel. Class! Now there will be no dust. And then I realized: the vacuum cleaner consumes 1.5 kW, the miter saw another 2 kW, not counting other devices, I looked sadly at the wire through which electricity was supplied to the shed, and realized that nothing would work out for me. I turned to electricians and asked them to install a three-phase line for me. These wonderful guys have been dynamizing me for a long time, and I think that I won’t be able to defeat them, I’ll have to go somewhere else.

I started setting up the workshop with a workbench. Moreover, in the end, I did it in the wrong place where I placed the dust removal system, and I had to move the vacuum cleaner.

The miter saw is recessed so that its own table is flush with the workbench. Thanks to the folding tabletop, a whole sheet of plywood can be placed here, which can be conveniently cut.

Then I installed the vice and spent a lot of time on it. The stand for the drill is not yet fixed, but is also built into the tabletop, it is convenient to use for drilling end holes.

Due to insufficient power supply, I didn’t even start the machine, I will continue to fight with the power engineers.

But all I’ve managed to make with my own hands so far is a sand painting table for my daughter:

I made it quite quickly, in about 20 hours, because by that time I already had all the necessary tools and equipment. Moreover, it took about 6 hours to process the blanks to give them the shape of a parallelepiped.

The table is simple: a box containing 8 meters of LED strip, a controller and a power supply. First, I processed the boards, processed the edge with a milling cutter and glued the entire structure. It turned out very crooked. If you look closely, you can see in the photo that I filled the seams at the joints with a mixture of sawdust and PVA glue. But it holds strong.

The compartment for tools and sand is screwed on with four barrel nuts. It was here that I realized the usefulness of a drill stand, because drilling into the end is very difficult.

Here you can see the screen itself, which is installed under plexiglass.

An LED strip is glued to it, on top of aluminum tape, with hot-melt adhesive. I thought that the tape would act as a reflector, but it turned out that it “dilutes” the spectrum of light. Plexiglass is quite easy to install. After the initial priming and painting, I inserted metal dowels, laid the glass and filled it with epoxy. It sits there like it’s native and won’t go anywhere.

I want to make two more tables, I already have blanks for them, and try to sell them, because the cost is very low. The most expensive things about them are the controller and LEDs. At the same time, I will develop my skills in processing such small-scale parts.

Source

Do-it-yourself carpentry workshop (carpentry) at the dacha

February 20, 2014. Read 76089 times

In the process of building a summer house or a country house with your own hands, a desire arises to make it so beautiful and individual that your friends and neighbors will be jealous. But even you have the ability and desire to carpenter, you need a tool and a room in which masterpieces of wooden art will be born. We invite you to consider building a carpentry workshop as the embodiment of your hobby. Although maybe later it can become your small business.

In this article we will look in detail at how to equip a carpentry workshop on your own using a ready-made example. The area of the workshop presented below is approximately 400 m² (but you can make it small). The entire workshop is divided into two rooms where the working processing machines are located.

Place for home keys

Do-it-yourself useful crafts from scrap materials are always incomparable for everyday life. Let's consider the option of a key hanger, since keys are the ones most often lost in the house.

We will need: a thick sheet of cardboard or thin plywood, thick napkins, hooks, glue, varnish, paints:

- We create a base for the key holder by cutting out a supporting wall from cardboard or plywood.

- We cut out small but equal-sized rectangles from cardboard so that they resemble bricks.

- Glue the bricks to the main cardboard.

- We generously lubricate the bricks with glue, put a napkin on top of them, which can be greased with glue in the same way for better impregnation.

- Using a pointed stick, we press the napkin into the gaps between the bricks to form corners. Leave to dry.

- After the panel has completely dried, we paint the panel; bronze paint is most suitable for the seams. After the first layer has dried, paint the second layer with a dry brush.

- We coat the product with varnish, and after it dries, we attach the hooks.

Which is better: building a new one or using an old one?

The carpentry shop will look much more functional in a new free-standing building for a number of reasons:

There is an opinion that a workshop for carpentry work at home should occupy up to 6-7 m2, but this is catastrophically not enough. In such an area it will not be possible to fit the maximum amount of equipment. Moreover, the recommended length of the room should be at least 4 m. Even if, by a lucky chance, you fit everything you need, you will not have any room left for normal work. There is nothing to say about storing material and finished products.

