RSS Article Feed:

Search articles:

Home production of chain-link mesh is important for both commercial and personal purposes.

It is advisable to make it manually for the household to create cages for rabbits and various enclosures. If you need large volumes, it is better to order a ready-made PVC mesh. To make chain-link mesh at home, there are two key methods: with and without a machine. At the same time, you can also create the machine yourself, since it is a structurally simple mechanism.

Video: making chain-link mesh at home

How to make a chain-link mesh without using a machine

It is quite possible to make a chain-link without a special machine, although the process will be quite labor-intensive. The material can be used metal wire or plastic.

Weaving a chain-link mesh from wire implies a clear algorithm of actions:

- We select a tool with which we will give precise bends to the wire.

- Selects a wide wooden board, the length of which is equal to the width of the future product.

- We drive nails into the board, observing a checkerboard pattern. Remember that the size of the cells depends on the distance between the nails.

- We cut rods of equal length using soft steel wire.

- We put on work gloves.

- We slowly bend the wire around each nail.

- The blanks are connected by weaving them into each other and rotating one of the rods around its axis, similar to screwing.

There is another way of weaving without a machine. For it you will need:

- Wire cutters that will be used to cut the wire into equal parts.

- Wire made of aluminum or other metal that can be deformed.

- Rulers made of wood or an electrode bent in half.

Next follow the instructions:

- Take a ruler or electrode and wrap the wire tightly around it. The turns should be located close to each other.

- Recheck the bends. Please note that the width of the ruler determines the size of the cells in the grid.

- Remove the wire, wind the second rod. Please note: you only need to wind in one direction.

- Stretch the removed blanks to equal width.

- Thread the resulting zigzag spirals into each other, making rotational movements.

- It is better to secure the first and last rows to avoid the mesh from falling apart.

- Plastic tape 3-5 mm wide or a long plastic tube of small diameter (2-3 mm). This material can be made from an ordinary plastic bottle.

- Alcohol lamp.

- Ruler.

It is possible to produce decorative chain-link mesh from plastic. To do this you need:

To create a plastic chain-link, follow these steps:

- Draw squares on the ruler that will serve to orient the tape.

- Use a clothespin to secure the edge of the tape or tube to the ruler.

Wind the material onto the ruler, heating each bend over an alcohol lamp for one second.

Weaving technology

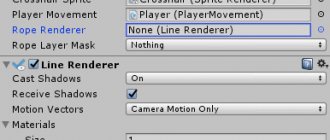

The scheme for weaving a chain-link mesh on a homemade machine includes drawings and steps based on them:

- the wire used is coated with machine oil or by using a special lubricating device on the machine itself;

- the wire end is bent with a hook;

- the product is pulled through the groove, secured to a knife inside the pipe;

- the shaft rotates due to the lever;

- the shaft is rotated until a waveform is obtained;

- the wire is divided into pieces of the required length;

- The wire is wound on an inverted bucket;

- 1.45 meters of wire gives 1 meter of chain-link mesh;

- before stretching the mesh, its parts are fastened to each other;

- the outermost wire is unscrewed, the ends of the chain-link are applied one to the other, the removed wire secures it;

- The finished bonded mesh is fixed to a fence or other object.

The tensioning and fastening of the chain-link is done with nails and slats. The stretched and secured mesh needs to be painted over with a brush. This will ensure complete penetration of the paint into the weave.

Using and making a homemade machine

Producing chain-link mesh at home using a machine is much easier and faster. Buying such a machine is expensive, but making it yourself is much cheaper. To make a machine for making chain-link mesh, you will need:

- A piece of pipe.

- Metal pieces from different types of metal.

- Plate.

- Bearing races.

- Welding device.

- Bulgarian.

- Rollers.

- Metal corners.

- File.

- Chalk.

- Rope.

- Sandpaper.