DIY carpentry workshop

It won't work with a garage either. This is a specialized place for the machine and risking its integrity during operation is not a suitable option. In addition, the workshop requires normal temperature conditions, which are difficult to maintain in the garage. It is also necessary to allocate space for storing car parts and tools. The barn is closer, but still unlikely to fit. Rather, such a solution will require radical redevelopment and reconstruction, commensurate with new construction. Carpentry requires a reliable foundation made of slabs. If the equipment is installed unstable, it will vibrate, which will ultimately lead to its failure. Having considered all the options, we decide to place the workshop in a newly built building.

bathhouse with veranda under one roof photo

Spectacular flowerpots made of cement and fabric

Cement and fabric planters will hold even large plants. DIY garden crafts are not inferior to finished products.

To make it you will need:

- thick cotton fabric;

- cement;

- old bucket or basin;

- polyethylene.

Procedure:

- Cover the selected container with polyethylene and secure it with tape or rope.

- Immerse the fabric in the prepared solution.

- Place the fabric on top of the bucket, carefully smooth it out and correct the folds.

- Leave for a day or two for the cement to completely harden.

- After two days, remove the mold. Lightly moisten the entire surface of the flowerpot and leave again for a while.

Try adding dyes to the solution, then the flowerpots will turn out even more beautiful.

Workshop project: where to start

The first step in designing is to determine what specific workshop work you will be doing. It is advisable to think through and write down all planned work, both in the near future and in the future. Based on this list, it is necessary to compile a list of auxiliary equipment necessary to complete the assigned tasks.

Next, determine the availability of the necessary tools (from a chisel and hammer to a drill and jigsaw), nails and screws, blanks and finished products. Don't forget to complete your list with a powder fire extinguisher and a first aid kit. Then determine how to arrange all the above things, what cabinets, racks and shelves are needed for this. Let's move on to the list of main equipment. The list must be completed:

After this, you need to add cabinets and racks with items from the first list to the second. Next, we determine the place for future blanks. The recommended minimum size of such a rack is 1 m × 6 m; it also needs to be added to the second list. Such a detailed list will allow you to calculate the dimensions of the future joinery.

Subtleties in drafting projects

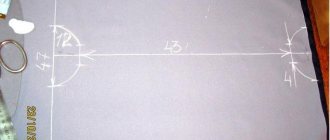

When all preparations are completed, it is time to design. The result of your efforts should be a document that is a project for the future workshop. For construction, there is no need to draw up construction drawings according to all the rules; detailed sketches indicating the actual dimensions of the future premises and the dimensions of the main and auxiliary equipment specified in the second list are sufficient.

There should be several sketches. It is difficult to indicate all the elements of a structure on one projection. Therefore, your sketches should include all the details down to the smallest detail. External and internal dimensions of the room and its elements are indicated without observing scale, but must reflect the actual position of objects and building elements.

An approximate calculation of the required area for a workshop will be the product of the area of all equipment, shelving and cabinets and a coefficient equal to 1.5-2. Still, if computer graphics looks like unplowed virgin soil to you, then the visual layout of the carpentry can be done using the old-fashioned method. Take a sheet of graph paper, draw on it the premises of the future carpentry on a scale of 1:20, agreeing with the approximate calculation and pre-made drawings.

From the same paper, cut out rectangles of equipment and auxiliary structures to scale, but according to real dimensions. This will make it possible to correctly place them in the workshop, taking into account workplaces and aisles. If necessary, you can move the rectangular layouts to determine the perfect workshop layout:

This will be your guide to further actions.

Features of rustic style for different rooms

The rustic style is universal and very suitable for a summer house, so all rooms can be decorated in it taking into account their characteristics.

We sew Roman blinds for the kitchen

The most current design for kitchen curtains is called cafe curtains. A rod, fishing line or twine is secured in the middle part of the window. Two small canvases are fixed on it. The upper part of the window is decorated with a lambrequin or curtains with tiebacks.

Another option that will look natural in a country kitchen is Roman blinds.

To create Roman blinds, you don’t need large pieces of fabric: you can get by with a scrap that is only enough to cover the opening

For a detailed master class on sewing Roman blinds, watch the video:

Living room, bedroom and dining room

If your dacha has these rooms, then decorate them with long country-style curtains with tiebacks. As additional decoration for the panels, you can use lace or fabric frills, satin ribbons, cords, buttons and beads.

Numerous ideas for rustic curtains are presented in the video:

Completion of the project: finishing touches

A few more necessary actions that must be completed in order to get a project that has the right to life. It is advisable to provide several rooms in the workshop:

These rooms will help divide areas of activity into zones and contribute to comfort during the work process. The diagram of the utility room with the dimensions of its furnishings must be made on the same sheet with the main workshop.

The storage area for long timber or lumber should be located opposite the front door for ease of storage. A machine for sawing workpieces should be placed near the rack. After receiving the layout of the carpentry, we move on to drawing up its sketch. We determine the material for the walls, their thickness and height. Select the type of roof and roofing material. Here it is recommended to rely on your wishes, budget and the ability to do it yourself.

An important issue in the design of a carpentry workshop is the development of a ventilation system. It must be forced, supply and exhaust. Such a system will ensure the removal of chips and harmful substances, complete air recirculation and microclimate regulation not only in the carpentry room, but also in the painting department. Draw on the sketch all the components of the ventilation, indicating the parameters and dimensions.

The final stage of design is the creation of a power supply circuit, lighting, both basic and individual for each workplace, and a grounding loop. Each workplace must be equipped with a grounded socket, each machine must be grounded. Upon completion, a sketch of the connection to the communications workshop building is made.

Construction of a carpentry workshop with your own hands

The location has been chosen, the project has been prepared, and the construction of the carpentry workshop can begin. Construction should be divided into several stages:

Foundation

Walls

Wall installation primarily depends on the selected material.

If the structure is wooden, then to fasten the lower crown when pouring the foundation along its perimeter it is necessary to lay threaded rods. Further construction of walls comes down to the construction of a wooden structure. The room can be made of brick or foam concrete blocks at your discretion. After making the box, install the window and door blocks. Make the roof according to a pre-prepared sketch with your own hands. Floors in a carpentry shop play an important role. It is usually made from several layers. A base of 5 mm thick sand is made on the foundation, then it is covered with roofing felt and boards are laid on top or an armored mesh is laid and poured with concrete. The second option is more reliable and popular.

If the carpentry is made of wood, then it is necessary to impregnate the walls with fire retardant compounds. Next, you need to bring all communication networks into the room and perform the wiring. All cable lines in cross-section must correspond to the current load imposed on them during further operation. In a workshop, wood is placed in metal pipes for fire safety purposes in case of a short circuit; in other buildings, corrugated pipes made of self-extinguishing polymers are used.

Next, we install and connect the ventilation system and machines, arrange cabinets and shelving, install shelves, and lay out tools.

Heating in the workshop is provided using oil radiators or autonomous water heating. An electric boiler can be used as a source of heating the coolant, and if it is possible to equip a room for a boiler room, gas or solid fuel boilers can be used. It is better not to use solid fuel boilers in a wooden workshop; there is a high probability of accidental fire.

Improvement of the play area

This playground is equipped for different ages of family members. If there are children of preschool or primary school age, the place is equipped in a fairy-tale or cartoon form.

Children enjoy playing on the swings and jumping on the “Giant Steps”. You don't need a lot of material to make them. Enough boards 30 mm thick, strong ropes, chains, old car tires. A wooden log or smooth metal pipe can be used for the central vertical support of the Giant Steps. Swings, trampolines, labyrinths, and slides are popular with children. When imagination and perseverance are connected, these elements are made from secondary items.

Preschool children need a sandbox. It can be made in the form of a car, boat, sea liner, fish, etc. The walls of the sandbox are arranged in an original way from plastic bottles or boards. To protect children from the bright sun, it is advisable to install a light ceiling.

The labyrinths and booms made from old painted car tires look great. Children love small fairy houses. Made from plywood or chipboard. Equipped with tables and stools. Tents, marquees, yarangas, tents, wigwams and even huts are popular in games. It all depends on imagination, creativity, and available material. Children enjoy participating in the arrangement of play areas.

Playground elements painted in bright colors are a hit with kids

Attract attention and attract the gaze of others

How to equip a carpentry workshop

General view of the workshop

Fig 1. General view of the workshop

In the center there is a sawing machine, near the wall there are blanking machines that allow you to end-process the board, make a cut, etc.

Figure 2. Procurement area

Prepared or processed wooden blanks, veneer, blanks for the façade of furniture, doors, etc. are stored here.