The most important part of the machine is the coiling unit. It consists of a screw and a knife with which the wire is curled. The size of the cells depends on the format of these components. Rotating, the knife creates turns of a certain size, and the auger sets the distance between them (pitch). A flat strip of steel acts as a coiling plate. At one end there should be a hole for the handle.

The auger is a hardened steel pipe with a spiral slot. In order to get such a groove, use a rope and chalk: attach a rope, outline it with chalk. Next, cut a slot according to the outlined pattern. Go over the cut with files and final sand with sandpaper. The length of the pipe should be sufficient to lay 3 full turns. There should be a space of no more than 1 mm between the knife and the pipe, otherwise the wire will be snagged. In this case, the knife should rotate absolutely freely, and its end should protrude 1-2 cm from the pipe.

For easy sliding of the wire, the corners and grooves must be well rounded and treated with oil.

You need to cut 2 pieces from a metal corner, equal in length to the pipe. We weld them to the pipe so that it seems to be located between them. This structure is fixed to the base by screwing it to the working surface through special holes. Place the machine itself so that it is convenient for you to rotate the handle, parallel to directing the spiral. Do not allow the workpieces to become tangled under any circumstances.

You can insert a piece of pipe into the center of the skein and attach a weight to the end of the wire by passing the end through the tension rollers. This helps get rid of wire ringing. The distance between the rollers is set using a screw.

Before large-scale production use of the machine, you need to check it by passing the wire through the device. If you get an even row with the desired shape and size of the cells, then the machine is assembled correctly.

Video: do-it-yourself manual machine for chain-link mesh

Terol Torg company: 3D fencing, gates, roller shutters

Home production of chain-link mesh is important for both commercial and personal purposes. It is advisable to make it manually for the household to create cages for rabbits and various enclosures. If you need large volumes, it is better to order a ready-made PVC mesh.

To make chain-link mesh at home, there are two key methods: with and without a machine. At the same time, you can also create the machine yourself, since it is a structurally simple mechanism.

: making chain-link mesh at home

Production of chain-link mesh as a business

You can make a good business in the home production of chain-link because of the demand for the product. They need it:

- Owners of cottages and gardens. The area is clearly visible through the mesh: if the owner is away with his neighbors, he still controls what is happening on his territory. The product is also needed as a support for a hedge.

- Animal farm owners. Chain-link is used for cages and enclosures.

- Enterprises using such mesh as a fence. The high strength of the wire used ensures the correct operation of the security service.

- Construction companies.

The business of selling chain-link mesh will always be profitable. In addition, there is little competition in this area.

This business has a number of advantages:

- Small starting capital. The purchase of materials is affordable for people of average income. This eliminates the need for bank loans and reduces payback time.

- Small production areas. At the start of a business, a room the size of a regular garage is enough. There is no need to create special conditions for storing products.

- Gradual increase in production and profit with the arrival of new clients.

The greatest demand for chain link is established in April-October, but you can start a business at any time of the year. The business itself is profitable, low-cost and profitable if you approach its organization correctly.

Interested?

For detailed information, contact us in a way convenient for you:

Source: terol.by

Do-it-yourself machine for chain-link mesh

Iron wire mesh is a very convenient building material for making a fence around a personal plot or vegetable garden. It helps for a long time and does not shade the plants, and it is not difficult to install this fence. The mesh also has one more advantage - it can probably be created with your own hands, at the right size and in the right quantity. There would be a wire.

Production and application of galvanized woven grating

In addition to the types of woven materials listed above, there is a mesh fabric made of galvanized wire. This galvanized woven mesh is available in different cell shapes. They can have the shape of a circle, square or rectangle. Woven mesh is produced on special automated equipment at modern industrial enterprises.

A woven mesh made of galvanized wire is simply installed and, if necessary, easily dismantled, which means it can be used several times, which provides significant cost savings. A woven metal mesh coated with polymer substances perfectly resists the effects of aggressive compounds and temperature changes. This material is often used in regions with harsh and maritime climates.

Grid fabrics are used not only in construction or mechanical engineering, but also in pharmaceuticals, oil and gas infrastructures, woven mesh is used in aviation and other farms.

- Installation of supports on hills, sloping areas;

- Fixation of the sea, river bottom, or shore;

- Protection of pipes and gas pipelines;

- Reinforcement of slopes and slopes;

- In landscape design: for framing flower beds, fountains, dividing a site into zones, installing parapets, stairs, fences;

- The “Reno mattress” can be laid at the bottom of an artificial reservoir in a suburban area - the water will remain clean much longer;

- For protection against mudflows, landslides, rockfalls, avalanches;

- To change the direction of flow;

- To create a stone foundation for installing lawns;

- Gabion technology is used to create garden figures

Machine for making mesh - chain-link

The main structural element is a bending unit, inside of which a flat mandrel knife rotates freely using a drive shaft. An electric motor with a gearbox with a power of 0.55 kW is used for the drive. The shaft rotation speed at the gearbox output is 60 rpm. Electric motor control by foot pedal.

The bending unit is universal. It allows you to weave a mesh with any cell size. To do this, it is necessary to make (Fig. 2) a pipe with a narrow through spiral groove (vitaer), two clamping half-rings and a mandrel knife (see Fig. 1).

The pipe must be thick-walled. In my design (Fig. 3, a) it has an outer diameter of 50 mm, an inner diameter of 40 mm, and a spiral pitch of 80 mm. The spiral groove is cut on a lathe. But you can also do it on a sharpening machine if you install a 14A50NSTZ cutting wheel with a thickness of 3 mm. Such abrasive wheels are used in manual machines for cutting metal. First, you need to make a template from thick paper (Fig. 3.5), stick it on the workpiece-tru6u with a gap between the turns of 3 mm and use a cutting wheel to cut a through spiral groove in the workpiece according to the template.

The width of the mandrel knife must correspond to the internal diameter of the pipe with a spiral groove of 40 mm. The remaining dimensions are not of fundamental importance; they will be determined by the type and dimensions of the bearing supports and gearbox used.

It is convenient to connect the drive shaft and gearbox using a detachable coupling that fits freely onto the square shank of the shaft. If necessary, the gearbox can be removed, put a drive handle on the square shaft shank and continue working with a manual drive.

In Fig. Figure 4 shows the movement of the wire when weaving the mesh. The wire enters the bending unit from the straightening-tensioning device. The tension is adjusted by a pressure screw 5, which presses the upper roller through a spring 6. Both rollers 7 on the cylindrical surface have annular grooves in which the wire is held during movement. Plate 4 with a hole directs the wire from the unwinding drum 1 exactly into the grooves of the rollers. Drum 1 for unwinding a coil of wire is made from a car wheel, cut in half. The disk halves are inserted into the bay and screwed together with bolts and nuts. To prevent the coil of wire from falling apart, small pieces of rods are welded to the sides of both halves of the disk. The drum axis rotates freely on the trestles. When moving, the wire must be continuously lubricated with any machine oil. This can be done as shown in Fig. 4, or using an oiled rag.

Tension fastening method

This option is most popular when used with guides. It allows you to create a more aesthetically pleasing and attractive fence. Horizontal guides are welded to the main supports in 2 or 3 places; the best choice for them would be a metal profile, but wood can also be used. This design is well suited for all types of soil, except heaving ones.

Attaching the chain-link mesh to a profile pipe with horizontal guides must be done in a certain sequence. The installation of posts and markings are similar to what is done when installing a sectional fence. The remaining steps are performed step by step.

- Fixing horizontal guides . It is performed on each pillar, above and below. If wooden slings are used, they are secured with through-bolt fastening. Metal ones are welded. A primitive solution is tension.

- Installation of the first section of the fence . A reinforcement bar passed through its edge helps securely secure the mesh to the corner post. It is this that is welded at 4 points to the base. It is better not to use wire or clamp twisting. The optimal thickness of a steel bar is 4 mm or more.