Fig 3. Cross-cutting machine

A cross-cutting machine is used to “cut” lumber. For example, 6 meter boards are shortened to 4 meters; the length is selected depending on the type of processing machine, the size of the room and the required dimensions of the finished product. Various waste after trimming lumber is stored at the bottom of the machine.

Fig 4. Drum grinding machine

Near the end machine there is a drum grinder, which is also made by hand.

Fig. 5. Hood - as an important factor in setting up a carpentry workshop

This drum sander hood is designed to collect all the wood dust after the sanding process.

Fig 6. Circular machine

Next to the drum sanding machine there is a circular one, which is also used for “rough” cutting of lumber.

In the center of the workshop there is a jointer, which was made in the USSR. The length of the table is 2800 cm and the width reaches 420 mm.

The thicknesser is located next to the jointer with a workpiece size of 420 mm.

Between the thicknesser and the jointer there is a powerful aspiration unit, which during the processing process collects all the wood dust into a special reservoir, which can then be easily cleaned.

DIY milling machine

The milling mechanism was borrowed from the factory machine, and the work table, frame, aspiration and control system were made independently. Milled titanium was used as a tabletop. The factory shaft from the milling machine was removed and a new one was machined according to the dimensions of the working part of the machine. The shaft turned out without any cones for the old landing cutters, which is very convenient.

DIY border for the path at the dacha

Milling machine shaft

Fig 11. Milling machine shaft

Fig 12. Lathe

Figure 13. ShLDB machine

Figure 14. Cross-cutting machine

Do-it-yourself carpentry will require not only specific skills for fine-tuning and assembling machines, but also significant financial costs for purchasing the necessary materials.

Factory-made Corvette 33 band saw

Fig. 15. Factory-made Corvette 33 band saw

Angle cross-cutting machine

Figure 16. Angle cross-cutting machine

Sharpening machines: emery, diamond and felt

Figure 17. Sharpening machines: emery, diamond and felt

These machines are used for sharpening chisels, drills and other working tools.

Figure 18. Slotting machine

Some elements from the slotting machine were borrowed from the factory milling machine. The frame base, desktop, and controls were made independently. The motor is used at 380 volts with a bearing mounted at the rear. The bearing was installed in order to increase the power of the engine, which simply did not work under such a load without modification.

Sliding slipway on tripods

Fig 19. Sliding slipway on tripods

Homemade universal machine (plane, saw)

Figure 20. Homemade universal machine (plane, saw)

The countertops are made of high quality and durable titanium.

Sawing and milling factory machine

Fig. 20. Saw-milling factory machine with the ability to adjust the height and angle of processing lumber.

Figure 21. Drilling machine

The picture shows a factory-made drilling machine from the times of the USSR. The engine was modified and the pulleys were re-sharpened.

Rack with hardware

Figure 23. Rack with hardware

Cabinet for chisels near the workbench

Fig 24. Cabinet for chisels near the workbench

Cabinet for working cutters

Figure 25. Cabinet for working cutters

Second room of the carpentry workshop

Fig 26. Homemade press

The dimensions of the press are 900 mm in length and 2700 mm in width. The workpiece is placed on plastic stops, which is then compressed by a press.

Universal sharpening machine

Figure 27. Universal sharpening machine

Here is a jointer and emery for sharpening cutters and knives.

Drum grinding machine brand JET 16-32

Fig. 28. JET 16-32 drum grinding machine with a modified work table and feed roller.

Drum grinding machine brand JET

Figure 29. JET drum grinding machine

Factory machine with modified support plates, internal aspiration casing installed.

Figure 30. Painting room

At this point, processed blanks are installed on tripods, which are subsequently painted and painted using a spray gun and brushes.

Compressor for painting

Figure 31. Compressor for painting

One of the mandatory conditions in a paint and varnish room is the creation of effective supply and exhaust ventilation. It should be noted that in winter, this room where painting work is taking place must be well heated. Otherwise, you will not be able to properly paint or apply varnish.

The slipway is located in the assembly and grinding room, where the final stages of processing of wood products take place. The slipway is made of high-quality laminated plywood, which is mounted on a metal frame with the ability to be adjusted in height. This is done in order to create a perfectly flat surface in rooms with uneven floors.

Additional photos of the carpentry workshop

Trimming saws are used for cutting (dissolving) workpieces. Near the trim, you can immediately organize a place to store wooden scraps that can be used in the future.