- Installation of the remaining sections. Each is fixed from pillar to post; in addition to fastening on vertical supports, additional fixation is performed horizontally. It can be carried out by welding using twisted wire or self-tapping screws.

It is worth considering that when deciding to attach horizontal guides to a rigid welded joint, you can get deformation and rupture after the first winter . Burying the pillars below the soil freezing level helps to avoid problems. You can also use wire tension.

In this case, a steel cable is passed through the upper part of each section, due to which the edges do not sag under their own weight.

It is quite easy to stretch the mesh this way. It is enough to throw a wire loop over 1 post, then pass it along the top of the mesh, after 2-3 supports, wrap it again several times. Work continues until the end of the span. At this stage, sagging is still possible. It can be eliminated by threading a rod and twisting it. Such a lever will give maximum efficiency with minimal physical effort; you can repeat the action for each flight.

How to weave a chain-link mesh with your own hands

Weaving the mesh occurs as follows. The wire must be threaded into the tension device and a hook with a length equal to approximately half the width of the mandrel knife bent at its end. Then you need to insert the hook into the spiral groove and hook it onto the edge of the knife. When the mandrel knife rotates, the wire is wound onto the mandrel, moving along a spiral groove, and comes out of the bending unit in the form of a wavy snake. The length of the snake is the width of the mesh. The table on which the mesh is weaved must also have the appropriate length. A wavy snake of a given length must be cut off at the bending unit with pliers, cutting the straight section of the wave approximately in half.

The finished snake needs to be moved away from you by the width of the cell and the machine turned on to wind the next snake. The new snake is woven (screwed) into the previous one without additional help. And so on. Particular attention should be paid to the quality of the snake. A good snake should be completely flat and lie on the table without being twisted by the propeller. This depends on the elasticity of the wire, its tension and the angle of twist of the mandrel knife along the longitudinal axis (Fig. 5).

To bend the mandrel knife, it is not necessary to disassemble the bending unit. To do this, you need to make two levers from a steel strip with cutouts at the ends equal to the thickness of the knife. The levers are put on the mandrel knife with cutouts on both sides of the vitaer and the front free end is twisted in the direction of rotation at an angle of 8.10 degrees. Using this machine, I produced 80 m of mesh, 1.5 m wide, with cells 80x80 mm*. For one linear meter of mesh it is necessary to wind 25 wavy snakes. One snake 1.5 m long requires 2.3 m of wire. With a wire diameter of 2.5 mm, one meter of mesh with 80x80 mm cells, 1.5 m wide, weighs 2.6 kg.

Wire movement pattern when weaving a mesh:

1 – coil of wire on the unwinding drum; 2 - wick; 3 – a can of machine oil; 4 – guide plate with hole; 5 – pressure screw; 6 - spring; 7 — rollers; 8 – bending unit; 9 – roll of finished mesh

* Note, ed. Indicating the cell size of 80×80 mm, the author gives the maximum cell size for “clearance”, i.e. indicates the length of the diagonals of square cells. In the article, when giving the dimensions of the cells a x a, by “a” we meant the length of the side of the rhombic cell. From this point of view, the cell size is a x a = 57 x 57 mm.

Types of equipment

Before you make a purchase, you need to know the advantages and disadvantages of different types of devices. There are three types of chain-link mesh production machine: manual, semi-automatic and automated.

Hand tools

Such devices are best suited for personal use. The equipment is compact and can be easily placed in a small room. This chain-link machine makes spiral-shaped blanks from wire, and weaving the mesh is done by hand.

The structure includes a frame and a screw. The latter is presented in the form of a bending shaft. The movement is carried out by rotating the lever; more advanced models are often equipped with a gearbox, which facilitates the procedure. While moving, the screw makes spiral blanks from wire.

Before starting work, you need to cut the wire into equal lengths. The length of the workpieces determines the height of the mesh; the size of the cells depends on the parameters of the screw, which are selected individually for each case.

In this video we will look at how to make a chain-link mesh with your own hands:

The maximum wire diameter that can be worked with manual equipment is 3 mm, the mesh size varies from 30 to 60 mm. An experienced worker can weave about 50 m of mesh in one shift. It should be noted that such structures are not designed to work on an industrial scale , because they have a low safety margin.

The purchase of equipment is justified if you plan to install fencing at home.

The best option on the market today is the BMP machine. It is simple and reliable in operation, characterized by compactness and light weight; the operator does not require special skills before starting work. The price of such a unit is about 17-20 thousand rubles.

Semi-automatic device

The most famous semi-automatic machine for the production of chain-link is ACP 15/2. The operation of the device must be under the control of an operator , who not only monitors the production, but also takes a direct part in the process. The equipment is characterized by ease of operation, ease of setup, compact dimensions and low cost.

The device can be used on production lines that are located in small areas. The unit independently bends the ends of the wire, winds the fabric, stops and cuts.

The device is a modern, improved model, has high performance, and is much quieter than its predecessors.

The machine makes products that meet all the requirements of GOST 5336-80. The mesh is produced with cell sizes from 2 to 6 cm, knitting is carried out in one wire. With such indicators, setting up the device is quite simple. The height of the finished chain-link roll is no more than 2 m, however, you can configure the equipment so that the maximum length is 3 m.

DIY metal mesh

In addition, metal woven mesh is also very popular in households, where it is used to build a fence around plots of land, is used in the manufacture of cages and in many other cases. You can purchase such important material either in our store or make it yourself. Moreover, the process is not as complicated as it seems at first glance. This will require a wire of appropriate length and thickness and a certain amount of effort.

To start work, you need to prepare a metal bus, for example, made of aluminum, approximately 70 - 80 cm long. The width is arbitrary - it depends on the required mesh size of the mesh being manufactured. Apply to the division bar at regular intervals. After this, the wire of the required diameter should be trimmed, and then proceed directly to work. One end of the wire must be held at the first division with your left hand and wound, successively moving it from the tire itself until the wire runs out. In a similar way, as many blanks are made as needed.

The next stage will require a flat area, for example, a floor, on which the process of weaving the mesh will take place. First, one wavy piece is placed on the floor, onto which a second one should then be braided, twisting the wire around its own axis. After one workpiece has been prepared, you should proceed to the next, continuing the process until the mesh is completely ready. The size of the prepared tire and the distances set between the marks on it affect what the dimensions of the mesh cells will be. Its height depends on the length chosen for the workpiece.

Wire winding knife

For soft wire, you will need a flat knife, and for stiffer wire, the knife must have a large twist angle.

A knife for hard wire must be made of durable metals, but for a flat knife any kind will do. The knife must fit exactly the dimensions of the pipe so that there are no gaps. This may cause the mechanism to jam. However, the knife should rotate in the pipe without difficulty. For a twisted knife, you need to take a plate 1-2 mm wider than the required size. It is clamped vertically in a vice, heated and the upper part is turned to the required limit. The untwisted parts are cut off, the shank is attached, and then the required width is adjusted. Part of the knife near the shank is hardened, and the rest is ground.

- When producing mesh, the machine must be stopped when the knife is positioned vertically.

- And the correct position of the spirals during connection is facilitated by the position of the bottom wire in the desired direction, using the table board for installation.

- Elastic wire can be annealed to make it more obedient. But this requires special skills, otherwise you may end up with different stiffness along the entire length.

- You must remember to change the knife if, after working with a stiff wire, you have to curl a less rigid one. Also, their step length will be different, so you need to screw in the spiral more carefully.

Using a handheld machine

If you plan to produce metal mesh in large quantities, it is advisable to choose a mechanized weaving method, which is more productive. This method involves the use of a manual machine, which you can also make yourself. Its components are the following elements:

- Machine base.

- A knife, which is a plate whose purpose is to wind turns.

- An auger, which is a pipe with through puzzles representing a spiral.

- A mechanism equipped with rollers to tension the wire.