In order to be able to produce any wooden product, it is better to equip the workshop with several trimming machines - with a six-meter longitudinal, with a transverse and with a rotating table.

3. Drum grinding machines

5. Electric jointers

7. Vertical milling machine

Vertical milling machine

Vertical milling machine

It is best to place a cabinet near the milling machine to store various cutters.

Cabinet for storing cutters

9. Grinding machines with reel and disk (ShlDB)

Grinding machines with reel and disc (ShlDB)

Grinding machines with reel and disc (ShlDB)

10. Band saws

This equipment is designed for cutting wood using a band saw. Unlike a circular saw and a cross-cut saw, this machine provides a lower roughness of the processed surface, which means that the surfaces (ends) obtained as a result of sawing do not require finishing.

It is better to equip your carpentry with two band saws - for sawing large and small parts.

11. Sharpening machines

12. Slotting machine

In woodworking, a slotting machine is necessary to create rectangular and oval grooves in wooden workpieces.

The work table, with the workpiece attached, can move along and across the body, as well as tilt at a certain angle, which allows you to create grooves of various configurations.

13. Sliding slipway

14. Drilling machine

A carpenter in the workshop cannot do without a drilling machine, which provides drilling of holes of various depths and diameters.

Near the drilling machine it is rational to place a cabinet with interchangeable tools - drills of various sizes.

Tool cabinet with replaceable tools

17. Place for metal work

The area for processing metal workpieces should be equipped with related equipment and tools (vise, anvil, hammer, pliers, etc.), which are best placed on the table and surrounding racks and shelves.

Place for metal work

The main equipment of a carpentry workshop is a reliable workbench for drawing, manual processing of wood products and other tabletop carpentry operations.

19. Area for painting and varnish work

The ideal option is to allocate not a zone, but an entire room for painting and varnishing wooden products. In any case, this place of work must be equipped with a good exhaust hood and have a window.

Paintwork area

20. Slipway for final assembly

Final assembly berth

Weights are used to facilitate the assembly and gluing of joinery products.

22. Storage space for carpentry tools

Shelves with tools (glue, tape, tape measure, screwdrivers, rulers, pencils, compasses, etc.) should be located close to the workbench.

Storage space for carpentry tools

Storage space for carpentry tools

To store chisels, it is better to select a cabinet where each tool will be in its designated place. Such orderliness will help improve work efficiency.

Storage space for carpentry tools

23. Space for storing hardware

It is better to package any metal fasteners (nuts, bolts, screws, nails, etc.) and accessories (handles, legs, guides, etc.) in separate jars and label each of them. Hardware distributed in containers is placed on shelves near the furniture assembly area.

Storage space for hardware

Before you make carpentry or a carpentry workshop at your dacha with your own hands, you need to purchase a suitable room, and then purchase all the necessary equipment. All of the above-described machines necessary for working in a carpentry workshop can be purchased from companies that sell metal-cutting and woodworking equipment on their websites or trading platforms. You can also visit special exhibitions and get acquainted in detail with the examples of carpentry devices presented in order to choose the best option for your carpentry.

Video tour of the carpentry workshop

Most of the woodworking carpentry machines used in the video were made independently using some ready-made factory elements that were refined and improved. Another important aspect in a carpentry workshop is effective suction. This article answers the question in more detail - how to make a carpentry workshop or carpentry shop with your own hands. As can be seen from the material described above, this is a labor-intensive and costly process. However, if you have all the necessary woodworking machines and tools, you can easily make not only wooden windows, doors, furniture and interior items, but also restore especially valuable wood products from past centuries. Good luck.

Source

Landscape design

To implement various ideas for a do-it-yourself garden on your site, you do not always need to invest a lot of time and effort. We tried to collect for you as many simple landscape design projects as possible.

For a more comfortable pastime at your summer cottage with family or friends, you can create special recreation areas.

These can be either round or rectangular concrete platforms, or terraces made of ordinary or composite boards.

Recreation areas with a dedicated fire pit are especially popular today. It’s great to gather at such venues in the evenings. You look in fascination at the flames flying out of the fire, breathe in the fresh air - beauty!

It would also be nice to have a pond at the dacha. Throw some fish in there or make a fountain, and admire the man-made world in moments of rest and relaxation.

Moreover, it will take no more than one day to make the simplest artificial reservoir. Here's a real example.

Agree, this is a small “price” for the feeling of boundless peace that admiring the end result of your work will give.