- Shaft controlled by a special handle.

The knife plate and screw are the main elements of the machine. They ensure the process during which the wire is curled by a spring.

Using the machine, the process of making mesh becomes quite simple. The machine itself should be firmly secured to the table. The prepared coil of wire is placed next to it, passing one end of the wire between the rollers, and it is installed in the mechanism intended for winding.

Using the handle, the mechanism is rotated, producing a wire that is already bent at the output. Rotate it until the length of the workpiece reaches the required dimensions, after which, using wire cutters, the wire is cut off. The next piece of wire is passed into the loop and the handle of the machine is rotated. Thus, the new workpiece captures the loops of the previously made one. The blade is increased with each new workpiece and so on until the required length of the blade is reached. Using pliers, bend the ends of the wire along the edges of the mesh.

The TsPVS mesh is very popular; you can purchase a ready-made mesh on the company’s website.

Source: cetka.info

Advantages of trellis structures

Trellis in landscape design has the following advantages::

- Protects against contact of fruits with the surface of the earth. Berries or vegetables remain clean.

- Provides high-quality ventilation, which prevents the appearance of fungal formations.

- Allows you to create uniform lighting.

- Makes watering, pruning and harvesting easier.

The support allows you to disguise unattractive areas in any area. Horizontal variations of supports are used for installing a gazebo. This option allows you to create shade in the area. A trellis is a wonderful device for decorating a garden area.

A woven mesh made of galvanized wire is simply installed and, if necessary, easily dismantled, which means it can be used several times, which provides significant cost savings.

LiveInternetLiveInternet

-Music

—Categories

- Stencils (48)

- A (16)

- A - THIS IS A TRANSLATOR OF TEXT PAGES (5)

- AND THIS IS INTERESTING. (60)

- AND I NEED THIS NOW (62)

- ALOE (11)

- Angels (21)

- ENGLISH LANGUAGE (22)

- PANSIES (19)

- ARTISTS (TO BE REMEMBERED) (43)

- Grandma's TREATMENTS (36)

- Continuous Knitting (29)

- BEAD MK (385)

- BEADED DIAGRAMS (419)

- beading (403)

- DIVINE HOLIDAYS (PICTURES WITH CODES) (54)

- MASTERITZ ACTIVITIES (45)

- BROOMSTICK (50)

- BRUGGE CROUSE (91)

- TO THE PIGGY BANK (436)

- TO THE PIGGY BANK (313)

- INSPIRATIONALS (23)

- VIDEO RECIPES. (80)

- VIDEO KNITTING (636)

- VINTAGE FRAMES (97)

- STAINED GLASS AND STAINED GLASS MK (20)

- hair (123)

- collars (108)

- ALL TYPES OF BAKER (39)

- ALL TYPES OF TEST (102)

- everything for Easter (5)

- ALL FROM PAPER, CARDBOARD. (45)

- All about Lyra (205)

- ALL ABOUT HONEY (38)

- EVERYTHING (6)

- PATTERNS (197)

- BAKERY (20)

- RIBBON EMBROIDERY (162)

- WE KNIT ARANS (9)

- KNITTING (197)

- KNITTING (IDEAS) (423)

- KNITTING - learning to crochet (42)

- KNITTING - learning to knit with KNITTES (31)

- crochet (979)

- CROCHET (winter) (22)

- CROCHET (summer) (275)

- CROCHETING (PATTERNS) (86)

- TAPE KNITTING (53)

- KNITTING MK AND MASTER CLASSES (219)

- knitting (271)

- KNITTING (winter) (62)

- KNITTING (summer) (17)

- KNITTING (PATTERNS) (65)

- KNITTING PATTERNS (461)

- TUNISIAN KNITTING (90)

- KNITTING SHORT ROWS (4)

- LOINT KNITTING (35)

- FREEFORM KNITTING (46)

- KNITTING "PINEAPPLES" (11)

- KNITTING(ROMANIAN LACE.) (114)

- KNITTING(POCKETS, etc., etc.) (101)

- KNITTING (READING PATTERNS SYMBOLS) (56)

- KNITTING, ALL CRIB SHEET TO HELP KNITTERS (113)

- KNITTED BED (96)

- KNITTED COATS AND CARDIGANS (296)

- Knitted buttons. (16)

- KNITTED RIBBERS (104)

- KNITTED CORDS (77)

- knitted jewelry (543)

- GANUTEL (59)

- HOROSCOPE (68)

- WE COOK IN POTS. (4)

- WALNUT JAM, etc. (11)

- mushrooms (50)

- DECORATION AND PAINTING OF BOTTLES (73)

- Decoupage (161)

- DECOUPAGE MK OR MASTER CLASS (236)

- DECOUPAGE_PICTURES FOR DECOUPAGE (437)

- WE MAKE CANDLES AND CANDLESTICKS (19)

- denyushki (96)

- DESSERTS (230)

- KIDS (61)

- CHILDREN (BLANKETS FOR THEM) (196)

- CHILDREN (fun and games) (3)

- CHILDREN'S HATS (15)

- JONGSAN@ JONGSAN (16)

- DIET - WILL WE LOSE WEIGHT? (80)

- for children (926)

- For kids (607)

- FOR CHILDREN WINTER (155)

- CHILDREN'S BAPTISM DRESSES (25)

- FOR CHILDREN SUMMER (205)

- BOOTIES FOR BABIES. (112)

- FOR HOME (308)

- for luck (76)

- HOMEMADE BREAD (21)

- HOME AND CHILDREN'S MAGIC (26)

- JACQUARD PATTERNS (102)

- PAINTING (178)

- LIVE FLOWERS (81)

- conspiracies. (97)

- here you will find a lot of interesting things (108)

- HEALTH (393)

- HEALTH MK (52)

- umbrellas (108)

- PASTA PRODUCTS (22)

- GINGER AND ALL FROM IT (14)

- INTERESTING TIPS FOR WOMEN (175)

- Irish lace (663)

- IRISH LACE VIDEO (64)

- Confessional (57)

- for tea (537)

- CACTUSES AND ROSES (16)

- KANZASHIKI (89)

- PORRIDGE IS OUR STRENGTH. (3)

- QUILING (41)

- BRUSHES AND THEIR PURPOSE (68)

- KNITTING BOOKS (226)

- comments (150)

- canning (233)

- CRACKELURE (27)

- beauty (40)

- cookie creams (74)

- Cereals and their beneficial properties.. (17)

- DOLLS (42)

- SWIMSUITS (106)

- CUISINES OF THE WORLD (68)

- kitchen (354)

- KITCHEN(CHICKEN DISHES) (166)

- LEAVES, FLOWERS THAT TREAT (53)

- PATCH BLANKETS (17)

- HORSES (67)

- ONION PEEL (6)

- M-O-R-O-J-E-N-N-O-EEEEEE (20)

- MAKEUP (75)

- MACRAME (37)

- MOM (29)

- MASTER CLASSES AND MK (127)

- MATRYOSHKA POSTS (20)

- FUR KNITTING (42)

- eggshell mosaic (23)

- PRAYERS (122)

- PRAYERS DREAMS OF THE HOLY VIRGIN (13)

- MOTIVATORS (22)

- My cookbook (97)

- music (368)

- MUSIC CHANSON (17)

- MUSIC-CLASSICS (0)

- CARTOONS (51)

- SOAPS AND PERFUME (101)

- SOFT TOYS (WE SEW OURSELVES) (127)

- DRINKS (41)

- DRINKS (93)

- WEIGHTLESS PICTURES (ON FEATHERS) (18)

- NON-CONVENTIONAL TREATMENT (5)

- NEW YEAR'S KITCHEN (26)

- NEW YEAR (130)

- SOCKS (263)

- NEEDS, USEFULITIES (117)

- CHARMS (26)

- shoes (161)

- VEGETABLE GARDEN (planting, shoots) (52)

- DIARY CLOTHES (143)

- papier mache (23)

- EASTER (67)

- EASTER-BAKING (42)

- PERGAMANO (6)

- translator (3)

- TRANSLATIONS FOR KNITTING (9)

- ALTERATIONS (38)

- SAND (11)

- PLASTIC BOTTLES (16)

- SCARVES (HOW MANY USES IT HAS) (13)

- newspaper weaving (198)

- FOIL WEAVING (4)

- let's tell fortunes (29)

- salt dough crafts (27)

- CONGRATULATIONS FOR ALL OCCASIONS OF LIFE (19)

- BEDDREADS (5)

- HEALTHY PRODUCTS (15)

- useful tips for computer (79)

- PLASTIC BAGS. (25)

- Let's have fun? (134)

- SIGNS (7)

- SEASONINGS (11)

- PARABLES (41)

- HAIRSTYLES (39)

- SHELLS (7)

- HAPPY BIRTHDAY FRAMES (38)

- FRAMES (489)

- DRAWING VIDEO LESSONS (49)

- draw on stones (27)

- draw on stones (41)

- DRAWING WITH HENNA (3)

- RITUALS (3)

- CHRISTMAS. (6)

- Daisies (18)

- RUNES (946)

- RUSSIAN TSARS (20)

- Fish (110)

- SALADS (115)

- SEAFOOD SALADS (10)

- NAPKINS (241)

- WEDDING BOUQUETS (14)

- SECRETS OF HEALTH (INUSIONS AND ALL RECIPES) (202)

- TALES (323)

- TALES-2 (79)

- TABLECLOUTS (63)

- SKELETING LEAVES (9)

- SCRAP KITS (122)

- SNOWFLAKES (76)

- SAUCES (23)

- poems (427)

- bags (155)

- KNITTING PATTERNS (81)

- CHEESE (13)

- FABRIC AND KNITTING (97)

- STOT PAINTING (135)

- Stencils and WHAT NEEDS TO BE XERIED (593)

- TURKISH HARNESSES (100)

- STUDY FROM 1ST TO 11TH GRADES (37)

- LEARNING TO DRAW (37)

- Baubles (112)

- A LOT OF FILM IN ONE BOTTLE))) (140)

- MOVIES (77)

- MOVIES and CARTOONS FOR CHILDREN (57)

- MOVIES ONLINE (107)

- MOVIES-SERIES (75)

- FOIL (5)

- FENG SHUI (15)

- cold porcelain (543)

- COLD PORCELAIN (ALL YOU NEED FOR THIS) (38)

- CLEAN (70)

- WONDERS OF THE WORLD (98)

- shawls (181)

- SCARVES,SNOODS (63)

- Hats (398)

- BEADED CURTAINS (44)

- this is interesting (series of messages) (77)

- EGGSHELLS (21)

Wire weaving. Working with wire mesh

Tuesday, October 02, 2012 23:57 + to quote book

Wire weaving. Working with wire mesh

Wire weaving. Working with wire mesh.

Wire mesh is a wonderful material because it is cheap, attractive and easily available. Its flexibility and lightness make it suitable for large-scale structures, which is why it is often used by sculptors. For simplicity, below we will call the horizontal (double twisted) sides of the hexagonal mesh cells twists, and the single sides - cores. It is recommended to wear gloves when working with wire mesh. Finish any project made from chicken wire by removing any sharp ends that stick out.

Required Tools

To create a hand-held apparatus for the manufacture of this product, you will need the following materials:

- metal in pieces;

- welding machine;

- file;

- rollers;

- sandpaper;

- bearing races;

- Bulgarian;

- plate;

- rope with chalk;

- metal corner.

Welding machine

The principle of operation of the machine is that the master guides the wire with one hand and rotates the machine handle with the other. When assembling, it is important to keep an eye on the spirals. They shouldn't get tangled.